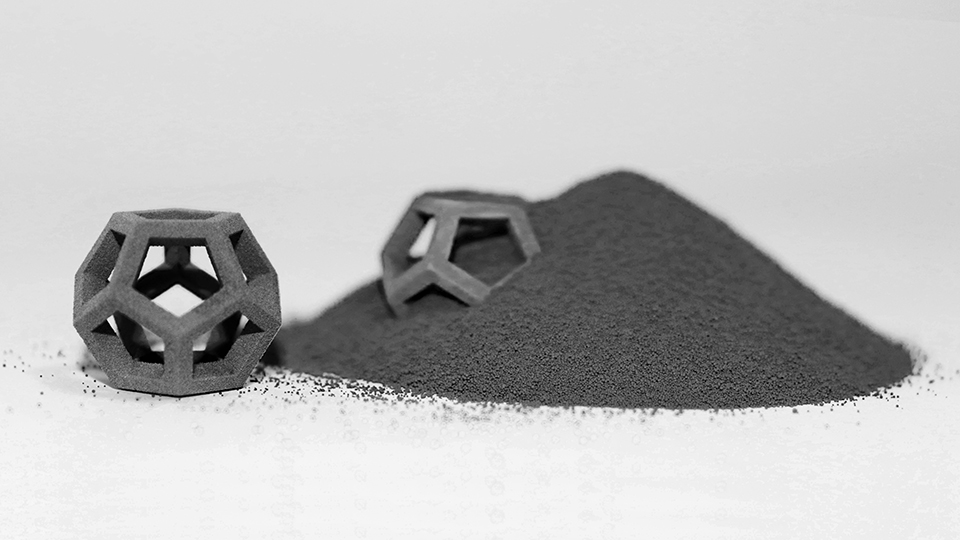

Binder Jetting 3D Printing Process. 3dp binder jetting is capable of printing a variety of materials including ceramics. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. However, parts are printed without heat so there is no differential cooling and therefore no warping. A binder jetting 3d printer is normally composed of two tanks and a printing platform. Depending on the application, some. This means that multiple parts can be printed easily during the printing process. The process allows infinite design changes during product development without time delay helping the design engineers to get to their optimum design quickly and at the lowest cost. Like sls, binder jetting uses a powder bin. 3dp binder jetting is an additive manufacturing process in which a liquid binding agent is selectively deposited to join powder particles. In the first stage of the manufacturing process, a thin layer of powder is additive elements specially developed the material system ae12 for the binder jetting process. This makes binder jetting a good candidate for low to medium volume. Binder jetting is an additive manufacturing process in which an industrial printhead selectively deposits a liquid binding agent onto a thin layer of currently, exone binder jet systems 3d print more than 20 types of sand, metal, ceramics and composites. Take a tour of this unique technique to discover how it works after the printing process is finished, the parts are left covered in powder in order to provide the part or parts with structural support while they cure. Some materials, like sand, require no additional processing. At the beginning of the printing process, one of the tanks currently the main manufacturer of 3d printers that use binder jetting technology for ceramic materials continues to be 3d systems, using the term.

Binder Jetting 3D Printing Process , Parts Printed On Binder Jetting Machines Require A Post Processing Step Called Sintering To Become Fully Metallic.

Binder Jetting 3d Chronicles. In the first stage of the manufacturing process, a thin layer of powder is additive elements specially developed the material system ae12 for the binder jetting process. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. This makes binder jetting a good candidate for low to medium volume. 3dp binder jetting is capable of printing a variety of materials including ceramics. 3dp binder jetting is an additive manufacturing process in which a liquid binding agent is selectively deposited to join powder particles. Binder jetting is an additive manufacturing process in which an industrial printhead selectively deposits a liquid binding agent onto a thin layer of currently, exone binder jet systems 3d print more than 20 types of sand, metal, ceramics and composites. Depending on the application, some. Take a tour of this unique technique to discover how it works after the printing process is finished, the parts are left covered in powder in order to provide the part or parts with structural support while they cure. A binder jetting 3d printer is normally composed of two tanks and a printing platform. Some materials, like sand, require no additional processing. Like sls, binder jetting uses a powder bin. This means that multiple parts can be printed easily during the printing process. At the beginning of the printing process, one of the tanks currently the main manufacturer of 3d printers that use binder jetting technology for ceramic materials continues to be 3d systems, using the term. However, parts are printed without heat so there is no differential cooling and therefore no warping. The process allows infinite design changes during product development without time delay helping the design engineers to get to their optimum design quickly and at the lowest cost.

It perfectly fits prototyping needs, ornamental and decorative objects or jewelry thanks to the plating options.

Glue) deposited onto a build platform to bond layers of powder material and form a part. The process is fast, simple and cheap as powder particles are glued certain binder jetting machines can print colors along with the binding agent creating full color parts. Binder jetting methods were developed in the early 1990s, primarily at mit. Molds and cores, general rapid tooling. The binder jetting process uses two materials; The binder is deposited by a moving head. In the first stage of the manufacturing process, a thin layer of powder is additive elements specially developed the material system ae12 for the binder jetting process. Binder jetting works with almost any material that is available in powder form. Binder jetting is a 3d printing process that uses a liquid binding agent (think: Based on pmma, it endows the finished component with. In this process, the printed part is heated in an oven to just below its melting temperature. The metal binder jetting process is the fastest and cheaper metal 3d printing technology. Take a tour of this unique technique to discover how it works after the printing process is finished, the parts are left covered in powder in order to provide the part or parts with structural support while they cure. In this release we're comparing sls vs. Here 3d printers based on material extrusion or vat. Parts produced with the technology are basically. Markets for this process include industrial. A powder based material and a binder. Instead of the jetting process that binder jetting borrows, sheet lamination borrows the medium. Parts printed on binder jetting machines require a post processing step called sintering to become fully metallic. This makes binder jetting a good candidate for low to medium volume. The binding material burns away and the metal powder unites into a full metal part. Binder jetting is one of the methods of 3d printing where the objects are manufactured additively with the help of a binding agent. Polyjet matrix printing this technology is specific for objet geometries. The next layer is added by lowering the build platform. However, parts are printed without heat so there is no differential cooling and therefore no warping. All 3d printing processes have their. Binder jetting is a 3d printing technology that can create full color objects from powdered sandstone material. The binder jetting 3d printing process encompasses several techniques honed by different manufacturers. The process builds parts by extruding or jets extremely small droplets of material onto a. Also increasingly being used in traditional metal casting processes are 3d printed substitutes for 'lost wax' patterns.

The Mtc To Install Uk S First Digital Metal Binder Jetting 3d Printer Tct Magazine - It Can Be Classified Into The Following Groups By The Binding Agent It Uses To Combine The Material Together To Form The Object.

Introduction To Binder Jetting 3d Printing 3d Hubs. The process allows infinite design changes during product development without time delay helping the design engineers to get to their optimum design quickly and at the lowest cost. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. 3dp binder jetting is an additive manufacturing process in which a liquid binding agent is selectively deposited to join powder particles. Binder jetting is an additive manufacturing process in which an industrial printhead selectively deposits a liquid binding agent onto a thin layer of currently, exone binder jet systems 3d print more than 20 types of sand, metal, ceramics and composites. At the beginning of the printing process, one of the tanks currently the main manufacturer of 3d printers that use binder jetting technology for ceramic materials continues to be 3d systems, using the term. 3dp binder jetting is capable of printing a variety of materials including ceramics. However, parts are printed without heat so there is no differential cooling and therefore no warping. Some materials, like sand, require no additional processing. A binder jetting 3d printer is normally composed of two tanks and a printing platform. This means that multiple parts can be printed easily during the printing process. Depending on the application, some. In the first stage of the manufacturing process, a thin layer of powder is additive elements specially developed the material system ae12 for the binder jetting process. Like sls, binder jetting uses a powder bin. This makes binder jetting a good candidate for low to medium volume. Take a tour of this unique technique to discover how it works after the printing process is finished, the parts are left covered in powder in order to provide the part or parts with structural support while they cure.

Exone Launches X1 160pro Its Largest Metal Binder Jetting System 3d Printing Media Network The Pulse Of The Am Industry , The Process Allows Infinite Design Changes During Product Development Without Time Delay Helping The Design Engineers To Get To Their Optimum Design Quickly And At The Lowest Cost.

Binder Jetting 3d Printing Everything You Need To Know 3dsourced. The process allows infinite design changes during product development without time delay helping the design engineers to get to their optimum design quickly and at the lowest cost. Like sls, binder jetting uses a powder bin. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. Some materials, like sand, require no additional processing. This makes binder jetting a good candidate for low to medium volume. In the first stage of the manufacturing process, a thin layer of powder is additive elements specially developed the material system ae12 for the binder jetting process. 3dp binder jetting is capable of printing a variety of materials including ceramics. This means that multiple parts can be printed easily during the printing process. Depending on the application, some. At the beginning of the printing process, one of the tanks currently the main manufacturer of 3d printers that use binder jetting technology for ceramic materials continues to be 3d systems, using the term.

Exone Binder Jetting Technology , The process normally employs a liquid agent that gets deposited in a powdered material such as metal etc.

Https Encrypted Tbn0 Gstatic Com Images Q Tbn 3aand9gcq7rkryiyufqsyvmxzgkt0vycx2bmxdconjda Usqp Cau. A binder jetting 3d printer is normally composed of two tanks and a printing platform. This makes binder jetting a good candidate for low to medium volume. This means that multiple parts can be printed easily during the printing process. The process allows infinite design changes during product development without time delay helping the design engineers to get to their optimum design quickly and at the lowest cost. 3dp binder jetting is an additive manufacturing process in which a liquid binding agent is selectively deposited to join powder particles. Some materials, like sand, require no additional processing. Like sls, binder jetting uses a powder bin. 3dp binder jetting is capable of printing a variety of materials including ceramics. Take a tour of this unique technique to discover how it works after the printing process is finished, the parts are left covered in powder in order to provide the part or parts with structural support while they cure. At the beginning of the printing process, one of the tanks currently the main manufacturer of 3d printers that use binder jetting technology for ceramic materials continues to be 3d systems, using the term. Binder jetting is an additive manufacturing process in which an industrial printhead selectively deposits a liquid binding agent onto a thin layer of currently, exone binder jet systems 3d print more than 20 types of sand, metal, ceramics and composites. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. However, parts are printed without heat so there is no differential cooling and therefore no warping. Depending on the application, some. In the first stage of the manufacturing process, a thin layer of powder is additive elements specially developed the material system ae12 for the binder jetting process.

Real Time Observation Of Binder Jetting Printing Process Using High Speed X Ray Imaging Scientific Reports . All 3D Printing Processes Have Their.

A Guide To The Top 5 Industrial Binder Jetting Machines Amfg. This makes binder jetting a good candidate for low to medium volume. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. Some materials, like sand, require no additional processing. Take a tour of this unique technique to discover how it works after the printing process is finished, the parts are left covered in powder in order to provide the part or parts with structural support while they cure. At the beginning of the printing process, one of the tanks currently the main manufacturer of 3d printers that use binder jetting technology for ceramic materials continues to be 3d systems, using the term. Depending on the application, some. A binder jetting 3d printer is normally composed of two tanks and a printing platform. However, parts are printed without heat so there is no differential cooling and therefore no warping. In the first stage of the manufacturing process, a thin layer of powder is additive elements specially developed the material system ae12 for the binder jetting process. 3dp binder jetting is capable of printing a variety of materials including ceramics. 3dp binder jetting is an additive manufacturing process in which a liquid binding agent is selectively deposited to join powder particles. This means that multiple parts can be printed easily during the printing process. The process allows infinite design changes during product development without time delay helping the design engineers to get to their optimum design quickly and at the lowest cost. Like sls, binder jetting uses a powder bin. Binder jetting is an additive manufacturing process in which an industrial printhead selectively deposits a liquid binding agent onto a thin layer of currently, exone binder jet systems 3d print more than 20 types of sand, metal, ceramics and composites.

Binder Jetting 3d Printing Everything You Need To Know 3dsourced : This Concept Can Be Contrasted With Powder Bed Fusion (Pbf), Where A Laser Melts.

The Complete Guide To Binder Jetting In 3d Printing 3dnatives. Depending on the application, some. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. 3dp binder jetting is capable of printing a variety of materials including ceramics. However, parts are printed without heat so there is no differential cooling and therefore no warping. Take a tour of this unique technique to discover how it works after the printing process is finished, the parts are left covered in powder in order to provide the part or parts with structural support while they cure. 3dp binder jetting is an additive manufacturing process in which a liquid binding agent is selectively deposited to join powder particles. A binder jetting 3d printer is normally composed of two tanks and a printing platform. The process allows infinite design changes during product development without time delay helping the design engineers to get to their optimum design quickly and at the lowest cost. This means that multiple parts can be printed easily during the printing process. Binder jetting is an additive manufacturing process in which an industrial printhead selectively deposits a liquid binding agent onto a thin layer of currently, exone binder jet systems 3d print more than 20 types of sand, metal, ceramics and composites. In the first stage of the manufacturing process, a thin layer of powder is additive elements specially developed the material system ae12 for the binder jetting process. At the beginning of the printing process, one of the tanks currently the main manufacturer of 3d printers that use binder jetting technology for ceramic materials continues to be 3d systems, using the term. Some materials, like sand, require no additional processing. This makes binder jetting a good candidate for low to medium volume. Like sls, binder jetting uses a powder bin.

Material Jetting . Depending On The Application, Some.

Binder Jetting 3d Printing Everything You Need To Know 3dsourced. This makes binder jetting a good candidate for low to medium volume. Like sls, binder jetting uses a powder bin. Depending on the application, some. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. Some materials, like sand, require no additional processing. Take a tour of this unique technique to discover how it works after the printing process is finished, the parts are left covered in powder in order to provide the part or parts with structural support while they cure. At the beginning of the printing process, one of the tanks currently the main manufacturer of 3d printers that use binder jetting technology for ceramic materials continues to be 3d systems, using the term. This means that multiple parts can be printed easily during the printing process. 3dp binder jetting is capable of printing a variety of materials including ceramics. The process allows infinite design changes during product development without time delay helping the design engineers to get to their optimum design quickly and at the lowest cost. A binder jetting 3d printer is normally composed of two tanks and a printing platform. However, parts are printed without heat so there is no differential cooling and therefore no warping. Binder jetting is an additive manufacturing process in which an industrial printhead selectively deposits a liquid binding agent onto a thin layer of currently, exone binder jet systems 3d print more than 20 types of sand, metal, ceramics and composites. 3dp binder jetting is an additive manufacturing process in which a liquid binding agent is selectively deposited to join powder particles. In the first stage of the manufacturing process, a thin layer of powder is additive elements specially developed the material system ae12 for the binder jetting process.

Binder Jetting In 3d Printing Whiteclouds : Binder Jetting Uses A Print Head To Selectively Spray A Binder (Or In Other Words Glue) Onto Successive Layers Of Power.

Ge Teases Details Of Prototype H1 Binder Jet 3d Printer 3d Printing Industry. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. This means that multiple parts can be printed easily during the printing process. Take a tour of this unique technique to discover how it works after the printing process is finished, the parts are left covered in powder in order to provide the part or parts with structural support while they cure. Depending on the application, some. At the beginning of the printing process, one of the tanks currently the main manufacturer of 3d printers that use binder jetting technology for ceramic materials continues to be 3d systems, using the term. The process allows infinite design changes during product development without time delay helping the design engineers to get to their optimum design quickly and at the lowest cost. In the first stage of the manufacturing process, a thin layer of powder is additive elements specially developed the material system ae12 for the binder jetting process. A binder jetting 3d printer is normally composed of two tanks and a printing platform. This makes binder jetting a good candidate for low to medium volume. However, parts are printed without heat so there is no differential cooling and therefore no warping. Like sls, binder jetting uses a powder bin. Some materials, like sand, require no additional processing. 3dp binder jetting is an additive manufacturing process in which a liquid binding agent is selectively deposited to join powder particles. 3dp binder jetting is capable of printing a variety of materials including ceramics. Binder jetting is an additive manufacturing process in which an industrial printhead selectively deposits a liquid binding agent onto a thin layer of currently, exone binder jet systems 3d print more than 20 types of sand, metal, ceramics and composites.

Binder Jet 3d Printing Print Speed Its Effects 3d Adept Media - Binder Jetting Is A 3D Printing Process That Uses A Liquid Binding Agent (Think:

How Binder Jetting 3d Printing Technology Works Manufactur3d. The process allows infinite design changes during product development without time delay helping the design engineers to get to their optimum design quickly and at the lowest cost. Some materials, like sand, require no additional processing. This makes binder jetting a good candidate for low to medium volume. 3dp binder jetting is capable of printing a variety of materials including ceramics. Depending on the application, some. Like sls, binder jetting uses a powder bin. A binder jetting 3d printer is normally composed of two tanks and a printing platform. 3dp binder jetting is an additive manufacturing process in which a liquid binding agent is selectively deposited to join powder particles. Take a tour of this unique technique to discover how it works after the printing process is finished, the parts are left covered in powder in order to provide the part or parts with structural support while they cure. In the first stage of the manufacturing process, a thin layer of powder is additive elements specially developed the material system ae12 for the binder jetting process. Binder jetting is an additive manufacturing process in which an industrial printhead selectively deposits a liquid binding agent onto a thin layer of currently, exone binder jet systems 3d print more than 20 types of sand, metal, ceramics and composites. At the beginning of the printing process, one of the tanks currently the main manufacturer of 3d printers that use binder jetting technology for ceramic materials continues to be 3d systems, using the term. This means that multiple parts can be printed easily during the printing process. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. However, parts are printed without heat so there is no differential cooling and therefore no warping.

The Complete Guide To Binder Jetting In 3d Printing 3dnatives : Binder Jetting, In Which A Liquid Binding Agent Is Deposited To Bind Powder Particles Together, Is An Effective Method Of 3D Printing Whose Benefits Only One Material Can Be Printed At A Time, And Hollow Parts Require Holes For The Excess Powder To Drain Out.

Guide To Metal 3d Printing Processes 3deo Metal Additive Manufacturing. Like sls, binder jetting uses a powder bin. In the first stage of the manufacturing process, a thin layer of powder is additive elements specially developed the material system ae12 for the binder jetting process. Take a tour of this unique technique to discover how it works after the printing process is finished, the parts are left covered in powder in order to provide the part or parts with structural support while they cure. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. This means that multiple parts can be printed easily during the printing process. Binder jetting is an additive manufacturing process in which an industrial printhead selectively deposits a liquid binding agent onto a thin layer of currently, exone binder jet systems 3d print more than 20 types of sand, metal, ceramics and composites. 3dp binder jetting is an additive manufacturing process in which a liquid binding agent is selectively deposited to join powder particles. This makes binder jetting a good candidate for low to medium volume. However, parts are printed without heat so there is no differential cooling and therefore no warping. At the beginning of the printing process, one of the tanks currently the main manufacturer of 3d printers that use binder jetting technology for ceramic materials continues to be 3d systems, using the term. Some materials, like sand, require no additional processing. 3dp binder jetting is capable of printing a variety of materials including ceramics. A binder jetting 3d printer is normally composed of two tanks and a printing platform. Depending on the application, some. The process allows infinite design changes during product development without time delay helping the design engineers to get to their optimum design quickly and at the lowest cost.

Exone Binder Jetting Technology . The Binder Is Deposited By A Moving Head.

Binder Jetting Bj Make. This means that multiple parts can be printed easily during the printing process. This makes binder jetting a good candidate for low to medium volume. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. At the beginning of the printing process, one of the tanks currently the main manufacturer of 3d printers that use binder jetting technology for ceramic materials continues to be 3d systems, using the term. In the first stage of the manufacturing process, a thin layer of powder is additive elements specially developed the material system ae12 for the binder jetting process. 3dp binder jetting is capable of printing a variety of materials including ceramics. The process allows infinite design changes during product development without time delay helping the design engineers to get to their optimum design quickly and at the lowest cost. Binder jetting is an additive manufacturing process in which an industrial printhead selectively deposits a liquid binding agent onto a thin layer of currently, exone binder jet systems 3d print more than 20 types of sand, metal, ceramics and composites. Some materials, like sand, require no additional processing. Like sls, binder jetting uses a powder bin. Take a tour of this unique technique to discover how it works after the printing process is finished, the parts are left covered in powder in order to provide the part or parts with structural support while they cure. Depending on the application, some. However, parts are printed without heat so there is no differential cooling and therefore no warping. A binder jetting 3d printer is normally composed of two tanks and a printing platform. 3dp binder jetting is an additive manufacturing process in which a liquid binding agent is selectively deposited to join powder particles.