3D Printing With Infill. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. All3dp is an editorially independent publication. Best infill for strength vs material used. Infill percentage in 3d printing. Infill provides the 3d print with internal support as the printer builds each layer. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Besides the actual printing process, infill will affect the strength or feel of the final product. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. What is infill in 3d printing? The infill the amount of material that occupies the internal part of the piece. Editorial content, on principle, can not be bought or influenced. This shape is the most efficient infill and fastest to print, the goto infill for most things. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you.

3D Printing With Infill - We All Know What Infill Is But, A Lithophane Is Not Your Ordinary 3D Print.

Gradient Infill For 3d Prints Cnc Kitchen. Editorial content, on principle, can not be bought or influenced. What is infill in 3d printing? We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Besides the actual printing process, infill will affect the strength or feel of the final product. All3dp is an editorially independent publication. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Best infill for strength vs material used. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill percentage in 3d printing. The infill the amount of material that occupies the internal part of the piece. This shape is the most efficient infill and fastest to print, the goto infill for most things. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. Infill provides the 3d print with internal support as the printer builds each layer.

If strength is critical to the function of a 3d printed part.

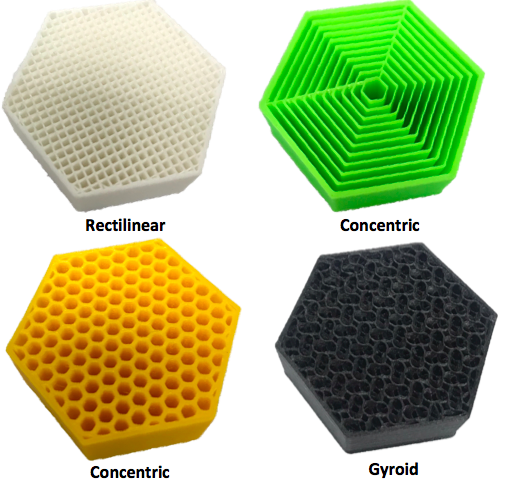

However, lowering your print speeds to the 35mm/s range will reduce your 3d print lines and imperfections. The workflow was based in the following processes in this instructables i aim to demonstrate, in a simple way, how to reinforce a specific region in a 3d printer part, by changing the part's infill. In addition to the leveled bed, the method of increasing surface stickiness is important. How many types of infill pattern have you tried? We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. I noticed that dropping the infill can dramatically reduce plastic consumption. The term 3d printing can refer to a variety of processes in which. The latest video from raspberry pi press takes a closer look at 3d printing infill patterns, and why you hackspace magazine. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Stefan from cnc kitchen on youtube is showing off some really cool experimentation in this video that take advantage of easy to use physical simulation software to create infills for your 3d. Your printer works and can print with satisfactory results. A 3d printed object often this is due to its great ability to last and withstand abrasion. There's more than one option when it comes to selecting infill patters for your 3d prints. Every day new 3d models from all over the world. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. To cover the wide range of designs print, both circular and rectangular objects were sliced. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). They are least likely to deform and provide the best support structure behind the walls of the strength and the speed combined makes triangular infill one of the best choices for infill in 3d printing. Download files and build them with your 3d printer, laser cutter, or cnc. A properly leveled bed is mandatory for good quality prints. In fact, i still have a hard time trying to decide just how dense i should make the infill on my various 3d designs that i create. Infill percentage has an impact on strength when increasing this parameter it's set during the preparation of a part for printing. There seem to be a never ending supply of inventive ways that home experimenters are forwarding 3d printing. But what are the differences, and. We all know what infill is but, a lithophane is not your ordinary 3d print. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Infill percentage in 3d printing. Thingiverse is a universe of things. However, lowering your print speeds to the 35mm/s range will reduce your 3d print lines and imperfections. The infill print speed therefore can be reduced to reduce print time since this area is not visible.

3d Printing Infill The Basics Simply Explained All3dp - The Cad Model Also Does Not.

How To Use Infill Percentage And Pattern Enhance Strength Save Material Tianse. Infill percentage in 3d printing. This shape is the most efficient infill and fastest to print, the goto infill for most things. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Best infill for strength vs material used. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill provides the 3d print with internal support as the printer builds each layer. What is infill in 3d printing? Besides the actual printing process, infill will affect the strength or feel of the final product. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). All3dp is an editorially independent publication. Editorial content, on principle, can not be bought or influenced. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. The infill the amount of material that occupies the internal part of the piece.

The Importance Of The Type Of Infill In 3d Printing : To Cover The Wide Range Of Designs Print, Both Circular And Rectangular Objects Were Sliced.

How To 3d Print Center For Applied Research. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Besides the actual printing process, infill will affect the strength or feel of the final product. What is infill in 3d printing? Best infill for strength vs material used. Infill percentage in 3d printing. The infill the amount of material that occupies the internal part of the piece. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to.

Sem Images Of 3d Printed Cha Scaffolds At Different Infill Densities Download Scientific Diagram . I'm printing in pla, and infill is needed to support horizontal surfaces.

Https Encrypted Tbn0 Gstatic Com Images Q Tbn 3aand9gcrhsqzwoojjqnijlnx Vjwc7nydn9bqb1teeg Usqp Cau. Besides the actual printing process, infill will affect the strength or feel of the final product. Infill percentage in 3d printing. The infill the amount of material that occupies the internal part of the piece. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Editorial content, on principle, can not be bought or influenced. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. All3dp is an editorially independent publication. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). What is infill in 3d printing? This shape is the most efficient infill and fastest to print, the goto infill for most things. Infill provides the 3d print with internal support as the printer builds each layer. Best infill for strength vs material used. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to.

What Is The Influence Of Infill Layer Height And Infill Pattern On My 3d Prints 3dprinteros . I'm Printing In Pla, And Infill Is Needed To Support Horizontal Surfaces.

3d Printing Infill Styles The What When And Why Of Using Infill Padt Inc The Blog. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. This shape is the most efficient infill and fastest to print, the goto infill for most things. The infill the amount of material that occupies the internal part of the piece. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Editorial content, on principle, can not be bought or influenced. Besides the actual printing process, infill will affect the strength or feel of the final product. Infill percentage in 3d printing. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Best infill for strength vs material used. What is infill in 3d printing? Infill provides the 3d print with internal support as the printer builds each layer. All3dp is an editorially independent publication.

What Is Infill In 3d Print Illusive Solutions : All3Dp Is An Editorially Independent Publication.

3d Printing A 3d Honeycomb Infill Concept Engineerdog. Best infill for strength vs material used. All3dp is an editorially independent publication. What is infill in 3d printing? Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. Editorial content, on principle, can not be bought or influenced. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Infill provides the 3d print with internal support as the printer builds each layer. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Besides the actual printing process, infill will affect the strength or feel of the final product. The infill the amount of material that occupies the internal part of the piece. This shape is the most efficient infill and fastest to print, the goto infill for most things. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Infill percentage in 3d printing.

Gradient Infill For 3d Prints Cnc Kitchen . Printers And Newer Materials, The Influence Of Print Parameters, Specifically.

Best 3d Printing Infill Pattern 3dprintscape Com. The infill the amount of material that occupies the internal part of the piece. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. This shape is the most efficient infill and fastest to print, the goto infill for most things. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Editorial content, on principle, can not be bought or influenced. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Infill percentage in 3d printing. Best infill for strength vs material used. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. What is infill in 3d printing? All3dp is an editorially independent publication. Besides the actual printing process, infill will affect the strength or feel of the final product. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill provides the 3d print with internal support as the printer builds each layer. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part).

Infill Pattern Options In Slic3r Infill Options For Bioprinting Support Allevi : The Term 3D Printing Can Refer To A Variety Of Processes In Which.

Simplify3d Announces Version 3 0 Of Universal 3d Printing Software Simplify3d Software. All3dp is an editorially independent publication. Best infill for strength vs material used. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. This shape is the most efficient infill and fastest to print, the goto infill for most things. The infill the amount of material that occupies the internal part of the piece. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Infill percentage in 3d printing. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. What is infill in 3d printing? Besides the actual printing process, infill will affect the strength or feel of the final product. Infill provides the 3d print with internal support as the printer builds each layer. Editorial content, on principle, can not be bought or influenced.

The Best Cura Infill Pattern For Your Needs All3dp : The Workflow Was Based In The Following Processes In This Instructables I Aim To Demonstrate, In A Simple Way, How To Reinforce A Specific Region In A 3D Printer Part, By Changing The Part's Infill.

Download Free Stl File 3d Print Infill Percentage Disks Makerware Profiles 3d Printer Design Cults. Best infill for strength vs material used. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). Besides the actual printing process, infill will affect the strength or feel of the final product. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Infill percentage in 3d printing. Infill provides the 3d print with internal support as the printer builds each layer. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. This shape is the most efficient infill and fastest to print, the goto infill for most things. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. What is infill in 3d printing? All3dp is an editorially independent publication. Editorial content, on principle, can not be bought or influenced. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. The infill the amount of material that occupies the internal part of the piece.

3d Printing Infill The Basics Simply Explained All3dp , The Cad Model Also Does Not.

Gradient Infill For 3d Prints Cnc Kitchen. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. Infill provides the 3d print with internal support as the printer builds each layer. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). What is infill in 3d printing? This shape is the most efficient infill and fastest to print, the goto infill for most things. The infill the amount of material that occupies the internal part of the piece. All3dp is an editorially independent publication. Infill percentage in 3d printing. Best infill for strength vs material used. Besides the actual printing process, infill will affect the strength or feel of the final product. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Editorial content, on principle, can not be bought or influenced. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you.

The Importance Of The Type Of Infill In 3d Printing : If Strength Is Critical To The Function Of A 3D Printed Part.

3d Printing Infill The Basics Simply Explained All3dp. The infill the amount of material that occupies the internal part of the piece. All3dp is an editorially independent publication. Infill percentage in 3d printing. This shape is the most efficient infill and fastest to print, the goto infill for most things. What is infill in 3d printing? Besides the actual printing process, infill will affect the strength or feel of the final product. Best infill for strength vs material used. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. Infill is added in the middle of the print so that the shell of the part is still stiff when you press on it. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Editorial content, on principle, can not be bought or influenced. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Infill provides the 3d print with internal support as the printer builds each layer. Normally, rolling programs allow the percentage of material to be modified from 0% (hollow part) to 100% (totally solid part). When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight.