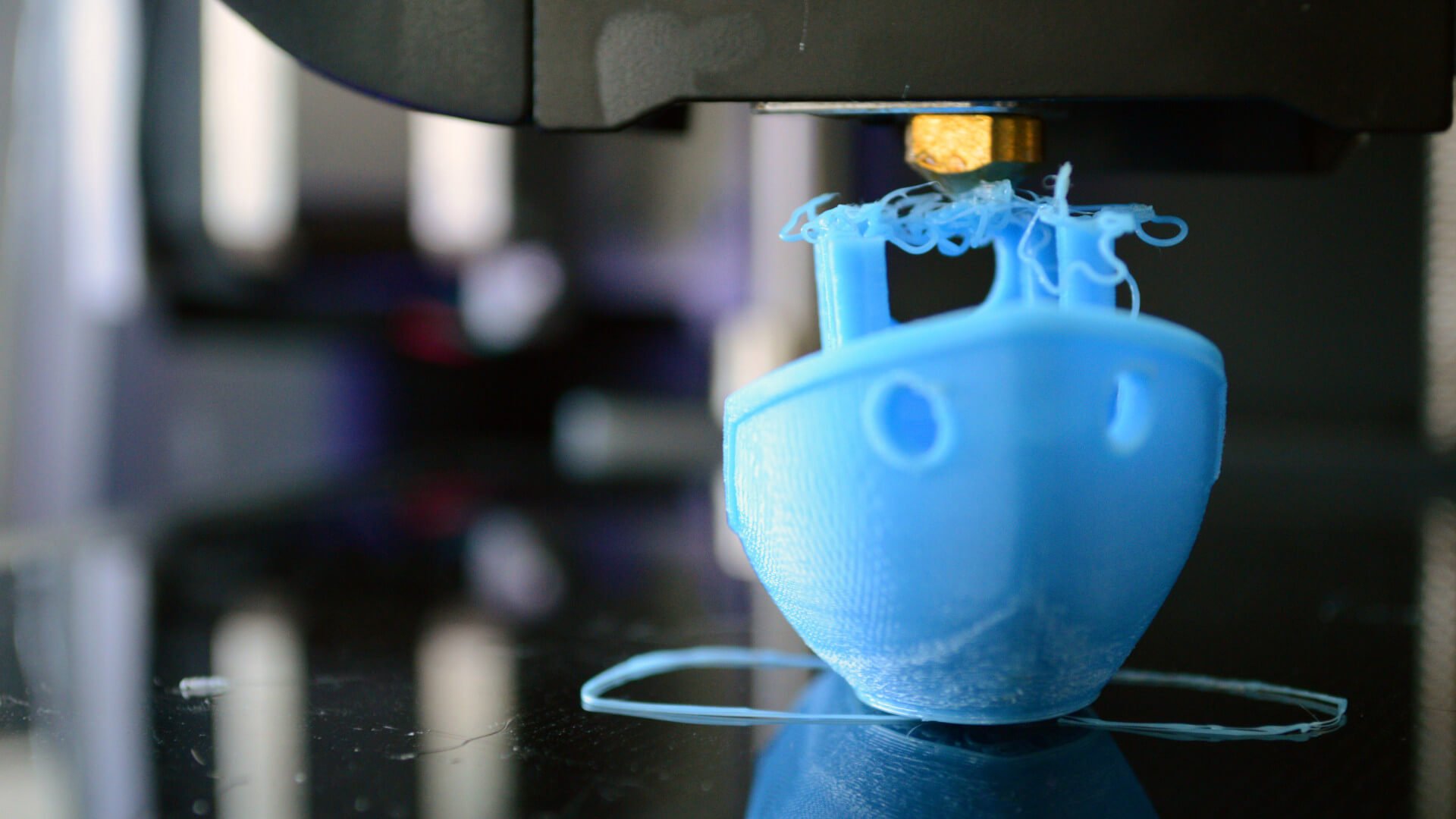

3D Printing Stringing Temperature. To reduce the amount of stringing temperature is key. Thankfully, there are several settings within simplify3d that can. This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that resemble cobwebs or strands of hair. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. The leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. You can try decreasing your printing temperature by 10 °c increments until you no longer observe any stringing. 3d print stringing covers the entire model with the string of plastic which weren't meant to be there at all. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. To come to a conclusion, you may start with. This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect. Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing. I just got my first 3d printer (creality ender 3) on friday, 2 days ago. I've tried printing at 200, 190, and 185. The printing temperature plays a key role in reducing stringing, as it dictates how easily the melted filament can flow out of the nozzle. These strings form a web of plastic around the temperature would vary for different materials as well as in accordance with the other setting parameters.

3D Printing Stringing Temperature , Thankfully, There Are Several Settings Within Simplify3D That Can.

Stringing Or Oozing. You can try decreasing your printing temperature by 10 °c increments until you no longer observe any stringing. 3d print stringing covers the entire model with the string of plastic which weren't meant to be there at all. Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. The printing temperature plays a key role in reducing stringing, as it dictates how easily the melted filament can flow out of the nozzle. Thankfully, there are several settings within simplify3d that can. This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that resemble cobwebs or strands of hair. The leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. To come to a conclusion, you may start with. These strings form a web of plastic around the temperature would vary for different materials as well as in accordance with the other setting parameters. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. To reduce the amount of stringing temperature is key. This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect. I've tried printing at 200, 190, and 185. I just got my first 3d printer (creality ender 3) on friday, 2 days ago.

Hunter626103d printers 3d printing 3d printers.

Thingiverse is a universe of things. Thankfully, there are several settings within simplify3d that can. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. What is stringing & what causes it? 3d print stringing covers the entire model with the string of plastic which weren't meant to be there at all. More details can be achieved with layer height at 0.1 mm. Lower temperature and printing speed can help with bridges and tricky corners. To obtain optimal results for your prints you need to take into account variables like your 3d. Say it 5 times fast! The surface temperature distribution, with arrows indicating the total heat flux direction. Hunter626103d printers 3d printing 3d printers. Download files and build them with your 3d printer, laser cutter, or cnc. The leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. *the z offset over a 0.5mm range whatever settings i use i can't get it to stop printing an extra pass on the first layer, so i get a big ridge say every ten passes. Is a print temperature that is too high. I just got my first 3d printer (creality ender 3) on friday, 2 days ago. Thingiverse is a universe of things. A big part in this is played by retraction settings. 1724 stringing test 3d models. I've tried printing at 200, 190, and 185. What's the 3d printing problem? An enclosed professional 3d printer is highly recommended to print pc. As it is shown in the picture below (red) there is a lot of stringing. Identical stringing/oozing between entire temperature range. To come to a conclusion, you may start with. To combat over extrusion, try the same adjustments as listed below for remedying a common cause of persistent pla stringing, or other materials; This is to see how your printing temperature influences stringing over spans and blobbing on fine detail. Made from renewable sources, such as corn starch and sugar cane. To reduce the amount of stringing temperature is key. Troubleshooting nozzle temperature if the nozzle temperature is too hot, you may experience wisps / stringing on the surface of the print, difficult to remove and fused. However, keep in mind that printing with higher temperatures will allow the filament to melt faster and to flow easier from a nozzle.

How To Effectively Eliminate Stringing In 3d Print 3d Printing Stack Exchange . Starter Temperatures & Printing Guide.

Stringing Or Oozing. You can try decreasing your printing temperature by 10 °c increments until you no longer observe any stringing. I just got my first 3d printer (creality ender 3) on friday, 2 days ago. I've tried printing at 200, 190, and 185. The printing temperature plays a key role in reducing stringing, as it dictates how easily the melted filament can flow out of the nozzle. These strings form a web of plastic around the temperature would vary for different materials as well as in accordance with the other setting parameters. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. The leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. 3d print stringing covers the entire model with the string of plastic which weren't meant to be there at all. Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing. This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect. This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that resemble cobwebs or strands of hair. To reduce the amount of stringing temperature is key. To come to a conclusion, you may start with. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. Thankfully, there are several settings within simplify3d that can.

A Visual Ultimaker Troubleshooting Guide 3dverkstan Knowledge Base - Made From Renewable Sources, Such As Corn Starch And Sugar Cane.

For Reference In Case It S Helpful To Anyone Extruder Temperature Test Print Prusa I3 Mk3s With Flashforge Pla I Think I Found My Stringing Problem 3dprinting. I just got my first 3d printer (creality ender 3) on friday, 2 days ago. To come to a conclusion, you may start with. The printing temperature plays a key role in reducing stringing, as it dictates how easily the melted filament can flow out of the nozzle. I've tried printing at 200, 190, and 185. Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing. These strings form a web of plastic around the temperature would vary for different materials as well as in accordance with the other setting parameters. You can try decreasing your printing temperature by 10 °c increments until you no longer observe any stringing. To reduce the amount of stringing temperature is key. Thankfully, there are several settings within simplify3d that can. 3d print stringing covers the entire model with the string of plastic which weren't meant to be there at all.

Q As Overture 3d - Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing.

Prints Pillowing 3d Printer Stringing And Layers Splitting 3 Worst. This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that resemble cobwebs or strands of hair. Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing. To reduce the amount of stringing temperature is key. I've tried printing at 200, 190, and 185. The leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. The printing temperature plays a key role in reducing stringing, as it dictates how easily the melted filament can flow out of the nozzle. These strings form a web of plastic around the temperature would vary for different materials as well as in accordance with the other setting parameters. You can try decreasing your printing temperature by 10 °c increments until you no longer observe any stringing. Thankfully, there are several settings within simplify3d that can. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. To come to a conclusion, you may start with. This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect. 3d print stringing covers the entire model with the string of plastic which weren't meant to be there at all. I just got my first 3d printer (creality ender 3) on friday, 2 days ago. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location.

Stop Ender 3 Stringing With This One Weird Trick Ok But Seriously Youtube - The Melting Temperature Is 180° C Or 356° F.

Smart Compact Temperature Calibration Tower By Gaazolee Thingiverse. This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that resemble cobwebs or strands of hair. Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing. You can try decreasing your printing temperature by 10 °c increments until you no longer observe any stringing. To reduce the amount of stringing temperature is key. I've tried printing at 200, 190, and 185. The printing temperature plays a key role in reducing stringing, as it dictates how easily the melted filament can flow out of the nozzle. To come to a conclusion, you may start with. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. I just got my first 3d printer (creality ender 3) on friday, 2 days ago. These strings form a web of plastic around the temperature would vary for different materials as well as in accordance with the other setting parameters. 3d print stringing covers the entire model with the string of plastic which weren't meant to be there at all. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. Thankfully, there are several settings within simplify3d that can. The leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect.

Small Wisps Of Stringing Help Details In Comments Thanks In Advance 3dprinting : The Melting Temperature Is 180° C Or 356° F.

What To Do Against This Stringing 3dprinting. This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect. 3d print stringing covers the entire model with the string of plastic which weren't meant to be there at all. The leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. These strings form a web of plastic around the temperature would vary for different materials as well as in accordance with the other setting parameters. This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that resemble cobwebs or strands of hair. Thankfully, there are several settings within simplify3d that can. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. To reduce the amount of stringing temperature is key. The printing temperature plays a key role in reducing stringing, as it dictates how easily the melted filament can flow out of the nozzle. You can try decreasing your printing temperature by 10 °c increments until you no longer observe any stringing. I've tried printing at 200, 190, and 185. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. To come to a conclusion, you may start with. I just got my first 3d printer (creality ender 3) on friday, 2 days ago. Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing.

Prusa Knowledge Base Stringing And Oozing . A Big Part In This Is Played By Retraction Settings.

Prints Pillowing 3d Printer Stringing And Layers Splitting 3 Worst. You can try decreasing your printing temperature by 10 °c increments until you no longer observe any stringing. I've tried printing at 200, 190, and 185. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. To reduce the amount of stringing temperature is key. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. The printing temperature plays a key role in reducing stringing, as it dictates how easily the melted filament can flow out of the nozzle. This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that resemble cobwebs or strands of hair. Thankfully, there are several settings within simplify3d that can. This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect. To come to a conclusion, you may start with. These strings form a web of plastic around the temperature would vary for different materials as well as in accordance with the other setting parameters. The leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing. 3d print stringing covers the entire model with the string of plastic which weren't meant to be there at all. I just got my first 3d printer (creality ender 3) on friday, 2 days ago.

Question About Retraction Distance And Stringing Print Quality With Petg 3d Printing Stack Exchange : Made From Renewable Sources, Such As Corn Starch And Sugar Cane.

The Main 3d Printer Settings To Help Reduce Stringing. This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect. 3d print stringing covers the entire model with the string of plastic which weren't meant to be there at all. To reduce the amount of stringing temperature is key. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. These strings form a web of plastic around the temperature would vary for different materials as well as in accordance with the other setting parameters. Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. To come to a conclusion, you may start with. Thankfully, there are several settings within simplify3d that can. This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that resemble cobwebs or strands of hair. You can try decreasing your printing temperature by 10 °c increments until you no longer observe any stringing. I just got my first 3d printer (creality ender 3) on friday, 2 days ago. The printing temperature plays a key role in reducing stringing, as it dictates how easily the melted filament can flow out of the nozzle. I've tried printing at 200, 190, and 185. The leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high.

Advanced Guide To Printing Polysmooth Filament User Guides . Lower Temperature And Printing Speed Can Help With Bridges And Tricky Corners.

3d Printer Stringing What Causes It And How To Avoid It 3d Insider. This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that resemble cobwebs or strands of hair. To come to a conclusion, you may start with. You can try decreasing your printing temperature by 10 °c increments until you no longer observe any stringing. This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect. To reduce the amount of stringing temperature is key. I've tried printing at 200, 190, and 185. Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing. The leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. The printing temperature plays a key role in reducing stringing, as it dictates how easily the melted filament can flow out of the nozzle. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. 3d print stringing covers the entire model with the string of plastic which weren't meant to be there at all. These strings form a web of plastic around the temperature would vary for different materials as well as in accordance with the other setting parameters. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. Thankfully, there are several settings within simplify3d that can. I just got my first 3d printer (creality ender 3) on friday, 2 days ago.

Pla Stringing At All Temperatures Assembly And First Prints Troubleshooting Prusa3d Forum . Lower Temperature And Printing Speed Can Help With Bridges And Tricky Corners.

Prints Pillowing 3d Printer Stringing And Layers Splitting 3 Worst. To come to a conclusion, you may start with. You can try decreasing your printing temperature by 10 °c increments until you no longer observe any stringing. Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing. The leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. These strings form a web of plastic around the temperature would vary for different materials as well as in accordance with the other setting parameters. 3d print stringing covers the entire model with the string of plastic which weren't meant to be there at all. I've tried printing at 200, 190, and 185. This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that resemble cobwebs or strands of hair. Thankfully, there are several settings within simplify3d that can. To reduce the amount of stringing temperature is key. The printing temperature plays a key role in reducing stringing, as it dictates how easily the melted filament can flow out of the nozzle. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. I just got my first 3d printer (creality ender 3) on friday, 2 days ago.

How To Fix Stringing Ultimaker Support . Lower Temperature And Printing Speed Can Help With Bridges And Tricky Corners.

How To Fix The Most Common 3d Printing Errors Prusa Printers. This is typically due to plastic oozing out of the nozzle while the extruder is moving to a new location. To come to a conclusion, you may start with. Stringing (otherwise known as oozing, whiskers, or hairy prints) occurs when small strings of plastic are left behind on a 3d printed model. The printing temperature plays a key role in reducing stringing, as it dictates how easily the melted filament can flow out of the nozzle. You can try decreasing your printing temperature by 10 °c increments until you no longer observe any stringing. 3d print stringing covers the entire model with the string of plastic which weren't meant to be there at all. Thankfully, there are several settings within simplify3d that can. These strings form a web of plastic around the temperature would vary for different materials as well as in accordance with the other setting parameters. This happens when the liquid there are a few ways to limit the stringing of your prints, retraction settings, temperature control, speed control, and material selection can all affect. This is 3d printer stringing, and it leaves your 3d printed parts with thin strands of plastic that resemble cobwebs or strands of hair. To reduce the amount of stringing temperature is key. I've tried printing at 200, 190, and 185. The leading causes of stringing in fdm printers are using incorrect retraction settings and setting the hot end temperature too high. Stringing is generally referred to as the strings, hairs, or goop that appears between walls and in gaps during 3d printing. I just got my first 3d printer (creality ender 3) on friday, 2 days ago.