3D Printing Under Extrusion. I'm not so good with english so here are pictures of. It goes on like this for a while then pla just stops coming out of the noozles. I'm not really sure but i think this happened because of under extrusion. Thing is that my print (first layer) started ok, not good nor perfect but ok and everything was going well but then all of a sudden, near the end of a print, quality drops drastically. Checked the feeder, and it has not. Trying the manual extrusion did not help, and i am just stuck now. Let's talk about how to avoid it. Each profile in simplify3d includes settings that are used to determine how much plastic the 3d printer should extrude. The most reliable way to test whether or not your printer is extruding enough plastic is to print a simple 20mm tall cube with at least 3 perimeter outlines. By carefully observing the printing process, you can identify problems with extrusion instability. This is very important when 3d. In different parts of the 3d prints, there is a change in the extruded thread, which will affect the final print quality. This can result in gaps, missing layers, insufficiently small layers, and even little try decreasing your print speed by 20 mm/s and observe the result. The print starts just fine, but an hour or so later, the material coming out of the noozle appears dotted, unevenly distributed. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them.

3D Printing Under Extrusion : In This Episode I Show You How To Identify Common Issues That Cause Under Extrusion In Your 3D Printer And How To Fix Them.

Under Extrusion Problems Or Clicking Sounds Here S Why And How To Fix. By carefully observing the printing process, you can identify problems with extrusion instability. Trying the manual extrusion did not help, and i am just stuck now. This is very important when 3d. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. I'm not so good with english so here are pictures of. The print starts just fine, but an hour or so later, the material coming out of the noozle appears dotted, unevenly distributed. The most reliable way to test whether or not your printer is extruding enough plastic is to print a simple 20mm tall cube with at least 3 perimeter outlines. I'm not really sure but i think this happened because of under extrusion. This can result in gaps, missing layers, insufficiently small layers, and even little try decreasing your print speed by 20 mm/s and observe the result. Checked the feeder, and it has not. Let's talk about how to avoid it. Thing is that my print (first layer) started ok, not good nor perfect but ok and everything was going well but then all of a sudden, near the end of a print, quality drops drastically. In different parts of the 3d prints, there is a change in the extruded thread, which will affect the final print quality. Each profile in simplify3d includes settings that are used to determine how much plastic the 3d printer should extrude. It goes on like this for a while then pla just stops coming out of the noozles.

3d printing materials compatible with extrusion 3d printers cover a wide range of plastic filaments (spools).

By carefully observing the printing process, you can identify problems with extrusion instability. 3.75 retraction speed 30mm/s extra restart 0.12 mm extrusion multi: In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. I'm not really sure but i think this happened because of under extrusion. Trying the manual extrusion did not help, and i am just stuck now. This can result in gaps, missing layers, insufficiently small layers, and even little try decreasing your print speed by 20 mm/s and observe the result. Download files and build them with your 3d printer, laser cutter, or cnc. The best 3d printers under $300. Five different colors and materials simultaneously without. The material is flowing well. Thing is that my print (first layer) started ok, not good nor perfect but ok and everything was going well but then all of a sudden, near the end of a print, quality drops drastically. The most reliable way to test whether or not your printer is extruding enough plastic is to print a simple 20mm tall cube with at least 3 perimeter outlines. You set up a print job to run. When the line width is adjusted to 0.35mm, we. Fused filament fabrication (fff), also known under the trademarked term fused deposition modeling (fdm), sometimes also called filament freeform fabrication. A plastic filament is melted and deposited on the build platform of the 3d printer to form the object layer by layer. This is very important when 3d. However dual extrusion 3d printing requires some extra care, both in preparation and in calibration, in order to solve most common problems. Hunter626103d printers 3d printing 3d printers. Next, let's analyze the contents of the form. I have been using my wanhao duplicator i3 with the stock hotend for the last 1.5 years and everything has been printing fine. I have been using makergeeks pla filament at 210c and have printed a lot of. Alibaba.com offers 1,780 extrusion 3d printing products. 220c (230 for first layer) bed temp: By carefully observing the printing process, you can identify problems with extrusion instability. 3d printing materials compatible with extrusion 3d printers cover a wide range of plastic filaments (spools). See more of custom extrusions 3d on facebook. To reduce resistance on the filament you can move the spool holder closer. Anet am8 (e3d v6 + titan bowden setup) extruder temp : 3d printing or additive manufacturing is a process of making three 3d printing is the opposite of subtractive manufacturing which is cutting out / hollowing out a piece of fdm works using a plastic filament which is unwound from a spool and is supplied to an extrusion. Print your own 3d scanner kit (for intricad triangle software) by ideabeansnz.

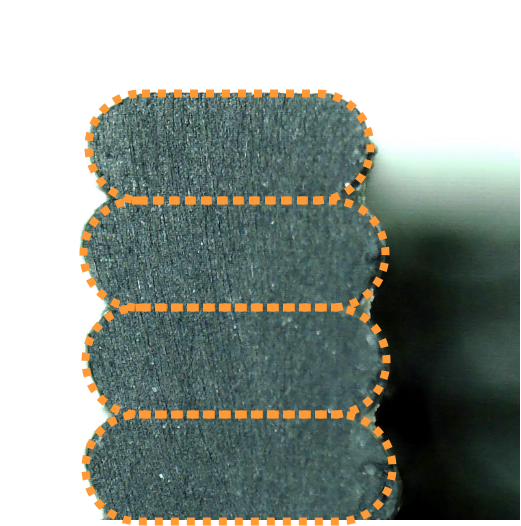

Strange Repeating Under Extrusion 5732 General Sunhokey 3d Printer Owners Groups Thingiverse , In Different Parts Of The 3D Prints, There Is A Change In The Extruded Thread, Which Will Affect The Final Print Quality.

3d Printing Forum 3d Print Board. I'm not really sure but i think this happened because of under extrusion. This can result in gaps, missing layers, insufficiently small layers, and even little try decreasing your print speed by 20 mm/s and observe the result. Let's talk about how to avoid it. Checked the feeder, and it has not. Trying the manual extrusion did not help, and i am just stuck now. Each profile in simplify3d includes settings that are used to determine how much plastic the 3d printer should extrude. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. By carefully observing the printing process, you can identify problems with extrusion instability. This is very important when 3d. The most reliable way to test whether or not your printer is extruding enough plastic is to print a simple 20mm tall cube with at least 3 perimeter outlines. Thing is that my print (first layer) started ok, not good nor perfect but ok and everything was going well but then all of a sudden, near the end of a print, quality drops drastically. In different parts of the 3d prints, there is a change in the extruded thread, which will affect the final print quality. The print starts just fine, but an hour or so later, the material coming out of the noozle appears dotted, unevenly distributed. I'm not so good with english so here are pictures of. It goes on like this for a while then pla just stops coming out of the noozles.

Extruding Too Little Much Plastic Raise3d B V . The Proposed Extrusion Model Enables Printing With.

3d Printing Inconsistent Extrusion Troubleshooting 3d Newb. I'm not really sure but i think this happened because of under extrusion. Trying the manual extrusion did not help, and i am just stuck now. Each profile in simplify3d includes settings that are used to determine how much plastic the 3d printer should extrude. Thing is that my print (first layer) started ok, not good nor perfect but ok and everything was going well but then all of a sudden, near the end of a print, quality drops drastically. I'm not so good with english so here are pictures of. The most reliable way to test whether or not your printer is extruding enough plastic is to print a simple 20mm tall cube with at least 3 perimeter outlines. Checked the feeder, and it has not. Let's talk about how to avoid it. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. It goes on like this for a while then pla just stops coming out of the noozles.

Under Extrusion Issue Album On Imgur , A wide variety of extrusion 3d printing options are available to you, such as paper printer, card printer, and bill printer.

Polymers Free Full Text Hardware Factors Influencing Strength Of Parts Obtained By Fused Filament Fabrication Html. This can result in gaps, missing layers, insufficiently small layers, and even little try decreasing your print speed by 20 mm/s and observe the result. By carefully observing the printing process, you can identify problems with extrusion instability. I'm not so good with english so here are pictures of. Each profile in simplify3d includes settings that are used to determine how much plastic the 3d printer should extrude. The print starts just fine, but an hour or so later, the material coming out of the noozle appears dotted, unevenly distributed. I'm not really sure but i think this happened because of under extrusion. In different parts of the 3d prints, there is a change in the extruded thread, which will affect the final print quality. Checked the feeder, and it has not. It goes on like this for a while then pla just stops coming out of the noozles. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. Trying the manual extrusion did not help, and i am just stuck now. Let's talk about how to avoid it. This is very important when 3d. Thing is that my print (first layer) started ok, not good nor perfect but ok and everything was going well but then all of a sudden, near the end of a print, quality drops drastically. The most reliable way to test whether or not your printer is extruding enough plastic is to print a simple 20mm tall cube with at least 3 perimeter outlines.

Musings On Under Extrusion Prepare To Rethink Your Understanding Sublime Layers . In This Episode I Show You How To Identify Common Issues That Cause Under Extrusion In Your 3D Printer And How To Fix Them.

The Solution To Under Extrusion Not Extruding Enough Plastic Gearbest Blog. Thing is that my print (first layer) started ok, not good nor perfect but ok and everything was going well but then all of a sudden, near the end of a print, quality drops drastically. This can result in gaps, missing layers, insufficiently small layers, and even little try decreasing your print speed by 20 mm/s and observe the result. In different parts of the 3d prints, there is a change in the extruded thread, which will affect the final print quality. Each profile in simplify3d includes settings that are used to determine how much plastic the 3d printer should extrude. By carefully observing the printing process, you can identify problems with extrusion instability. It goes on like this for a while then pla just stops coming out of the noozles. I'm not so good with english so here are pictures of. The most reliable way to test whether or not your printer is extruding enough plastic is to print a simple 20mm tall cube with at least 3 perimeter outlines. I'm not really sure but i think this happened because of under extrusion. Checked the feeder, and it has not. The print starts just fine, but an hour or so later, the material coming out of the noozle appears dotted, unevenly distributed. This is very important when 3d. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. Trying the manual extrusion did not help, and i am just stuck now. Let's talk about how to avoid it.

Prusa Knowledge Base Under Extrusion : Printed Parts Can Have High Dimensional Accurately However If Simplify3D Implemented Three.

Prusa Knowledge Base Extrusion Multiplier Calibration. This is very important when 3d. Let's talk about how to avoid it. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. In different parts of the 3d prints, there is a change in the extruded thread, which will affect the final print quality. Trying the manual extrusion did not help, and i am just stuck now. Each profile in simplify3d includes settings that are used to determine how much plastic the 3d printer should extrude. It goes on like this for a while then pla just stops coming out of the noozles. Thing is that my print (first layer) started ok, not good nor perfect but ok and everything was going well but then all of a sudden, near the end of a print, quality drops drastically. I'm not really sure but i think this happened because of under extrusion. By carefully observing the printing process, you can identify problems with extrusion instability. The print starts just fine, but an hour or so later, the material coming out of the noozle appears dotted, unevenly distributed. I'm not so good with english so here are pictures of. Checked the feeder, and it has not. The most reliable way to test whether or not your printer is extruding enough plastic is to print a simple 20mm tall cube with at least 3 perimeter outlines. This can result in gaps, missing layers, insufficiently small layers, and even little try decreasing your print speed by 20 mm/s and observe the result.

Poor Extrusion At The Start Of Layers 3d Printing 3d Printers Talk Manufacturing 3d Hubs : Check Out Our Gallery Or Contact Us For Examples Of Our Work.

Intermittent Underextrusion 3dprinting. I'm not so good with english so here are pictures of. Let's talk about how to avoid it. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. I'm not really sure but i think this happened because of under extrusion. By carefully observing the printing process, you can identify problems with extrusion instability. Trying the manual extrusion did not help, and i am just stuck now. The most reliable way to test whether or not your printer is extruding enough plastic is to print a simple 20mm tall cube with at least 3 perimeter outlines. It goes on like this for a while then pla just stops coming out of the noozles. Checked the feeder, and it has not. The print starts just fine, but an hour or so later, the material coming out of the noozle appears dotted, unevenly distributed. This can result in gaps, missing layers, insufficiently small layers, and even little try decreasing your print speed by 20 mm/s and observe the result. Each profile in simplify3d includes settings that are used to determine how much plastic the 3d printer should extrude. In different parts of the 3d prints, there is a change in the extruded thread, which will affect the final print quality. This is very important when 3d. Thing is that my print (first layer) started ok, not good nor perfect but ok and everything was going well but then all of a sudden, near the end of a print, quality drops drastically.

Cura Underextruding After Printing Internal Features Ultimaker Cura Ultimaker Community Of 3d Printing Experts - The Material Is Flowing Well.

Troubleshooting Deltaprintr. Checked the feeder, and it has not. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. The most reliable way to test whether or not your printer is extruding enough plastic is to print a simple 20mm tall cube with at least 3 perimeter outlines. In different parts of the 3d prints, there is a change in the extruded thread, which will affect the final print quality. I'm not really sure but i think this happened because of under extrusion. This is very important when 3d. I'm not so good with english so here are pictures of. This can result in gaps, missing layers, insufficiently small layers, and even little try decreasing your print speed by 20 mm/s and observe the result. Let's talk about how to avoid it. The print starts just fine, but an hour or so later, the material coming out of the noozle appears dotted, unevenly distributed. Thing is that my print (first layer) started ok, not good nor perfect but ok and everything was going well but then all of a sudden, near the end of a print, quality drops drastically. Trying the manual extrusion did not help, and i am just stuck now. It goes on like this for a while then pla just stops coming out of the noozles. By carefully observing the printing process, you can identify problems with extrusion instability. Each profile in simplify3d includes settings that are used to determine how much plastic the 3d printer should extrude.

Under Extrusion In Random Spots No Category Talk Manufacturing 3d Hubs . You Leave The Room Thinking All Is Right With The World.

Ender 3 Under Extruding 3d Printing Talk Manufacturing 3d Hubs. Let's talk about how to avoid it. This is very important when 3d. Trying the manual extrusion did not help, and i am just stuck now. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. I'm not so good with english so here are pictures of. The most reliable way to test whether or not your printer is extruding enough plastic is to print a simple 20mm tall cube with at least 3 perimeter outlines. I'm not really sure but i think this happened because of under extrusion. In different parts of the 3d prints, there is a change in the extruded thread, which will affect the final print quality. Each profile in simplify3d includes settings that are used to determine how much plastic the 3d printer should extrude. The print starts just fine, but an hour or so later, the material coming out of the noozle appears dotted, unevenly distributed. It goes on like this for a while then pla just stops coming out of the noozles. This can result in gaps, missing layers, insufficiently small layers, and even little try decreasing your print speed by 20 mm/s and observe the result. Checked the feeder, and it has not. Thing is that my print (first layer) started ok, not good nor perfect but ok and everything was going well but then all of a sudden, near the end of a print, quality drops drastically. By carefully observing the printing process, you can identify problems with extrusion instability.

New Gear Solved Underextrusion Problems In 3d Printing Electroninjection : The Material Is Flowing Well.

Results Of 3d Printing Speed Calibration A Under Extrusion Speed B Download Scientific Diagram. I'm not so good with english so here are pictures of. Checked the feeder, and it has not. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. By carefully observing the printing process, you can identify problems with extrusion instability. It goes on like this for a while then pla just stops coming out of the noozles. Let's talk about how to avoid it. Each profile in simplify3d includes settings that are used to determine how much plastic the 3d printer should extrude. I'm not really sure but i think this happened because of under extrusion. Thing is that my print (first layer) started ok, not good nor perfect but ok and everything was going well but then all of a sudden, near the end of a print, quality drops drastically. The most reliable way to test whether or not your printer is extruding enough plastic is to print a simple 20mm tall cube with at least 3 perimeter outlines. This can result in gaps, missing layers, insufficiently small layers, and even little try decreasing your print speed by 20 mm/s and observe the result. This is very important when 3d. In different parts of the 3d prints, there is a change in the extruded thread, which will affect the final print quality. The print starts just fine, but an hour or so later, the material coming out of the noozle appears dotted, unevenly distributed. Trying the manual extrusion did not help, and i am just stuck now.

What Could Be Causing This Under Extrusion Mpselectminiowners . 3.75 Retraction Speed 30Mm/S Extra Restart 0.12 Mm Extrusion Multi:

Results Of 3d Printing Speed Calibration A Under Extrusion Speed B Download Scientific Diagram. This is very important when 3d. Checked the feeder, and it has not. Each profile in simplify3d includes settings that are used to determine how much plastic the 3d printer should extrude. Let's talk about how to avoid it. The most reliable way to test whether or not your printer is extruding enough plastic is to print a simple 20mm tall cube with at least 3 perimeter outlines. I'm not really sure but i think this happened because of under extrusion. It goes on like this for a while then pla just stops coming out of the noozles. This can result in gaps, missing layers, insufficiently small layers, and even little try decreasing your print speed by 20 mm/s and observe the result. I'm not so good with english so here are pictures of. In this episode i show you how to identify common issues that cause under extrusion in your 3d printer and how to fix them. Trying the manual extrusion did not help, and i am just stuck now. The print starts just fine, but an hour or so later, the material coming out of the noozle appears dotted, unevenly distributed. By carefully observing the printing process, you can identify problems with extrusion instability. Thing is that my print (first layer) started ok, not good nor perfect but ok and everything was going well but then all of a sudden, near the end of a print, quality drops drastically. In different parts of the 3d prints, there is a change in the extruded thread, which will affect the final print quality.