3D Printing Weak Infill. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Infill density the infill density defines the amount of plastic used on the inside of the print. Honeycomb (cubic) is probably the most popular 3d printing infill pattern out there. When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible. I always wonder which infill pattern is the. Editorial content, on principle, can not be bought or influenced. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. All3dp is an editorially independent publication. Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions Joel the 3d printing nerd made a great video. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. In this post we talk about how the infill can affect the properties of the piece you want to obtain, and we give you advice on how to choose the best filling all users of 3d printers know that 3d printed parts have two distinct zones, the shell and the fill (infill). Infill patterns can easily be overlooked when you're 3d printing but they make a big difference in your quality. A lot of 3d printer users will recommend it because it has such. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print.

3D Printing Weak Infill - Shell And Infill Properties Impact The Performance And Cost Of Fdm 3D Printing.

Bone Like Infill Setting In Cura More Infill Near The Edges Less In The Middle More Strength Less Material 3dprinting. Infill patterns can easily be overlooked when you're 3d printing but they make a big difference in your quality. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Honeycomb (cubic) is probably the most popular 3d printing infill pattern out there. Editorial content, on principle, can not be bought or influenced. Infill density the infill density defines the amount of plastic used on the inside of the print. Joel the 3d printing nerd made a great video. When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. I always wonder which infill pattern is the. Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions In this post we talk about how the infill can affect the properties of the piece you want to obtain, and we give you advice on how to choose the best filling all users of 3d printers know that 3d printed parts have two distinct zones, the shell and the fill (infill). A lot of 3d printer users will recommend it because it has such. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. All3dp is an editorially independent publication.

Although this is handy when it comes to removing prints 3d printer troubleshooting:

How many types of infill pattern have you tried? Shell and infill properties impact the performance and cost of fdm 3d printing. Hunter626103d printers 3d printing 3d printers. Say it 5 times fast! Moroccan stars and catfill showed poorer performance in terms of strength and while the tests conducted only covered a small range of the possible materials and machines used today in desktop 3d printing, it does offer a. As of right now i can choose from a total of 7 different infill. Gaps between infill and outer wall. In this post we talk about how the infill can affect the properties of the piece you want to obtain, and we give you advice on how to choose the best filling all users of 3d printers know that 3d printed parts have two distinct zones, the shell and the fill (infill). Furthermore, hexagonal infills start to look very similar to linear past 30% infill. Infill percentage and pattern influence print weight, material usage, strength, print time and sometimes decorative properties. Printing at higher infill densities will of course make your object stronger, but at the cost of more materials, longer printing times, and reduced the specific infill pattern you use will have a huge effect on the strength of the finished part. Finally we made a test on the anisotropy of a 3d printed part: Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions The guide is organized into a table with the following format. A lot of 3d printer users will recommend it because it has such. The infill inside your 3d printed part plays a very important role in the overall strength of your model. But what are the differences, and. How many types of infill pattern have you tried? Most 3d printers use some form of detachable print base. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. Infill shows on top or bottom surfaces due to insufficient number of. In 3d printing, the term infill refers to the structure that is printed inside an object. Rectangular infill is the only infill type that can achieve a 100% dense part because it consists of a grid of parallel and perpendicular extrusions. Check the print base is secure. This is by far the most common issue and is really easy to resolve. Thingiverse is a universe of things. I'm relatively new to 3d printing, and wanted to get a few things understood. Learn how to optimize these features for your 3d printed part. Consider 0% infill or infill where required if you are printing a model which has no strength requirement, other than to support its own weight. There are a lot of concepts within the desktop 3d printing space which sometimes are a bit complicated to understand. Amongst the ten standard types.

Infill And Strength Functional Design Doesn T Stop At The Cad Desk 3d Printing For Beginners , Best Infill For Strength Vs Material Used.

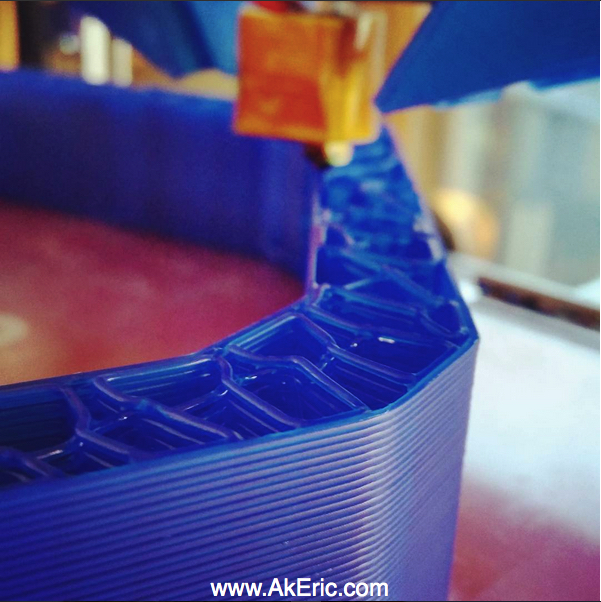

Simplify3d Ak Eric Part 3. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Infill patterns can easily be overlooked when you're 3d printing but they make a big difference in your quality. Infill density the infill density defines the amount of plastic used on the inside of the print. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. I always wonder which infill pattern is the. A lot of 3d printer users will recommend it because it has such. Joel the 3d printing nerd made a great video. When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible. Editorial content, on principle, can not be bought or influenced. Honeycomb (cubic) is probably the most popular 3d printing infill pattern out there. Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions In this post we talk about how the infill can affect the properties of the piece you want to obtain, and we give you advice on how to choose the best filling all users of 3d printers know that 3d printed parts have two distinct zones, the shell and the fill (infill). All3dp is an editorially independent publication. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong.

Infill Issues Weak Internal Structure Improve Your 3d Prints Ultimaker Community Of 3d Printing Experts : Rectangular Infill Is The Only Infill Type That Can Achieve A 100% Dense Part Because It Consists Of A Grid Of Parallel And Perpendicular Extrusions.

Infill Issues Weak Internal Structure Improve Your 3d Prints Ultimaker Community Of 3d Printing Experts. Honeycomb (cubic) is probably the most popular 3d printing infill pattern out there. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. Joel the 3d printing nerd made a great video. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Infill density the infill density defines the amount of plastic used on the inside of the print. In this post we talk about how the infill can affect the properties of the piece you want to obtain, and we give you advice on how to choose the best filling all users of 3d printers know that 3d printed parts have two distinct zones, the shell and the fill (infill). When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill patterns can easily be overlooked when you're 3d printing but they make a big difference in your quality. Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible.

Weak Infill , Printing at higher infill densities will of course make your object stronger, but at the cost of more materials, longer printing times, and reduced the specific infill pattern you use will have a huge effect on the strength of the finished part.

Ultimaker Cura Infill Issues Weird Vertical Pillars Due To Underextrusion 3d Printing Stack Exchange. In this post we talk about how the infill can affect the properties of the piece you want to obtain, and we give you advice on how to choose the best filling all users of 3d printers know that 3d printed parts have two distinct zones, the shell and the fill (infill). A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. I always wonder which infill pattern is the. A lot of 3d printer users will recommend it because it has such. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. All3dp is an editorially independent publication. Editorial content, on principle, can not be bought or influenced. Infill patterns can easily be overlooked when you're 3d printing but they make a big difference in your quality. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions Joel the 3d printing nerd made a great video. When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible. Honeycomb (cubic) is probably the most popular 3d printing infill pattern out there. Infill density the infill density defines the amount of plastic used on the inside of the print.

Stringy Weak Infill And Missing Layers In The Middle Of A Print 3dprinting : Gaps Between Infill And Outer Wall.

What Causes Solid Walls With Weak Infill Ultimaker Cura Ultimaker Community Of 3d Printing Experts. The infill inside your 3d printed part plays a very important role in the overall strength of your model. A lot of 3d printer users will recommend it because it has such. Honeycomb (cubic) is probably the most popular 3d printing infill pattern out there. Infill density the infill density defines the amount of plastic used on the inside of the print. Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions Editorial content, on principle, can not be bought or influenced. All3dp is an editorially independent publication. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible. I always wonder which infill pattern is the. Joel the 3d printing nerd made a great video. Infill patterns can easily be overlooked when you're 3d printing but they make a big difference in your quality. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. In this post we talk about how the infill can affect the properties of the piece you want to obtain, and we give you advice on how to choose the best filling all users of 3d printers know that 3d printed parts have two distinct zones, the shell and the fill (infill).

Optimizing Strength Of 3d Printed Parts 3dpros - Check The Print Base Is Secure.

Very Bad Infill Blobbing And Stringing With Petg 3dprinting. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill patterns can easily be overlooked when you're 3d printing but they make a big difference in your quality. The infill inside your 3d printed part plays a very important role in the overall strength of your model. All3dp is an editorially independent publication. Honeycomb (cubic) is probably the most popular 3d printing infill pattern out there. Joel the 3d printing nerd made a great video. Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions A lot of 3d printer users will recommend it because it has such. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. Infill density the infill density defines the amount of plastic used on the inside of the print. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. I always wonder which infill pattern is the. When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible. Editorial content, on principle, can not be bought or influenced. In this post we talk about how the infill can affect the properties of the piece you want to obtain, and we give you advice on how to choose the best filling all users of 3d printers know that 3d printed parts have two distinct zones, the shell and the fill (infill).

Creatbot 3d Printer : If Your Infill Appears To Be Weak Or Stringy, You May Want To Adjust A Few Settings Within The Software To Add Additional Strength To This Section Of Your Print.

Mechanical Testing 3d Printed Parts Results And Recommendations Engineerdog. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. Infill density the infill density defines the amount of plastic used on the inside of the print. The infill inside your 3d printed part plays a very important role in the overall strength of your model. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Honeycomb (cubic) is probably the most popular 3d printing infill pattern out there. I always wonder which infill pattern is the. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible. In this post we talk about how the infill can affect the properties of the piece you want to obtain, and we give you advice on how to choose the best filling all users of 3d printers know that 3d printed parts have two distinct zones, the shell and the fill (infill). A lot of 3d printer users will recommend it because it has such. Editorial content, on principle, can not be bought or influenced. Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions Joel the 3d printing nerd made a great video. Infill patterns can easily be overlooked when you're 3d printing but they make a big difference in your quality. All3dp is an editorially independent publication.

Selecting The Optimal Shell And Infill Parameters For Fdm 3d Printing 3d Hubs , This Shape Is The Most Efficient Infill And Fastest To Print, The Goto Infill For Most Things.

Poor Extrusion At The Start Of Layers 3d Printing 3d Printers Talk Manufacturing 3d Hubs. Honeycomb (cubic) is probably the most popular 3d printing infill pattern out there. Editorial content, on principle, can not be bought or influenced. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill patterns can easily be overlooked when you're 3d printing but they make a big difference in your quality. The infill inside your 3d printed part plays a very important role in the overall strength of your model. When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible. A lot of 3d printer users will recommend it because it has such. All3dp is an editorially independent publication. Infill density the infill density defines the amount of plastic used on the inside of the print. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions I always wonder which infill pattern is the. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. Joel the 3d printing nerd made a great video. In this post we talk about how the infill can affect the properties of the piece you want to obtain, and we give you advice on how to choose the best filling all users of 3d printers know that 3d printed parts have two distinct zones, the shell and the fill (infill).

Ultimaker Cura Infill Issues Weird Vertical Pillars Due To Underextrusion 3d Printing Stack Exchange - The Latest Video From Raspberry Pi Press Takes A Closer Look At 3D Printing Infill Patterns, And Why You Hackspace Magazine.

Selecting The Optimal Shell And Infill Parameters For Fdm 3d Printing 3d Hubs. All3dp is an editorially independent publication. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. I always wonder which infill pattern is the. A lot of 3d printer users will recommend it because it has such. The infill inside your 3d printed part plays a very important role in the overall strength of your model. In this post we talk about how the infill can affect the properties of the piece you want to obtain, and we give you advice on how to choose the best filling all users of 3d printers know that 3d printed parts have two distinct zones, the shell and the fill (infill). Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions Joel the 3d printing nerd made a great video. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. Editorial content, on principle, can not be bought or influenced. Honeycomb (cubic) is probably the most popular 3d printing infill pattern out there. Infill density the infill density defines the amount of plastic used on the inside of the print. When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill patterns can easily be overlooked when you're 3d printing but they make a big difference in your quality.

Weak Infill - Consider 0% Infill Or Infill Where Required If You Are Printing A Model Which Has No Strength Requirement, Other Than To Support Its Own Weight.

Selecting The Optimal Shell And Infill Parameters For Fdm 3d Printing 3d Hubs. Honeycomb (cubic) is probably the most popular 3d printing infill pattern out there. Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible. Infill patterns can easily be overlooked when you're 3d printing but they make a big difference in your quality. A lot of 3d printer users will recommend it because it has such. In this post we talk about how the infill can affect the properties of the piece you want to obtain, and we give you advice on how to choose the best filling all users of 3d printers know that 3d printed parts have two distinct zones, the shell and the fill (infill). Infill density the infill density defines the amount of plastic used on the inside of the print. Joel the 3d printing nerd made a great video. Editorial content, on principle, can not be bought or influenced. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. All3dp is an editorially independent publication. I always wonder which infill pattern is the. The infill inside your 3d printed part plays a very important role in the overall strength of your model. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong.

How To Solve 3d Print Insufficient Fill Gearbest Blog . Consider 0% Infill Or Infill Where Required If You Are Printing A Model Which Has No Strength Requirement, Other Than To Support Its Own Weight.

What Causes Solid Walls With Weak Infill Ultimaker Cura Ultimaker Community Of 3d Printing Experts. Editorial content, on principle, can not be bought or influenced. Infill density the infill density defines the amount of plastic used on the inside of the print. When you print with flexible filaments, the amount of infill you for prints that you will be using for display, try to print with as little of an infill percentage as possible. All3dp is an editorially independent publication. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. A low infill print will feel cheap and weak, while higher percentages feel heavier and strong. I always wonder which infill pattern is the. In this post we talk about how the infill can affect the properties of the piece you want to obtain, and we give you advice on how to choose the best filling all users of 3d printers know that 3d printed parts have two distinct zones, the shell and the fill (infill). A lot of 3d printer users will recommend it because it has such. Honeycomb (cubic) is probably the most popular 3d printing infill pattern out there. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Joel the 3d printing nerd made a great video. If your infill appears to be weak or stringy, you may want to adjust a few settings within the software to add additional strength to this section of your print. Infill patterns can easily be overlooked when you're 3d printing but they make a big difference in your quality. Quick 2d infills are used for quick, but weak models 3d infills are used to make the object equally strong in all directions