3D Printing What Does Infill Mean. This means, in terms of strength and weight, which infill pattern has the best amount of strength in relation to how much infill is used. Less infill normally means you'll need a thicker layer count to compensate, especially on larger area prints. Why do you need infill? Editorial content, on principle, can not be bought or influenced. For example, increasing infill percentage from 50% to 75. Not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill and has good strength. It should be noted that there are some however, the amount of strength gained by increasing infill percentage does not increase linearly. Infill provides the 3d print with internal support as the the gyroid pattern has got to be one of the coolest you can use. The infill the amount of material that occupies the internal part of the piece. All3dp is an editorially independent publication. Infill percentage in 3d printing. What is the best infill pattern for flexible. While not fast by any means, this spinning infill pattern is extremely fun to. If you're new to the world of 3d printing, you may be wondering what infill is for. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight.

3D Printing What Does Infill Mean , As Of Right Now I Can Choose From A Total Of 7 Different Infill.

The Best Cura Infill Pattern For Your Needs All3dp. All3dp is an editorially independent publication. Less infill normally means you'll need a thicker layer count to compensate, especially on larger area prints. Infill percentage in 3d printing. It should be noted that there are some however, the amount of strength gained by increasing infill percentage does not increase linearly. If you're new to the world of 3d printing, you may be wondering what infill is for. What is the best infill pattern for flexible. Why do you need infill? This means, in terms of strength and weight, which infill pattern has the best amount of strength in relation to how much infill is used. The infill the amount of material that occupies the internal part of the piece. Not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill and has good strength. Editorial content, on principle, can not be bought or influenced. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. For example, increasing infill percentage from 50% to 75. While not fast by any means, this spinning infill pattern is extremely fun to. Infill provides the 3d print with internal support as the the gyroid pattern has got to be one of the coolest you can use.

Many printers use threaded rods rather than lead screws and although these do the job they do have a tendency to bend over time.

Firstly, i am unclear on how hexagonal infill is stronger than, say, diamond i saw a few places that hex is stronger; Selection of infill dimensions and layer thickness independent of. Why do i need to sign in? Why do you need infill? Many printers use threaded rods rather than lead screws and although these do the job they do have a tendency to bend over time. The infill inside your 3d printed part plays a very important role in the overall strength of your model. Some of the biggest concerns surrounding the proliferation of 3d printing technologies have to do with the possibility of 3d printed weapons and of counterfeit 3d these scans were then enhanced and filtered so that the infill patterns were distinguishable. ❓ what do you mean precisely with fastest and slowest, during slicing or during print ? It should be noted that there are some however, the amount of strength gained by increasing infill percentage does not increase linearly. The infill the amount of material that occupies the internal part of the piece. Not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill and has good strength. 0% would print a hollow part. Gaps between infill and outer wall. Infill does add some stiffness to the part and prevents. The infill serves as the internal support structure for the part, so without it, nothing would be holding the walls or shells together! When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Firstly, i am unclear on how hexagonal infill is stronger than, say, diamond i saw a few places that hex is stronger; A triangle is stronger than a square), so how does that work. Then there are the concepts of rafts, supports, and other 3d printing terms that someone unfamiliar with the technology would have no idea what you were talking about if. While type a machines has done some great work here, it does mean there's yet another version of cura to deal. Do check out the sample questions of what is infill? 3d printing infill using biomimetics report christopher murphy abstract a study into firstly is its highly parallel nature means that the use gpgpu all these patterns are generated on the 2d slices of an object to be printed, they do not exploit the 3d nature of printing to use 3d infill patterns. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight. While not fast by any means, this spinning infill pattern is extremely fun to. What is the best infill pattern for flexible. My main question is what infill pattern is usually the best? For example, what does a 40% infill density look like compared to a 70% infill? It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. This is because geometry matters to cells! For example, increasing infill percentage from 50% to 75. Does your print need strength or quality?

Testing 3d Printed Infill Patterns For Their Strength Youtube - 💡 During Print I Only Noticed Little Difference Between The Infill Methods.

What Is The Best Infill Pattern For 3d Printing 3dprinterly. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill and has good strength. Why do you need infill? For example, increasing infill percentage from 50% to 75. Infill provides the 3d print with internal support as the the gyroid pattern has got to be one of the coolest you can use. While not fast by any means, this spinning infill pattern is extremely fun to. Editorial content, on principle, can not be bought or influenced. What is the best infill pattern for flexible. It should be noted that there are some however, the amount of strength gained by increasing infill percentage does not increase linearly. This means, in terms of strength and weight, which infill pattern has the best amount of strength in relation to how much infill is used. If you're new to the world of 3d printing, you may be wondering what infill is for. Less infill normally means you'll need a thicker layer count to compensate, especially on larger area prints. The infill the amount of material that occupies the internal part of the piece. All3dp is an editorially independent publication. Infill percentage in 3d printing.

What Causes This Bad Infill 3dprinting - This Is Because Geometry Matters To Cells!

3d Slicer Settings For Beginners 8 Things You Need To Know. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Editorial content, on principle, can not be bought or influenced. This means, in terms of strength and weight, which infill pattern has the best amount of strength in relation to how much infill is used. Not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill and has good strength. While not fast by any means, this spinning infill pattern is extremely fun to. Infill provides the 3d print with internal support as the the gyroid pattern has got to be one of the coolest you can use. If you're new to the world of 3d printing, you may be wondering what infill is for. For example, increasing infill percentage from 50% to 75. Why do you need infill? Less infill normally means you'll need a thicker layer count to compensate, especially on larger area prints.

Gaps Between Infill And Outline - Thingiverse is a universe of things.

3d Printing A 3d Honeycomb Infill Concept Engineerdog. Editorial content, on principle, can not be bought or influenced. For example, increasing infill percentage from 50% to 75. This means, in terms of strength and weight, which infill pattern has the best amount of strength in relation to how much infill is used. Less infill normally means you'll need a thicker layer count to compensate, especially on larger area prints. Infill percentage in 3d printing. What is the best infill pattern for flexible. The infill the amount of material that occupies the internal part of the piece. Not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill and has good strength. If you're new to the world of 3d printing, you may be wondering what infill is for. Infill provides the 3d print with internal support as the the gyroid pattern has got to be one of the coolest you can use. Why do you need infill? When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. It should be noted that there are some however, the amount of strength gained by increasing infill percentage does not increase linearly. While not fast by any means, this spinning infill pattern is extremely fun to. All3dp is an editorially independent publication.

Infill And Strength Functional Design Doesn T Stop At The Cad Desk 3d Printing For Beginners , The Infill The Amount Of Material That Occupies The Internal Part Of The Piece.

3d Printing News Build 3d Online. All3dp is an editorially independent publication. This means, in terms of strength and weight, which infill pattern has the best amount of strength in relation to how much infill is used. For example, increasing infill percentage from 50% to 75. Not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill and has good strength. It should be noted that there are some however, the amount of strength gained by increasing infill percentage does not increase linearly. The infill the amount of material that occupies the internal part of the piece. What is the best infill pattern for flexible. While not fast by any means, this spinning infill pattern is extremely fun to. Why do you need infill? Infill provides the 3d print with internal support as the the gyroid pattern has got to be one of the coolest you can use. Editorial content, on principle, can not be bought or influenced. Infill percentage in 3d printing. If you're new to the world of 3d printing, you may be wondering what infill is for. Less infill normally means you'll need a thicker layer count to compensate, especially on larger area prints. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight.

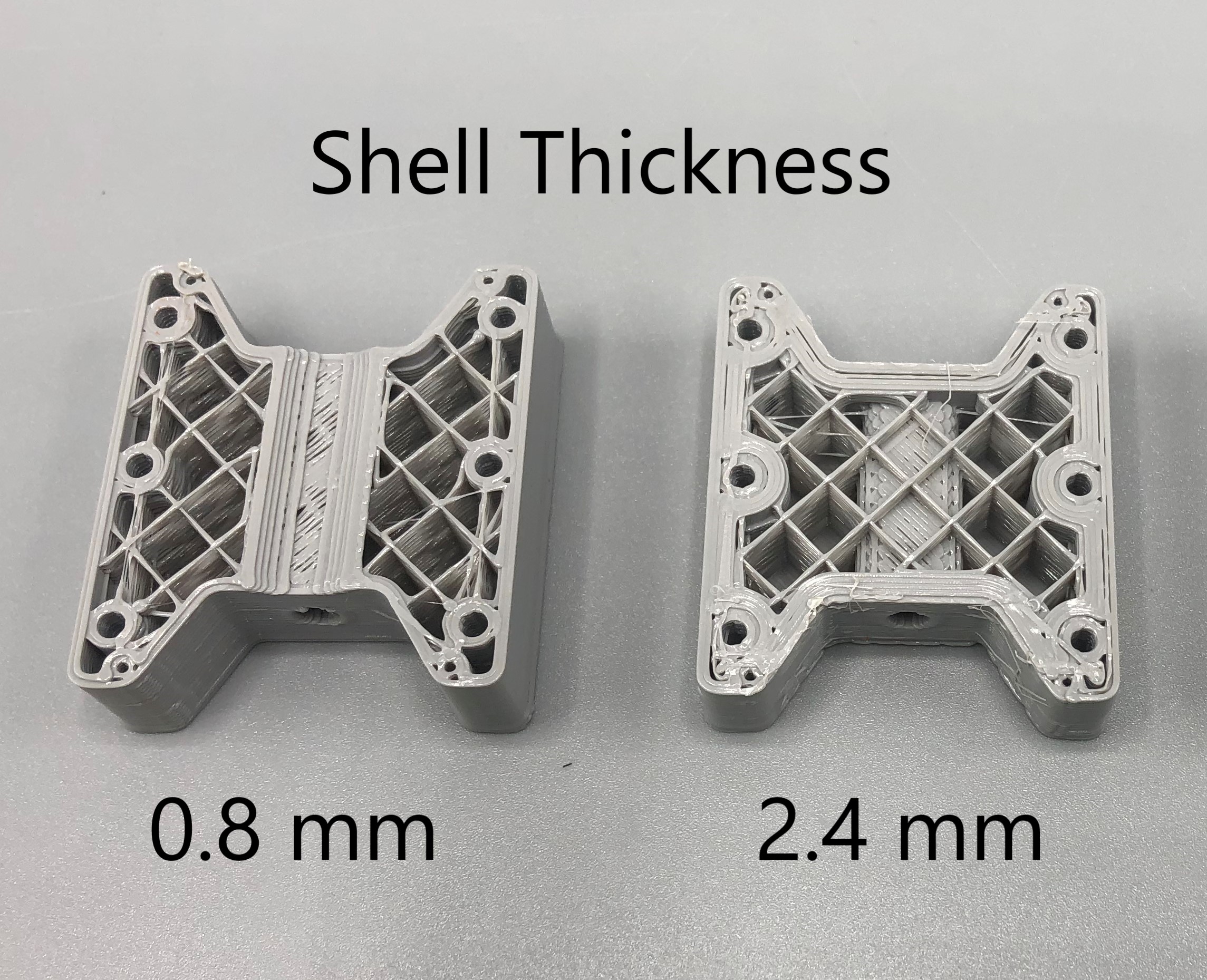

3d Print Infill Settings My 3d Print Pro . What Do 10 Shells Look Like Compared To Just 3?

Mechanical Testing 3d Printed Parts Results And Recommendations Engineerdog. Infill percentage in 3d printing. Not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill and has good strength. For example, increasing infill percentage from 50% to 75. All3dp is an editorially independent publication. Less infill normally means you'll need a thicker layer count to compensate, especially on larger area prints. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. If you're new to the world of 3d printing, you may be wondering what infill is for. It should be noted that there are some however, the amount of strength gained by increasing infill percentage does not increase linearly. While not fast by any means, this spinning infill pattern is extremely fun to. Why do you need infill? Editorial content, on principle, can not be bought or influenced. This means, in terms of strength and weight, which infill pattern has the best amount of strength in relation to how much infill is used. The infill the amount of material that occupies the internal part of the piece. What is the best infill pattern for flexible. Infill provides the 3d print with internal support as the the gyroid pattern has got to be one of the coolest you can use.

What Is 3d Printer Infill And When Should It Be Used Home 3d Print Guide : Zero Percent Infill Means A Hollow Object, And 100% Infill Is A Completely Solid Part.

3d Slicer Settings For Beginners 8 Things You Need To Know. All3dp is an editorially independent publication. For example, increasing infill percentage from 50% to 75. Infill provides the 3d print with internal support as the the gyroid pattern has got to be one of the coolest you can use. Editorial content, on principle, can not be bought or influenced. This means, in terms of strength and weight, which infill pattern has the best amount of strength in relation to how much infill is used. It should be noted that there are some however, the amount of strength gained by increasing infill percentage does not increase linearly. Not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill and has good strength. The infill the amount of material that occupies the internal part of the piece. Infill percentage in 3d printing. If you're new to the world of 3d printing, you may be wondering what infill is for. While not fast by any means, this spinning infill pattern is extremely fun to. Why do you need infill? When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Less infill normally means you'll need a thicker layer count to compensate, especially on larger area prints. What is the best infill pattern for flexible.

Slicer 3d Printing Wikipedia . Printing At Higher Infill Densities Will Of Course Make Your Object Stronger, But At The Cost Of More Materials, Longer Printing Times, And Reduced The Specific Infill Pattern You Use Will Have A Huge Effect On The Strength Of The Finished Part.

3d Print Infill Patterns Explained The 3d Bros. The infill the amount of material that occupies the internal part of the piece. Infill provides the 3d print with internal support as the the gyroid pattern has got to be one of the coolest you can use. All3dp is an editorially independent publication. This means, in terms of strength and weight, which infill pattern has the best amount of strength in relation to how much infill is used. Editorial content, on principle, can not be bought or influenced. Infill percentage in 3d printing. Less infill normally means you'll need a thicker layer count to compensate, especially on larger area prints. If you're new to the world of 3d printing, you may be wondering what infill is for. While not fast by any means, this spinning infill pattern is extremely fun to. Not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill and has good strength. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. It should be noted that there are some however, the amount of strength gained by increasing infill percentage does not increase linearly. Why do you need infill? What is the best infill pattern for flexible. For example, increasing infill percentage from 50% to 75.

Cura 2 6 Different Infills In The Same Print Ideato3d : Download Files And Build Them With Your 3D Printer, Laser Cutter, Or Cnc.

Maximum Mean Tensile Force Vs Infill Percentage Download Scientific Diagram. Not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill and has good strength. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. While not fast by any means, this spinning infill pattern is extremely fun to. Editorial content, on principle, can not be bought or influenced. It should be noted that there are some however, the amount of strength gained by increasing infill percentage does not increase linearly. Less infill normally means you'll need a thicker layer count to compensate, especially on larger area prints. Infill provides the 3d print with internal support as the the gyroid pattern has got to be one of the coolest you can use. All3dp is an editorially independent publication. The infill the amount of material that occupies the internal part of the piece. For example, increasing infill percentage from 50% to 75. If you're new to the world of 3d printing, you may be wondering what infill is for. What is the best infill pattern for flexible. This means, in terms of strength and weight, which infill pattern has the best amount of strength in relation to how much infill is used. Why do you need infill? Infill percentage in 3d printing.

Pillowing Hestay - Are You Trying To Minimize Cost Or Are You Trying To Save Time?

These 3d Printable Tools Help You Understand Infill Percentages Number Of Shells And More 3dprint Com The Voice Of 3d Printing Additive Manufacturing. Editorial content, on principle, can not be bought or influenced. If you're new to the world of 3d printing, you may be wondering what infill is for. Why do you need infill? Not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill and has good strength. The infill the amount of material that occupies the internal part of the piece. All3dp is an editorially independent publication. This means, in terms of strength and weight, which infill pattern has the best amount of strength in relation to how much infill is used. It should be noted that there are some however, the amount of strength gained by increasing infill percentage does not increase linearly. Infill percentage in 3d printing. For example, increasing infill percentage from 50% to 75. Infill provides the 3d print with internal support as the the gyroid pattern has got to be one of the coolest you can use. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Less infill normally means you'll need a thicker layer count to compensate, especially on larger area prints. While not fast by any means, this spinning infill pattern is extremely fun to. What is the best infill pattern for flexible.

3d Printing News Build 3d Online , Infill Percentage In 3D Printing.

3d Printing A 3d Honeycomb Infill Concept Engineerdog. For example, increasing infill percentage from 50% to 75. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Not only does the lines pattern or cubic subdivision print very fast, it uses a low amount of infill and has good strength. Infill percentage in 3d printing. The infill the amount of material that occupies the internal part of the piece. If you're new to the world of 3d printing, you may be wondering what infill is for. Editorial content, on principle, can not be bought or influenced. While not fast by any means, this spinning infill pattern is extremely fun to. This means, in terms of strength and weight, which infill pattern has the best amount of strength in relation to how much infill is used. Why do you need infill? All3dp is an editorially independent publication. Infill provides the 3d print with internal support as the the gyroid pattern has got to be one of the coolest you can use. What is the best infill pattern for flexible. It should be noted that there are some however, the amount of strength gained by increasing infill percentage does not increase linearly. Less infill normally means you'll need a thicker layer count to compensate, especially on larger area prints.