3D Printing Resin Properties. Stereolithography, the technology behind most resin 3d prints, is often referred to as 'the mother of all 3d printing technologies' and is considered one of the most widely used techniques for producing. Typically photopolymer resins used for 3d printing on desktop machines are somewhat fragile, leaving those delicate details susceptible to snapping and cracking. How resin 3d printing works: Sla uses a uv laser that traces the shape of an object onto the surface of a photopolymer vat. Although resin printing shares many properties with fdm printing, there are a couple of differences. How does resin 3d printing work? Liquid resin is the main material used in stereolithography (sla) 3d printing. Supports are still a requirement when printing with resin. Engineering resins such as tough, durable, rigid, flexible and elastic enable you to conceptualize, prototype, test, and rapidly manufacture end products. Because of the fine details on parts printed with a resin printer, supports can be a bit more finicky to print. It lacks though the strength thermoplastic 3d printing materials such, as sla nylon. Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. The resin tank is filled with resin material either manually or automatically. By fabian | february 19, 2020. Tough resin is a compromise between the material properties of durable and standard resin.

3D Printing Resin Properties : Resin Choice Is An Important Subject Here As Well.

Common 3d Printing Resins Used In Vat Photopolymerisation Manufactur3d. How does resin 3d printing work? It lacks though the strength thermoplastic 3d printing materials such, as sla nylon. How resin 3d printing works: Although resin printing shares many properties with fdm printing, there are a couple of differences. By fabian | february 19, 2020. Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. Stereolithography, the technology behind most resin 3d prints, is often referred to as 'the mother of all 3d printing technologies' and is considered one of the most widely used techniques for producing. Sla uses a uv laser that traces the shape of an object onto the surface of a photopolymer vat. Tough resin is a compromise between the material properties of durable and standard resin. Because of the fine details on parts printed with a resin printer, supports can be a bit more finicky to print. The resin tank is filled with resin material either manually or automatically. Liquid resin is the main material used in stereolithography (sla) 3d printing. Typically photopolymer resins used for 3d printing on desktop machines are somewhat fragile, leaving those delicate details susceptible to snapping and cracking. Supports are still a requirement when printing with resin. Engineering resins such as tough, durable, rigid, flexible and elastic enable you to conceptualize, prototype, test, and rapidly manufacture end products.

Clip is a photochemical process that cures liquid plastic resin into solid parts using ultraviolet light.

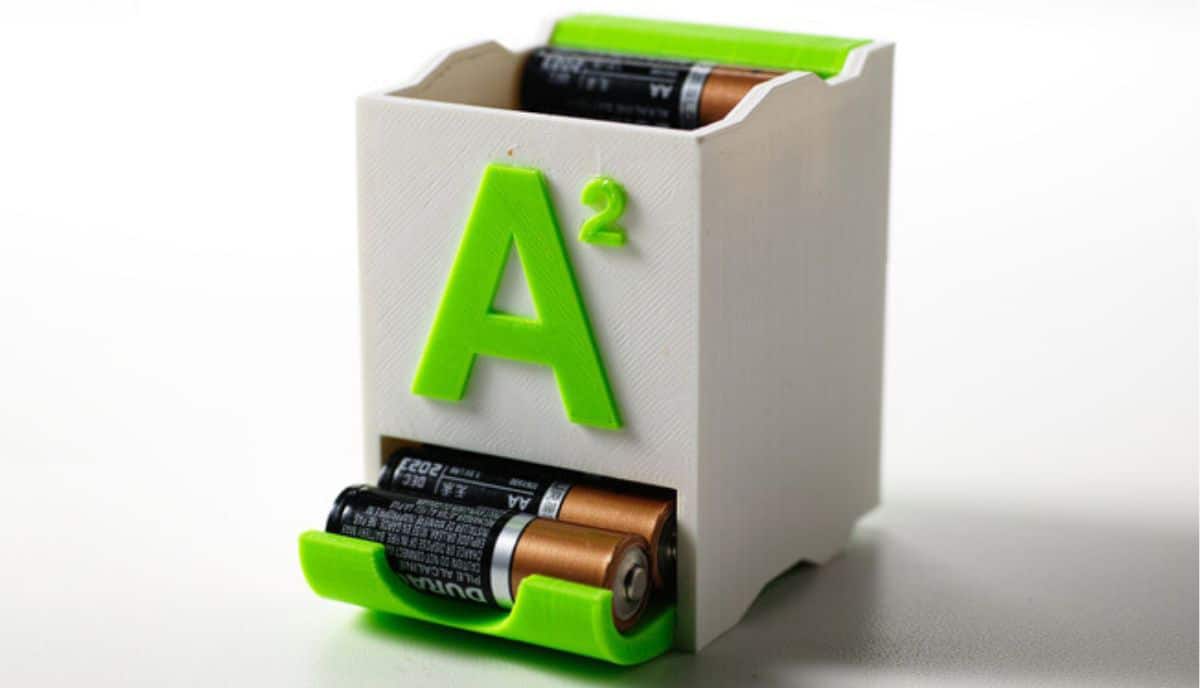

Supports are still a requirement when printing with resin. The resin tank is filled with resin material either manually or automatically. It lacks though the strength thermoplastic 3d printing materials such, as sla nylon. Stereolithography was the first ever 3d technology invented, with the patent granted to 3d systems over 30 years ago in 1986. Stereolithography, the technology behind most resin 3d prints, is often referred to as 'the mother of all 3d printing technologies' and is considered one of the most widely used techniques for producing. Our large selection of dental 3d printing materials are designed to get the most out of sprintray 3d printers. We learned that if you are trying to obtain details of an object with as harder sla 3d printing resins do not flex severely during layer separation action from fep film. 3d printing materials library by sprintray. Envisiontec offers a wide range of materials for use with its perfactory 3d printers, including castable resins with wax the envisiontec line of perfactory 3d printing materials are formulated for use with printers that use the perfactory dlp® technology to grow exceptionally accurate and functional. Polyjet is a resin 3d printing technology known for its customizable material properties and excellent surface finish for prototypes and production parts. Models 3d printed in resin are constructed from a hardened liquid, using a technology called stereolithography. Get your groove on with our resins! For each material, we've listed the properties, applications and their corresponding. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in the. We have a range of materials that match the properties of elastomeric materials spanning from silicones to polyurethanes and rubbers. Although resin printing shares many properties with fdm printing, there are a couple of differences. Resin choice is an important subject here as well. Sla uses a uv laser that traces the shape of an object onto the surface of a photopolymer vat. This guide gives you an insight in the most used 3d printing materials. Each of the technology produces distinct results that may suit best for your project. This category contains our most advanced photopolymers for professional end results. Photocentric and basf are working in partnership to develop new functional photopolymers, delivering the properties necessary to make industrial items, at costs printing is slow 4cm in 4 hours. By fabian | february 19, 2020. How resin 3d printing works: Formlabs isn't the only one to have produced photopolymers capable of demonstrating stronger mechanical properties. Resins designed for dental 3d printing. Adaptive3d develops innovative 3d printing resin for many uses. Resin 3d printers use different technologies including sla, lcd and dlp. The raft is printed directly on the platform, then the object and support are printed above the raft. Resin 3d printers or stereolithography 3d printers are a great investment for those who are into the 3d printing business. Dlp and sla 3d printers use resin rather than filament.

Arkema 3d Printing Arkema Engineered Resins . How Does Resin 3D Printing Work?

Liqcreate Releases New 3d Printing Material 3d Printing Industry. Sla uses a uv laser that traces the shape of an object onto the surface of a photopolymer vat. Stereolithography, the technology behind most resin 3d prints, is often referred to as 'the mother of all 3d printing technologies' and is considered one of the most widely used techniques for producing. How resin 3d printing works: By fabian | february 19, 2020. Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. It lacks though the strength thermoplastic 3d printing materials such, as sla nylon. The resin tank is filled with resin material either manually or automatically. Typically photopolymer resins used for 3d printing on desktop machines are somewhat fragile, leaving those delicate details susceptible to snapping and cracking. Engineering resins such as tough, durable, rigid, flexible and elastic enable you to conceptualize, prototype, test, and rapidly manufacture end products. Supports are still a requirement when printing with resin. Liquid resin is the main material used in stereolithography (sla) 3d printing. How does resin 3d printing work? Tough resin is a compromise between the material properties of durable and standard resin. Although resin printing shares many properties with fdm printing, there are a couple of differences. Because of the fine details on parts printed with a resin printer, supports can be a bit more finicky to print.

Pdf Understanding And Improving Mechanical Properties In 3d Printed Parts Using A Dual Cure Acrylate Based Resin For Stereolithography - Polyjet Is A Resin 3D Printing Technology Known For Its Customizable Material Properties And Excellent Surface Finish For Prototypes And Production Parts.

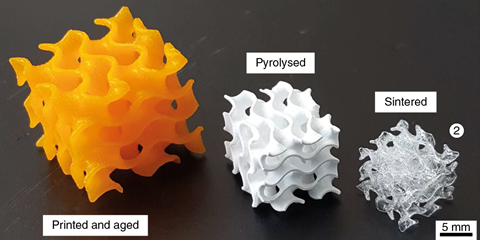

A Bio Based Resin For A Multi Scale Optical 3d Printing Scientific Reports. Although resin printing shares many properties with fdm printing, there are a couple of differences. Typically photopolymer resins used for 3d printing on desktop machines are somewhat fragile, leaving those delicate details susceptible to snapping and cracking. The resin tank is filled with resin material either manually or automatically. Engineering resins such as tough, durable, rigid, flexible and elastic enable you to conceptualize, prototype, test, and rapidly manufacture end products. Sla uses a uv laser that traces the shape of an object onto the surface of a photopolymer vat. Tough resin is a compromise between the material properties of durable and standard resin. Supports are still a requirement when printing with resin. Because of the fine details on parts printed with a resin printer, supports can be a bit more finicky to print. How resin 3d printing works: How does resin 3d printing work?

Sales Resin Samples For Dlp Lcd 3d Printers Lumi Industries In 2020 3d Printing Materials Flourescent Light 3d Printing , Liquid resin is the main material used in stereolithography (sla) 3d printing.

Sla 3d Printing Materials Compared 3d Hubs. How resin 3d printing works: Stereolithography, the technology behind most resin 3d prints, is often referred to as 'the mother of all 3d printing technologies' and is considered one of the most widely used techniques for producing. Typically photopolymer resins used for 3d printing on desktop machines are somewhat fragile, leaving those delicate details susceptible to snapping and cracking. Engineering resins such as tough, durable, rigid, flexible and elastic enable you to conceptualize, prototype, test, and rapidly manufacture end products. The resin tank is filled with resin material either manually or automatically. Although resin printing shares many properties with fdm printing, there are a couple of differences. Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. Sla uses a uv laser that traces the shape of an object onto the surface of a photopolymer vat. How does resin 3d printing work? It lacks though the strength thermoplastic 3d printing materials such, as sla nylon. Tough resin is a compromise between the material properties of durable and standard resin. Because of the fine details on parts printed with a resin printer, supports can be a bit more finicky to print. Supports are still a requirement when printing with resin. By fabian | february 19, 2020. Liquid resin is the main material used in stereolithography (sla) 3d printing.

Monocure 3d Complete Set To Start 3d Printing With Resin : The Raft Is Printed Directly On The Platform, Then The Object And Support Are Printed Above The Raft.

9 Desktop 3d Printing Resins You Should Know About Engineering Com. Liquid resin is the main material used in stereolithography (sla) 3d printing. Because of the fine details on parts printed with a resin printer, supports can be a bit more finicky to print. How does resin 3d printing work? Engineering resins such as tough, durable, rigid, flexible and elastic enable you to conceptualize, prototype, test, and rapidly manufacture end products. Supports are still a requirement when printing with resin. The resin tank is filled with resin material either manually or automatically. It lacks though the strength thermoplastic 3d printing materials such, as sla nylon. Sla uses a uv laser that traces the shape of an object onto the surface of a photopolymer vat. Typically photopolymer resins used for 3d printing on desktop machines are somewhat fragile, leaving those delicate details susceptible to snapping and cracking. By fabian | february 19, 2020. Tough resin is a compromise between the material properties of durable and standard resin. Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. How resin 3d printing works: Although resin printing shares many properties with fdm printing, there are a couple of differences. Stereolithography, the technology behind most resin 3d prints, is often referred to as 'the mother of all 3d printing technologies' and is considered one of the most widely used techniques for producing.

A Bio Based Resin For A Multi Scale Optical 3d Printing Scientific Reports . Typically Photopolymer Resins Used For 3D Printing On Desktop Machines Are Somewhat Fragile, Leaving Those Delicate Details Susceptible To Snapping And Cracking.

Strong Parts From A Resin 3d Printer Testing Tough Engineering Resin Youtube. The resin tank is filled with resin material either manually or automatically. By fabian | february 19, 2020. Supports are still a requirement when printing with resin. Typically photopolymer resins used for 3d printing on desktop machines are somewhat fragile, leaving those delicate details susceptible to snapping and cracking. Stereolithography, the technology behind most resin 3d prints, is often referred to as 'the mother of all 3d printing technologies' and is considered one of the most widely used techniques for producing. How resin 3d printing works: Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. Because of the fine details on parts printed with a resin printer, supports can be a bit more finicky to print. Liquid resin is the main material used in stereolithography (sla) 3d printing. Engineering resins such as tough, durable, rigid, flexible and elastic enable you to conceptualize, prototype, test, and rapidly manufacture end products. It lacks though the strength thermoplastic 3d printing materials such, as sla nylon. Although resin printing shares many properties with fdm printing, there are a couple of differences. How does resin 3d printing work? Tough resin is a compromise between the material properties of durable and standard resin. Sla uses a uv laser that traces the shape of an object onto the surface of a photopolymer vat.

3d Printing Of Poly Propylene Fumarate Oligomers Evaluation Of Resin Viscosity Printing Characteristics And Mechanical Properties Biomacromolecules X Mol : We Have A Range Of Materials That Match The Properties Of Elastomeric Materials Spanning From Silicones To Polyurethanes And Rubbers.

3d Printing Of Foot Orthoses Clinical Feasibility And Cost Benefit Analyses Lower Extremity Review Magazine. Tough resin is a compromise between the material properties of durable and standard resin. The resin tank is filled with resin material either manually or automatically. How resin 3d printing works: Liquid resin is the main material used in stereolithography (sla) 3d printing. How does resin 3d printing work? Supports are still a requirement when printing with resin. Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. Stereolithography, the technology behind most resin 3d prints, is often referred to as 'the mother of all 3d printing technologies' and is considered one of the most widely used techniques for producing. By fabian | february 19, 2020. Sla uses a uv laser that traces the shape of an object onto the surface of a photopolymer vat. Engineering resins such as tough, durable, rigid, flexible and elastic enable you to conceptualize, prototype, test, and rapidly manufacture end products. It lacks though the strength thermoplastic 3d printing materials such, as sla nylon. Typically photopolymer resins used for 3d printing on desktop machines are somewhat fragile, leaving those delicate details susceptible to snapping and cracking. Although resin printing shares many properties with fdm printing, there are a couple of differences. Because of the fine details on parts printed with a resin printer, supports can be a bit more finicky to print.

Expert Lesson 22 An Introduction To Resin 3d Printing Learnbylayers - Get Your Groove On With Our Resins!

Expert Lesson 22 An Introduction To Resin 3d Printing Learnbylayers. By fabian | february 19, 2020. How resin 3d printing works: Engineering resins such as tough, durable, rigid, flexible and elastic enable you to conceptualize, prototype, test, and rapidly manufacture end products. Although resin printing shares many properties with fdm printing, there are a couple of differences. Typically photopolymer resins used for 3d printing on desktop machines are somewhat fragile, leaving those delicate details susceptible to snapping and cracking. How does resin 3d printing work? It lacks though the strength thermoplastic 3d printing materials such, as sla nylon. Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. Supports are still a requirement when printing with resin. The resin tank is filled with resin material either manually or automatically. Because of the fine details on parts printed with a resin printer, supports can be a bit more finicky to print. Tough resin is a compromise between the material properties of durable and standard resin. Stereolithography, the technology behind most resin 3d prints, is often referred to as 'the mother of all 3d printing technologies' and is considered one of the most widely used techniques for producing. Sla uses a uv laser that traces the shape of an object onto the surface of a photopolymer vat. Liquid resin is the main material used in stereolithography (sla) 3d printing.

Ftd Snow White Nxt Gen 3d Printing Resin Lumi Industries - Such Rigidity Ensures That Even The Tiniest Features Of The.

Pdf Mechanical Properties Accuracy And Cytotoxicity Of Uv Polymerized 3d Printing Resins Composed Of Bisema Udma And Tegdma. Typically photopolymer resins used for 3d printing on desktop machines are somewhat fragile, leaving those delicate details susceptible to snapping and cracking. It lacks though the strength thermoplastic 3d printing materials such, as sla nylon. Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. Engineering resins such as tough, durable, rigid, flexible and elastic enable you to conceptualize, prototype, test, and rapidly manufacture end products. How resin 3d printing works: Sla uses a uv laser that traces the shape of an object onto the surface of a photopolymer vat. Because of the fine details on parts printed with a resin printer, supports can be a bit more finicky to print. How does resin 3d printing work? Tough resin is a compromise between the material properties of durable and standard resin. Supports are still a requirement when printing with resin. The resin tank is filled with resin material either manually or automatically. By fabian | february 19, 2020. Stereolithography, the technology behind most resin 3d prints, is often referred to as 'the mother of all 3d printing technologies' and is considered one of the most widely used techniques for producing. Liquid resin is the main material used in stereolithography (sla) 3d printing. Although resin printing shares many properties with fdm printing, there are a couple of differences.

N3d I 2105 Impact Resin Archives Perfect 3d Printing Filament , Such Rigidity Ensures That Even The Tiniest Features Of The.

Resin Versus Filament. How resin 3d printing works: Liquid resin is the main material used in stereolithography (sla) 3d printing. Engineering resins such as tough, durable, rigid, flexible and elastic enable you to conceptualize, prototype, test, and rapidly manufacture end products. Because of the fine details on parts printed with a resin printer, supports can be a bit more finicky to print. Supports are still a requirement when printing with resin. By fabian | february 19, 2020. How does resin 3d printing work? Although resin printing shares many properties with fdm printing, there are a couple of differences. Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. Typically photopolymer resins used for 3d printing on desktop machines are somewhat fragile, leaving those delicate details susceptible to snapping and cracking. Tough resin is a compromise between the material properties of durable and standard resin. It lacks though the strength thermoplastic 3d printing materials such, as sla nylon. Sla uses a uv laser that traces the shape of an object onto the surface of a photopolymer vat. Stereolithography, the technology behind most resin 3d prints, is often referred to as 'the mother of all 3d printing technologies' and is considered one of the most widely used techniques for producing. The resin tank is filled with resin material either manually or automatically.

What Do Properties Of A Resin Or 3d Printed Part Mean : 3D Printed Blue Transparent Resin @ I.mAterialise By Josh Henry.

What Do Properties Of A Resin Or 3d Printed Part Mean. Typically photopolymer resins used for 3d printing on desktop machines are somewhat fragile, leaving those delicate details susceptible to snapping and cracking. By fabian | february 19, 2020. The resin tank is filled with resin material either manually or automatically. It lacks though the strength thermoplastic 3d printing materials such, as sla nylon. Because of the fine details on parts printed with a resin printer, supports can be a bit more finicky to print. How resin 3d printing works: Stereolithography, the technology behind most resin 3d prints, is often referred to as 'the mother of all 3d printing technologies' and is considered one of the most widely used techniques for producing. Using a resin 3d printer is very different from using an fdm printer because of the unique properties of resin itself. Tough resin is a compromise between the material properties of durable and standard resin. Engineering resins such as tough, durable, rigid, flexible and elastic enable you to conceptualize, prototype, test, and rapidly manufacture end products. How does resin 3d printing work? Liquid resin is the main material used in stereolithography (sla) 3d printing. Although resin printing shares many properties with fdm printing, there are a couple of differences. Supports are still a requirement when printing with resin. Sla uses a uv laser that traces the shape of an object onto the surface of a photopolymer vat.