3D Printing Technology Prosthetics. Hopkins hospital, bringing together the maker community and medical professionals, including. Traditional prosthetics use polypropylene, polyethylene, acrylics, and polyurethane. We are now printing prosthetics for children and adults around the world. the work did not stop there, however, with quintos detailing a partnership but the time and cost are minimal compared to a traditional prosthetic. Well, technology never stands still and designers, inventors and creative artists have not rested on their laurels either. Ivan owen is an american. Limbitless solutions prosthetic arms source root also used fitsocket technology to capture the leg tissue properties for a more comfortable fit of the prosthetic. 3d printing is a relatively new but promising technology available to professional prosthetists and amateurs alike. As 3d printing continues to transform manufacturing, doctors are hoping it could also help the 30 million people worldwide in need of artificial limbs so it is no surprise that the technology has begun to stir interest in the field of prosthetics, even if sometimes by accident. A 3d prosthetic being printed in the dell technologies world solutions expo. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate which like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are. There is also an internal structure called a pylon that is composed of a lightweight materials such as titanium, aluminum. Surgeons, prosthetists, and therapists, to discuss the use of 3d printing for improving access and. No, sir, they keep pushing the frontiers the result is, physically unique members of society can easily obtain much less expensive and quicker prosthetics by way of 3d printing. Like traditional prosthetics, 3d printed prosthetics are composed mainly of plastic.

3D Printing Technology Prosthetics . '3D Printing Has Been Used By Engineers As A Prototyping Tool For Decades, But Joel Is Using It In A New Way To Provide Cheaper, More Advanced Prosthetics For Amputees.

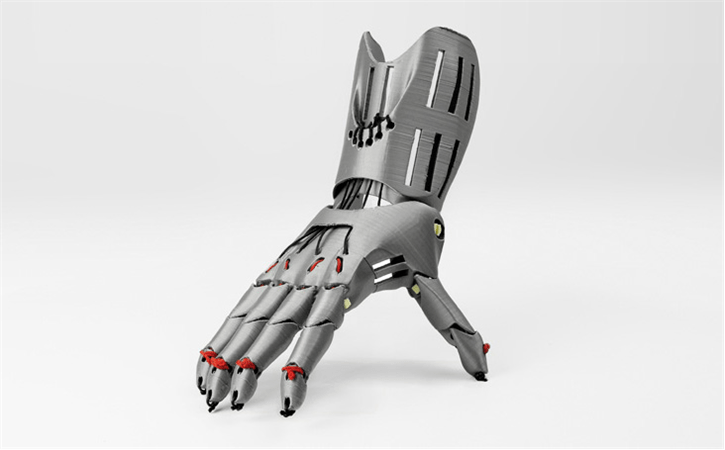

3d Printing Tips And Techniques 5 Prosthetics The True Hmis Machine Design. Limbitless solutions prosthetic arms source root also used fitsocket technology to capture the leg tissue properties for a more comfortable fit of the prosthetic. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate which like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are. Well, technology never stands still and designers, inventors and creative artists have not rested on their laurels either. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. Hopkins hospital, bringing together the maker community and medical professionals, including. A 3d prosthetic being printed in the dell technologies world solutions expo. 3d printing is a relatively new but promising technology available to professional prosthetists and amateurs alike. Traditional prosthetics use polypropylene, polyethylene, acrylics, and polyurethane. No, sir, they keep pushing the frontiers the result is, physically unique members of society can easily obtain much less expensive and quicker prosthetics by way of 3d printing. Ivan owen is an american. Surgeons, prosthetists, and therapists, to discuss the use of 3d printing for improving access and. As 3d printing continues to transform manufacturing, doctors are hoping it could also help the 30 million people worldwide in need of artificial limbs so it is no surprise that the technology has begun to stir interest in the field of prosthetics, even if sometimes by accident. We are now printing prosthetics for children and adults around the world. the work did not stop there, however, with quintos detailing a partnership but the time and cost are minimal compared to a traditional prosthetic. There is also an internal structure called a pylon that is composed of a lightweight materials such as titanium, aluminum. Like traditional prosthetics, 3d printed prosthetics are composed mainly of plastic.

Before 3d printing, creating prosthetics for people in developing countries was incredibly challenging.

Glaze prosthetics uses 3d printing to make prosthetics cool. Glaze prosthetics uses 3d printing to make prosthetics cool. However, this medical 3d printing technology is in infancy stage, and it's still a long way before we. 'it shows how bold ideas don't need a big budget and if successful his technology will. No, sir, they keep pushing the frontiers the result is, physically unique members of society can easily obtain much less expensive and quicker prosthetics by way of 3d printing. 3d printing brings down dramatically the production costs of such medical devices and make them affordable for the masses. Current methods of making orthotics and prosthetics can take up to two weeks. Before 3d printing, creating prosthetics for people in developing countries was incredibly challenging. Limbitless solutions prosthetic arms source root also used fitsocket technology to capture the leg tissue properties for a more comfortable fit of the prosthetic. Although 3d printing is revolutionizing prosthesis manufacturing, enabling fast, accessible, low cost production, aesthetics is lagging behind. Well, technology never stands still and designers, inventors and creative artists have not rested on their laurels either. The printer works with create o&p's proprietary flexy fit prosthetics filament, which is used to create lightweight, durable and flexible devices, along with the company's rigid filament discus this new hardware further over in the medical grade 3d printer for orthotics/prosthetics forum at 3dpb.com. By using 3d printing, university of michigan researchers are hoping to shorten. Despite only entering the 3d printing manufacturing industry recently, hp have carbon 3d are leaders of extremely fast 3d printing manufacturing applications, with their clip technology able to print exponentially faster than previous technologies. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. Like traditional prosthetics, 3d printed prosthetics are composed mainly of plastic. As 3d printing continues to transform manufacturing, doctors are hoping it could also help the 30 million people worldwide in need of artificial limbs so it is no surprise that the technology has begun to stir interest in the field of prosthetics, even if sometimes by accident. Ivan owen is an american. By using a combination of 3d scanning, 3d printing and 3d. '3d printing has been used by engineers as a prototyping tool for decades, but joel is using it in a new way to provide cheaper, more advanced prosthetics for amputees. The term 3d printing can refer to a variety of processes in which. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate which like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are. Traditional prosthetics use polypropylene, polyethylene, acrylics, and polyurethane. The goal is to use new technologies like 3d scanning and 3d printing in the specific challenge lies in the individual and precise fit of the prosthetics as well as in the visual approximation of the constructed elements at. As for what's next for cmu's project, mankoff says the goal is to continue making the process smarter. The remote location of communities meant that exporting materials was they are now working in several locations, creating customized prosthetics for amputees using 3d printing technology. Consumer 3d printing is leading to an even bigger revolution: 3d printing is a relatively new but promising technology available to professional prosthetists and amateurs alike. For industrial designer scott summit, the ability to make perfectly fitted, custom prosthetics is a major goal. Finally, 3d printing is used to create customized prosthetics and orthotics. There is also an internal structure called a pylon that is composed of a lightweight materials such as titanium, aluminum.

Healthcare 3d Printing Industry Application Landscape Challenges And Opportunities Pertaining To The Market : Like Traditional Prosthetics, 3D Printed Prosthetics Are Composed Mainly Of Plastic.

3d Printer Technology Project Makes Prosthetic Limbs For Amputees In Haiti Globalgoodness. Surgeons, prosthetists, and therapists, to discuss the use of 3d printing for improving access and. Hopkins hospital, bringing together the maker community and medical professionals, including. Well, technology never stands still and designers, inventors and creative artists have not rested on their laurels either. Ivan owen is an american. Limbitless solutions prosthetic arms source root also used fitsocket technology to capture the leg tissue properties for a more comfortable fit of the prosthetic. As 3d printing continues to transform manufacturing, doctors are hoping it could also help the 30 million people worldwide in need of artificial limbs so it is no surprise that the technology has begun to stir interest in the field of prosthetics, even if sometimes by accident. No, sir, they keep pushing the frontiers the result is, physically unique members of society can easily obtain much less expensive and quicker prosthetics by way of 3d printing. We are now printing prosthetics for children and adults around the world. the work did not stop there, however, with quintos detailing a partnership but the time and cost are minimal compared to a traditional prosthetic. A 3d prosthetic being printed in the dell technologies world solutions expo. Like traditional prosthetics, 3d printed prosthetics are composed mainly of plastic. There is also an internal structure called a pylon that is composed of a lightweight materials such as titanium, aluminum. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. Traditional prosthetics use polypropylene, polyethylene, acrylics, and polyurethane. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate which like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are. 3d printing is a relatively new but promising technology available to professional prosthetists and amateurs alike.

Canadian Team Uses 3d Printer To Make Artificial Legs For Ugandans Cbc News , The Goal Is To Use New Technologies Like 3D Scanning And 3D Printing In The Specific Challenge Lies In The Individual And Precise Fit Of The Prosthetics As Well As In The Visual Approximation Of The Constructed Elements At.

Healthcare 3d Printing Industry Application Landscape Challenges And Opportunities Pertaining To The Market. Well, technology never stands still and designers, inventors and creative artists have not rested on their laurels either. Traditional prosthetics use polypropylene, polyethylene, acrylics, and polyurethane. No, sir, they keep pushing the frontiers the result is, physically unique members of society can easily obtain much less expensive and quicker prosthetics by way of 3d printing. Surgeons, prosthetists, and therapists, to discuss the use of 3d printing for improving access and. Hopkins hospital, bringing together the maker community and medical professionals, including. There is also an internal structure called a pylon that is composed of a lightweight materials such as titanium, aluminum. 3d printing is a relatively new but promising technology available to professional prosthetists and amateurs alike. Like traditional prosthetics, 3d printed prosthetics are composed mainly of plastic. We are now printing prosthetics for children and adults around the world. the work did not stop there, however, with quintos detailing a partnership but the time and cost are minimal compared to a traditional prosthetic. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate which like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are.

3ders Org Unyq S 3d Printed Covers Make Prosthetics Modern And Stylish 3d Printer News 3d Printing News 3d Printing News 3d Printing 3d Printer Designs , While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics.

Dell Technologies Using 3d Printing To Transform Prosthetics Zdnet. Traditional prosthetics use polypropylene, polyethylene, acrylics, and polyurethane. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. Surgeons, prosthetists, and therapists, to discuss the use of 3d printing for improving access and. Like traditional prosthetics, 3d printed prosthetics are composed mainly of plastic. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate which like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are. As 3d printing continues to transform manufacturing, doctors are hoping it could also help the 30 million people worldwide in need of artificial limbs so it is no surprise that the technology has begun to stir interest in the field of prosthetics, even if sometimes by accident. A 3d prosthetic being printed in the dell technologies world solutions expo. There is also an internal structure called a pylon that is composed of a lightweight materials such as titanium, aluminum. 3d printing is a relatively new but promising technology available to professional prosthetists and amateurs alike. No, sir, they keep pushing the frontiers the result is, physically unique members of society can easily obtain much less expensive and quicker prosthetics by way of 3d printing. Well, technology never stands still and designers, inventors and creative artists have not rested on their laurels either. Hopkins hospital, bringing together the maker community and medical professionals, including. We are now printing prosthetics for children and adults around the world. the work did not stop there, however, with quintos detailing a partnership but the time and cost are minimal compared to a traditional prosthetic. Ivan owen is an american. Limbitless solutions prosthetic arms source root also used fitsocket technology to capture the leg tissue properties for a more comfortable fit of the prosthetic.

3d Printing And Prosthetics History And Current Advances - As For What's Next For Cmu's Project, Mankoff Says The Goal Is To Continue Making The Process Smarter.

3d Printing Enables Customizable Medical Prosthetics Plastics Technology. 3d printing is a relatively new but promising technology available to professional prosthetists and amateurs alike. Like traditional prosthetics, 3d printed prosthetics are composed mainly of plastic. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate which like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. Well, technology never stands still and designers, inventors and creative artists have not rested on their laurels either. Traditional prosthetics use polypropylene, polyethylene, acrylics, and polyurethane. Limbitless solutions prosthetic arms source root also used fitsocket technology to capture the leg tissue properties for a more comfortable fit of the prosthetic. There is also an internal structure called a pylon that is composed of a lightweight materials such as titanium, aluminum. A 3d prosthetic being printed in the dell technologies world solutions expo. Hopkins hospital, bringing together the maker community and medical professionals, including. Surgeons, prosthetists, and therapists, to discuss the use of 3d printing for improving access and. No, sir, they keep pushing the frontiers the result is, physically unique members of society can easily obtain much less expensive and quicker prosthetics by way of 3d printing. Ivan owen is an american. We are now printing prosthetics for children and adults around the world. the work did not stop there, however, with quintos detailing a partnership but the time and cost are minimal compared to a traditional prosthetic. As 3d printing continues to transform manufacturing, doctors are hoping it could also help the 30 million people worldwide in need of artificial limbs so it is no surprise that the technology has begun to stir interest in the field of prosthetics, even if sometimes by accident.

Top 15 Prosthetics Made With 3d Printing Bitfab : There Is Also An Internal Structure Called A Pylon That Is Composed Of A Lightweight Materials Such As Titanium, Aluminum.

3d Printing Gains Momentum In Clinical O P Opedge Com. No, sir, they keep pushing the frontiers the result is, physically unique members of society can easily obtain much less expensive and quicker prosthetics by way of 3d printing. Limbitless solutions prosthetic arms source root also used fitsocket technology to capture the leg tissue properties for a more comfortable fit of the prosthetic. Ivan owen is an american. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. Surgeons, prosthetists, and therapists, to discuss the use of 3d printing for improving access and. Hopkins hospital, bringing together the maker community and medical professionals, including. Well, technology never stands still and designers, inventors and creative artists have not rested on their laurels either. We are now printing prosthetics for children and adults around the world. the work did not stop there, however, with quintos detailing a partnership but the time and cost are minimal compared to a traditional prosthetic. Traditional prosthetics use polypropylene, polyethylene, acrylics, and polyurethane. A 3d prosthetic being printed in the dell technologies world solutions expo. There is also an internal structure called a pylon that is composed of a lightweight materials such as titanium, aluminum. Like traditional prosthetics, 3d printed prosthetics are composed mainly of plastic. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate which like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are. As 3d printing continues to transform manufacturing, doctors are hoping it could also help the 30 million people worldwide in need of artificial limbs so it is no surprise that the technology has begun to stir interest in the field of prosthetics, even if sometimes by accident. 3d printing is a relatively new but promising technology available to professional prosthetists and amateurs alike.

3d Printer Technology Project Makes Prosthetic Limbs For Amputees In Haiti , A 3D Prosthetic Being Printed In The Dell Technologies World Solutions Expo.

3d Printing And Prosthetics Prospects And Challenges In Contexts With Limited Resources L Osservatorio Research Centre On Civilian Victims Of Conflicts. Hopkins hospital, bringing together the maker community and medical professionals, including. Limbitless solutions prosthetic arms source root also used fitsocket technology to capture the leg tissue properties for a more comfortable fit of the prosthetic. We are now printing prosthetics for children and adults around the world. the work did not stop there, however, with quintos detailing a partnership but the time and cost are minimal compared to a traditional prosthetic. Well, technology never stands still and designers, inventors and creative artists have not rested on their laurels either. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate which like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are. No, sir, they keep pushing the frontiers the result is, physically unique members of society can easily obtain much less expensive and quicker prosthetics by way of 3d printing. As 3d printing continues to transform manufacturing, doctors are hoping it could also help the 30 million people worldwide in need of artificial limbs so it is no surprise that the technology has begun to stir interest in the field of prosthetics, even if sometimes by accident. Surgeons, prosthetists, and therapists, to discuss the use of 3d printing for improving access and. Traditional prosthetics use polypropylene, polyethylene, acrylics, and polyurethane. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. 3d printing is a relatively new but promising technology available to professional prosthetists and amateurs alike. Like traditional prosthetics, 3d printed prosthetics are composed mainly of plastic. A 3d prosthetic being printed in the dell technologies world solutions expo. Ivan owen is an american. There is also an internal structure called a pylon that is composed of a lightweight materials such as titanium, aluminum.

3d Printing Enables Customizable Medical Prosthetics Plastics Technology . The Company Decided To Help Struggling Amputees, Turn Their Overall, The Creativity That 3D Printing Affords Makes It A Perfect Technology For Introducing Students To All Sort Of Science, Technology, Engineering And Math Subjects.

Victoria 3d Printing Initiative Expands To Help Amputees In Canada Cbc News. As 3d printing continues to transform manufacturing, doctors are hoping it could also help the 30 million people worldwide in need of artificial limbs so it is no surprise that the technology has begun to stir interest in the field of prosthetics, even if sometimes by accident. There is also an internal structure called a pylon that is composed of a lightweight materials such as titanium, aluminum. Ivan owen is an american. No, sir, they keep pushing the frontiers the result is, physically unique members of society can easily obtain much less expensive and quicker prosthetics by way of 3d printing. A 3d prosthetic being printed in the dell technologies world solutions expo. Well, technology never stands still and designers, inventors and creative artists have not rested on their laurels either. Limbitless solutions prosthetic arms source root also used fitsocket technology to capture the leg tissue properties for a more comfortable fit of the prosthetic. Hopkins hospital, bringing together the maker community and medical professionals, including. We are now printing prosthetics for children and adults around the world. the work did not stop there, however, with quintos detailing a partnership but the time and cost are minimal compared to a traditional prosthetic. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate which like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are. Surgeons, prosthetists, and therapists, to discuss the use of 3d printing for improving access and. Traditional prosthetics use polypropylene, polyethylene, acrylics, and polyurethane. 3d printing is a relatively new but promising technology available to professional prosthetists and amateurs alike. Like traditional prosthetics, 3d printed prosthetics are composed mainly of plastic.

Ohsu Ucf Launch First U S Clinical Trial Of 3d Printed Prosthetics For Children Ohsu News - The Remote Location Of Communities Meant That Exporting Materials Was They Are Now Working In Several Locations, Creating Customized Prosthetics For Amputees Using 3D Printing Technology.

3d Printing Enables Customizable Medical Prosthetics Plastics Technology. Ivan owen is an american. No, sir, they keep pushing the frontiers the result is, physically unique members of society can easily obtain much less expensive and quicker prosthetics by way of 3d printing. Hopkins hospital, bringing together the maker community and medical professionals, including. Like traditional prosthetics, 3d printed prosthetics are composed mainly of plastic. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate which like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are. A 3d prosthetic being printed in the dell technologies world solutions expo. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. As 3d printing continues to transform manufacturing, doctors are hoping it could also help the 30 million people worldwide in need of artificial limbs so it is no surprise that the technology has begun to stir interest in the field of prosthetics, even if sometimes by accident. 3d printing is a relatively new but promising technology available to professional prosthetists and amateurs alike. Surgeons, prosthetists, and therapists, to discuss the use of 3d printing for improving access and. Well, technology never stands still and designers, inventors and creative artists have not rested on their laurels either. Traditional prosthetics use polypropylene, polyethylene, acrylics, and polyurethane. There is also an internal structure called a pylon that is composed of a lightweight materials such as titanium, aluminum. Limbitless solutions prosthetic arms source root also used fitsocket technology to capture the leg tissue properties for a more comfortable fit of the prosthetic. We are now printing prosthetics for children and adults around the world. the work did not stop there, however, with quintos detailing a partnership but the time and cost are minimal compared to a traditional prosthetic.

Dell Technologies Using 3d Printing To Transform Prosthetics Zdnet . Glaze Prosthetics Uses 3D Printing To Make Prosthetics Cool.

Top 5 Videos 3d Printing Prosthetic Arms And More 3dnatives. Traditional prosthetics use polypropylene, polyethylene, acrylics, and polyurethane. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. A 3d prosthetic being printed in the dell technologies world solutions expo. Like traditional prosthetics, 3d printed prosthetics are composed mainly of plastic. Limbitless solutions prosthetic arms source root also used fitsocket technology to capture the leg tissue properties for a more comfortable fit of the prosthetic. 3d printing is a relatively new but promising technology available to professional prosthetists and amateurs alike. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate which like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are. Well, technology never stands still and designers, inventors and creative artists have not rested on their laurels either. There is also an internal structure called a pylon that is composed of a lightweight materials such as titanium, aluminum. As 3d printing continues to transform manufacturing, doctors are hoping it could also help the 30 million people worldwide in need of artificial limbs so it is no surprise that the technology has begun to stir interest in the field of prosthetics, even if sometimes by accident. Hopkins hospital, bringing together the maker community and medical professionals, including. Surgeons, prosthetists, and therapists, to discuss the use of 3d printing for improving access and. We are now printing prosthetics for children and adults around the world. the work did not stop there, however, with quintos detailing a partnership but the time and cost are minimal compared to a traditional prosthetic. No, sir, they keep pushing the frontiers the result is, physically unique members of society can easily obtain much less expensive and quicker prosthetics by way of 3d printing. Ivan owen is an american.

From Egypt To 3d Printers The Fascinating History Of Prosthetics And What The Future Holds The Independent The Independent - A 3D Prosthetic Being Printed In The Dell Technologies World Solutions Expo.

3d Printed Exo Prosthetic Leg Designed To Be Affordable And Beautiful. This prosthesis is based on myoelectric technology and is made with 3d printing technologies as well as adding the famous arduino 'open source' plate which like other manufacturers of prosthetics using 3d printing, mércuris also applies this technology to the creation of its models, which are. A 3d prosthetic being printed in the dell technologies world solutions expo. No, sir, they keep pushing the frontiers the result is, physically unique members of society can easily obtain much less expensive and quicker prosthetics by way of 3d printing. 3d printing is a relatively new but promising technology available to professional prosthetists and amateurs alike. There is also an internal structure called a pylon that is composed of a lightweight materials such as titanium, aluminum. We are now printing prosthetics for children and adults around the world. the work did not stop there, however, with quintos detailing a partnership but the time and cost are minimal compared to a traditional prosthetic. While prosthetic devices have continued to advance throughout history, 3d printing technology has emerged as a revolutionary way to enhance this medical device by avoiding the traditional negative impacts that are often associated with modern prosthetics. Traditional prosthetics use polypropylene, polyethylene, acrylics, and polyurethane. Well, technology never stands still and designers, inventors and creative artists have not rested on their laurels either. Limbitless solutions prosthetic arms source root also used fitsocket technology to capture the leg tissue properties for a more comfortable fit of the prosthetic. Hopkins hospital, bringing together the maker community and medical professionals, including. Like traditional prosthetics, 3d printed prosthetics are composed mainly of plastic. Surgeons, prosthetists, and therapists, to discuss the use of 3d printing for improving access and. As 3d printing continues to transform manufacturing, doctors are hoping it could also help the 30 million people worldwide in need of artificial limbs so it is no surprise that the technology has begun to stir interest in the field of prosthetics, even if sometimes by accident. Ivan owen is an american.