3D Printing Retraction Explained. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. Ok, so if retraction doesn't pull filament back up through. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. Dialing in retraction helps you get the best possible part every time. Too much and the molten filament will solidify. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. Too little and you still get the effects above. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even in the same way, the solid filament above the melt zone does not retract the molten filament with it. Editorial content, on principle, can not be bought or influenced. All3dp is an editorially independent publication. Today, we cover retraction, a crucial part of basic tuning! Molten plastic is then layered to produce a model. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle the retraction setting determines how many millimetres. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print.

3D Printing Retraction Explained . Molten Filament Extrusion Is An Inexact Science At Best.

3d Printing Inconsistent Extrusion Troubleshooting 3d Newb. Too much and the molten filament will solidify. All3dp is an editorially independent publication. Today, we cover retraction, a crucial part of basic tuning! In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle the retraction setting determines how many millimetres. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. Molten plastic is then layered to produce a model. Editorial content, on principle, can not be bought or influenced. Too little and you still get the effects above. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even in the same way, the solid filament above the melt zone does not retract the molten filament with it. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. Dialing in retraction helps you get the best possible part every time. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Ok, so if retraction doesn't pull filament back up through. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached.

Dialing in retraction helps you get the best possible part every time.

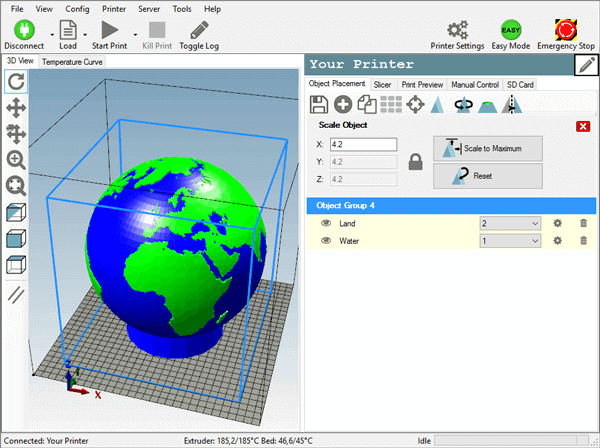

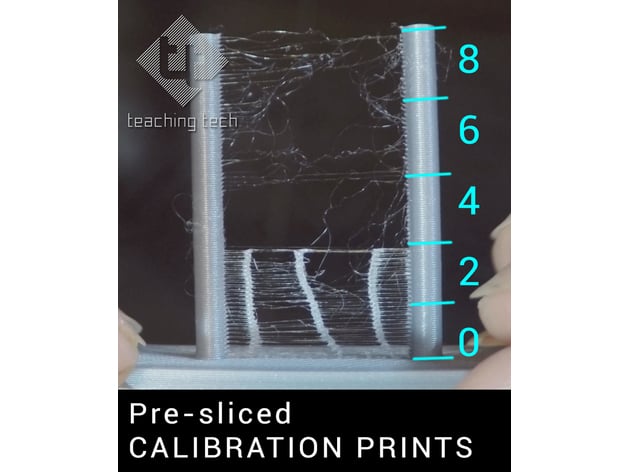

Retraction is the most important setting to adjust when trying to troubleshoot stringing in your prints. Learn how to 3d print. Thingiverse is a universe of things. At shapeways we use a range of different 3d printing technologies to create your 3d prints depending on the material you choose. Editorial content, on principle, can not be bought or influenced. Over the last few decades, it has been making the process of 3d printing begins by making a graphic model of the object to be printed. Molten filament extrusion is an inexact science at best. Download files and build them with your 3d printer, laser cutter, or cnc. Read our 3d printer troubleshooting guide to the most common 3d printing problems and their solutions. Too much and the molten filament will solidify. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. Instead of generating extra e moves, the slicer just outputs. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. This determines how fast the filament is retracted from the nozzle. We will also go through the relevant ultimaker cura slicer software settings and explain what each setting does and enable: When your file is sliced, it's ready for your 3d printer. We use terms like white strong & flexible, frosted ultra detail and full color sandstone to describe the. Turns on and off retraction. Too little and you still get the effects above. Dialing in retraction helps you get the best possible part every time. The retraction speed is the speed at which the filament is retracted, or pulled back (by the extruder stepper), and the retraction length is the amount that is pulled back. If you print cooler or add a cooling fan you may be able to prevent this. Retraction is the most important setting to adjust when trying to troubleshoot stringing in your prints. There are several types of 3d printing, which. Each vary in the way they form plastic and metal parts and can differ in material selection, surface finish, durability, and manufacturing speed and cost. Metal 3d printing takes flight. You've checked the model, seen retraction is an important factor when it comes to quality of finish and can be enabled through most slicing software. News, information, links, help and fun related to 3d printing, 3d printers, additive manufacturing, etc. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. To overcome this your slicing software needs to 'retract' the print medium during head movement when not printing.

How This Result For Ooze Retraction Calibration Test 3dprinting , We Use Terms Like White Strong & Flexible, Frosted Ultra Detail And Full Color Sandstone To Describe The.

Psa Limit Your Combing Distance 3dprinting. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Ok, so if retraction doesn't pull filament back up through. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even in the same way, the solid filament above the melt zone does not retract the molten filament with it. Too much and the molten filament will solidify. Editorial content, on principle, can not be bought or influenced. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle the retraction setting determines how many millimetres. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. Dialing in retraction helps you get the best possible part every time. Molten plastic is then layered to produce a model. Too little and you still get the effects above. Today, we cover retraction, a crucial part of basic tuning! All3dp is an editorially independent publication.

The Ultimate Guide To 3d Printer Extruder Dyze Design . While 3D Printing On A Standard Fdm Printer, The Filament Is Pushed With An Extruder Motor That Has A Gear Attached.

3d Printer Retraction Calibration Vol Ii Calibration Generator Program Release. Too little and you still get the effects above. Editorial content, on principle, can not be bought or influenced. Dialing in retraction helps you get the best possible part every time. Too much and the molten filament will solidify. Ok, so if retraction doesn't pull filament back up through. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even in the same way, the solid filament above the melt zone does not retract the molten filament with it. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle the retraction setting determines how many millimetres. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. Today, we cover retraction, a crucial part of basic tuning! All3dp is an editorially independent publication.

3d Printer Retraction Calibration Vol Ii Calibration Generator Program Release . The term 3d printing can refer to a variety of processes in which.

Retracted Article 3d Printed Highly Flexible Strain Sensor Based On Tpu Graphene Composite For Feedback From High Speed Robotic Applications Journal Of Materials Chemistry C Rsc Publishing. Editorial content, on principle, can not be bought or influenced. Too little and you still get the effects above. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even in the same way, the solid filament above the melt zone does not retract the molten filament with it. Dialing in retraction helps you get the best possible part every time. Molten plastic is then layered to produce a model. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. All3dp is an editorially independent publication. Too much and the molten filament will solidify. Today, we cover retraction, a crucial part of basic tuning! When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle the retraction setting determines how many millimetres. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. Ok, so if retraction doesn't pull filament back up through. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached.

Https Encrypted Tbn0 Gstatic Com Images Q Tbn 3aand9gcsi52p Nfh0ilcuojbqvetgskt0ugzqusmaow Usqp Cau . Molten Filament Extrusion Is An Inexact Science At Best.

3d Printer Retraction Speed What Does It Mean All3dp. Too much and the molten filament will solidify. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. Ok, so if retraction doesn't pull filament back up through. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle the retraction setting determines how many millimetres. Molten plastic is then layered to produce a model. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. Editorial content, on principle, can not be bought or influenced. Today, we cover retraction, a crucial part of basic tuning! Too little and you still get the effects above. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Dialing in retraction helps you get the best possible part every time. All3dp is an editorially independent publication. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even in the same way, the solid filament above the melt zone does not retract the molten filament with it.

The Insidious Problem Of 3d Print Retraction Fabbaloo , In This Article, We Explore 3D Printer Retraction Speed, Why Retraction Is Employed, And How Retraction Settings Are Tweaked To Produce The Perfect Print.

3d Printer Retraction Calibration Vol Ii Calibration Generator Program Release. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Editorial content, on principle, can not be bought or influenced. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. Too little and you still get the effects above. Too much and the molten filament will solidify. Ok, so if retraction doesn't pull filament back up through. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle the retraction setting determines how many millimetres. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even in the same way, the solid filament above the melt zone does not retract the molten filament with it. Molten plastic is then layered to produce a model. Dialing in retraction helps you get the best possible part every time. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. All3dp is an editorially independent publication. Today, we cover retraction, a crucial part of basic tuning!

Some Calibration Photographs Improve Your 3d Prints Ultimaker Community Of 3d Printing Experts : Be Sure You'vE Calibrated Your Slicer Filament Settings Before Trying To Find The Perfect Retraction Settings.

10 Advanced 3d Slicer Settings That Will Save Your Prints. Dialing in retraction helps you get the best possible part every time. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. Ok, so if retraction doesn't pull filament back up through. Molten plastic is then layered to produce a model. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even in the same way, the solid filament above the melt zone does not retract the molten filament with it. Editorial content, on principle, can not be bought or influenced. Today, we cover retraction, a crucial part of basic tuning! In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. Too little and you still get the effects above. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Too much and the molten filament will solidify. All3dp is an editorially independent publication. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle the retraction setting determines how many millimetres. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum.

What I Ve Learned From A Month Of 3d Printing Stuff Jason Does - All3Dp Is An Editorially Independent Publication.

Creatbot 3d Printer. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Dialing in retraction helps you get the best possible part every time. Molten plastic is then layered to produce a model. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. Ok, so if retraction doesn't pull filament back up through. All3dp is an editorially independent publication. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. Too little and you still get the effects above. Too much and the molten filament will solidify. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle the retraction setting determines how many millimetres. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. Today, we cover retraction, a crucial part of basic tuning! By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even in the same way, the solid filament above the melt zone does not retract the molten filament with it. Editorial content, on principle, can not be bought or influenced.

The 3d Benchy Torture Test That Pushes 3d Printers To The Limit 3d Printing Industry - Try Printing Cooler, If Retraction Is Causing The Holes In The Print It Means It's Pulling Soft Plastic Back Off The Print During The Retraction.

All 3d Printing Filaments Types Explained Detailed Guide 3d Insider. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle the retraction setting determines how many millimetres. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. Molten plastic is then layered to produce a model. Too little and you still get the effects above. Today, we cover retraction, a crucial part of basic tuning! Dialing in retraction helps you get the best possible part every time. Ok, so if retraction doesn't pull filament back up through. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. Too much and the molten filament will solidify. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even in the same way, the solid filament above the melt zone does not retract the molten filament with it. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. All3dp is an editorially independent publication. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. Editorial content, on principle, can not be bought or influenced.

Retraction Just Say No To Oozing Matterhackers , Ok, So If Retraction Doesn't Pull Filament Back Up Through.

Retraction Just Say No To Oozing Matterhackers. Too much and the molten filament will solidify. All3dp is an editorially independent publication. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. Editorial content, on principle, can not be bought or influenced. Today, we cover retraction, a crucial part of basic tuning! While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even in the same way, the solid filament above the melt zone does not retract the molten filament with it. Too little and you still get the effects above. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Dialing in retraction helps you get the best possible part every time. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle the retraction setting determines how many millimetres. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. Ok, so if retraction doesn't pull filament back up through. Molten plastic is then layered to produce a model.

What Is Retraction In 3d Printing Definition And Adjustments - Too Little And You Still Get The Effects Above.

Retraction Just Say No To Oozing Matterhackers. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. Editorial content, on principle, can not be bought or influenced. Dialing in retraction helps you get the best possible part every time. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. Too little and you still get the effects above. Ok, so if retraction doesn't pull filament back up through. In 3d printing, retraction pertains to the process of physically retracting material within the printing head during movement. Too much and the molten filament will solidify. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we can help you reduce and even in the same way, the solid filament above the melt zone does not retract the molten filament with it. Molten plastic is then layered to produce a model. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Today, we cover retraction, a crucial part of basic tuning! When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle the retraction setting determines how many millimetres. All3dp is an editorially independent publication.