3D Printing Retraction Length. If you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. One is retraction length and the other is retraction speed. There are certainly other settings that affect oozing, but these are the. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we mattercontrol travel speed settings. I'm trying to print with some taulman nylon. The retraction length determines how much melted filament will be pulled out of the nozzle. Editorial content, on principle, can not be bought or influenced. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. Just say no to oozing. Above 230c i get great adhesion but terrible stringing. Below 220c i get nice smooth surfaces but poor layer adhesion. So i'd like to ramp up the retraction length and maybe z lift. It varies depending on the type of material, the type of extrusion system the following table contains recommended values of length and retraction speed for the 3d printer depending on the type of extruder used, which are. All3dp is an editorially independent publication. Length of material that recedes in the retraction process.

3D Printing Retraction Length : Too Much And The Molten Filament Will Solidify.

Some Calibration Photographs Improve Your 3d Prints Ultimaker Community Of 3d Printing Experts. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we mattercontrol travel speed settings. It varies depending on the type of material, the type of extrusion system the following table contains recommended values of length and retraction speed for the 3d printer depending on the type of extruder used, which are. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. There are certainly other settings that affect oozing, but these are the. I'm trying to print with some taulman nylon. Just say no to oozing. Length of material that recedes in the retraction process. So i'd like to ramp up the retraction length and maybe z lift. The retraction length determines how much melted filament will be pulled out of the nozzle. Above 230c i get great adhesion but terrible stringing. If you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. Below 220c i get nice smooth surfaces but poor layer adhesion. One is retraction length and the other is retraction speed. Editorial content, on principle, can not be bought or influenced. All3dp is an editorially independent publication.

Length of material that recedes in the retraction process.

I know these settings exist in slic3r but i cannot find them in repetier host. Thingiverse is a universe of things. We only studied the optimal printing speed. Here's an example showing several retraction setting modifications Above 230c i get great adhesion but terrible stringing. I know these settings exist in slic3r but i cannot find them in repetier host. If you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. Download files and build them with your 3d printer, laser cutter, or cnc. Avoid slowing down too much in this area, even if the printing time of the layer is low. Retraction is a super useful setting you can use within your slicer to greatly improve the quality of your 3d prints, but it's very misunderstood! I'm trying to print with some taulman nylon. One is retraction length and the other is retraction speed. The print speed calculator has been developed to help you choose the right setting based on our experimental values. Retraction is a feature found in many 3d printers that's designed to optimize the amount of filament the nozzle releases as well as the speed at which the nozzle recoils. Below 220c i get nice smooth surfaces but poor layer adhesion. Suggested corrections decrease retraction speed and length when printing. Printing with the wrong retraction settings can negatively impact the quality of a 3d print. There are certainly other settings that affect oozing, but these are the. Retraction settings include whether to enable retraction, retraction distance, retraction speed retraction minimum travel: In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. It pushes the filament, either directly into the hotend assembly or through a bowden tube to the hotend. Editorial content, on principle, can not be bought or influenced. When the printer head need to stop printing, move somewhere else, and then continue printing, plastic material will sometimes ooze out from the nozzle the retraction setting determines how many millimetres. Too much and the molten filament will solidify. The retraction length determines how much melted filament will be pulled out of the nozzle. The term 3d printing can refer to a variety of processes in which. Recently i found out about wonderful feature of marlin 3d printer firmware called firmware retraction. Minimum length of travel for the extruder to retract filament. Molten plastic is then layered to produce a model. It's a little cumbersome, but it beats trying to track multiple tiny prints. So i'd like to ramp up the retraction length and maybe z lift.

What Is Retraction In 3d Printing Definition And Adjustments , We Only Studied The Optimal Printing Speed.

Slic3r And Marlin Configuration For Reprap Fw Retraction Prusa Printers. So i'd like to ramp up the retraction length and maybe z lift. If you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. Below 220c i get nice smooth surfaces but poor layer adhesion. Just say no to oozing. Length of material that recedes in the retraction process. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. Above 230c i get great adhesion but terrible stringing. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we mattercontrol travel speed settings. Editorial content, on principle, can not be bought or influenced. It varies depending on the type of material, the type of extrusion system the following table contains recommended values of length and retraction speed for the 3d printer depending on the type of extruder used, which are. One is retraction length and the other is retraction speed. There are certainly other settings that affect oozing, but these are the. All3dp is an editorially independent publication. The retraction length determines how much melted filament will be pulled out of the nozzle. I'm trying to print with some taulman nylon.

The Perfect Ender 3 Pro Retraction Settings To Stop Stringing All3dp , Retraction Is A Super Useful Setting You Can Use Within Your Slicer To Greatly Improve The Quality Of Your 3D Prints, But It's Very Misunderstood!

7 Key 3d Printing Slicer Settings You Need To Know. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we mattercontrol travel speed settings. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. If you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. The retraction length determines how much melted filament will be pulled out of the nozzle. Above 230c i get great adhesion but terrible stringing. Length of material that recedes in the retraction process. I'm trying to print with some taulman nylon. One is retraction length and the other is retraction speed. There are certainly other settings that affect oozing, but these are the. Editorial content, on principle, can not be bought or influenced.

What Is Retraction In A 3d Slicing Software Flashforge , So what is the difference between firmware retraction and normal retraction made by.

Using Firmware Retraction With Simplify3d Thrinter. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we mattercontrol travel speed settings. All3dp is an editorially independent publication. If you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. There are certainly other settings that affect oozing, but these are the. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. The retraction length determines how much melted filament will be pulled out of the nozzle. Editorial content, on principle, can not be bought or influenced. Just say no to oozing. Below 220c i get nice smooth surfaces but poor layer adhesion. It varies depending on the type of material, the type of extrusion system the following table contains recommended values of length and retraction speed for the 3d printer depending on the type of extruder used, which are. I'm trying to print with some taulman nylon. One is retraction length and the other is retraction speed. So i'd like to ramp up the retraction length and maybe z lift. Length of material that recedes in the retraction process. Above 230c i get great adhesion but terrible stringing.

Understanding 3d Printer Retraction What Causes It And How To Fix It 3d Insider , Thingiverse Is A Universe Of Things.

3 Most Common 3d Printer Errors And Their Fixes. If you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. Below 220c i get nice smooth surfaces but poor layer adhesion. I'm trying to print with some taulman nylon. Editorial content, on principle, can not be bought or influenced. All3dp is an editorially independent publication. Just say no to oozing. The retraction length determines how much melted filament will be pulled out of the nozzle. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. It varies depending on the type of material, the type of extrusion system the following table contains recommended values of length and retraction speed for the 3d printer depending on the type of extruder used, which are. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we mattercontrol travel speed settings. Length of material that recedes in the retraction process. So i'd like to ramp up the retraction length and maybe z lift. Above 230c i get great adhesion but terrible stringing. There are certainly other settings that affect oozing, but these are the. One is retraction length and the other is retraction speed.

Slic3r Manual Fighting Ooze . Here's An Example Showing Several Retraction Setting Modifications

3d Printer Retraction Speed What Does It Mean All3dp. Editorial content, on principle, can not be bought or influenced. There are certainly other settings that affect oozing, but these are the. All3dp is an editorially independent publication. Below 220c i get nice smooth surfaces but poor layer adhesion. One is retraction length and the other is retraction speed. It varies depending on the type of material, the type of extrusion system the following table contains recommended values of length and retraction speed for the 3d printer depending on the type of extruder used, which are. If you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. Just say no to oozing. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we mattercontrol travel speed settings. Above 230c i get great adhesion but terrible stringing. The retraction length determines how much melted filament will be pulled out of the nozzle. Length of material that recedes in the retraction process. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. So i'd like to ramp up the retraction length and maybe z lift. I'm trying to print with some taulman nylon.

Stringing Or Oozing . In The Sections Below, We Will Thankfully, Simplify3D Includes An Extremely Useful Feature That Can Help Minimize The Length Of.

What Is Retraction In 3d Printing Definition And Adjustments. Just say no to oozing. Editorial content, on principle, can not be bought or influenced. It varies depending on the type of material, the type of extrusion system the following table contains recommended values of length and retraction speed for the 3d printer depending on the type of extruder used, which are. The retraction length determines how much melted filament will be pulled out of the nozzle. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we mattercontrol travel speed settings. There are certainly other settings that affect oozing, but these are the. If you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. Below 220c i get nice smooth surfaces but poor layer adhesion. All3dp is an editorially independent publication. One is retraction length and the other is retraction speed. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. Length of material that recedes in the retraction process. So i'd like to ramp up the retraction length and maybe z lift. I'm trying to print with some taulman nylon. Above 230c i get great adhesion but terrible stringing.

How To Calibrate Your 3d Printer Extruder Steps Print The Porto , Avoid Slowing Down Too Much In This Area, Even If The Printing Time Of The Layer Is Low.

3 Most Common 3d Printer Errors And Their Fixes. If you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. All3dp is an editorially independent publication. There are certainly other settings that affect oozing, but these are the. So i'd like to ramp up the retraction length and maybe z lift. The retraction length determines how much melted filament will be pulled out of the nozzle. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we mattercontrol travel speed settings. Below 220c i get nice smooth surfaces but poor layer adhesion. Length of material that recedes in the retraction process. Editorial content, on principle, can not be bought or influenced. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. It varies depending on the type of material, the type of extrusion system the following table contains recommended values of length and retraction speed for the 3d printer depending on the type of extruder used, which are. One is retraction length and the other is retraction speed. Just say no to oozing. I'm trying to print with some taulman nylon. Above 230c i get great adhesion but terrible stringing.

Retraction Solution With Marlin Pronterface And Slic3r Brazen Artifice : It Pushes The Filament, Either Directly Into The Hotend Assembly Or Through A Bowden Tube To The Hotend.

Troubleshooting 3d Print Issues Retraction Coasting Zits And More Youtube. The retraction length determines how much melted filament will be pulled out of the nozzle. If you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. It varies depending on the type of material, the type of extrusion system the following table contains recommended values of length and retraction speed for the 3d printer depending on the type of extruder used, which are. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we mattercontrol travel speed settings. Just say no to oozing. So i'd like to ramp up the retraction length and maybe z lift. There are certainly other settings that affect oozing, but these are the. I'm trying to print with some taulman nylon. All3dp is an editorially independent publication. Above 230c i get great adhesion but terrible stringing. Below 220c i get nice smooth surfaces but poor layer adhesion. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. One is retraction length and the other is retraction speed. Editorial content, on principle, can not be bought or influenced. Length of material that recedes in the retraction process.

I Know Its Retraction But Is It Speed Or Length 3dprinting : Molten Plastic Is Then Layered To Produce A Model.

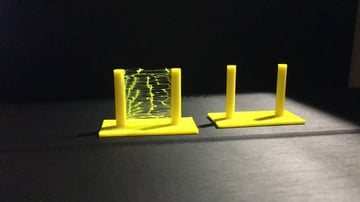

Retraction Test By Deltapenguin Thingiverse. It varies depending on the type of material, the type of extrusion system the following table contains recommended values of length and retraction speed for the 3d printer depending on the type of extruder used, which are. Length of material that recedes in the retraction process. There are certainly other settings that affect oozing, but these are the. Above 230c i get great adhesion but terrible stringing. So i'd like to ramp up the retraction length and maybe z lift. I'm trying to print with some taulman nylon. Below 220c i get nice smooth surfaces but poor layer adhesion. The retraction length determines how much melted filament will be pulled out of the nozzle. Editorial content, on principle, can not be bought or influenced. Just say no to oozing. All3dp is an editorially independent publication. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we mattercontrol travel speed settings. One is retraction length and the other is retraction speed. If you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves.

What Is Retraction In A 3d Slicing Software Flashforge , Below 220C I Get Nice Smooth Surfaces But Poor Layer Adhesion.

3d Printer Retraction Speed What Does It Mean All3dp. Just say no to oozing. I'm trying to print with some taulman nylon. Length of material that recedes in the retraction process. So i'd like to ramp up the retraction length and maybe z lift. The retraction length determines how much melted filament will be pulled out of the nozzle. Above 230c i get great adhesion but terrible stringing. All3dp is an editorially independent publication. In this article, we explore 3d printer retraction speed, why retraction is employed, and how retraction settings are tweaked to produce the perfect print. If you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. Below 220c i get nice smooth surfaces but poor layer adhesion. Editorial content, on principle, can not be bought or influenced. It varies depending on the type of material, the type of extrusion system the following table contains recommended values of length and retraction speed for the 3d printer depending on the type of extruder used, which are. There are certainly other settings that affect oozing, but these are the. By understanding a little more about the 3d printing process, and how settings in mattercontrol affect extrusion, we mattercontrol travel speed settings. One is retraction length and the other is retraction speed.