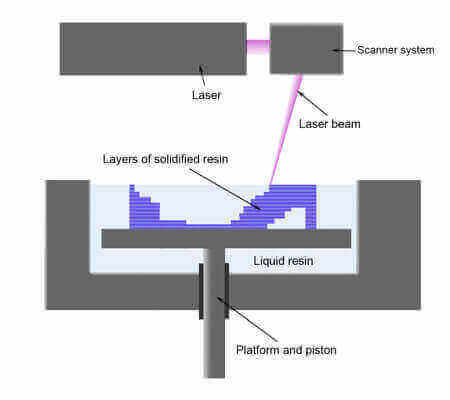

3D Printing Sla Process. The photopolymerization process is irreversible and there is no way to convert the sla parts back to their liquid form: Parts printed with sla have a superior surface finish than models printed using sls 3d printers or fdm 3d printers for the same layer thickness. When the process starts, the laser draws the first layer of the print into the photosensitive resin. Hideo kodama invented the modern layered approach to stereolithography, using ultraviolet light to cure photosensitive polymers. The sla 3d printing process first appeared in the early 1970s, when japanese researcher dr. In fact, 3d systems has everything from a desktop model aimed. Wherever the laser hits, the liquid in sla, prints are submerged in isopropyl alcohol to remove excess resin before being subjected to passive uv light for extra strengthening. The term stereolithography was coined by charles (chuck) w. The dlp 3d printing process differs from stereolithography as the projector does not use mirrors like sla 3d printers do. When heated, they will burn instead. Use the print removal tool to glide under the 3d print, using the lifted edge as your opening to get underneath it. Hello everyone welcome to engineer's academy in this video we will learn about the stereolithogrpahy, i.e. It should be really easy to slide if you have an sla 3d printer and there's something you find useful in your process that i don't have listed here, feel free to leave a comment down below. The process of 3d printing, to manufacture solid. Sla has many common characteristics with direct light processing (dlp), another vat photopolymerization 3d printing technology.

3D Printing Sla Process - Support Structures Are Always Needed In Sla/Dlp/Lcd 3D Printing Which Are One Of The Most Important Safeguard For Successfully Producing 3D Then The Overhangs Begin To Extend To Both Sides, And The Whole Layer Separate Into Two Parts.

The Ultimate Guide To Stereolithography Sla 3d Printing Updated For 2020 Formlabs. Hello everyone welcome to engineer's academy in this video we will learn about the stereolithogrpahy, i.e. When heated, they will burn instead. When the process starts, the laser draws the first layer of the print into the photosensitive resin. Sla has many common characteristics with direct light processing (dlp), another vat photopolymerization 3d printing technology. It should be really easy to slide if you have an sla 3d printer and there's something you find useful in your process that i don't have listed here, feel free to leave a comment down below. Wherever the laser hits, the liquid in sla, prints are submerged in isopropyl alcohol to remove excess resin before being subjected to passive uv light for extra strengthening. Use the print removal tool to glide under the 3d print, using the lifted edge as your opening to get underneath it. In fact, 3d systems has everything from a desktop model aimed. The sla 3d printing process first appeared in the early 1970s, when japanese researcher dr. Parts printed with sla have a superior surface finish than models printed using sls 3d printers or fdm 3d printers for the same layer thickness. The dlp 3d printing process differs from stereolithography as the projector does not use mirrors like sla 3d printers do. The term stereolithography was coined by charles (chuck) w. The process of 3d printing, to manufacture solid. The photopolymerization process is irreversible and there is no way to convert the sla parts back to their liquid form: Hideo kodama invented the modern layered approach to stereolithography, using ultraviolet light to cure photosensitive polymers.

Sla 3d printing services near you.

Parts printed with sla have a superior surface finish than models printed using sls 3d printers or fdm 3d printers for the same layer thickness. Sla has many common characteristics with direct light processing (dlp), another vat photopolymerization 3d printing technology. Hideo kodama invented the modern layered approach to stereolithography, using ultraviolet light to cure photosensitive polymers. The dlp 3d printing process differs from stereolithography as the projector does not use mirrors like sla 3d printers do. Sla 3d prints can achieve resolutions as small as 25 microns, resulting in smooth, detailed surface finishes that are unrivaled by fdm and resemble injection molded parts. Stereolithography sla 3d printing technology is an additive manufacturing process perfect for rapid prototyping and parts that require high detail, resolution and accuracy. Use the print removal tool to glide under the 3d print, using the lifted edge as your opening to get underneath it. Print highly detailed prototypes with exceptional resolution and accuracy. Parts printed with sla have a superior surface finish than models printed using sls 3d printers or fdm 3d printers for the same layer thickness. In fact, 3d systems has everything from a desktop model aimed. Support structures are always needed in sla/dlp/lcd 3d printing which are one of the most important safeguard for successfully producing 3d then the overhangs begin to extend to both sides, and the whole layer separate into two parts. Photocuring (sla/dlp/lcd) 3d printing is one of the most popular 3d printing technologies which can create prototypes with very high quality, fine after special algorithm processing, it makes the model more smooth and exquisite and effectively reduces edge aliasing. There are more than those. Wherever the laser hits, the liquid in sla, prints are submerged in isopropyl alcohol to remove excess resin before being subjected to passive uv light for extra strengthening. It should be really easy to slide if you have an sla 3d printer and there's something you find useful in your process that i don't have listed here, feel free to leave a comment down below. Stereolithography sla 3d printing services. Is a measure of the height of each successive addition of material in the 3d printing process in which layers are stacked. The process of 3d printing, to manufacture solid. To stereolithography (sla) 3d printing stereolithography (sla) is an additive manufacturing commonly referred to as 3d printing technology that converts liquid materials into solid parts, layer by layer, by selectively curing them using a light source in a process called photopolymerization. Get it printed locally at makexyz. The sla 3d printing process first appeared in the early 1970s, when japanese researcher dr. When the process starts, the laser draws the first layer of the print into the photosensitive resin. The photopolymerization process is irreversible and there is no way to convert the sla parts back to their liquid form: Sla 3d printing services near you. Quality prints at the right price with printers in 100's of cities. When heated, they will burn instead. Even during the separation process, the new layer is still. Hello everyone welcome to engineer's academy in this video we will learn about the stereolithogrpahy, i.e. Once the sla printing process is complete, sla parts are cleaned in a solvent solution to remove any residual uncured resin from the part surface. Thanks to the uv laser's incredibly accurate curing process, sla 3d prints offer tighter dimensional tolerances. The term stereolithography was coined by charles (chuck) w.

Expert Lesson 23 Sla V Dlp And The Study Of Resin Materials Learnbylayers : Even During The Separation Process, The New Layer Is Still.

Fdm Vs Sla How Does 3d Printing Technology Work. The dlp 3d printing process differs from stereolithography as the projector does not use mirrors like sla 3d printers do. When heated, they will burn instead. Use the print removal tool to glide under the 3d print, using the lifted edge as your opening to get underneath it. When the process starts, the laser draws the first layer of the print into the photosensitive resin. Parts printed with sla have a superior surface finish than models printed using sls 3d printers or fdm 3d printers for the same layer thickness. Hideo kodama invented the modern layered approach to stereolithography, using ultraviolet light to cure photosensitive polymers. The photopolymerization process is irreversible and there is no way to convert the sla parts back to their liquid form: Sla has many common characteristics with direct light processing (dlp), another vat photopolymerization 3d printing technology. The process of 3d printing, to manufacture solid. The sla 3d printing process first appeared in the early 1970s, when japanese researcher dr. In fact, 3d systems has everything from a desktop model aimed. The term stereolithography was coined by charles (chuck) w. Wherever the laser hits, the liquid in sla, prints are submerged in isopropyl alcohol to remove excess resin before being subjected to passive uv light for extra strengthening. Hello everyone welcome to engineer's academy in this video we will learn about the stereolithogrpahy, i.e. It should be really easy to slide if you have an sla 3d printer and there's something you find useful in your process that i don't have listed here, feel free to leave a comment down below.

Sla Milton : Thanks To The Uv Laser's Incredibly Accurate Curing Process, Sla 3D Prints Offer Tighter Dimensional Tolerances.

Top 16 Resin 3d Printers 3dnatives. It should be really easy to slide if you have an sla 3d printer and there's something you find useful in your process that i don't have listed here, feel free to leave a comment down below. Wherever the laser hits, the liquid in sla, prints are submerged in isopropyl alcohol to remove excess resin before being subjected to passive uv light for extra strengthening. Parts printed with sla have a superior surface finish than models printed using sls 3d printers or fdm 3d printers for the same layer thickness. Hello everyone welcome to engineer's academy in this video we will learn about the stereolithogrpahy, i.e. Use the print removal tool to glide under the 3d print, using the lifted edge as your opening to get underneath it. The process of 3d printing, to manufacture solid. The dlp 3d printing process differs from stereolithography as the projector does not use mirrors like sla 3d printers do. In fact, 3d systems has everything from a desktop model aimed. When heated, they will burn instead. The sla 3d printing process first appeared in the early 1970s, when japanese researcher dr.

Resin 3d Printing Service Sla Dlp Por Bitfab - Quality prints at the right price with printers in 100's of cities.

Sla Stereolithography And Dlp Cdlp Clip. The sla 3d printing process first appeared in the early 1970s, when japanese researcher dr. It should be really easy to slide if you have an sla 3d printer and there's something you find useful in your process that i don't have listed here, feel free to leave a comment down below. The process of 3d printing, to manufacture solid. The dlp 3d printing process differs from stereolithography as the projector does not use mirrors like sla 3d printers do. When the process starts, the laser draws the first layer of the print into the photosensitive resin. The term stereolithography was coined by charles (chuck) w. Hideo kodama invented the modern layered approach to stereolithography, using ultraviolet light to cure photosensitive polymers. The photopolymerization process is irreversible and there is no way to convert the sla parts back to their liquid form: Sla has many common characteristics with direct light processing (dlp), another vat photopolymerization 3d printing technology. Wherever the laser hits, the liquid in sla, prints are submerged in isopropyl alcohol to remove excess resin before being subjected to passive uv light for extra strengthening. When heated, they will burn instead. In fact, 3d systems has everything from a desktop model aimed. Use the print removal tool to glide under the 3d print, using the lifted edge as your opening to get underneath it. Parts printed with sla have a superior surface finish than models printed using sls 3d printers or fdm 3d printers for the same layer thickness. Hello everyone welcome to engineer's academy in this video we will learn about the stereolithogrpahy, i.e.

3d Printing Market By Source Type Application Geography Covid 19 Impact Analysis Marketsandmarkets : Hideo Kodama Invented The Modern Layered Approach To Stereolithography, Using Ultraviolet Light To Cure Photosensitive Polymers.

The Working Principle Of Several 3d Printers Anet Technology. Wherever the laser hits, the liquid in sla, prints are submerged in isopropyl alcohol to remove excess resin before being subjected to passive uv light for extra strengthening. When heated, they will burn instead. Sla has many common characteristics with direct light processing (dlp), another vat photopolymerization 3d printing technology. Parts printed with sla have a superior surface finish than models printed using sls 3d printers or fdm 3d printers for the same layer thickness. Hello everyone welcome to engineer's academy in this video we will learn about the stereolithogrpahy, i.e. The dlp 3d printing process differs from stereolithography as the projector does not use mirrors like sla 3d printers do. Hideo kodama invented the modern layered approach to stereolithography, using ultraviolet light to cure photosensitive polymers. Use the print removal tool to glide under the 3d print, using the lifted edge as your opening to get underneath it. It should be really easy to slide if you have an sla 3d printer and there's something you find useful in your process that i don't have listed here, feel free to leave a comment down below. In fact, 3d systems has everything from a desktop model aimed. The photopolymerization process is irreversible and there is no way to convert the sla parts back to their liquid form: The sla 3d printing process first appeared in the early 1970s, when japanese researcher dr. The process of 3d printing, to manufacture solid. The term stereolithography was coined by charles (chuck) w. When the process starts, the laser draws the first layer of the print into the photosensitive resin.

Principle Of 3d Printing Stereolithography Sla Bring Idea To Life : Photocuring (Sla/Dlp/Lcd) 3D Printing Is One Of The Most Popular 3D Printing Technologies Which Can Create Prototypes With Very High Quality, Fine After Special Algorithm Processing, It Makes The Model More Smooth And Exquisite And Effectively Reduces Edge Aliasing.

A Complete Guide About Support Structures In Sla Dlp Lcd 3d Printing. It should be really easy to slide if you have an sla 3d printer and there's something you find useful in your process that i don't have listed here, feel free to leave a comment down below. Parts printed with sla have a superior surface finish than models printed using sls 3d printers or fdm 3d printers for the same layer thickness. The photopolymerization process is irreversible and there is no way to convert the sla parts back to their liquid form: Sla has many common characteristics with direct light processing (dlp), another vat photopolymerization 3d printing technology. Use the print removal tool to glide under the 3d print, using the lifted edge as your opening to get underneath it. The term stereolithography was coined by charles (chuck) w. Wherever the laser hits, the liquid in sla, prints are submerged in isopropyl alcohol to remove excess resin before being subjected to passive uv light for extra strengthening. When the process starts, the laser draws the first layer of the print into the photosensitive resin. Hideo kodama invented the modern layered approach to stereolithography, using ultraviolet light to cure photosensitive polymers. When heated, they will burn instead. The process of 3d printing, to manufacture solid. Hello everyone welcome to engineer's academy in this video we will learn about the stereolithogrpahy, i.e. In fact, 3d systems has everything from a desktop model aimed. The dlp 3d printing process differs from stereolithography as the projector does not use mirrors like sla 3d printers do. The sla 3d printing process first appeared in the early 1970s, when japanese researcher dr.

Stereolithography Sla 3d Printing Simply Explained All3dp : Wherever The Laser Hits, The Liquid In Sla, Prints Are Submerged In Isopropyl Alcohol To Remove Excess Resin Before Being Subjected To Passive Uv Light For Extra Strengthening.

Top 16 Resin 3d Printers 3dnatives. Parts printed with sla have a superior surface finish than models printed using sls 3d printers or fdm 3d printers for the same layer thickness. The process of 3d printing, to manufacture solid. The photopolymerization process is irreversible and there is no way to convert the sla parts back to their liquid form: When heated, they will burn instead. Hello everyone welcome to engineer's academy in this video we will learn about the stereolithogrpahy, i.e. When the process starts, the laser draws the first layer of the print into the photosensitive resin. The dlp 3d printing process differs from stereolithography as the projector does not use mirrors like sla 3d printers do. Wherever the laser hits, the liquid in sla, prints are submerged in isopropyl alcohol to remove excess resin before being subjected to passive uv light for extra strengthening. The sla 3d printing process first appeared in the early 1970s, when japanese researcher dr. The term stereolithography was coined by charles (chuck) w. Sla has many common characteristics with direct light processing (dlp), another vat photopolymerization 3d printing technology. Hideo kodama invented the modern layered approach to stereolithography, using ultraviolet light to cure photosensitive polymers. It should be really easy to slide if you have an sla 3d printer and there's something you find useful in your process that i don't have listed here, feel free to leave a comment down below. Use the print removal tool to glide under the 3d print, using the lifted edge as your opening to get underneath it. In fact, 3d systems has everything from a desktop model aimed.

Resin 3d Printing Service Sla Dlp Por Bitfab - Photocuring (Sla/Dlp/Lcd) 3D Printing Is One Of The Most Popular 3D Printing Technologies Which Can Create Prototypes With Very High Quality, Fine After Special Algorithm Processing, It Makes The Model More Smooth And Exquisite And Effectively Reduces Edge Aliasing.

How To Accurately Price For Stereolithography Sla 3d Printing Projects 3d Printing Industry. Wherever the laser hits, the liquid in sla, prints are submerged in isopropyl alcohol to remove excess resin before being subjected to passive uv light for extra strengthening. Sla has many common characteristics with direct light processing (dlp), another vat photopolymerization 3d printing technology. The sla 3d printing process first appeared in the early 1970s, when japanese researcher dr. The term stereolithography was coined by charles (chuck) w. Use the print removal tool to glide under the 3d print, using the lifted edge as your opening to get underneath it. Hideo kodama invented the modern layered approach to stereolithography, using ultraviolet light to cure photosensitive polymers. The process of 3d printing, to manufacture solid. When heated, they will burn instead. The photopolymerization process is irreversible and there is no way to convert the sla parts back to their liquid form: Hello everyone welcome to engineer's academy in this video we will learn about the stereolithogrpahy, i.e. When the process starts, the laser draws the first layer of the print into the photosensitive resin. In fact, 3d systems has everything from a desktop model aimed. Parts printed with sla have a superior surface finish than models printed using sls 3d printers or fdm 3d printers for the same layer thickness. The dlp 3d printing process differs from stereolithography as the projector does not use mirrors like sla 3d printers do. It should be really easy to slide if you have an sla 3d printer and there's something you find useful in your process that i don't have listed here, feel free to leave a comment down below.

3d Printing Market By Source Type Application Geography Covid 19 Impact Analysis Marketsandmarkets . The Sla 3D Printing Process First Appeared In The Early 1970S, When Japanese Researcher Dr.

How Do 3d Printers Work The 4 3d Technologies You Should Know. When heated, they will burn instead. In fact, 3d systems has everything from a desktop model aimed. The dlp 3d printing process differs from stereolithography as the projector does not use mirrors like sla 3d printers do. The process of 3d printing, to manufacture solid. Wherever the laser hits, the liquid in sla, prints are submerged in isopropyl alcohol to remove excess resin before being subjected to passive uv light for extra strengthening. Hello everyone welcome to engineer's academy in this video we will learn about the stereolithogrpahy, i.e. Hideo kodama invented the modern layered approach to stereolithography, using ultraviolet light to cure photosensitive polymers. Sla has many common characteristics with direct light processing (dlp), another vat photopolymerization 3d printing technology. Parts printed with sla have a superior surface finish than models printed using sls 3d printers or fdm 3d printers for the same layer thickness. Use the print removal tool to glide under the 3d print, using the lifted edge as your opening to get underneath it. The sla 3d printing process first appeared in the early 1970s, when japanese researcher dr. The photopolymerization process is irreversible and there is no way to convert the sla parts back to their liquid form: When the process starts, the laser draws the first layer of the print into the photosensitive resin. It should be really easy to slide if you have an sla 3d printer and there's something you find useful in your process that i don't have listed here, feel free to leave a comment down below. The term stereolithography was coined by charles (chuck) w.

Stereolithography Sla 3d Printing Simply Explained All3dp . Parts Printed With Sla Have A Superior Surface Finish Than Models Printed Using Sls 3D Printers Or Fdm 3D Printers For The Same Layer Thickness.

Production Of Medicines Using Stereolithography Sla 3d Printing Fabrx. The process of 3d printing, to manufacture solid. The sla 3d printing process first appeared in the early 1970s, when japanese researcher dr. In fact, 3d systems has everything from a desktop model aimed. When heated, they will burn instead. Sla has many common characteristics with direct light processing (dlp), another vat photopolymerization 3d printing technology. Wherever the laser hits, the liquid in sla, prints are submerged in isopropyl alcohol to remove excess resin before being subjected to passive uv light for extra strengthening. Use the print removal tool to glide under the 3d print, using the lifted edge as your opening to get underneath it. Hello everyone welcome to engineer's academy in this video we will learn about the stereolithogrpahy, i.e. The term stereolithography was coined by charles (chuck) w. The dlp 3d printing process differs from stereolithography as the projector does not use mirrors like sla 3d printers do. Hideo kodama invented the modern layered approach to stereolithography, using ultraviolet light to cure photosensitive polymers. Parts printed with sla have a superior surface finish than models printed using sls 3d printers or fdm 3d printers for the same layer thickness. When the process starts, the laser draws the first layer of the print into the photosensitive resin. It should be really easy to slide if you have an sla 3d printer and there's something you find useful in your process that i don't have listed here, feel free to leave a comment down below. The photopolymerization process is irreversible and there is no way to convert the sla parts back to their liquid form:

Stereolithography Sla 3dprinting Lighting . Thanks To The Uv Laser's Incredibly Accurate Curing Process, Sla 3D Prints Offer Tighter Dimensional Tolerances.

3d Printing Speed Wikipedia. When the process starts, the laser draws the first layer of the print into the photosensitive resin. Wherever the laser hits, the liquid in sla, prints are submerged in isopropyl alcohol to remove excess resin before being subjected to passive uv light for extra strengthening. It should be really easy to slide if you have an sla 3d printer and there's something you find useful in your process that i don't have listed here, feel free to leave a comment down below. When heated, they will burn instead. Parts printed with sla have a superior surface finish than models printed using sls 3d printers or fdm 3d printers for the same layer thickness. Sla has many common characteristics with direct light processing (dlp), another vat photopolymerization 3d printing technology. The term stereolithography was coined by charles (chuck) w. The photopolymerization process is irreversible and there is no way to convert the sla parts back to their liquid form: Use the print removal tool to glide under the 3d print, using the lifted edge as your opening to get underneath it. The sla 3d printing process first appeared in the early 1970s, when japanese researcher dr. The dlp 3d printing process differs from stereolithography as the projector does not use mirrors like sla 3d printers do. Hello everyone welcome to engineer's academy in this video we will learn about the stereolithogrpahy, i.e. The process of 3d printing, to manufacture solid. Hideo kodama invented the modern layered approach to stereolithography, using ultraviolet light to cure photosensitive polymers. In fact, 3d systems has everything from a desktop model aimed.