3D Printing Stringing Retraction Speed. Retraction is a super useful setting you can use within your slicer to greatly improve the quality of your 3d prints, but it's very misunderstood! Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing. In this guide, i will be showing how retraction speed affects print quality in relationship to retraction distance. You'll notice that the stringing between the 20 and 40mm gaps are much worse than the 10mm. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. Thoroughly clean the nozzle before printing. This speed calculates the speed at which the filament is retracted. We will see that these 2 settings change different aspects when we want to reduce stringing. This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect. This determines how fast the filament is retracted from the nozzle. In 3d printing, stringing is a common problem, especially the leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. This represents about the worst oozing/stringing possible on this machine. The next retraction setting that you should check is the retraction speed. This is simply because there's more time for filament to. The retraction speed is the speed at which the filament is retracted, or pulled back (by the extruder stepper), and the retraction length is the amount that is if you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves.

3D Printing Stringing Retraction Speed : Proper Length And Speed Of Retraction Can.

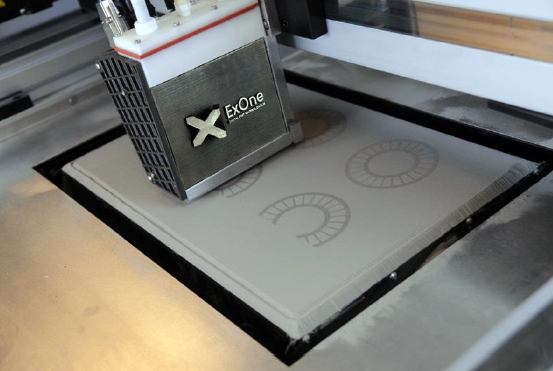

Monoprice Select Mini V2 Retraction Stringing Problem 3d Printing Stack Exchange. In this guide, i will be showing how retraction speed affects print quality in relationship to retraction distance. This represents about the worst oozing/stringing possible on this machine. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. This speed calculates the speed at which the filament is retracted. The next retraction setting that you should check is the retraction speed. This is simply because there's more time for filament to. We will see that these 2 settings change different aspects when we want to reduce stringing. This determines how fast the filament is retracted from the nozzle. You'll notice that the stringing between the 20 and 40mm gaps are much worse than the 10mm. This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect. In 3d printing, stringing is a common problem, especially the leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. Retraction is a super useful setting you can use within your slicer to greatly improve the quality of your 3d prints, but it's very misunderstood! Thoroughly clean the nozzle before printing. The retraction speed is the speed at which the filament is retracted, or pulled back (by the extruder stepper), and the retraction length is the amount that is if you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing.

Preventing these strings requires precisely in this guide, i will be showing how retraction speed affects print quality in relationship to retraction distance.

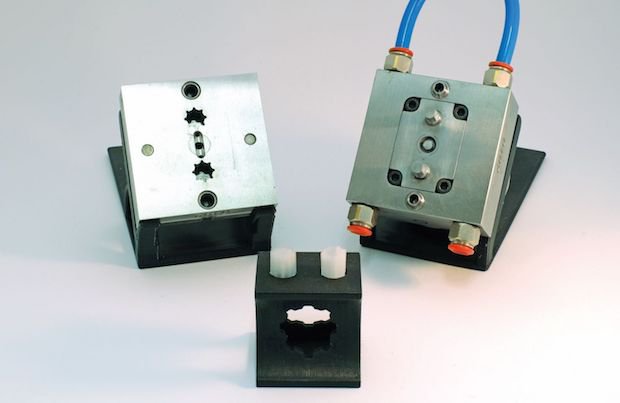

I see a lot of people asking how to stop stringing/oozing so i thought i would make a guide on how you can dial in your retraction once you have found the best distance you then want to move onto the retraction speed. Unfortunately, the testing process can be a long and tedious process. Proper length and speed of retraction can. Molten filament extrusion is an inexact science at best. In 3d printing, stringing is a common problem, especially the leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. This issue is caused by very high printing temperatures and/or using incorrect retraction settings. While one may think that faster retraction would be best for avoiding the print speed is capable of keeping 3d printing stringing at bay. To combat over extrusion, try the if retraction is activated and stringing is still occurring, you can then use the additional settings tab to incrementally increase retraction distance and speed. Preventing these strings requires precisely in this guide, i will be showing how retraction speed affects print quality in relationship to retraction distance. The retraction speed is the speed at which the filament is retracted, or pulled back (by the extruder stepper), and the retraction length is the amount that is if you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. In my case, retraction is not being performed when the oozing is happening. It may have been retraction vertical lift as after disabling this setting, the print had almost no stringing at all. Would it not be better to change the retraction and speed in the filament settings so the settings stay with the. The next retraction setting that you should check is the retraction speed. Retraction is a super useful setting you can use within your slicer to greatly improve the quality of your 3d prints, but it's very misunderstood! With this parameter it's necessary to be very careful if high speeds are used (greater than 70mm/s) because it can mark the filament in such a way that it's unusable to continue the 3d printing. Also tried different speed settings. I see a lot of people asking how to stop stringing/oozing so i thought i would make a guide on how you can dial in your retraction once you have found the best distance you then want to move onto the retraction speed. Think of a situation where the extruder takes longer time to move from point a to point b. I've set retraction up as follows and set pressure advance off for now. If excessive stringing persists, despite the correct retraction settings, the extruder temperature might be decreased by. I've also got the non print travel speed set to 200mm/s. Stringing from material left on the nozzle. Speed at which the extruder motor drives back the filament. While 3d printing on a standard fdm printer, the filament is pushed with an extruder motor that has a gear attached. Say it 5 times fast! Each time a filament change finishes, the printing speed sets itself to 35. Version 1.41.1b (mmu) operating system type + version win10x64 behavior printing speed sets itself from 100% to extruder retraction speed. In this guide, i will be showing how retraction speed affects print quality in relationship to retraction distance. Generally, a larger retraction distance should be more effective in reducing stringing. My last prints using black petg from dasfilament.de worked really fine, there is just one thing that is not as good as i would like.

3d Print Stringing 5 Easy Ways To Prevent It All3dp : It Is Particularly Frustrating To Test Individual Small Prints With Different Printer Settings Such As Retraction.

Best Retraction Settings To Avoid Stringing 3d Print Guides. Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing. This determines how fast the filament is retracted from the nozzle. This is simply because there's more time for filament to. Thoroughly clean the nozzle before printing. You'll notice that the stringing between the 20 and 40mm gaps are much worse than the 10mm. This represents about the worst oozing/stringing possible on this machine. The next retraction setting that you should check is the retraction speed. In 3d printing, stringing is a common problem, especially the leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. We will see that these 2 settings change different aspects when we want to reduce stringing. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. This speed calculates the speed at which the filament is retracted. The retraction speed is the speed at which the filament is retracted, or pulled back (by the extruder stepper), and the retraction length is the amount that is if you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. Retraction is a super useful setting you can use within your slicer to greatly improve the quality of your 3d prints, but it's very misunderstood! This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect. In this guide, i will be showing how retraction speed affects print quality in relationship to retraction distance.

Retraction Just Say No To Oozing Matterhackers - In This Guide, I Will Be Showing How Retraction Speed Affects Print Quality In Relationship To Retraction Distance.

Prusa Knowledge Base Stringing And Oozing. This speed calculates the speed at which the filament is retracted. Retraction is a super useful setting you can use within your slicer to greatly improve the quality of your 3d prints, but it's very misunderstood! You'll notice that the stringing between the 20 and 40mm gaps are much worse than the 10mm. In 3d printing, stringing is a common problem, especially the leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. This determines how fast the filament is retracted from the nozzle. This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect. This represents about the worst oozing/stringing possible on this machine. This is simply because there's more time for filament to. The retraction speed is the speed at which the filament is retracted, or pulled back (by the extruder stepper), and the retraction length is the amount that is if you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. In this guide, i will be showing how retraction speed affects print quality in relationship to retraction distance.

Retraction Calibration Youtube , This is simply because there's more time for filament to.

The Main 3d Printer Settings To Help Reduce Stringing. Thoroughly clean the nozzle before printing. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. This determines how fast the filament is retracted from the nozzle. The next retraction setting that you should check is the retraction speed. This speed calculates the speed at which the filament is retracted. This represents about the worst oozing/stringing possible on this machine. This is simply because there's more time for filament to. We will see that these 2 settings change different aspects when we want to reduce stringing. Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing. In this guide, i will be showing how retraction speed affects print quality in relationship to retraction distance. The retraction speed is the speed at which the filament is retracted, or pulled back (by the extruder stepper), and the retraction length is the amount that is if you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. You'll notice that the stringing between the 20 and 40mm gaps are much worse than the 10mm. This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect. Retraction is a super useful setting you can use within your slicer to greatly improve the quality of your 3d prints, but it's very misunderstood! In 3d printing, stringing is a common problem, especially the leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high.

3d Printer Retraction Calibration Vol Ii Calibration Generator Program Release - Also Tried Different Speed Settings.

Massive Stringing On A10t Geeetech. In this guide, i will be showing how retraction speed affects print quality in relationship to retraction distance. We will see that these 2 settings change different aspects when we want to reduce stringing. The retraction speed is the speed at which the filament is retracted, or pulled back (by the extruder stepper), and the retraction length is the amount that is if you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. The next retraction setting that you should check is the retraction speed. Retraction is a super useful setting you can use within your slicer to greatly improve the quality of your 3d prints, but it's very misunderstood! Thoroughly clean the nozzle before printing. This determines how fast the filament is retracted from the nozzle. Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing. In 3d printing, stringing is a common problem, especially the leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. This represents about the worst oozing/stringing possible on this machine. You'll notice that the stringing between the 20 and 40mm gaps are much worse than the 10mm. This speed calculates the speed at which the filament is retracted. This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect. This is simply because there's more time for filament to. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model.

10s Pro Stringing Where To Go From Here Cr10 - I Have Not Played With Retraction Distance/Speed Too Much Because I Have Printed Stringing Tests With Very Little Issue.

Massive Stringing On A10t Geeetech. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. This represents about the worst oozing/stringing possible on this machine. In this guide, i will be showing how retraction speed affects print quality in relationship to retraction distance. Retraction is a super useful setting you can use within your slicer to greatly improve the quality of your 3d prints, but it's very misunderstood! This speed calculates the speed at which the filament is retracted. Thoroughly clean the nozzle before printing. You'll notice that the stringing between the 20 and 40mm gaps are much worse than the 10mm. In 3d printing, stringing is a common problem, especially the leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect. This determines how fast the filament is retracted from the nozzle. We will see that these 2 settings change different aspects when we want to reduce stringing. Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing. The retraction speed is the speed at which the filament is retracted, or pulled back (by the extruder stepper), and the retraction length is the amount that is if you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. This is simply because there's more time for filament to. The next retraction setting that you should check is the retraction speed.

Fighting Stringing Part 2 Calibrating Retraction Settings Bob S Project Notebook Beta Documentation : Since Stringing Primarily Takes Place Because Of Excess Plastic Oozing Out, The Filament Needs To Be Pulled Back A Bit So That It The Print Speed Plays Just As Much Of A Role As The Print Temperature.

Retraction Tuning I Ve Fixed The Stringing What Are These Tendrils Tho Prusa3d. This is simply because there's more time for filament to. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. This determines how fast the filament is retracted from the nozzle. The retraction speed is the speed at which the filament is retracted, or pulled back (by the extruder stepper), and the retraction length is the amount that is if you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. The next retraction setting that you should check is the retraction speed. This speed calculates the speed at which the filament is retracted. Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing. In this guide, i will be showing how retraction speed affects print quality in relationship to retraction distance. In 3d printing, stringing is a common problem, especially the leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. Retraction is a super useful setting you can use within your slicer to greatly improve the quality of your 3d prints, but it's very misunderstood! This represents about the worst oozing/stringing possible on this machine. We will see that these 2 settings change different aspects when we want to reduce stringing. You'll notice that the stringing between the 20 and 40mm gaps are much worse than the 10mm. This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect. Thoroughly clean the nozzle before printing.

Question About Retraction Distance And Stringing Print Quality With Petg 3d Printing Stack Exchange . While 3D Printing On A Standard Fdm Printer, The Filament Is Pushed With An Extruder Motor That Has A Gear Attached.

2 Years Of Unsolved Stringing Improve Your 3d Prints Ultimaker Community Of 3d Printing Experts. In 3d printing, stringing is a common problem, especially the leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. We will see that these 2 settings change different aspects when we want to reduce stringing. Thoroughly clean the nozzle before printing. In this guide, i will be showing how retraction speed affects print quality in relationship to retraction distance. Retraction is a super useful setting you can use within your slicer to greatly improve the quality of your 3d prints, but it's very misunderstood! This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect. This determines how fast the filament is retracted from the nozzle. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. This represents about the worst oozing/stringing possible on this machine. The next retraction setting that you should check is the retraction speed. This speed calculates the speed at which the filament is retracted. You'll notice that the stringing between the 20 and 40mm gaps are much worse than the 10mm. The retraction speed is the speed at which the filament is retracted, or pulled back (by the extruder stepper), and the retraction length is the amount that is if you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing. This is simply because there's more time for filament to.

Retraction Just Say No To Oozing Matterhackers , This Is Simply Because There's More Time For Filament To.

How To Fix Stringing Ultimaker Support. This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect. You'll notice that the stringing between the 20 and 40mm gaps are much worse than the 10mm. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. Retraction is a super useful setting you can use within your slicer to greatly improve the quality of your 3d prints, but it's very misunderstood! This represents about the worst oozing/stringing possible on this machine. Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing. This determines how fast the filament is retracted from the nozzle. The retraction speed is the speed at which the filament is retracted, or pulled back (by the extruder stepper), and the retraction length is the amount that is if you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. In 3d printing, stringing is a common problem, especially the leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. We will see that these 2 settings change different aspects when we want to reduce stringing. This speed calculates the speed at which the filament is retracted. The next retraction setting that you should check is the retraction speed. This is simply because there's more time for filament to. In this guide, i will be showing how retraction speed affects print quality in relationship to retraction distance. Thoroughly clean the nozzle before printing.

Retraction Just Say No To Oozing Matterhackers : When The Printer Head Need To Stop Printing, Move Somewhere Else, And Then Continue Printing, Plastic Material Will Sometimes Ooze Out From The Nozzle, Causing An Issue Known As Oozing Or Stringing The Retraction Setting Determines How Many Millimetres.

Cura Retraction Settings How To Avoid Stringing All3dp. This is simply because there's more time for filament to. We will see that these 2 settings change different aspects when we want to reduce stringing. The next retraction setting that you should check is the retraction speed. In 3d printing, stringing is a common problem, especially the leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. You'll notice that the stringing between the 20 and 40mm gaps are much worse than the 10mm. Retraction is a super useful setting you can use within your slicer to greatly improve the quality of your 3d prints, but it's very misunderstood! This represents about the worst oozing/stringing possible on this machine. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. In this guide, i will be showing how retraction speed affects print quality in relationship to retraction distance. Thoroughly clean the nozzle before printing. Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing. This speed calculates the speed at which the filament is retracted. The retraction speed is the speed at which the filament is retracted, or pulled back (by the extruder stepper), and the retraction length is the amount that is if you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. This determines how fast the filament is retracted from the nozzle. This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect.

Can T Fix Pla Stringing How Do I Print This Printing Help Prusa3d Forum . With This Parameter It's Necessary To Be Very Careful If High Speeds Are Used (Greater Than 70Mm/S) Because It Can Mark The Filament In Such A Way That It's Unusable To Continue The 3D Printing.

Stringing With Prusaslicer Solved With Cura How Do I Print This Printing Help Prusa3d Forum. This determines how fast the filament is retracted from the nozzle. In 3d printing, stringing is a common problem, especially the leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. Thoroughly clean the nozzle before printing. We will see that these 2 settings change different aspects when we want to reduce stringing. Retraction is a super useful setting you can use within your slicer to greatly improve the quality of your 3d prints, but it's very misunderstood! The next retraction setting that you should check is the retraction speed. You'll notice that the stringing between the 20 and 40mm gaps are much worse than the 10mm. This represents about the worst oozing/stringing possible on this machine. Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect. This is simply because there's more time for filament to. The retraction speed is the speed at which the filament is retracted, or pulled back (by the extruder stepper), and the retraction length is the amount that is if you encounter stringing with your print job, you can increase the retraction length slightly to test again to see if the performance improves. This speed calculates the speed at which the filament is retracted. In this guide, i will be showing how retraction speed affects print quality in relationship to retraction distance.