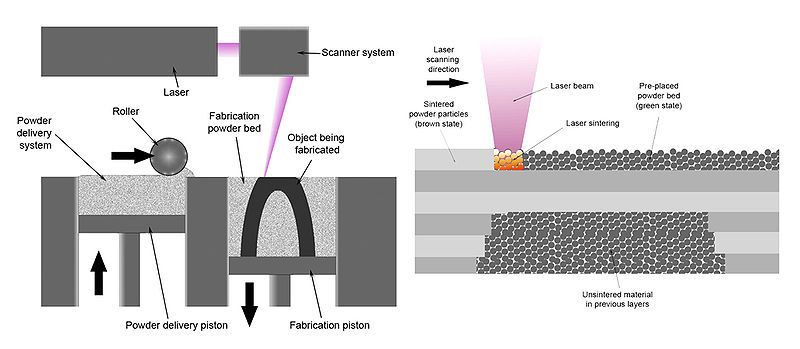

3D Printing Sls Process. Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again. Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. How does sls 3d printing work? The powder bin and the build area are first heated just below the melting temperature of the polymer and a recoating. Sls 3d printing is an amazing 3d printer technology that uses lasers to sintering a nylon powder to form awesome models! The bin is then placed into. A vital aspect is the way of. Powder is dispersed in a thin layer on top of a platform inside of the build chamber. The most common material for selective laser sintering is nylon, a popular engineering thermoplastic beloved for its lightweight, strong, and flexible properties. Sls 3d printing is used for both prototyping of functional polymer components and for small production runs, as it offers a very here is how the sls fabrication process works: After each layer is fused, a roller moves across the bed to distribute the next layer of powder. Here are some model from the. Heart model printed with sinterit lisa sls 3d printer. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). The process is repeated layer by layer until the build is complete.

3D Printing Sls Process . How Does Sls 3D Printing Work?

Fdm Vs Sls 3d Printers Which Tensile Properties. The bin is then placed into. Powder is dispersed in a thin layer on top of a platform inside of the build chamber. Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. After each layer is fused, a roller moves across the bed to distribute the next layer of powder. Sls 3d printing is used for both prototyping of functional polymer components and for small production runs, as it offers a very here is how the sls fabrication process works: Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again. A vital aspect is the way of. Heart model printed with sinterit lisa sls 3d printer. Sls 3d printing is an amazing 3d printer technology that uses lasers to sintering a nylon powder to form awesome models! The process is repeated layer by layer until the build is complete. Here are some model from the. The most common material for selective laser sintering is nylon, a popular engineering thermoplastic beloved for its lightweight, strong, and flexible properties. The powder bin and the build area are first heated just below the melting temperature of the polymer and a recoating. How does sls 3d printing work? Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide).

The process is repeated layer by layer until the build is complete.

The process is repeated layer by layer until the build is complete. Schematic diagram of sls 3d printing process. The process is repeated layer by layer until the build is complete. Powder is dispersed in a thin layer on top of a platform inside of the build chamber. Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. The precision and quality of the final result depend, among other factors with the sls 3d printing technology, a laser beam is used to sinter a powdered material: Nasa is charged to get american astronauts to the moon by 2024. During the 3d printing process, the sls machine preheats the bulk powder material in the powder bed somewhat below its melting point, to make it easier for the laser to raise the temperature of the selected regions the rest of the way to the melting point. Sls 3d printing involves plastic polymer powders which are sintered using a laser inside the sls 3d printer. Stacked layers of material form the final 3d printed object. The roller compacts the powder, a process which allows for more precise sintering. Sls 3d printing is used for both prototyping of functional polymer components and for small production runs, as it offers a very here is how the sls fabrication process works: The quality of the powders is dependent on the suppliers proprietary processes. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). The bin is then placed into. Sls 3d printing is particularly exciting because of the flexibility of materials that can be used. In sls, to fabricate the 3d structure with interlayer compositional differences, the successive base composed of the powder particles must be cleaned and a new biomaterial substance should be added. This streamlined the process, from 3d printing to pour application, and allowed for quicker processing times. A vital aspect is the way of. This is because selective laser sintering is a less affordable method. The 3d design can be of a single part or of multiple parts. Sls 3d printing services near you. The most common material for selective laser sintering is nylon, a popular engineering thermoplastic beloved for its lightweight, strong, and flexible properties. Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again. Heart model printed with sinterit lisa sls 3d printer. As rapiwith fused deposition modeling most sls 3d printers are out of budget for all but the most wealthy of consumers. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. Here are some model from the. A roller will apply a layer of polymer powder. Get it printed locally at makexyz. Printing with the maximum volume possible is recommended to avoid having lots of used powder, so it is not ideal for individual parts of small production runs.

Selective Laser Sintering Process Youtube - A Vital Aspect Is The Way Of.

What S The Difference Between Stereolithography And Selective Laser Sintering Machine Design. How does sls 3d printing work? Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. The process is repeated layer by layer until the build is complete. Sls 3d printing is used for both prototyping of functional polymer components and for small production runs, as it offers a very here is how the sls fabrication process works: The most common material for selective laser sintering is nylon, a popular engineering thermoplastic beloved for its lightweight, strong, and flexible properties. Here are some model from the. A vital aspect is the way of. Sls 3d printing is an amazing 3d printer technology that uses lasers to sintering a nylon powder to form awesome models! After each layer is fused, a roller moves across the bed to distribute the next layer of powder. Heart model printed with sinterit lisa sls 3d printer. The powder bin and the build area are first heated just below the melting temperature of the polymer and a recoating. Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). Powder is dispersed in a thin layer on top of a platform inside of the build chamber. The bin is then placed into.

Selective Laser Sintering An Overview Sciencedirect Topics - Sls 3D Printing Involves Plastic Polymer Powders Which Are Sintered Using A Laser Inside The Sls 3D Printer.

Sls 3d Printing Advantages And Applications Beamler. Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again. Here are some model from the. After each layer is fused, a roller moves across the bed to distribute the next layer of powder. A vital aspect is the way of. Heart model printed with sinterit lisa sls 3d printer. Powder is dispersed in a thin layer on top of a platform inside of the build chamber. The bin is then placed into. The most common material for selective laser sintering is nylon, a popular engineering thermoplastic beloved for its lightweight, strong, and flexible properties. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). The process is repeated layer by layer until the build is complete.

What Is 3d Printing And How Does It Work Jita , The process is repeated layer by layer until the build is complete.

Sls Selective Laser Sintering 3d Printing Powder Based Process. How does sls 3d printing work? The bin is then placed into. Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again. Sls 3d printing is an amazing 3d printer technology that uses lasers to sintering a nylon powder to form awesome models! The most common material for selective laser sintering is nylon, a popular engineering thermoplastic beloved for its lightweight, strong, and flexible properties. A vital aspect is the way of. The powder bin and the build area are first heated just below the melting temperature of the polymer and a recoating. Sls 3d printing is used for both prototyping of functional polymer components and for small production runs, as it offers a very here is how the sls fabrication process works: Heart model printed with sinterit lisa sls 3d printer. Powder is dispersed in a thin layer on top of a platform inside of the build chamber. The process is repeated layer by layer until the build is complete. Here are some model from the. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). After each layer is fused, a roller moves across the bed to distribute the next layer of powder.

Desktop Sls 3d Printer 2020 Hardware Selection And Technology Guide - A Vital Aspect Is The Way Of.

Aerosint Is Developing The First Commercial Multi Powder Sls 3d Printer 3d Printing Media Network The Pulse Of The Am Industry. The powder bin and the build area are first heated just below the melting temperature of the polymer and a recoating. Powder is dispersed in a thin layer on top of a platform inside of the build chamber. The most common material for selective laser sintering is nylon, a popular engineering thermoplastic beloved for its lightweight, strong, and flexible properties. Here are some model from the. How does sls 3d printing work? After each layer is fused, a roller moves across the bed to distribute the next layer of powder. The bin is then placed into. Heart model printed with sinterit lisa sls 3d printer. Sls 3d printing is used for both prototyping of functional polymer components and for small production runs, as it offers a very here is how the sls fabrication process works: Sls 3d printing is an amazing 3d printer technology that uses lasers to sintering a nylon powder to form awesome models! Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. The process is repeated layer by layer until the build is complete. Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). A vital aspect is the way of.

3d Printer Types The Complete List Pick 3d Printer : The Roller Compacts The Powder, A Process Which Allows For More Precise Sintering.

Sls Wax Printer Reprap. How does sls 3d printing work? Heart model printed with sinterit lisa sls 3d printer. Sls 3d printing is used for both prototyping of functional polymer components and for small production runs, as it offers a very here is how the sls fabrication process works: Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again. Sls 3d printing is an amazing 3d printer technology that uses lasers to sintering a nylon powder to form awesome models! Here are some model from the. Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. The most common material for selective laser sintering is nylon, a popular engineering thermoplastic beloved for its lightweight, strong, and flexible properties. A vital aspect is the way of. The process is repeated layer by layer until the build is complete. After each layer is fused, a roller moves across the bed to distribute the next layer of powder. Powder is dispersed in a thin layer on top of a platform inside of the build chamber. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). The bin is then placed into. The powder bin and the build area are first heated just below the melting temperature of the polymer and a recoating.

The Complete Guide To Selective Laser Sintering Sls In 3d Printing 3dnatives , Sls 3D Printing Is Used For Both Prototyping Of Functional Polymer Components And For Small Production Runs, As It Offers A Very Here Is How The Sls Fabrication Process Works:

Selective Laser Sintering Process Youtube. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). How does sls 3d printing work? Here are some model from the. Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again. The powder bin and the build area are first heated just below the melting temperature of the polymer and a recoating. Sls 3d printing is an amazing 3d printer technology that uses lasers to sintering a nylon powder to form awesome models! Sls 3d printing is used for both prototyping of functional polymer components and for small production runs, as it offers a very here is how the sls fabrication process works: Heart model printed with sinterit lisa sls 3d printer. After each layer is fused, a roller moves across the bed to distribute the next layer of powder. Powder is dispersed in a thin layer on top of a platform inside of the build chamber. The process is repeated layer by layer until the build is complete. The most common material for selective laser sintering is nylon, a popular engineering thermoplastic beloved for its lightweight, strong, and flexible properties. Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. A vital aspect is the way of. The bin is then placed into.

Fdm Vs Sls 3d Printers Which Tensile Properties . The Powder Bin And The Build Area Are First Heated Just Below The Melting Temperature Of The Polymer And A Recoating.

3d Printing Materials Selection Guide Sla Sls Dmls. Sls 3d printing is an amazing 3d printer technology that uses lasers to sintering a nylon powder to form awesome models! How does sls 3d printing work? A vital aspect is the way of. After each layer is fused, a roller moves across the bed to distribute the next layer of powder. The most common material for selective laser sintering is nylon, a popular engineering thermoplastic beloved for its lightweight, strong, and flexible properties. Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. Sls 3d printing is used for both prototyping of functional polymer components and for small production runs, as it offers a very here is how the sls fabrication process works: Here are some model from the. Heart model printed with sinterit lisa sls 3d printer. Powder is dispersed in a thin layer on top of a platform inside of the build chamber. Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again. The process is repeated layer by layer until the build is complete. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). The bin is then placed into. The powder bin and the build area are first heated just below the melting temperature of the polymer and a recoating.

Made For Me Offers Tips On Sls 3d Printing With Nylon Enjoy Greater Durability Versatility For Complex Models 3dprint Com The Voice Of 3d Printing Additive Manufacturing , Stacked Layers Of Material Form The Final 3D Printed Object.

Sls 3d Printing Advantages And Applications Beamler. After each layer is fused, a roller moves across the bed to distribute the next layer of powder. Sls 3d printing is an amazing 3d printer technology that uses lasers to sintering a nylon powder to form awesome models! Heart model printed with sinterit lisa sls 3d printer. Powder is dispersed in a thin layer on top of a platform inside of the build chamber. Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. The bin is then placed into. How does sls 3d printing work? Here are some model from the. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). The process is repeated layer by layer until the build is complete. Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again. The powder bin and the build area are first heated just below the melting temperature of the polymer and a recoating. The most common material for selective laser sintering is nylon, a popular engineering thermoplastic beloved for its lightweight, strong, and flexible properties. Sls 3d printing is used for both prototyping of functional polymer components and for small production runs, as it offers a very here is how the sls fabrication process works: A vital aspect is the way of.

Sls Selective Laser Sintering 3d Printing Powder Based Process . A Vital Aspect Is The Way Of.

Fdm Vs Sla Vs Sls 3d Supply Guys. Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. Sls 3d printing is used for both prototyping of functional polymer components and for small production runs, as it offers a very here is how the sls fabrication process works: How does sls 3d printing work? The powder bin and the build area are first heated just below the melting temperature of the polymer and a recoating. The process is repeated layer by layer until the build is complete. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). Here are some model from the. The most common material for selective laser sintering is nylon, a popular engineering thermoplastic beloved for its lightweight, strong, and flexible properties. After each layer is fused, a roller moves across the bed to distribute the next layer of powder. Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again. A vital aspect is the way of. The bin is then placed into. Heart model printed with sinterit lisa sls 3d printer. Sls 3d printing is an amazing 3d printer technology that uses lasers to sintering a nylon powder to form awesome models! Powder is dispersed in a thin layer on top of a platform inside of the build chamber.

First High Speed Sintering 3d Printer Unveiled By Voxeljet 3d Printing Industry , Sls 3D Printing Is Used For Both Prototyping Of Functional Polymer Components And For Small Production Runs, As It Offers A Very Here Is How The Sls Fabrication Process Works:

What Is 3d Printing And How Does It Work Jita. Heart model printed with sinterit lisa sls 3d printer. How does sls 3d printing work? The powder bin and the build area are first heated just below the melting temperature of the polymer and a recoating. A vital aspect is the way of. Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. After each layer is fused, a roller moves across the bed to distribute the next layer of powder. The most common material for selective laser sintering is nylon, a popular engineering thermoplastic beloved for its lightweight, strong, and flexible properties. The bin is then placed into. Here are some model from the. Powder is dispersed in a thin layer on top of a platform inside of the build chamber. The process is repeated layer by layer until the build is complete. Sls 3d printing is used for both prototyping of functional polymer components and for small production runs, as it offers a very here is how the sls fabrication process works: Sls 3d printing is an amazing 3d printer technology that uses lasers to sintering a nylon powder to form awesome models! Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again.