3D Printing What Is Infill. All3dp is an editorially independent publication. There are several infill patterns but for speed the best infill pattern is the lines pattern, while for strength, cubic. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Besides the actual printing process, infill will affect the strength or feel of the final product. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. The infill the amount of material that occupies the internal part of the piece. Infill provides the 3d print with internal support as the printer builds each layer. Editorial content, on principle, can not be bought or influenced. To keep all3dp free and independent. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. What is infill in 3d printing? With such a low percentage, the long printing times of complex figures or objects that. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. There is a little more to infill patterns than i first realized, so i will go into. Infill percentage in 3d printing.

3D Printing What Is Infill - I Noticed That Dropping The Infill Can Dramatically Reduce Plastic Consumption.

How To Make Stronger 3d Prints Shells Vs Infill Additive Manufacturing Podcast Youtube. Besides the actual printing process, infill will affect the strength or feel of the final product. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. The infill the amount of material that occupies the internal part of the piece. Infill provides the 3d print with internal support as the printer builds each layer. Editorial content, on principle, can not be bought or influenced. There are several infill patterns but for speed the best infill pattern is the lines pattern, while for strength, cubic. All3dp is an editorially independent publication. Infill percentage in 3d printing. To keep all3dp free and independent. With such a low percentage, the long printing times of complex figures or objects that. There is a little more to infill patterns than i first realized, so i will go into. What is infill in 3d printing?

The term 3d printing can refer to a variety of processes in which.

However, lowering your print speeds to the 35mm/s range will reduce your 3d print lines and imperfections. There are a lot of concepts within the desktop 3d printing space which sometimes are a bit complicated to understand. Learn how infill %, infill patterns and layer height impact the strength of a 3d print. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with. I'm printing in pla, and infill is needed to support horizontal surfaces. In 3d printing, the term infill refers to the structure that is printed inside an object. This means your printer will print 10 solid perimeters before attempting to place any infill. Infill provides the 3d print with internal support as the printer builds each layer. The four most common infill shapes are for cheap rapid prints rectangular infill it the best selection due to its quick print speed. Best infill for strength vs material used. But what are the differences, and why should. Infill percentage and pattern influence print weight, material usage, strength, print time and sometimes decorative properties. So what's the smallest % infill you have found you can get away with? Besides the actual printing process, infill will affect the strength or feel of the final product. How many types of infill pattern have you tried? It has gotten 72 views and also has 4.9 rating. The infill in 3d printing can be carried out with the following types: I use hexagons very much, but do lines and. The infill inside your 3d printed part plays a very important role in the overall strength of your model. You can download free what is infill? Basically the final 3d printed model will have different infill densities depending on the region of the model. While 3d printed objects are typically made of a single material, that material can be made of many different substances. One of the most popular is abs plastic, the colorful, extruded plastic used in most home printers. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. They are least likely to deform and provide the best support structure behind the walls of the strength and the speed combined makes triangular infill one of the best choices for infill in 3d printing. Increasing infill % means a higher amount of material is used (= higher cost) and printing time is longer. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. If strength is critical to the function of a 3d printed part honeycomb or triangular. Triangular infill is the strongest infill pattern because triangles are the strongest shape. It is extruded in a designated percentage and pattern, which is set in the slicing software. 3d printing, additive manufacturing, build, cube, fdm, fused deposition modeling, grabcad, hardware, infill, material, raster, spacing, stratasys, tips, weight.

Gradient Infill New Efficient Infill For 3d Prints Youtube , The Infill The Amount Of Material That Occupies The Internal Part Of The Piece.

Designpoint Metal 3d Printing Redefined Quickly 3d Print Metal Parts. There are several infill patterns but for speed the best infill pattern is the lines pattern, while for strength, cubic. To keep all3dp free and independent. What is infill in 3d printing? Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Besides the actual printing process, infill will affect the strength or feel of the final product. The infill the amount of material that occupies the internal part of the piece. All3dp is an editorially independent publication. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill percentage in 3d printing. Infill provides the 3d print with internal support as the printer builds each layer. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. With such a low percentage, the long printing times of complex figures or objects that. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. There is a little more to infill patterns than i first realized, so i will go into. Editorial content, on principle, can not be bought or influenced.

The Difference That One Checkbox In Cura Can Make Infill Before Walls 3dprinting - The Latest Video From Raspberry Pi Press Takes A Closer Look At 3D Printing Infill Patterns, And Why You May Want There's More Than One Option When It Comes To Selecting Infill Patters For Your 3D Prints.

Gradient Infill Puts More Plastic Where You Want It Hackaday. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. What is infill in 3d printing? Editorial content, on principle, can not be bought or influenced. Besides the actual printing process, infill will affect the strength or feel of the final product. All3dp is an editorially independent publication. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. There is a little more to infill patterns than i first realized, so i will go into. To keep all3dp free and independent. With such a low percentage, the long printing times of complex figures or objects that. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight.

Spotty Infill Issue Ultimaker 3d Printers Ultimaker Community Of 3d Printing Experts . We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill.

What Are The Advantages Of Gyroid Infill 3d Printing Stack Exchange. There are several infill patterns but for speed the best infill pattern is the lines pattern, while for strength, cubic. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Besides the actual printing process, infill will affect the strength or feel of the final product. Infill provides the 3d print with internal support as the printer builds each layer. There is a little more to infill patterns than i first realized, so i will go into. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. With such a low percentage, the long printing times of complex figures or objects that. To keep all3dp free and independent. Editorial content, on principle, can not be bought or influenced. Infill percentage in 3d printing. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. What is infill in 3d printing? We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. All3dp is an editorially independent publication. The infill the amount of material that occupies the internal part of the piece.

How To Use 3d Print Infill Settings Increase Strength Save Filament , If You Are Using A.4Mm Nozzle, That Will Result In 4Mm Thickness.

How To Strengthen 3d Printed Parts In 5 Simple Ways Manufactur3d. Infill percentage in 3d printing. There are several infill patterns but for speed the best infill pattern is the lines pattern, while for strength, cubic. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. With such a low percentage, the long printing times of complex figures or objects that. There is a little more to infill patterns than i first realized, so i will go into. Besides the actual printing process, infill will affect the strength or feel of the final product. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Editorial content, on principle, can not be bought or influenced. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. All3dp is an editorially independent publication. What is infill in 3d printing? The infill the amount of material that occupies the internal part of the piece. To keep all3dp free and independent. Infill provides the 3d print with internal support as the printer builds each layer.

3d Printing Infill And Density Visual 3d Printing Diy 3d Printer Designs 3d Printer Kit : Printing At The Fastest Possible Setting.

3d Printing Infill The Basics Simply Explained All3dp. What is infill in 3d printing? When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Editorial content, on principle, can not be bought or influenced. There is a little more to infill patterns than i first realized, so i will go into. With such a low percentage, the long printing times of complex figures or objects that. Besides the actual printing process, infill will affect the strength or feel of the final product. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Infill percentage in 3d printing. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. To keep all3dp free and independent. All3dp is an editorially independent publication. Infill provides the 3d print with internal support as the printer builds each layer. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. There are several infill patterns but for speed the best infill pattern is the lines pattern, while for strength, cubic. The infill the amount of material that occupies the internal part of the piece.

Awesome Demonstration Of Different Infill Percentages 3dprinting : If Strength Is Critical To The Function Of A 3D Printed Part Honeycomb Or Triangular.

Infill For Fdm 3d Printing 3 Space. Infill percentage in 3d printing. Infill provides the 3d print with internal support as the printer builds each layer. There is a little more to infill patterns than i first realized, so i will go into. All3dp is an editorially independent publication. Editorial content, on principle, can not be bought or influenced. With such a low percentage, the long printing times of complex figures or objects that. The infill the amount of material that occupies the internal part of the piece. There are several infill patterns but for speed the best infill pattern is the lines pattern, while for strength, cubic. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. To keep all3dp free and independent. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. What is infill in 3d printing? Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Besides the actual printing process, infill will affect the strength or feel of the final product. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints.

Testing 3d Printed Infill Patterns For Their Strength Youtube , The Latest Video From Raspberry Pi Press Takes A Closer Look At 3D Printing Infill Patterns, And Why You May Want There's More Than One Option When It Comes To Selecting Infill Patters For Your 3D Prints.

What Is Infill Xometry. What is infill in 3d printing? Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. The infill the amount of material that occupies the internal part of the piece. There is a little more to infill patterns than i first realized, so i will go into. Besides the actual printing process, infill will affect the strength or feel of the final product. To keep all3dp free and independent. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Infill percentage in 3d printing. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. All3dp is an editorially independent publication. Infill provides the 3d print with internal support as the printer builds each layer. There are several infill patterns but for speed the best infill pattern is the lines pattern, while for strength, cubic. With such a low percentage, the long printing times of complex figures or objects that. Editorial content, on principle, can not be bought or influenced.

Selecting The Optimal Shell And Infill Parameters For Fdm 3d Printing 3d Hubs - Sometimes Parts Were Gotten Stronger With Minimal Infill But Good Wall Thickness Than Parts With.

3d Printing A 3d Honeycomb Infill Concept Engineerdog. The infill the amount of material that occupies the internal part of the piece. Besides the actual printing process, infill will affect the strength or feel of the final product. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Editorial content, on principle, can not be bought or influenced. Infill provides the 3d print with internal support as the printer builds each layer. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. All3dp is an editorially independent publication. To keep all3dp free and independent. With such a low percentage, the long printing times of complex figures or objects that. What is infill in 3d printing? Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Infill percentage in 3d printing. There are several infill patterns but for speed the best infill pattern is the lines pattern, while for strength, cubic. There is a little more to infill patterns than i first realized, so i will go into. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight.

3d Printing Infill Styles The What When And Why Of Using Infill Padt Inc The Blog - The Infill Is Responsible For Connecting The Outer If Your Infill Appears To Be Weak Or Stringy, You May Want To Adjust A Few Settings Within The Software To Add Additional Strength To This Section Of Your Print.

3d Printing A 3d Honeycomb Infill Concept Engineerdog. All3dp is an editorially independent publication. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Editorial content, on principle, can not be bought or influenced. Besides the actual printing process, infill will affect the strength or feel of the final product. What is infill in 3d printing? With such a low percentage, the long printing times of complex figures or objects that. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. There is a little more to infill patterns than i first realized, so i will go into. The infill the amount of material that occupies the internal part of the piece. There are several infill patterns but for speed the best infill pattern is the lines pattern, while for strength, cubic. Infill provides the 3d print with internal support as the printer builds each layer. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. To keep all3dp free and independent. Infill percentage in 3d printing.

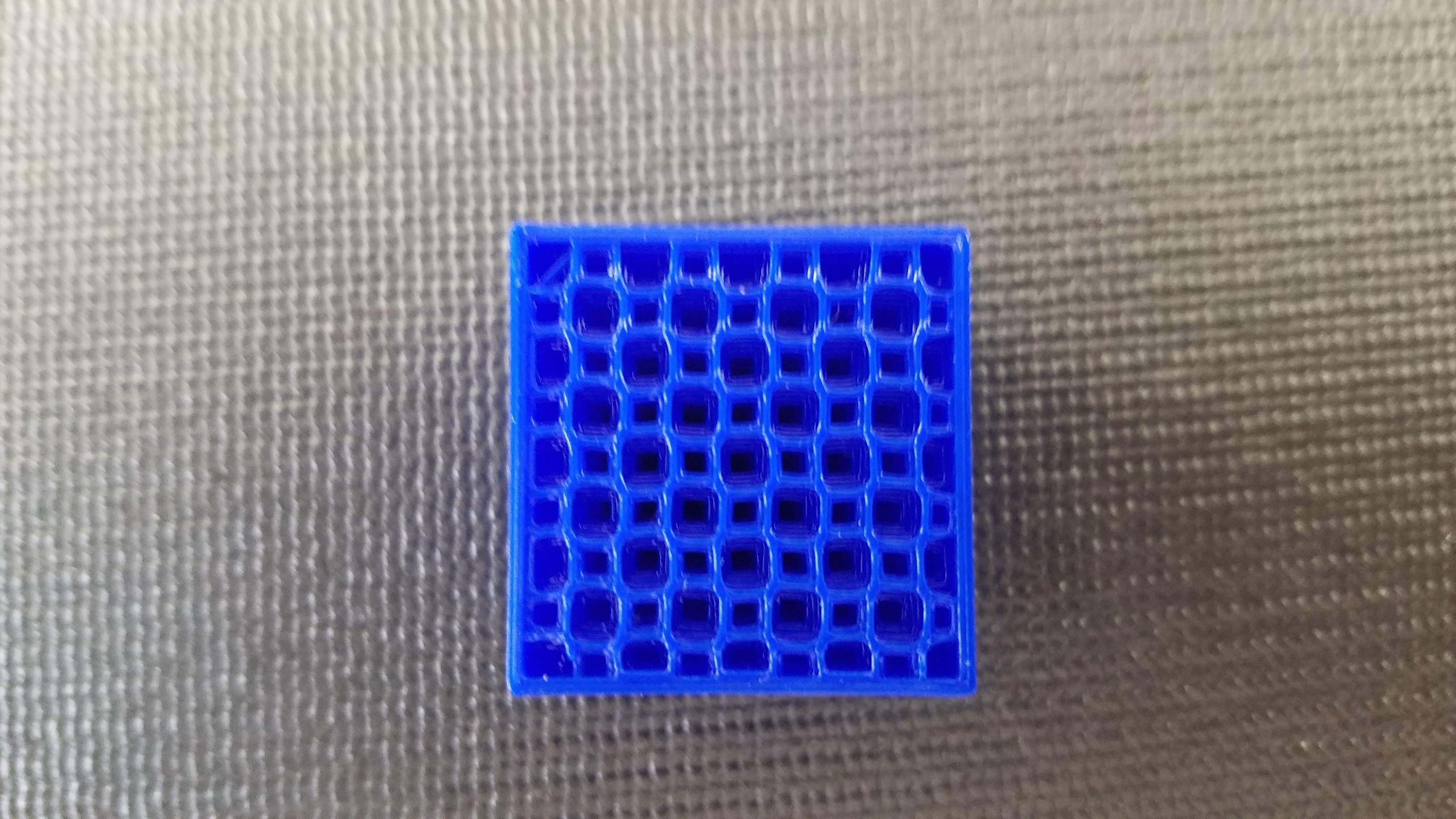

Sample Of Infill Patterns Cubic Infill Shown In Left And Grid Shown Download Scientific Diagram , What Is Infill In 3D Printing?

What Is 3d Printer Infill And When Should It Be Used Home 3d Print Guide. Besides the actual printing process, infill will affect the strength or feel of the final product. There is a little more to infill patterns than i first realized, so i will go into. Infill patterns are sometimes overlooked in 3d printing because it's just one part of many settings for your prints. Editorial content, on principle, can not be bought or influenced. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. There are several infill patterns but for speed the best infill pattern is the lines pattern, while for strength, cubic. All3dp is an editorially independent publication. To keep all3dp free and independent. Infill percentage in 3d printing. With such a low percentage, the long printing times of complex figures or objects that. The infill the amount of material that occupies the internal part of the piece. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Infill provides the 3d print with internal support as the printer builds each layer. What is infill in 3d printing?