3D Printing Wall Problems. Infill is visible from the outside. Print doesn't stick to print bed. Suggested corrections draw thicker wall thicknesses to suit add printing media below this area if the overhang is too difficult to manage for the 3d printer. Gaps between infill and outer wall. I don't have a heated bed, is this a problem? We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Different printers print rigid.ink best at different settings, so don't be afraid to experiment. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. Infill looks messy and incomplete. Break possible the walls of your 3d print are either too thin or not suitable for this small size. Avoid slowing down too much in this area, even. There were other quality problems too with this print, and you can already see that in the walls there are holes: I did another round of bed leveling and z alignment to make sure the adhesion is good and a test print came out quite fine in all corners and the center. Side walls are not smooth, lines are visible on the side of the print. My print print edges are bending (warping).

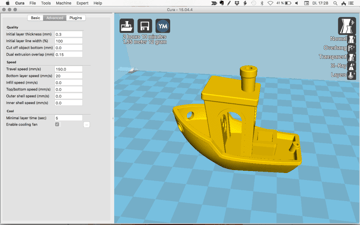

3D Printing Wall Problems - Printable Scenery > 3D Printers | Printing > Creality Ender 3 Cura 4.4.1 Settings.

Outside Wall Layer Adhesion Issues Petg Fixmyprint. My print print edges are bending (warping). Break possible the walls of your 3d print are either too thin or not suitable for this small size. I did another round of bed leveling and z alignment to make sure the adhesion is good and a test print came out quite fine in all corners and the center. Suggested corrections draw thicker wall thicknesses to suit add printing media below this area if the overhang is too difficult to manage for the 3d printer. Side walls are not smooth, lines are visible on the side of the print. Infill is visible from the outside. There were other quality problems too with this print, and you can already see that in the walls there are holes: Gaps between infill and outer wall. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Avoid slowing down too much in this area, even. Infill looks messy and incomplete. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. Different printers print rigid.ink best at different settings, so don't be afraid to experiment. Print doesn't stick to print bed. I don't have a heated bed, is this a problem?

Scientists have now seen a solution to this structural problem.

Just looking for some advice on how to improve the outer wall quality of my prints? If you don't know the name of your problem, you can make reference to the following 19 problems. I'm printing this object from thingiverse. Also consider different resin options. 19 common 3d printing problems: However, other factors, such as the alignment, size, and overall design of your 3d model, can also influence the recommended. One 3d printer hobbyist described a problem where they had 4 perimeter shells, where the first outer 2 shells people who experience 3d print walls not sticking together looked all around for solutions, but it ended up being as simple as checking their belts for looseness. It's not bad but it could be better. Many printing problems can be traced back to wall thickness issues. Different printers print rigid.ink best at different settings, so don't be afraid to experiment. They developed a model with which engineers can now easily determine the dimensions and printing. That might help to hold it's shape. Put in simple terms, this common 3d printing issue simply implies that the printer is taking in more this problem is one of the most asked questions in our 3d printing faq. I've used cura and simplify3d and both give me approximately the same results. The wall should be solid instead. The filament has a super resilient characteristic to all misconfiguration types. Print doesn't stick to print bed. If the printer is at the very edge of its capability the amount of plastic being extruded will be reduced but the print keeps going normally. In cura you need to toggle thin walls. Gaps between infill and outer wall. If you go to the. There were other quality problems too with this print, and you can already see that in the walls there are holes: Scientists have now seen a solution to this structural problem. Infill is visible from the outside. Since many 3d printing problems are caused by inappropriate wall thickness, it is important that the wall thickness of the 3d model is assigned minimum wall thickness may depend on the structure and the design of the 3d part. For instance, using a lower value for the extrusion multiplier (to get smoother outer walls) means that. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Most 3d printing issues are caused by a hardware component failure or wrong software settings, and can easily be. Printable scenery > 3d printers | printing > creality ender 3 cura 4.4.1 settings. My notes and disclaimers on 3d printing and miscellaneous other tech projects he is intelligent, but not experienced. I have a robo 3d r1 plus+ with an e3d v6 hot end installed on it.

A Visual Ultimaker Troubleshooting Guide 3dverkstan Knowledge Base , Just Looking For Some Advice On How To Improve The Outer Wall Quality Of My Prints?

3d Printing Troubleshooting Guide How To Solve 3d Printing Problems. I did another round of bed leveling and z alignment to make sure the adhesion is good and a test print came out quite fine in all corners and the center. I don't have a heated bed, is this a problem? My print print edges are bending (warping). Infill is visible from the outside. Break possible the walls of your 3d print are either too thin or not suitable for this small size. There were other quality problems too with this print, and you can already see that in the walls there are holes: Gaps between infill and outer wall. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Suggested corrections draw thicker wall thicknesses to suit add printing media below this area if the overhang is too difficult to manage for the 3d printer. Side walls are not smooth, lines are visible on the side of the print. Infill looks messy and incomplete. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. Different printers print rigid.ink best at different settings, so don't be afraid to experiment. Print doesn't stick to print bed. Avoid slowing down too much in this area, even.

3d Printer Troubleshooting Guide Matterhackers . My Print Print Edges Are Bending (Warping).

Ultimate 3d Print Quality Troubleshooting Guide 2018 All 44 Problems. Gaps between infill and outer wall. Side walls are not smooth, lines are visible on the side of the print. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. Infill is visible from the outside. Different printers print rigid.ink best at different settings, so don't be afraid to experiment. There were other quality problems too with this print, and you can already see that in the walls there are holes: Print doesn't stick to print bed. Suggested corrections draw thicker wall thicknesses to suit add printing media below this area if the overhang is too difficult to manage for the 3d printer. My print print edges are bending (warping). Infill looks messy and incomplete.

How To Make 3d Printed Lego And Lego Duplo Parts Prusa Printers , Infill looks messy and incomplete.

How To Make 3d Printed Lego And Lego Duplo Parts Prusa Printers. Break possible the walls of your 3d print are either too thin or not suitable for this small size. I don't have a heated bed, is this a problem? There were other quality problems too with this print, and you can already see that in the walls there are holes: Gaps between infill and outer wall. Suggested corrections draw thicker wall thicknesses to suit add printing media below this area if the overhang is too difficult to manage for the 3d printer. Side walls are not smooth, lines are visible on the side of the print. My print print edges are bending (warping). Print doesn't stick to print bed. Avoid slowing down too much in this area, even. Infill looks messy and incomplete. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Different printers print rigid.ink best at different settings, so don't be afraid to experiment. Infill is visible from the outside. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. I did another round of bed leveling and z alignment to make sure the adhesion is good and a test print came out quite fine in all corners and the center.

3d Printing Problems And Solutions Fixes You Need To Know : Is This An Extrusion Issue On The Printer?

3d Printing Problem Waved Walls 3d Printing Stack Exchange. I did another round of bed leveling and z alignment to make sure the adhesion is good and a test print came out quite fine in all corners and the center. Gaps between infill and outer wall. Side walls are not smooth, lines are visible on the side of the print. Suggested corrections draw thicker wall thicknesses to suit add printing media below this area if the overhang is too difficult to manage for the 3d printer. Break possible the walls of your 3d print are either too thin or not suitable for this small size. There were other quality problems too with this print, and you can already see that in the walls there are holes: We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Avoid slowing down too much in this area, even. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. Different printers print rigid.ink best at different settings, so don't be afraid to experiment. My print print edges are bending (warping). Infill looks messy and incomplete. Print doesn't stick to print bed. I don't have a heated bed, is this a problem? Infill is visible from the outside.

How To Hollow Out Your 3d Model Help Center I Materialise - If The Printer Is At The Very Edge Of Its Capability The Amount Of Plastic Being Extruded Will Be Reduced But The Print Keeps Going Normally.

How To Solve The Most Common 3d Printing Problems 3d Printing For Beginners. Side walls are not smooth, lines are visible on the side of the print. My print print edges are bending (warping). This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. Infill is visible from the outside. Avoid slowing down too much in this area, even. Infill looks messy and incomplete. Break possible the walls of your 3d print are either too thin or not suitable for this small size. I don't have a heated bed, is this a problem? I did another round of bed leveling and z alignment to make sure the adhesion is good and a test print came out quite fine in all corners and the center. Suggested corrections draw thicker wall thicknesses to suit add printing media below this area if the overhang is too difficult to manage for the 3d printer. Print doesn't stick to print bed. There were other quality problems too with this print, and you can already see that in the walls there are holes: Different printers print rigid.ink best at different settings, so don't be afraid to experiment. Gaps between infill and outer wall. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them.

Architects Here S The Problem With 3d Printed Buildings Architizer Journal - Avoid Slowing Down Too Much In This Area, Even.

3 Rules To Avoid Support Structures When 3d Printing. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. Gaps between infill and outer wall. Infill looks messy and incomplete. Avoid slowing down too much in this area, even. Different printers print rigid.ink best at different settings, so don't be afraid to experiment. My print print edges are bending (warping). I don't have a heated bed, is this a problem? Break possible the walls of your 3d print are either too thin or not suitable for this small size. Print doesn't stick to print bed. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. There were other quality problems too with this print, and you can already see that in the walls there are holes: I did another round of bed leveling and z alignment to make sure the adhesion is good and a test print came out quite fine in all corners and the center. Infill is visible from the outside. Suggested corrections draw thicker wall thicknesses to suit add printing media below this area if the overhang is too difficult to manage for the 3d printer. Side walls are not smooth, lines are visible on the side of the print.

Ultimate 3d Print Quality Troubleshooting Guide 2018 All 44 Problems - And So Enters Our 3D Printing Wall Thickness Recommendations!

Troubleshooting Guide To Common 3d Printing Problems All3dp. Infill is visible from the outside. I don't have a heated bed, is this a problem? I did another round of bed leveling and z alignment to make sure the adhesion is good and a test print came out quite fine in all corners and the center. Avoid slowing down too much in this area, even. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. Gaps between infill and outer wall. Print doesn't stick to print bed. My print print edges are bending (warping). Different printers print rigid.ink best at different settings, so don't be afraid to experiment. Infill looks messy and incomplete. There were other quality problems too with this print, and you can already see that in the walls there are holes: We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Suggested corrections draw thicker wall thicknesses to suit add printing media below this area if the overhang is too difficult to manage for the 3d printer. Break possible the walls of your 3d print are either too thin or not suitable for this small size. Side walls are not smooth, lines are visible on the side of the print.

How To Prevent Overshoot Corners Or Round Edges Improve Your 3d Prints Ultimaker Community Of 3d Printing Experts . One 3D Printer Hobbyist Described A Problem Where They Had 4 Perimeter Shells, Where The First Outer 2 Shells People Who Experience 3D Print Walls Not Sticking Together Looked All Around For Solutions, But It Ended Up Being As Simple As Checking Their Belts For Looseness.

Identify And Correct 3d Printing Problems Cults. My print print edges are bending (warping). This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. Side walls are not smooth, lines are visible on the side of the print. Print doesn't stick to print bed. Avoid slowing down too much in this area, even. Infill looks messy and incomplete. I did another round of bed leveling and z alignment to make sure the adhesion is good and a test print came out quite fine in all corners and the center. Break possible the walls of your 3d print are either too thin or not suitable for this small size. Different printers print rigid.ink best at different settings, so don't be afraid to experiment. Suggested corrections draw thicker wall thicknesses to suit add printing media below this area if the overhang is too difficult to manage for the 3d printer. Gaps between infill and outer wall. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. There were other quality problems too with this print, and you can already see that in the walls there are holes: Infill is visible from the outside. I don't have a heated bed, is this a problem?

3d Printing Problems And Solutions Fixes You Need To Know : Discover The Five Biggest Problems With 3D Printing And Some Solutions To Make For A Better Experience And Future Of Additive Manufacturing.

Print Quality Guide. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Gaps between infill and outer wall. Print doesn't stick to print bed. I don't have a heated bed, is this a problem? My print print edges are bending (warping). Suggested corrections draw thicker wall thicknesses to suit add printing media below this area if the overhang is too difficult to manage for the 3d printer. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. Different printers print rigid.ink best at different settings, so don't be afraid to experiment. Avoid slowing down too much in this area, even. Infill looks messy and incomplete. Side walls are not smooth, lines are visible on the side of the print. I did another round of bed leveling and z alignment to make sure the adhesion is good and a test print came out quite fine in all corners and the center. Infill is visible from the outside. Break possible the walls of your 3d print are either too thin or not suitable for this small size. There were other quality problems too with this print, and you can already see that in the walls there are holes:

3d Printing Using Concrete Extrusion A Roadmap For Research Sciencedirect . They Developed A Model With Which Engineers Can Now Easily Determine The Dimensions And Printing.

Troubleshooting Guide To 19 Common 3d Printing Problems Part One Geeetech Blog. I did another round of bed leveling and z alignment to make sure the adhesion is good and a test print came out quite fine in all corners and the center. Print doesn't stick to print bed. Side walls are not smooth, lines are visible on the side of the print. There were other quality problems too with this print, and you can already see that in the walls there are holes: Avoid slowing down too much in this area, even. Suggested corrections draw thicker wall thicknesses to suit add printing media below this area if the overhang is too difficult to manage for the 3d printer. Break possible the walls of your 3d print are either too thin or not suitable for this small size. Infill looks messy and incomplete. I don't have a heated bed, is this a problem? Infill is visible from the outside. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Gaps between infill and outer wall. Different printers print rigid.ink best at different settings, so don't be afraid to experiment. My print print edges are bending (warping).