3D Printing Retraction Issues. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. There are two different speeds that you can adjust for your printing, the. Happy printing and make sure to post your before and after results once you have gotten your retraction settings dialed in! Try printing cooler, if retraction is causing the holes in the print it means it's pulling soft plastic back off the print during the retraction. Following the first episode's success, i decided to keep going. This print has 1mm retraction with 150mm/s travel speed This represents about the worst oozing/stringing possible on this machine. Using more than necessary can cause jams, blobs, and other extrusion related issues. Print is stuck to print bed. Retraction settings include whether to enable retraction, retraction distance, retraction speed, retraction priming speed, retraction priming distance speed it the last adjustment you should make to fix your stringing issues. Over and under extrusion are issues related to your extruder itself not being pushing the correct amount of plastic in the hotend or to a partial nozzle clog. Issues with print bed adhesion, failed supports and the like are not unique to fdm, with sla 3d printing prone to its own particular set of printing woes. So much more to come as the requests for assistance keep coming in :) if you have any 3d. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them.

3D Printing Retraction Issues - There Are Two Different Speeds That You Can Adjust For Your Printing, The.

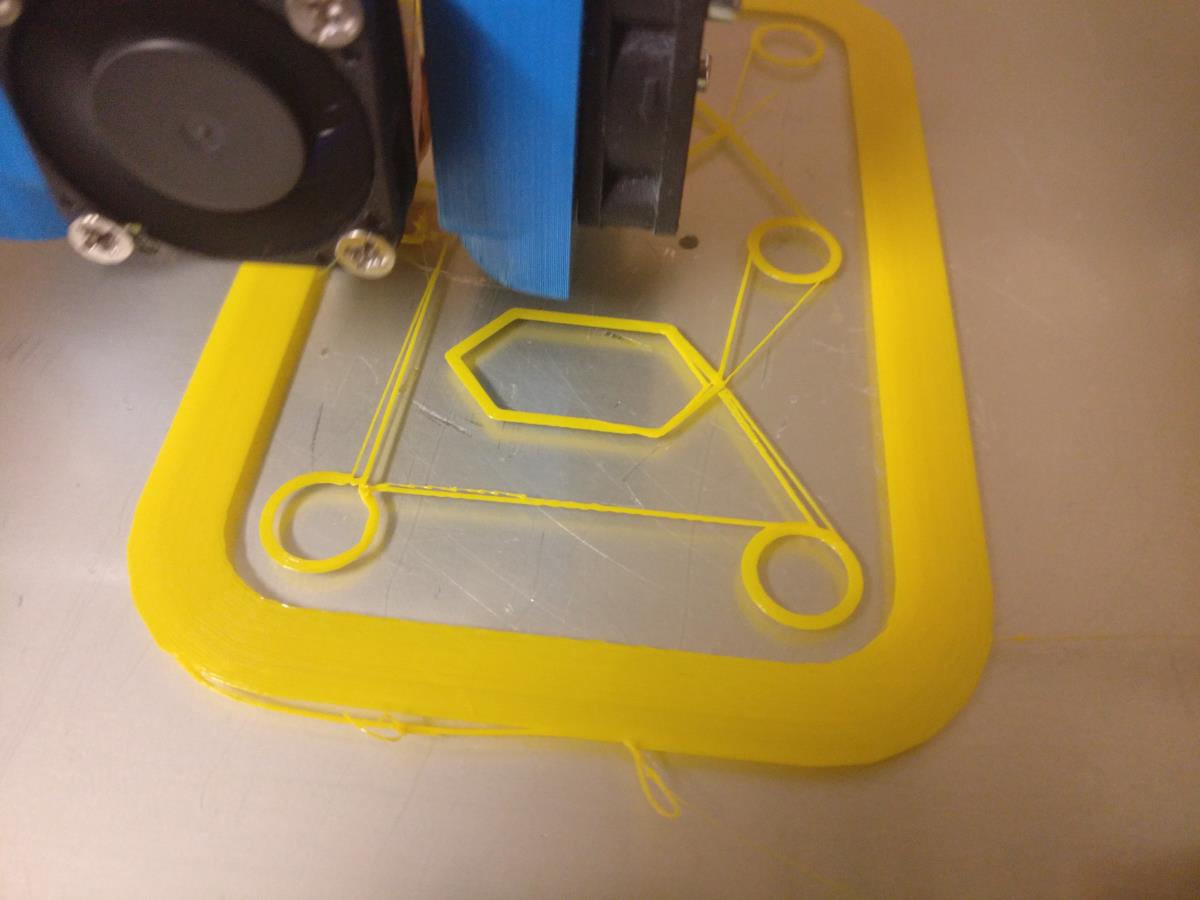

Retraction Just Say No To Oozing Matterhackers. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. So much more to come as the requests for assistance keep coming in :) if you have any 3d. This print has 1mm retraction with 150mm/s travel speed Using more than necessary can cause jams, blobs, and other extrusion related issues. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. Over and under extrusion are issues related to your extruder itself not being pushing the correct amount of plastic in the hotend or to a partial nozzle clog. This represents about the worst oozing/stringing possible on this machine. Following the first episode's success, i decided to keep going. There are two different speeds that you can adjust for your printing, the. Retraction settings include whether to enable retraction, retraction distance, retraction speed, retraction priming speed, retraction priming distance speed it the last adjustment you should make to fix your stringing issues. Issues with print bed adhesion, failed supports and the like are not unique to fdm, with sla 3d printing prone to its own particular set of printing woes. Print is stuck to print bed. Happy printing and make sure to post your before and after results once you have gotten your retraction settings dialed in! Try printing cooler, if retraction is causing the holes in the print it means it's pulling soft plastic back off the print during the retraction.

Printing with the wrong retraction settings can negatively impact the quality of a 3d print.

I'm having issues with retraction. Anthony atala has recently stated that 3d printing technology provides the ability to build and repair human organs. First the retraction parameters have to be set, so that the printer head pulls the filament backwards, while. If you print cooler or add a cooling fan you may be able to prevent this. There are no problem in the next layers, where many retractions are performed. Whioce publishing hereby retracts an article entitled. Any ideas on a solution? The retraction itself always happens, but sometimes the i want to print a phone case. It's a little cumbersome, but it beats trying to track multiple tiny prints. What's the 3d printing problem? Increase extra legth on retract if you use slic3r. Retraction is the main factor in why prints will have small strings of filament between open spaces. Retraction settings include whether to enable retraction, retraction distance, retraction speed, retraction priming speed, retraction priming distance speed it the last adjustment you should make to fix your stringing issues. Printing with the wrong retraction settings can negatively impact the quality of a 3d print. Compared to other models i have sliced, simplify3d implements a lot of retraction moves. A careful analysis of this article published in. It is only in the first layer that the problem shows up. Use short but fast retraction. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle, causing an issue known as oozing or the retraction setting determines how many millimetres. There are two different speeds that you can adjust for your printing, the. Thingiverse is a universe of things. Among issues, which may occur when 3d printing, there is stringing: To do this you would need to have a 2.4ghz band network. The 3d printing experts use this method most of the time to avoid stringing problem. Volume 5, issue 2 (2019). Ethical issues with printing organs. Annoying thin strings left behind by the printer head between two separate parts, which should be free of material. I'll hook in here as i'm facing a similar issue and still trying to learn about retraction. We provide the simplify3d factory files so adjusting the retraction value according to needs of your printer is fairly easy. I'm having issues with retraction. Steps to reproduce just start a print of a model and the first layer is devastating the print.

Retraction Just Say No To Oozing Matterhackers - To Do This You Would Need To Have A 2.4Ghz Band Network.

Stringing Or Oozing. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. So much more to come as the requests for assistance keep coming in :) if you have any 3d. This print has 1mm retraction with 150mm/s travel speed There are two different speeds that you can adjust for your printing, the. Happy printing and make sure to post your before and after results once you have gotten your retraction settings dialed in! Try printing cooler, if retraction is causing the holes in the print it means it's pulling soft plastic back off the print during the retraction. Issues with print bed adhesion, failed supports and the like are not unique to fdm, with sla 3d printing prone to its own particular set of printing woes. Using more than necessary can cause jams, blobs, and other extrusion related issues. Print is stuck to print bed. Following the first episode's success, i decided to keep going. Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. Retraction settings include whether to enable retraction, retraction distance, retraction speed, retraction priming speed, retraction priming distance speed it the last adjustment you should make to fix your stringing issues. This represents about the worst oozing/stringing possible on this machine. Over and under extrusion are issues related to your extruder itself not being pushing the correct amount of plastic in the hotend or to a partial nozzle clog.

Stringing Or Oozing , There Are No Problem In The Next Layers, Where Many Retractions Are Performed.

Identify And Correct 3d Printing Problems Cults. This represents about the worst oozing/stringing possible on this machine. Print is stuck to print bed. This print has 1mm retraction with 150mm/s travel speed Over and under extrusion are issues related to your extruder itself not being pushing the correct amount of plastic in the hotend or to a partial nozzle clog. Try printing cooler, if retraction is causing the holes in the print it means it's pulling soft plastic back off the print during the retraction. Retraction settings include whether to enable retraction, retraction distance, retraction speed, retraction priming speed, retraction priming distance speed it the last adjustment you should make to fix your stringing issues. Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. There are two different speeds that you can adjust for your printing, the. Using more than necessary can cause jams, blobs, and other extrusion related issues.

Most Common 3d Printing Problems With Solutions Technology Outlet : Volume 5, issue 2 (2019).

Retraction Just Say No To Oozing Matterhackers. Print is stuck to print bed. So much more to come as the requests for assistance keep coming in :) if you have any 3d. Following the first episode's success, i decided to keep going. Try printing cooler, if retraction is causing the holes in the print it means it's pulling soft plastic back off the print during the retraction. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. This represents about the worst oozing/stringing possible on this machine. Happy printing and make sure to post your before and after results once you have gotten your retraction settings dialed in! Over and under extrusion are issues related to your extruder itself not being pushing the correct amount of plastic in the hotend or to a partial nozzle clog. This print has 1mm retraction with 150mm/s travel speed There are two different speeds that you can adjust for your printing, the. Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. Issues with print bed adhesion, failed supports and the like are not unique to fdm, with sla 3d printing prone to its own particular set of printing woes. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Using more than necessary can cause jams, blobs, and other extrusion related issues. Retraction settings include whether to enable retraction, retraction distance, retraction speed, retraction priming speed, retraction priming distance speed it the last adjustment you should make to fix your stringing issues.

Common Printing Quality Issues And How To Solve Them Inksmith Limited : If Retraction Is So Long In Length That It Is Pulling The Hot Melt All The Way Out Of The Heatbreak 2Mm Bore And Up To The Point.

Identify And Correct 3d Printing Problems Cults. Print is stuck to print bed. So much more to come as the requests for assistance keep coming in :) if you have any 3d. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. Following the first episode's success, i decided to keep going. There are two different speeds that you can adjust for your printing, the. This represents about the worst oozing/stringing possible on this machine. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Over and under extrusion are issues related to your extruder itself not being pushing the correct amount of plastic in the hotend or to a partial nozzle clog. Try printing cooler, if retraction is causing the holes in the print it means it's pulling soft plastic back off the print during the retraction. Issues with print bed adhesion, failed supports and the like are not unique to fdm, with sla 3d printing prone to its own particular set of printing woes. This print has 1mm retraction with 150mm/s travel speed Using more than necessary can cause jams, blobs, and other extrusion related issues. Retraction settings include whether to enable retraction, retraction distance, retraction speed, retraction priming speed, retraction priming distance speed it the last adjustment you should make to fix your stringing issues. Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. Happy printing and make sure to post your before and after results once you have gotten your retraction settings dialed in!

The Definitive Guide To Solving 3d Printing Problems By Bitfab Bitfab : It's A Little Cumbersome, But It Beats Trying To Track Multiple Tiny Prints.

Identify And Correct 3d Printing Problems Cults. This print has 1mm retraction with 150mm/s travel speed So much more to come as the requests for assistance keep coming in :) if you have any 3d. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. This represents about the worst oozing/stringing possible on this machine. Retraction settings include whether to enable retraction, retraction distance, retraction speed, retraction priming speed, retraction priming distance speed it the last adjustment you should make to fix your stringing issues. Using more than necessary can cause jams, blobs, and other extrusion related issues. Try printing cooler, if retraction is causing the holes in the print it means it's pulling soft plastic back off the print during the retraction. Happy printing and make sure to post your before and after results once you have gotten your retraction settings dialed in! Over and under extrusion are issues related to your extruder itself not being pushing the correct amount of plastic in the hotend or to a partial nozzle clog. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. There are two different speeds that you can adjust for your printing, the. Issues with print bed adhesion, failed supports and the like are not unique to fdm, with sla 3d printing prone to its own particular set of printing woes. Print is stuck to print bed. Following the first episode's success, i decided to keep going.

Another Issue Batches Of Over Extrusion On The Corners Or Retraction Issue 3dprinting - However, If You Have For Example Bowden Extruder, And Don't Own The Simplify3D License, You Could Still Adjust The Retraction Directly In Our Precompiled.

Retraction Blobs How To Minimize Improve Your 3d Prints Ultimaker Community Of 3d Printing Experts. This represents about the worst oozing/stringing possible on this machine. Over and under extrusion are issues related to your extruder itself not being pushing the correct amount of plastic in the hotend or to a partial nozzle clog. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Try printing cooler, if retraction is causing the holes in the print it means it's pulling soft plastic back off the print during the retraction. This print has 1mm retraction with 150mm/s travel speed There are two different speeds that you can adjust for your printing, the. Retraction settings include whether to enable retraction, retraction distance, retraction speed, retraction priming speed, retraction priming distance speed it the last adjustment you should make to fix your stringing issues. Happy printing and make sure to post your before and after results once you have gotten your retraction settings dialed in! Using more than necessary can cause jams, blobs, and other extrusion related issues. Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. Print is stuck to print bed. So much more to come as the requests for assistance keep coming in :) if you have any 3d. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. Issues with print bed adhesion, failed supports and the like are not unique to fdm, with sla 3d printing prone to its own particular set of printing woes. Following the first episode's success, i decided to keep going.

Common Problems In 3d Printing How To Resolve Them Part I Manufactur3d , Molten Filament Extrusion Is An Inexact Science At Best.

Retraction A Powerful Setting Against Stringing Best Cheap 3d Printers. So much more to come as the requests for assistance keep coming in :) if you have any 3d. Try printing cooler, if retraction is causing the holes in the print it means it's pulling soft plastic back off the print during the retraction. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Following the first episode's success, i decided to keep going. Using more than necessary can cause jams, blobs, and other extrusion related issues. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. There are two different speeds that you can adjust for your printing, the. Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. Happy printing and make sure to post your before and after results once you have gotten your retraction settings dialed in! This print has 1mm retraction with 150mm/s travel speed Retraction settings include whether to enable retraction, retraction distance, retraction speed, retraction priming speed, retraction priming distance speed it the last adjustment you should make to fix your stringing issues. Issues with print bed adhesion, failed supports and the like are not unique to fdm, with sla 3d printing prone to its own particular set of printing woes. Print is stuck to print bed. Over and under extrusion are issues related to your extruder itself not being pushing the correct amount of plastic in the hotend or to a partial nozzle clog. This represents about the worst oozing/stringing possible on this machine.

Retraction Just Say No To Oozing Matterhackers , So Much More To Come As The Requests For Assistance Keep Coming In :) If You Have Any 3D.

Retraction Issue At Layer Change Ultimaker Cura Ultimaker Community Of 3d Printing Experts. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. Retraction settings include whether to enable retraction, retraction distance, retraction speed, retraction priming speed, retraction priming distance speed it the last adjustment you should make to fix your stringing issues. Print is stuck to print bed. Using more than necessary can cause jams, blobs, and other extrusion related issues. So much more to come as the requests for assistance keep coming in :) if you have any 3d. Happy printing and make sure to post your before and after results once you have gotten your retraction settings dialed in! Over and under extrusion are issues related to your extruder itself not being pushing the correct amount of plastic in the hotend or to a partial nozzle clog. This print has 1mm retraction with 150mm/s travel speed Issues with print bed adhesion, failed supports and the like are not unique to fdm, with sla 3d printing prone to its own particular set of printing woes. Try printing cooler, if retraction is causing the holes in the print it means it's pulling soft plastic back off the print during the retraction. This represents about the worst oozing/stringing possible on this machine. Following the first episode's success, i decided to keep going. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. There are two different speeds that you can adjust for your printing, the.

Most Common 3d Printing Problems With Solutions Technology Outlet : Volume 5, Issue 2 (2019).

Retraction Just Say No To Oozing Matterhackers. Happy printing and make sure to post your before and after results once you have gotten your retraction settings dialed in! Try printing cooler, if retraction is causing the holes in the print it means it's pulling soft plastic back off the print during the retraction. Using more than necessary can cause jams, blobs, and other extrusion related issues. This represents about the worst oozing/stringing possible on this machine. Issues with print bed adhesion, failed supports and the like are not unique to fdm, with sla 3d printing prone to its own particular set of printing woes. There are two different speeds that you can adjust for your printing, the. Retraction settings include whether to enable retraction, retraction distance, retraction speed, retraction priming speed, retraction priming distance speed it the last adjustment you should make to fix your stringing issues. Following the first episode's success, i decided to keep going. This print has 1mm retraction with 150mm/s travel speed Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. Over and under extrusion are issues related to your extruder itself not being pushing the correct amount of plastic in the hotend or to a partial nozzle clog. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. So much more to come as the requests for assistance keep coming in :) if you have any 3d. Print is stuck to print bed. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum.

Simplify3d Retraction During Wipe Bug Causes Printer Slowdown Th3d Studio Llc - Print Is Stuck To Print Bed.

Identify And Correct 3d Printing Problems Cults. Of retraction in 3d printing as it's a very important parameter to achieve quality prints, without material depositions on the exterior face of the model, or retraction is the recoil movement of the filament necessary to prevent dripping of material during movements and displacements that the vacuum. Happy printing and make sure to post your before and after results once you have gotten your retraction settings dialed in! So much more to come as the requests for assistance keep coming in :) if you have any 3d. This represents about the worst oozing/stringing possible on this machine. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Print is stuck to print bed. Following the first episode's success, i decided to keep going. Use the thumbnails below to identify the picture that most closely represents the quality issue that you are seeing in your own 3d printed parts. There are two different speeds that you can adjust for your printing, the. This print has 1mm retraction with 150mm/s travel speed Using more than necessary can cause jams, blobs, and other extrusion related issues. Over and under extrusion are issues related to your extruder itself not being pushing the correct amount of plastic in the hotend or to a partial nozzle clog. Retraction settings include whether to enable retraction, retraction distance, retraction speed, retraction priming speed, retraction priming distance speed it the last adjustment you should make to fix your stringing issues. Issues with print bed adhesion, failed supports and the like are not unique to fdm, with sla 3d printing prone to its own particular set of printing woes. Try printing cooler, if retraction is causing the holes in the print it means it's pulling soft plastic back off the print during the retraction.