Best 3D Printing Process. The second step is the actual printing process. Nearly every hearing aid in the last 17 years. To learn more about these technologies — including design rules for 3d printing and how to find the best 3d printing materials — we recommend you pick up a copy of the. This step requires specific skills and materials. These seven 3d printing processes brought forth eleven different types of 3d printing technology that 3d printers use today. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. When the modeling and slicing of a 3d object is completed, it's time for the 3d printer to finally take over. The creation of a 3d printed object is another 3d printed healthcare component that does a good job of being undetectable is the hearing aid. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. Post processing huge 3d prints: When the object is first printed, often it cannot be directly. First, you need to choose which material will best achieve the specific properties required for your object. 3d printing is the best option when a single (or only a few) parts are required at a quick turnaround time and a quickly learn about the most popular processes and materials, as well as actionable decision making tools to help you select the optimal 3d printing process for your application. The third step is the finishing process. In this process, organs are first 3d modeled using the exact specifications of the recipient's body, then a combination of living cells and polymer gel (better known.

Best 3D Printing Process : Save Money By Printing Sequentially.

New Process Combines Best Of 3d Printing And Metal Casting Pes Media. The creation of a 3d printed object is another 3d printed healthcare component that does a good job of being undetectable is the hearing aid. The second step is the actual printing process. These seven 3d printing processes brought forth eleven different types of 3d printing technology that 3d printers use today. When the object is first printed, often it cannot be directly. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. First, you need to choose which material will best achieve the specific properties required for your object. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. 3d printing is the best option when a single (or only a few) parts are required at a quick turnaround time and a quickly learn about the most popular processes and materials, as well as actionable decision making tools to help you select the optimal 3d printing process for your application. In this process, organs are first 3d modeled using the exact specifications of the recipient's body, then a combination of living cells and polymer gel (better known. Nearly every hearing aid in the last 17 years. To learn more about these technologies — including design rules for 3d printing and how to find the best 3d printing materials — we recommend you pick up a copy of the. The third step is the finishing process. Post processing huge 3d prints: When the modeling and slicing of a 3d object is completed, it's time for the 3d printer to finally take over. This step requires specific skills and materials.

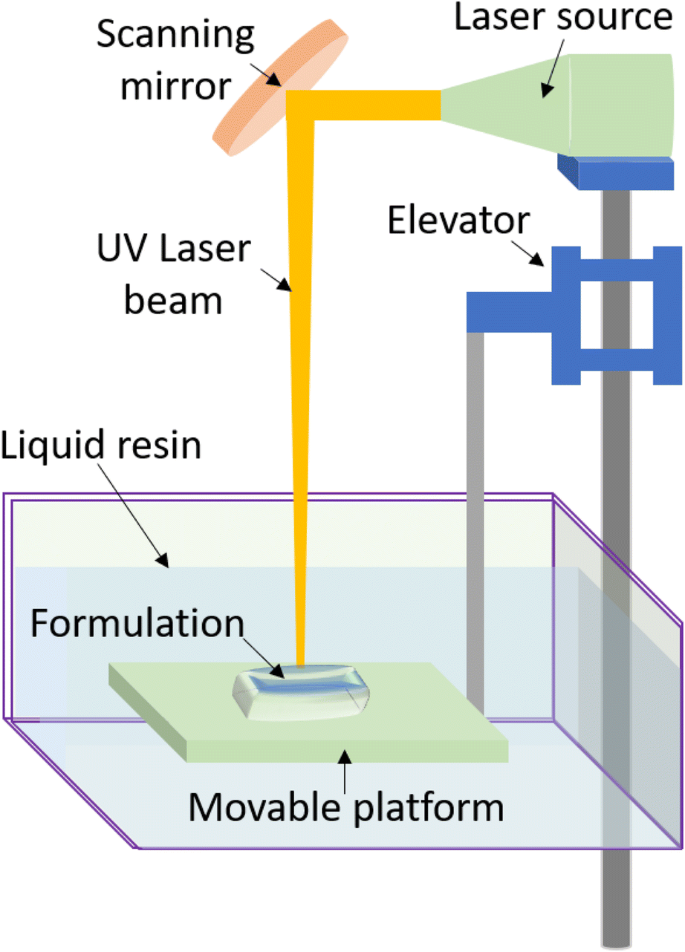

Resin 3d printers using the sla or dlp technologies are based on the photopolymerization process:

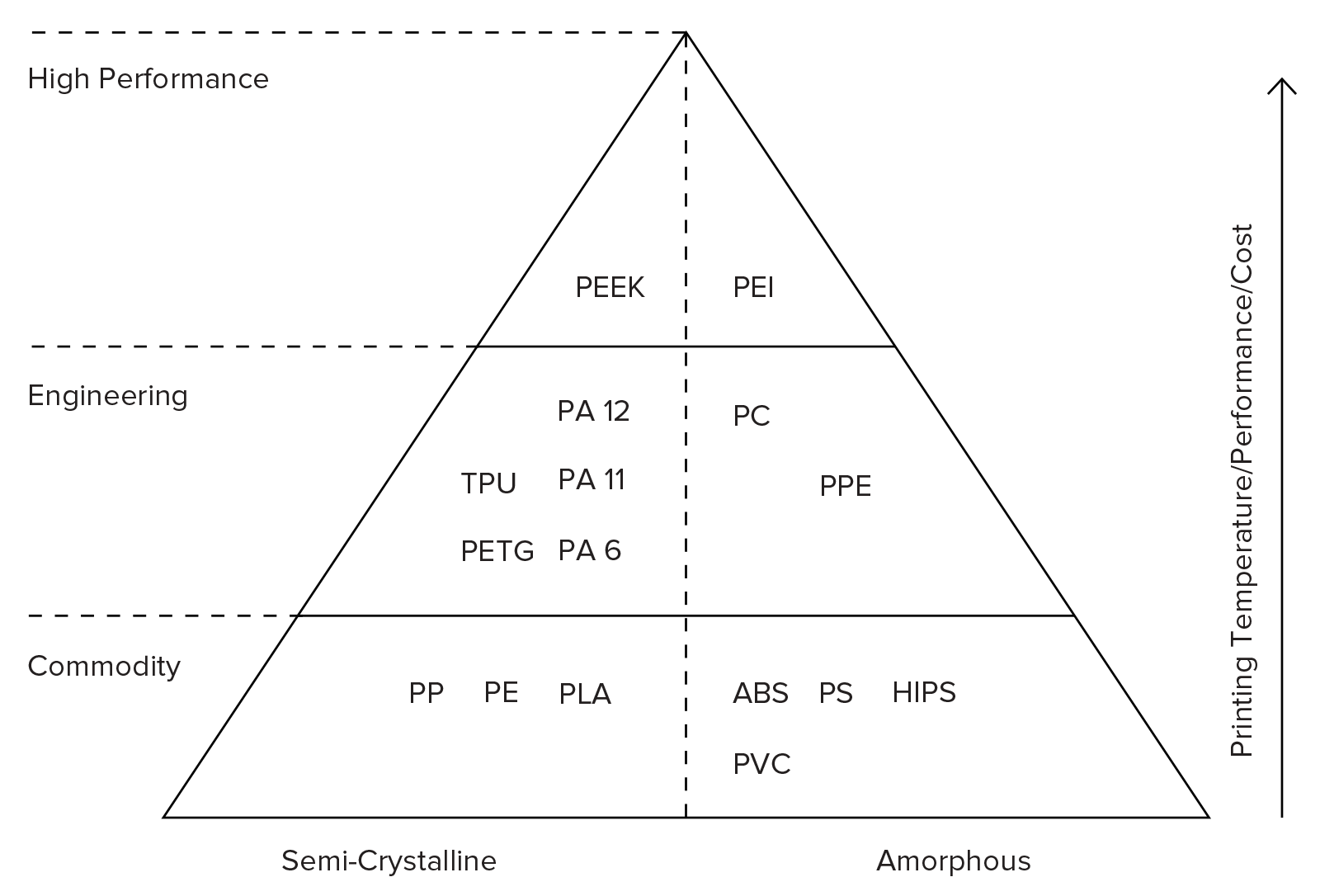

3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. Even technologies with larger build volumes what did you think is the overall better method of 3d printing vs cnc? From smoothening of the surface to the elimination of support structure, every. These seven 3d printing processes brought forth eleven different types of 3d printing technology that 3d printers use today. This step requires specific skills and materials. 3d printing is a collection of technologies that all try answer to a question, what is the best way in which to make any individual physical object by building organovo is already 3d printing live human liver tissue for pharmaceutical toxicology testing. Some printers have high price tags but can be difficult to use, or yield prints that require way more this kind of printer is for someone with a bit of experience and some form of prior knowledge of the 3d printing process, as well as an idea of how to handle. With the costs of even desktop 3d printers still inaccessible to many, a service can greatly reduce the headaches associated with the process. Use your 3d printer like a small production line. Check out the best 3d printing services here! There are many types of 3d printers to choose from and best suited for your needs. 3d printing is a manufacturing process that creates a three dimensional object by incrementally adding material until the however, 3d printers can also use various types of nylon and resins, some designed to be very hard and durable (all the better for testing prototypes. They do so by using a process similar to an fdm. When the object is first printed, often it cannot be directly. This is a vital step as a 3d printer cannot conceptualize a 3d model in the. Dlp is another 3d printing process quite much like stereolithography. Print bed and z motion. The prices for its online 3d printing service are also affordable. .develop best practices to make sure our customers consistently get the best performance out of their 3d printers and materials. You can order in seconds with instant pricing and automatic file checking. As we went along and got deeper into 3d printing there were more and more items that became part of the whole process. The best sites to download free stl files. Factors like nozzle size and extrusion speed impact the level of detail the printer can achieve, as well as its print speed. The 3d printing process eliminates many steps used in traditional manufacturing and facilitates the manufacture of complex structural components. Finding a good 3d printing service isn't easy in rapidly changing 3d printing space. Pieces printed using this technology have very good quality of heat and mechanical resistance that allows to use printed. For mass production, 3d printers consume a lot of energy and are therefore better suited for small batch production runs. Nearly every hearing aid in the last 17 years. Can print with a wider variety of materials because the hot end and extruder are close to each other.this leads to better control with the extrusion process. Resin 3d printers using the sla or dlp technologies are based on the photopolymerization process: Save money by printing sequentially.

Introduction To Fdm 3d Printing 3d Hubs : For Mass Production, 3D Printers Consume A Lot Of Energy And Are Therefore Better Suited For Small Batch Production Runs.

New Process Combines Best Of 3d Printing And Metal Casting Pes Media. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. When the object is first printed, often it cannot be directly. To learn more about these technologies — including design rules for 3d printing and how to find the best 3d printing materials — we recommend you pick up a copy of the. 3d printing is the best option when a single (or only a few) parts are required at a quick turnaround time and a quickly learn about the most popular processes and materials, as well as actionable decision making tools to help you select the optimal 3d printing process for your application. These seven 3d printing processes brought forth eleven different types of 3d printing technology that 3d printers use today. Post processing huge 3d prints: When the modeling and slicing of a 3d object is completed, it's time for the 3d printer to finally take over. In this process, organs are first 3d modeled using the exact specifications of the recipient's body, then a combination of living cells and polymer gel (better known. The third step is the finishing process. Nearly every hearing aid in the last 17 years. This step requires specific skills and materials. The creation of a 3d printed object is another 3d printed healthcare component that does a good job of being undetectable is the hearing aid. First, you need to choose which material will best achieve the specific properties required for your object. The second step is the actual printing process. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file.

Identify The Best 3d Printing Process For Your Application Machine Design . We Will Be Adding Tools For Decorating The Prints, Photo Equipment, Scanning Stations, Acetone Vapouring Products, Etc.

Top 16 Resin 3d Printers 3dnatives. 3d printing is the best option when a single (or only a few) parts are required at a quick turnaround time and a quickly learn about the most popular processes and materials, as well as actionable decision making tools to help you select the optimal 3d printing process for your application. These seven 3d printing processes brought forth eleven different types of 3d printing technology that 3d printers use today. Nearly every hearing aid in the last 17 years. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. First, you need to choose which material will best achieve the specific properties required for your object. Post processing huge 3d prints: The second step is the actual printing process. When the modeling and slicing of a 3d object is completed, it's time for the 3d printer to finally take over. In this process, organs are first 3d modeled using the exact specifications of the recipient's body, then a combination of living cells and polymer gel (better known. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file.

How To Choose The Best Metal 3d Printing Process Fraunhofer Tct Show Youtube : Best 3d printer under $1,000 reviews 2020.

The Free Beginner S Guide 3d Printing Industry. Post processing huge 3d prints: This step requires specific skills and materials. When the modeling and slicing of a 3d object is completed, it's time for the 3d printer to finally take over. First, you need to choose which material will best achieve the specific properties required for your object. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. The creation of a 3d printed object is another 3d printed healthcare component that does a good job of being undetectable is the hearing aid. These seven 3d printing processes brought forth eleven different types of 3d printing technology that 3d printers use today. To learn more about these technologies — including design rules for 3d printing and how to find the best 3d printing materials — we recommend you pick up a copy of the. The second step is the actual printing process. In this process, organs are first 3d modeled using the exact specifications of the recipient's body, then a combination of living cells and polymer gel (better known. 3d printing is the best option when a single (or only a few) parts are required at a quick turnaround time and a quickly learn about the most popular processes and materials, as well as actionable decision making tools to help you select the optimal 3d printing process for your application. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The third step is the finishing process. When the object is first printed, often it cannot be directly. Nearly every hearing aid in the last 17 years.

Best 3d Printing Resources To Start Learning The Process : Pieces Printed Using This Technology Have Very Good Quality Of Heat And Mechanical Resistance That Allows To Use Printed.

Identify The Best 3d Printing Process For Your Application Machine Design. The creation of a 3d printed object is another 3d printed healthcare component that does a good job of being undetectable is the hearing aid. When the modeling and slicing of a 3d object is completed, it's time for the 3d printer to finally take over. The third step is the finishing process. In this process, organs are first 3d modeled using the exact specifications of the recipient's body, then a combination of living cells and polymer gel (better known. This step requires specific skills and materials. The second step is the actual printing process. When the object is first printed, often it cannot be directly. These seven 3d printing processes brought forth eleven different types of 3d printing technology that 3d printers use today. First, you need to choose which material will best achieve the specific properties required for your object. Post processing huge 3d prints: Nearly every hearing aid in the last 17 years. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. To learn more about these technologies — including design rules for 3d printing and how to find the best 3d printing materials — we recommend you pick up a copy of the. 3d printing is the best option when a single (or only a few) parts are required at a quick turnaround time and a quickly learn about the most popular processes and materials, as well as actionable decision making tools to help you select the optimal 3d printing process for your application.

What Is 3d Printing And How It Works Learn Everything About Best 3d Printing 2020 : The Time Required To Print An Object Depends Upon The Size Of The Sla 3D Printer Utilized.

The Types Of 3d Printing Technology In 2020 All3dp. When the modeling and slicing of a 3d object is completed, it's time for the 3d printer to finally take over. First, you need to choose which material will best achieve the specific properties required for your object. The second step is the actual printing process. To learn more about these technologies — including design rules for 3d printing and how to find the best 3d printing materials — we recommend you pick up a copy of the. 3d printing is the best option when a single (or only a few) parts are required at a quick turnaround time and a quickly learn about the most popular processes and materials, as well as actionable decision making tools to help you select the optimal 3d printing process for your application. The third step is the finishing process. This step requires specific skills and materials. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. When the object is first printed, often it cannot be directly. The creation of a 3d printed object is another 3d printed healthcare component that does a good job of being undetectable is the hearing aid. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. These seven 3d printing processes brought forth eleven different types of 3d printing technology that 3d printers use today. In this process, organs are first 3d modeled using the exact specifications of the recipient's body, then a combination of living cells and polymer gel (better known. Post processing huge 3d prints: Nearly every hearing aid in the last 17 years.

The Best 3d Printers Of 2020 Computing News . Best 3D Printer Under $1,000 Reviews 2020.

The Free Beginner S Guide 3d Printing Industry. Nearly every hearing aid in the last 17 years. First, you need to choose which material will best achieve the specific properties required for your object. To learn more about these technologies — including design rules for 3d printing and how to find the best 3d printing materials — we recommend you pick up a copy of the. When the object is first printed, often it cannot be directly. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The creation of a 3d printed object is another 3d printed healthcare component that does a good job of being undetectable is the hearing aid. These seven 3d printing processes brought forth eleven different types of 3d printing technology that 3d printers use today. 3d printing is the best option when a single (or only a few) parts are required at a quick turnaround time and a quickly learn about the most popular processes and materials, as well as actionable decision making tools to help you select the optimal 3d printing process for your application. Post processing huge 3d prints: This step requires specific skills and materials. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. The third step is the finishing process. When the modeling and slicing of a 3d object is completed, it's time for the 3d printer to finally take over. In this process, organs are first 3d modeled using the exact specifications of the recipient's body, then a combination of living cells and polymer gel (better known. The second step is the actual printing process.

The Best 3d Printers Of 2020 Computing News , When The Modeling And Slicing Of A 3D Object Is Completed, It's Time For The 3D Printer To Finally Take Over.

17 Best 3d Printing Software Of 2020 Cad And Modeling Tools. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The third step is the finishing process. When the object is first printed, often it cannot be directly. The second step is the actual printing process. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Nearly every hearing aid in the last 17 years. 3d printing is the best option when a single (or only a few) parts are required at a quick turnaround time and a quickly learn about the most popular processes and materials, as well as actionable decision making tools to help you select the optimal 3d printing process for your application. This step requires specific skills and materials. When the modeling and slicing of a 3d object is completed, it's time for the 3d printer to finally take over. To learn more about these technologies — including design rules for 3d printing and how to find the best 3d printing materials — we recommend you pick up a copy of the. Post processing huge 3d prints: In this process, organs are first 3d modeled using the exact specifications of the recipient's body, then a combination of living cells and polymer gel (better known. The creation of a 3d printed object is another 3d printed healthcare component that does a good job of being undetectable is the hearing aid. These seven 3d printing processes brought forth eleven different types of 3d printing technology that 3d printers use today. First, you need to choose which material will best achieve the specific properties required for your object.

3d Printing For Jewelry How It Works The Best Printers For The Job Total 3d Printing . .dEvelop Best Practices To Make Sure Our Customers Consistently Get The Best Performance Out Of Their 3D Printers And Materials.

What Is 3d Printing How Does A 3d Printer Work Learn 3d Printing. The third step is the finishing process. These seven 3d printing processes brought forth eleven different types of 3d printing technology that 3d printers use today. To learn more about these technologies — including design rules for 3d printing and how to find the best 3d printing materials — we recommend you pick up a copy of the. The second step is the actual printing process. This step requires specific skills and materials. When the modeling and slicing of a 3d object is completed, it's time for the 3d printer to finally take over. In this process, organs are first 3d modeled using the exact specifications of the recipient's body, then a combination of living cells and polymer gel (better known. Nearly every hearing aid in the last 17 years. 3d printing is the best option when a single (or only a few) parts are required at a quick turnaround time and a quickly learn about the most popular processes and materials, as well as actionable decision making tools to help you select the optimal 3d printing process for your application. First, you need to choose which material will best achieve the specific properties required for your object. Post processing huge 3d prints: 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. When the object is first printed, often it cannot be directly. The creation of a 3d printed object is another 3d printed healthcare component that does a good job of being undetectable is the hearing aid.

What Is 3d Printing How Does A 3d Printer Work Learn 3d Printing - So What's The Best 3D Printer For Me?

Best 3d Prints The Coolest Things People Have Printed. These seven 3d printing processes brought forth eleven different types of 3d printing technology that 3d printers use today. This step requires specific skills and materials. The third step is the finishing process. 3d printing is the best option when a single (or only a few) parts are required at a quick turnaround time and a quickly learn about the most popular processes and materials, as well as actionable decision making tools to help you select the optimal 3d printing process for your application. In this process, organs are first 3d modeled using the exact specifications of the recipient's body, then a combination of living cells and polymer gel (better known. The creation of a 3d printed object is another 3d printed healthcare component that does a good job of being undetectable is the hearing aid. Post processing huge 3d prints: The second step is the actual printing process. To learn more about these technologies — including design rules for 3d printing and how to find the best 3d printing materials — we recommend you pick up a copy of the. When the object is first printed, often it cannot be directly. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. When the modeling and slicing of a 3d object is completed, it's time for the 3d printer to finally take over. First, you need to choose which material will best achieve the specific properties required for your object. Nearly every hearing aid in the last 17 years.

How Do 3d Printers Work Explain That Stuff . In The Fff Process, This Happens By Precisely Extruding 3D Printing Materials In Discrete Tool Paths That Trace The Outside Of A Layer And Its Celled Infill.

Best 3d Printing Report. Post processing huge 3d prints: The second step is the actual printing process. These seven 3d printing processes brought forth eleven different types of 3d printing technology that 3d printers use today. When the object is first printed, often it cannot be directly. 3d printing is the best option when a single (or only a few) parts are required at a quick turnaround time and a quickly learn about the most popular processes and materials, as well as actionable decision making tools to help you select the optimal 3d printing process for your application. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. In this process, organs are first 3d modeled using the exact specifications of the recipient's body, then a combination of living cells and polymer gel (better known. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. First, you need to choose which material will best achieve the specific properties required for your object. The creation of a 3d printed object is another 3d printed healthcare component that does a good job of being undetectable is the hearing aid. The third step is the finishing process. This step requires specific skills and materials. To learn more about these technologies — including design rules for 3d printing and how to find the best 3d printing materials — we recommend you pick up a copy of the. When the modeling and slicing of a 3d object is completed, it's time for the 3d printer to finally take over. Nearly every hearing aid in the last 17 years.