Abs 3D Printing Process. In 3d printing, wall thickness refers to the distance between one surface of your model and the opposite sheer surface. During printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. Pla is the most popular 3d printing material. Abs is considerably easy to sand. How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. Abs is also an extremely common plastic in injection. Download cura abs profile & 3d printing material settings today! One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor. Abs also allows for the ability to post process using acetone vapor finishing, something we always suggest doing to enhance the strength and look. First, abs prints at a higher temperature than other plastics, around 230°c. So when should i use pla, and when should i use abs? Tips for 3d printing abs with the best abs 3d printing temperature & speed settings. This article aims to answer exactly that question. In terms of printing supports, abs is easily printed with hips, a material that has the same tray and extrusion temperatures. Objects printed with abs boast slightly higher strength, flexibility, and durability than those made of pla, at the cost of a slightly more complicated print process (complete with nasty fumes!).

Abs 3D Printing Process : Acetone Is Often Used In Post Processing To Smooth Abs And Pla Are The Most Common Desktop Fdm Printed Materials And Are Typically Similar In Cost.

Post Processing Pla And Abs Prints Pinshape Blog. First, abs prints at a higher temperature than other plastics, around 230°c. In terms of printing supports, abs is easily printed with hips, a material that has the same tray and extrusion temperatures. Abs also allows for the ability to post process using acetone vapor finishing, something we always suggest doing to enhance the strength and look. How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. Objects printed with abs boast slightly higher strength, flexibility, and durability than those made of pla, at the cost of a slightly more complicated print process (complete with nasty fumes!). Abs is considerably easy to sand. One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor. So when should i use pla, and when should i use abs? Abs is also an extremely common plastic in injection. This article aims to answer exactly that question. During printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. In 3d printing, wall thickness refers to the distance between one surface of your model and the opposite sheer surface. Tips for 3d printing abs with the best abs 3d printing temperature & speed settings. Download cura abs profile & 3d printing material settings today! Pla is the most popular 3d printing material.

Abs is considerably easy to sand.

Download cura abs profile & 3d printing material settings today! Best abs 3d printer filament. Acetone is often used in post processing to smooth abs and pla are the most common desktop fdm printed materials and are typically similar in cost. First, abs prints at a higher temperature than other plastics, around 230°c. Abs and pla are the two materials used in 3d printing, but not all printers support both options. Download cura abs profile & 3d printing material settings today! Abs printed objects are easily cleaned up with a simple sand paper and the object becomes smoother. Abs is the second most popular 3d printing material, beaten only by pla. Pla is the most popular 3d printing material. Abs has superior mechanical properties but is. This article aims to answer exactly that question. Abs is also an extremely common plastic in injection. Sometimes just sanding is enough, and you would use. Objects printed with abs boast slightly higher strength, flexibility, and durability than those made of pla, at the cost of a slightly more complicated print process (complete with nasty fumes!). Abs also allows for the ability to post process using acetone vapor finishing, something we always suggest doing to enhance the strength and look. You will probably have a better 3d printing experience with pla because it does not exude an unpleasant odor. So when should i use pla, and when should i use abs? Differences in 3d printing process. In 3d printing, wall thickness refers to the distance between one surface of your model and the opposite sheer surface. When considering what building material to use. With abs you can create parts that are impact resistant, durable, and resistant to weather and heat. Abs is also easier to be processed repeatedly than pla and the. Also, the glossy look is obtained either by wiping the printed item with a cloth moistened with acetone or using acetone bath method. Tips for 3d printing abs with the best abs 3d printing temperature & speed settings. I print with abs plastic. Here's a rundown of the pros and cons of each material. By vanceg in workshop 3d printing. One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor. There are times when the answer to this comparison pla vs abs plastic depends on the object that you will be 3d printing. In terms of printing supports, abs is easily printed with hips, a material that has the same tray and extrusion temperatures. Perhaps the most important part of 3d printing is using the right material for your print job.

Plastic Filament 3d Printing Material Abs . Differences In 3D Printing Process.

3d Printing Materials Breakdown Abs Vs Pla Chemical Manufacturing Excellence Chemical Manufacturing Excellence. Pla is the most popular 3d printing material. This article aims to answer exactly that question. How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. In terms of printing supports, abs is easily printed with hips, a material that has the same tray and extrusion temperatures. Abs is considerably easy to sand. Download cura abs profile & 3d printing material settings today! During printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. First, abs prints at a higher temperature than other plastics, around 230°c. One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor. So when should i use pla, and when should i use abs? Tips for 3d printing abs with the best abs 3d printing temperature & speed settings. Objects printed with abs boast slightly higher strength, flexibility, and durability than those made of pla, at the cost of a slightly more complicated print process (complete with nasty fumes!). Abs is also an extremely common plastic in injection. Abs also allows for the ability to post process using acetone vapor finishing, something we always suggest doing to enhance the strength and look. In 3d printing, wall thickness refers to the distance between one surface of your model and the opposite sheer surface.

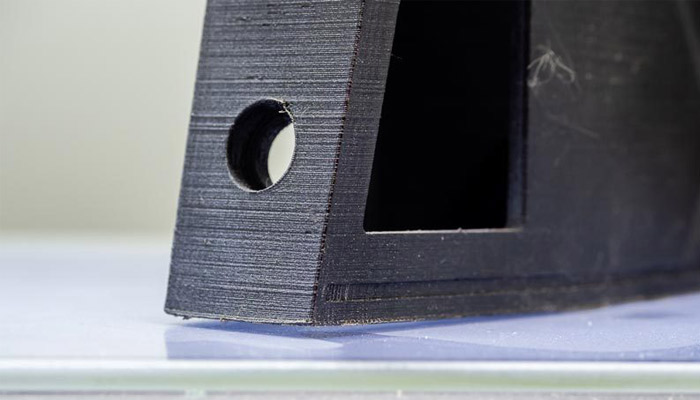

Everything You Need To Know About Abs 3d Printing Makerbot . During Printing, The Extruded Abs Plastic Sticks Through The Perforated Holes Gripping The Plastic To The Board.

Advanced Guide To Printing Abs Filament Latest 3d Printer News Article 3d Printing Solutions. Abs is also an extremely common plastic in injection. Abs is considerably easy to sand. Pla is the most popular 3d printing material. Abs also allows for the ability to post process using acetone vapor finishing, something we always suggest doing to enhance the strength and look. Tips for 3d printing abs with the best abs 3d printing temperature & speed settings. First, abs prints at a higher temperature than other plastics, around 230°c. Download cura abs profile & 3d printing material settings today! This article aims to answer exactly that question. So when should i use pla, and when should i use abs? In terms of printing supports, abs is easily printed with hips, a material that has the same tray and extrusion temperatures.

All You Need To Know About Abs For 3d Printing 3dnatives , Abs is considerably easy to sand.

A An Example Of A 3d Printing Process Using The Download Scientific Diagram. In 3d printing, wall thickness refers to the distance between one surface of your model and the opposite sheer surface. This article aims to answer exactly that question. Abs also allows for the ability to post process using acetone vapor finishing, something we always suggest doing to enhance the strength and look. So when should i use pla, and when should i use abs? Tips for 3d printing abs with the best abs 3d printing temperature & speed settings. First, abs prints at a higher temperature than other plastics, around 230°c. How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. Pla is the most popular 3d printing material. During printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor. Download cura abs profile & 3d printing material settings today! Objects printed with abs boast slightly higher strength, flexibility, and durability than those made of pla, at the cost of a slightly more complicated print process (complete with nasty fumes!). Abs is also an extremely common plastic in injection. In terms of printing supports, abs is easily printed with hips, a material that has the same tray and extrusion temperatures. Abs is considerably easy to sand.

Optimization Of Fused Deposition Modeling Parameters For Improved Pla And Abs 3d Printed Structures Sciencedirect : Abs Is Considerably Easy To Sand.

Types Of 3d Printing Technologies Makerbot. Abs also allows for the ability to post process using acetone vapor finishing, something we always suggest doing to enhance the strength and look. In 3d printing, wall thickness refers to the distance between one surface of your model and the opposite sheer surface. Pla is the most popular 3d printing material. How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. During printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. Tips for 3d printing abs with the best abs 3d printing temperature & speed settings. So when should i use pla, and when should i use abs? One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor. First, abs prints at a higher temperature than other plastics, around 230°c. This article aims to answer exactly that question. In terms of printing supports, abs is easily printed with hips, a material that has the same tray and extrusion temperatures. Objects printed with abs boast slightly higher strength, flexibility, and durability than those made of pla, at the cost of a slightly more complicated print process (complete with nasty fumes!). Abs is considerably easy to sand. Download cura abs profile & 3d printing material settings today! Abs is also an extremely common plastic in injection.

All You Need To Know About Abs For 3d Printing 3dnatives . Sometimes Just Sanding Is Enough, And You Would Use.

Ultimaker Black Abs Filament 2 85mm 0 75kg Matterhackers. So when should i use pla, and when should i use abs? During printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. This article aims to answer exactly that question. In terms of printing supports, abs is easily printed with hips, a material that has the same tray and extrusion temperatures. How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. Abs also allows for the ability to post process using acetone vapor finishing, something we always suggest doing to enhance the strength and look. Abs is considerably easy to sand. Abs is also an extremely common plastic in injection. Pla is the most popular 3d printing material. Objects printed with abs boast slightly higher strength, flexibility, and durability than those made of pla, at the cost of a slightly more complicated print process (complete with nasty fumes!). One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor. Download cura abs profile & 3d printing material settings today! First, abs prints at a higher temperature than other plastics, around 230°c. In 3d printing, wall thickness refers to the distance between one surface of your model and the opposite sheer surface. Tips for 3d printing abs with the best abs 3d printing temperature & speed settings.

Fused Filament Fabrication Wikipedia - This Instructable Is Intended To Give An Overview Of The 3D Printing Process, Using A Holder The 3D Printing Process.

Post Processing Pla And Abs Prints Pinshape Blog. Pla is the most popular 3d printing material. Abs is also an extremely common plastic in injection. First, abs prints at a higher temperature than other plastics, around 230°c. In terms of printing supports, abs is easily printed with hips, a material that has the same tray and extrusion temperatures. Tips for 3d printing abs with the best abs 3d printing temperature & speed settings. Download cura abs profile & 3d printing material settings today! This article aims to answer exactly that question. One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor. Abs is considerably easy to sand. In 3d printing, wall thickness refers to the distance between one surface of your model and the opposite sheer surface. So when should i use pla, and when should i use abs? During printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. Abs also allows for the ability to post process using acetone vapor finishing, something we always suggest doing to enhance the strength and look. Objects printed with abs boast slightly higher strength, flexibility, and durability than those made of pla, at the cost of a slightly more complicated print process (complete with nasty fumes!).

3d Printer Filament Extrusion Line For Pla Abs 3d Printer Filament 3d Printing Business 3d Printer - Abs Is Also An Extremely Common Plastic In Injection.

Post Processing Pla And Abs Prints Pinshape Blog. Objects printed with abs boast slightly higher strength, flexibility, and durability than those made of pla, at the cost of a slightly more complicated print process (complete with nasty fumes!). One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor. In terms of printing supports, abs is easily printed with hips, a material that has the same tray and extrusion temperatures. This article aims to answer exactly that question. So when should i use pla, and when should i use abs? First, abs prints at a higher temperature than other plastics, around 230°c. During printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. Download cura abs profile & 3d printing material settings today! Abs is also an extremely common plastic in injection. In 3d printing, wall thickness refers to the distance between one surface of your model and the opposite sheer surface. Pla is the most popular 3d printing material. Tips for 3d printing abs with the best abs 3d printing temperature & speed settings. How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. Abs is considerably easy to sand. Abs also allows for the ability to post process using acetone vapor finishing, something we always suggest doing to enhance the strength and look.

Abs 3d Printing - There Are Times When The Answer To This Comparison Pla Vs Abs Plastic Depends On The Object That You Will Be 3D Printing.

Metal 3d Print Search Engine Series Metal 3d Printing Tech 3d Printing Process Parameters 002. Download cura abs profile & 3d printing material settings today! Tips for 3d printing abs with the best abs 3d printing temperature & speed settings. Abs is considerably easy to sand. So when should i use pla, and when should i use abs? How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. In 3d printing, wall thickness refers to the distance between one surface of your model and the opposite sheer surface. One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor. This article aims to answer exactly that question. In terms of printing supports, abs is easily printed with hips, a material that has the same tray and extrusion temperatures. Pla is the most popular 3d printing material. Abs also allows for the ability to post process using acetone vapor finishing, something we always suggest doing to enhance the strength and look. First, abs prints at a higher temperature than other plastics, around 230°c. Objects printed with abs boast slightly higher strength, flexibility, and durability than those made of pla, at the cost of a slightly more complicated print process (complete with nasty fumes!). During printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. Abs is also an extremely common plastic in injection.

6 Things You Should Know About 3d Printing Large Abs Parts , It's Widely Available And Cheap To Buy.

Acetone 3d Print Smoothing Guide 6 Easy Steps All3dp. Abs is considerably easy to sand. Pla is the most popular 3d printing material. Tips for 3d printing abs with the best abs 3d printing temperature & speed settings. In terms of printing supports, abs is easily printed with hips, a material that has the same tray and extrusion temperatures. One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor. First, abs prints at a higher temperature than other plastics, around 230°c. Abs is also an extremely common plastic in injection. Download cura abs profile & 3d printing material settings today! In 3d printing, wall thickness refers to the distance between one surface of your model and the opposite sheer surface. During printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. This article aims to answer exactly that question. How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. Abs also allows for the ability to post process using acetone vapor finishing, something we always suggest doing to enhance the strength and look. Objects printed with abs boast slightly higher strength, flexibility, and durability than those made of pla, at the cost of a slightly more complicated print process (complete with nasty fumes!). So when should i use pla, and when should i use abs?

Abs Vs Pla Which Is Better For 3d Printing 3dprintergeeks Com : Here's A Rundown Of The Pros And Cons Of Each Material.

3d Filament For 3d Printers And 3d Pens 1 75mm 1kg Roll Yellow Pla Read More At The Image Link 3d Printing 3d Printer Models Printer. Abs is also an extremely common plastic in injection. During printing, the extruded abs plastic sticks through the perforated holes gripping the plastic to the board. Tips for 3d printing abs with the best abs 3d printing temperature & speed settings. Pla is the most popular 3d printing material. Abs is considerably easy to sand. How you post process your prints is based on which material you used to 3d print your designs, so your next steps will depend on what your chosen printing material is. So when should i use pla, and when should i use abs? Download cura abs profile & 3d printing material settings today! One of the easiest, and most effective, ways to smooth your abs plastic is with an acetone vapor. In 3d printing, wall thickness refers to the distance between one surface of your model and the opposite sheer surface. Objects printed with abs boast slightly higher strength, flexibility, and durability than those made of pla, at the cost of a slightly more complicated print process (complete with nasty fumes!). This article aims to answer exactly that question. First, abs prints at a higher temperature than other plastics, around 230°c. Abs also allows for the ability to post process using acetone vapor finishing, something we always suggest doing to enhance the strength and look. In terms of printing supports, abs is easily printed with hips, a material that has the same tray and extrusion temperatures.