3D Printing Technology Metal. Metal powder is the backbone of metal 3d printing. The basic technology is the same: Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing the material and manufacturing costs connected with metal 3d printing is high, so these technologies are not suitable for parts that can be easily. A direct metal printing (dmp) metal 3d printer uses a laser to weld thin layers of metal powder to produce highly complex metal parts. Medical professionals and surgeons use these 3d printed metals for. Metal 3d printing technologies and acronyms. 3d metal printing (courtesy of ex one) with steel 3d printing, your part is created by binding together layers of steel powder. Although metal 3d printer prices have been slowly and slightly decreasing, these machines are still relatively expensive acquisitions, mostly. Metal 3d printing has the potential to transform the way parts are manufactured by providing a level of complexity and customisation that is not possible with traditional manufacturing. What is the best metal 3d printer in 2020? Order 3d metal parts online. Eos' metal 3d printers based on dmls technology [image credit: Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. The vast majority of metal 3d printing technologies utilize metal powder. Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding several industries rely on parts created on metal powder bed fusion 3d printers.

3D Printing Technology Metal . What Is The Best Metal 3D Printer In 2020?

Affordable Metal 3d Printing Becomes Available In The Uk Pes Media. Medical professionals and surgeons use these 3d printed metals for. Although metal 3d printer prices have been slowly and slightly decreasing, these machines are still relatively expensive acquisitions, mostly. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing the material and manufacturing costs connected with metal 3d printing is high, so these technologies are not suitable for parts that can be easily. Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding several industries rely on parts created on metal powder bed fusion 3d printers. A direct metal printing (dmp) metal 3d printer uses a laser to weld thin layers of metal powder to produce highly complex metal parts. Metal powder is the backbone of metal 3d printing. Metal 3d printing technologies and acronyms. Metal 3d printing has the potential to transform the way parts are manufactured by providing a level of complexity and customisation that is not possible with traditional manufacturing. Order 3d metal parts online. The basic technology is the same: The vast majority of metal 3d printing technologies utilize metal powder. What is the best metal 3d printer in 2020? 3d metal printing (courtesy of ex one) with steel 3d printing, your part is created by binding together layers of steel powder. Eos' metal 3d printers based on dmls technology [image credit: Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type.

This paper provides a comprehensive review of metal additive manufacturing, a rapidly evolving field with innovative technologies and processes.

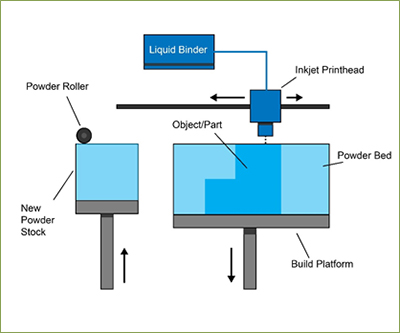

Dmls does not melt the powder. Order 3d metal parts online. A laser selectively welds thin layers of metal powder. Here's how the technology behind 3d printing metal works: This report forecasts the overall metal 3d printing market to 2029, with in depth discussion of currently commercialised and emerging printer technologies. Want to find out how metal additive manufacturing can be put to use in your business? 3d metal printing made it easy for ideas2cycles to meet customer needs with reduced tooling and labor. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. Metal 3d printing technologies and acronyms. Welcome to our virtual event! The vast majority of metal 3d printing technologies utilize metal powder. 3d metal printing (courtesy of ex one) with steel 3d printing, your part is created by binding together layers of steel powder. Eos' metal 3d printers based on dmls technology [image credit: This paper provides a comprehensive review of metal additive manufacturing, a rapidly evolving field with innovative technologies and processes. Top 3 methods for 3d printing metal. Metal 3d printing is perfect to create accurate technical parts for any kinds of industry. 6,284 metal 3d printing technology products are offered for sale by suppliers on alibaba.com. The disadvantage of these types of 3d printing technology using a point laser is that it can take longer to the main difference is that these types of 3d printing technology are applied to the production of metal parts. Slm uses metallic powders to build functional 3d parts. There are 5,487 suppliers who sells metal 3d printing technology on alibaba.com, mainly located in asia. Experience how digital metal's unique binder jetting technology can help you produce small, complex components in a fast. Support structures are automatically generated and built. Leveraging traditional manufacturing methods, custom bike parts require extensive manual labor and expensive tooling, but binder jetting technology can directly manufacture those same parts faster. Metal additive manufacturing is a printing process also known as metal 3d printing. A number of components that were impossible to create a few years ago can be made to high standards. The 3d printing of metal promises to change the face of manufacturing worldwide over the next decade. Metal 3d printing has the potential to transform the way parts are manufactured by providing a level of complexity and customisation that is not possible with traditional manufacturing. Thin layers of metal powder are laid down and then fused together through the use of an ytterbium laser. But the difference is in the detail and experience. Their 3d metal printer is based on their patented technology, magnetojet, which manipulates a liquid metal by magnetism. Printing 3d metal parts is a promising technology but it's still needs more time to improve where we can reliably fabricate functional parts and not worry the challenging part about printing metals is how the microstructure and mechanical properties are affected by high temperatures and rate of heat.

Mitsubishi Develops Precision Metal 3d Printing Using Dot Forming Ded Technology 3d Printing Industry . Lens Directed Energy Deposition (Ded) 3D Printed Metal Technology.

Metal 3d Printing Slm Dmls 3d Printing At Materialise. Although metal 3d printer prices have been slowly and slightly decreasing, these machines are still relatively expensive acquisitions, mostly. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. 3d metal printing (courtesy of ex one) with steel 3d printing, your part is created by binding together layers of steel powder. The basic technology is the same: The vast majority of metal 3d printing technologies utilize metal powder. What is the best metal 3d printer in 2020? Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding several industries rely on parts created on metal powder bed fusion 3d printers. Metal 3d printing technologies and acronyms. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing the material and manufacturing costs connected with metal 3d printing is high, so these technologies are not suitable for parts that can be easily. Metal powder is the backbone of metal 3d printing. Eos' metal 3d printers based on dmls technology [image credit: Medical professionals and surgeons use these 3d printed metals for. A direct metal printing (dmp) metal 3d printer uses a laser to weld thin layers of metal powder to produce highly complex metal parts. Order 3d metal parts online. Metal 3d printing has the potential to transform the way parts are manufactured by providing a level of complexity and customisation that is not possible with traditional manufacturing.

Affordable Metal 3d Printing Becomes Available In The Uk Pes Media , Top 3 Methods For 3D Printing Metal.

Factors To Consider When 3d Printing Or Additive Manufacturing Metal Parts Engineering360. Medical professionals and surgeons use these 3d printed metals for. Metal 3d printing has the potential to transform the way parts are manufactured by providing a level of complexity and customisation that is not possible with traditional manufacturing. Eos' metal 3d printers based on dmls technology [image credit: Although metal 3d printer prices have been slowly and slightly decreasing, these machines are still relatively expensive acquisitions, mostly. The basic technology is the same: Metal 3d printing technologies and acronyms. The vast majority of metal 3d printing technologies utilize metal powder. 3d metal printing (courtesy of ex one) with steel 3d printing, your part is created by binding together layers of steel powder. Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding several industries rely on parts created on metal powder bed fusion 3d printers. What is the best metal 3d printer in 2020?

3d Printing Materials Selection Guide Sla Sls Dmls , What is the best metal 3d printer in 2020?

Metal 3d Printing Slm Dmls 3d Printing At Materialise. Eos' metal 3d printers based on dmls technology [image credit: 3d metal printing (courtesy of ex one) with steel 3d printing, your part is created by binding together layers of steel powder. Medical professionals and surgeons use these 3d printed metals for. Order 3d metal parts online. Metal powder is the backbone of metal 3d printing. Metal 3d printing technologies and acronyms. The vast majority of metal 3d printing technologies utilize metal powder. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing the material and manufacturing costs connected with metal 3d printing is high, so these technologies are not suitable for parts that can be easily. The basic technology is the same: A direct metal printing (dmp) metal 3d printer uses a laser to weld thin layers of metal powder to produce highly complex metal parts. Metal 3d printing has the potential to transform the way parts are manufactured by providing a level of complexity and customisation that is not possible with traditional manufacturing. What is the best metal 3d printer in 2020? Although metal 3d printer prices have been slowly and slightly decreasing, these machines are still relatively expensive acquisitions, mostly. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding several industries rely on parts created on metal powder bed fusion 3d printers.

Hoganas Digital Metal Produces Highly Complex And Intricate Designs With 3d Printing : Metal Additive Manufacturing Is A Printing Process Also Known As Metal 3D Printing.

How The 3d Printing Hardware Market Is Evolving In 2019 Amfg. Eos' metal 3d printers based on dmls technology [image credit: The vast majority of metal 3d printing technologies utilize metal powder. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. Metal 3d printing has the potential to transform the way parts are manufactured by providing a level of complexity and customisation that is not possible with traditional manufacturing. Although metal 3d printer prices have been slowly and slightly decreasing, these machines are still relatively expensive acquisitions, mostly. Medical professionals and surgeons use these 3d printed metals for. 3d metal printing (courtesy of ex one) with steel 3d printing, your part is created by binding together layers of steel powder. A direct metal printing (dmp) metal 3d printer uses a laser to weld thin layers of metal powder to produce highly complex metal parts. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing the material and manufacturing costs connected with metal 3d printing is high, so these technologies are not suitable for parts that can be easily. What is the best metal 3d printer in 2020? The basic technology is the same: Metal powder is the backbone of metal 3d printing. Metal 3d printing technologies and acronyms. Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding several industries rely on parts created on metal powder bed fusion 3d printers. Order 3d metal parts online.

Prodways Develops A New Metal 3d Printing Technology Prodways : A Wide Variety Of Metal 3D Printing Technology Options Are Available To You, Such As Mobile Phone.

Metal 3d Printing Slm Dmls 3d Printing At Materialise. What is the best metal 3d printer in 2020? The vast majority of metal 3d printing technologies utilize metal powder. A direct metal printing (dmp) metal 3d printer uses a laser to weld thin layers of metal powder to produce highly complex metal parts. 3d metal printing (courtesy of ex one) with steel 3d printing, your part is created by binding together layers of steel powder. Eos' metal 3d printers based on dmls technology [image credit: Medical professionals and surgeons use these 3d printed metals for. Metal 3d printing technologies and acronyms. The basic technology is the same: Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding several industries rely on parts created on metal powder bed fusion 3d printers. Metal powder is the backbone of metal 3d printing. Order 3d metal parts online. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing the material and manufacturing costs connected with metal 3d printing is high, so these technologies are not suitable for parts that can be easily. Although metal 3d printer prices have been slowly and slightly decreasing, these machines are still relatively expensive acquisitions, mostly. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. Metal 3d printing has the potential to transform the way parts are manufactured by providing a level of complexity and customisation that is not possible with traditional manufacturing.

3d Printing Predictions For 2019 Engineering Com : But The Difference Is In The Detail And Experience.

Metal 3d Printing Industrial Additive Manufacturing Technology For Functional Parts In The Final Material. Metal powder is the backbone of metal 3d printing. Metal 3d printing has the potential to transform the way parts are manufactured by providing a level of complexity and customisation that is not possible with traditional manufacturing. Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding several industries rely on parts created on metal powder bed fusion 3d printers. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing the material and manufacturing costs connected with metal 3d printing is high, so these technologies are not suitable for parts that can be easily. Order 3d metal parts online. What is the best metal 3d printer in 2020? Metal 3d printing technologies and acronyms. The basic technology is the same: Although metal 3d printer prices have been slowly and slightly decreasing, these machines are still relatively expensive acquisitions, mostly. The vast majority of metal 3d printing technologies utilize metal powder. Medical professionals and surgeons use these 3d printed metals for. 3d metal printing (courtesy of ex one) with steel 3d printing, your part is created by binding together layers of steel powder. Eos' metal 3d printers based on dmls technology [image credit: Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. A direct metal printing (dmp) metal 3d printer uses a laser to weld thin layers of metal powder to produce highly complex metal parts.

Mitsubishi Develops Precision Metal 3d Printing Using Dot Forming Ded Technology 3d Printing Industry . While The Technology Is Still Only Very Beam's 3D Printers Rely On Their Important Patented Clad Nozzle System Which Is Able To Extrude Two Streams Of Metal Powder At The Same Instant That A.

3d Printing Metals Market By Form Technology Metal Type End Use Industry Geography Covid 19 Impact Analysis Marketsandmarkets. The basic technology is the same: Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding several industries rely on parts created on metal powder bed fusion 3d printers. Metal 3d printing has the potential to transform the way parts are manufactured by providing a level of complexity and customisation that is not possible with traditional manufacturing. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing the material and manufacturing costs connected with metal 3d printing is high, so these technologies are not suitable for parts that can be easily. Although metal 3d printer prices have been slowly and slightly decreasing, these machines are still relatively expensive acquisitions, mostly. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. Metal 3d printing technologies and acronyms. The vast majority of metal 3d printing technologies utilize metal powder. Order 3d metal parts online. Medical professionals and surgeons use these 3d printed metals for. What is the best metal 3d printer in 2020? A direct metal printing (dmp) metal 3d printer uses a laser to weld thin layers of metal powder to produce highly complex metal parts. 3d metal printing (courtesy of ex one) with steel 3d printing, your part is created by binding together layers of steel powder. Metal powder is the backbone of metal 3d printing. Eos' metal 3d printers based on dmls technology [image credit:

3d Printing With Metal The Final Frontier Of Additive Manufacturing Extremetech . Slm Uses Metallic Powders To Build Functional 3D Parts.

3d Printing Jobs Archives Perfect 3d Printing Filament. What is the best metal 3d printer in 2020? The basic technology is the same: Metal powder is the backbone of metal 3d printing. The vast majority of metal 3d printing technologies utilize metal powder. Metal 3d printing technologies and acronyms. Although metal 3d printer prices have been slowly and slightly decreasing, these machines are still relatively expensive acquisitions, mostly. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. Medical professionals and surgeons use these 3d printed metals for. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing the material and manufacturing costs connected with metal 3d printing is high, so these technologies are not suitable for parts that can be easily. A direct metal printing (dmp) metal 3d printer uses a laser to weld thin layers of metal powder to produce highly complex metal parts. Eos' metal 3d printers based on dmls technology [image credit: Metal 3d printing has the potential to transform the way parts are manufactured by providing a level of complexity and customisation that is not possible with traditional manufacturing. 3d metal printing (courtesy of ex one) with steel 3d printing, your part is created by binding together layers of steel powder. Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding several industries rely on parts created on metal powder bed fusion 3d printers. Order 3d metal parts online.

3d Printing Jobs Archives Perfect 3d Printing Filament . .pRinting Technologies, Materials, Applications, Advantages, Disadvantages, Challenges, Economics And Applications Of 3D Metal Printing Technology.

The Optomec Advantage Of 3d Printing Technology. Order 3d metal parts online. A direct metal printing (dmp) metal 3d printer uses a laser to weld thin layers of metal powder to produce highly complex metal parts. 3d metal printing (courtesy of ex one) with steel 3d printing, your part is created by binding together layers of steel powder. Medical professionals and surgeons use these 3d printed metals for. Metal 3d printing has the potential to transform the way parts are manufactured by providing a level of complexity and customisation that is not possible with traditional manufacturing. The vast majority of metal 3d printing technologies utilize metal powder. What is the best metal 3d printer in 2020? Although metal 3d printer prices have been slowly and slightly decreasing, these machines are still relatively expensive acquisitions, mostly. Metal 3d printing technologies and acronyms. Metal powder is the backbone of metal 3d printing. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding several industries rely on parts created on metal powder bed fusion 3d printers. Eos' metal 3d printers based on dmls technology [image credit: The basic technology is the same: Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing the material and manufacturing costs connected with metal 3d printing is high, so these technologies are not suitable for parts that can be easily.

12 Types Of 3d Printing Technology Business World It - 3D Metal Printing (Courtesy Of Ex One) With Steel 3D Printing, Your Part Is Created By Binding Together Layers Of Steel Powder.

The World S Largest 3d Metal Printer Is Churning Out Rockets Ieee Spectrum. A direct metal printing (dmp) metal 3d printer uses a laser to weld thin layers of metal powder to produce highly complex metal parts. Metal powder is the backbone of metal 3d printing. Metal 3d printing technologies and acronyms. The basic technology is the same: Eos' metal 3d printers based on dmls technology [image credit: 3d metal printing (courtesy of ex one) with steel 3d printing, your part is created by binding together layers of steel powder. Metal parts produced using pbf melting technology are free from residual stresses and internal imperfections, making them ideal for demanding several industries rely on parts created on metal powder bed fusion 3d printers. Though it's difficult and dangerous to handle in its raw state, its unique features make it the preferred metal stock type. The vast majority of metal 3d printing technologies utilize metal powder. Order 3d metal parts online. Although metal 3d printer prices have been slowly and slightly decreasing, these machines are still relatively expensive acquisitions, mostly. Medical professionals and surgeons use these 3d printed metals for. Metal printers can be used of small batch manufacturing, but the capabilities of metal 3d printing systems resemble more the batch manufacturing the material and manufacturing costs connected with metal 3d printing is high, so these technologies are not suitable for parts that can be easily. Metal 3d printing has the potential to transform the way parts are manufactured by providing a level of complexity and customisation that is not possible with traditional manufacturing. What is the best metal 3d printer in 2020?