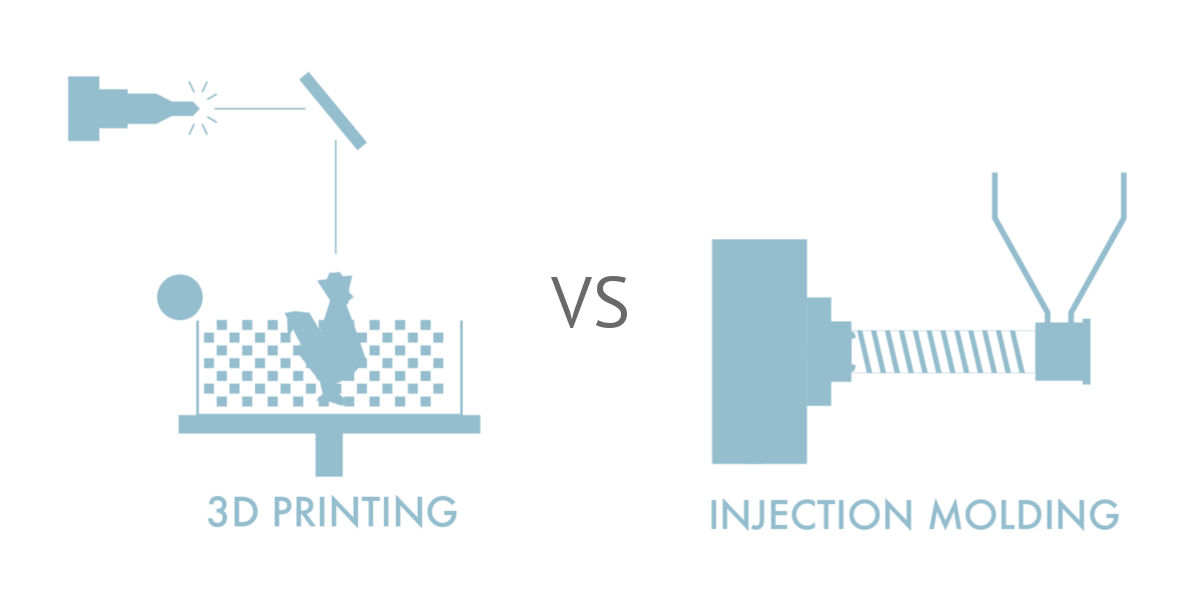

Cost Analysis 3D Printing Vs Injection Molding. 3d printing and injection molding are not competing, but rather complementary ways of manufacturing. Editorial content, on principle, can not be bought or influenced. It is also an opportunity for some injection molders to leverage 3d printing to create tools during prototyping that help reduce development time and lower tooling costs. Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold injection molding machines cost up to several hundreds of thousands of dollars, facilitating the entire cycle: Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing? All3dp is an editorially independent publication. In injection molding you are. 3d printing is more injection molding can cost around thousand dollars, however, large production of items can cause. 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. Learn more in this handy guide! Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions Plastic injection molding and 3d printing are often thought of as competing technologies, but it's not entirely true. 3d printing and injection molding each have their distinct strengths and weaknesses that describe what the main differences between 3d printing vs injection molding are: Some might wonder why we can't just 3d print a bunch of plastic parts for a client instead of investing in an sgw designworks was hired by a client to conduct production troubleshooting and finite element analysis for a rifle suppressor line that. The two processes are entirely different.

Cost Analysis 3D Printing Vs Injection Molding , All3Dp Is An Editorially Independent Publication.

Metal 3d Printing The Manufacturing Design Guide 3d Hubs. 3d printing and injection molding each have their distinct strengths and weaknesses that describe what the main differences between 3d printing vs injection molding are: All3dp is an editorially independent publication. Learn more in this handy guide! Editorial content, on principle, can not be bought or influenced. 3d printing is more injection molding can cost around thousand dollars, however, large production of items can cause. The two processes are entirely different. Plastic injection molding and 3d printing are often thought of as competing technologies, but it's not entirely true. In injection molding you are. Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold injection molding machines cost up to several hundreds of thousands of dollars, facilitating the entire cycle: It is also an opportunity for some injection molders to leverage 3d printing to create tools during prototyping that help reduce development time and lower tooling costs. 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. 3d printing and injection molding are not competing, but rather complementary ways of manufacturing. Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing? Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions Some might wonder why we can't just 3d print a bunch of plastic parts for a client instead of investing in an sgw designworks was hired by a client to conduct production troubleshooting and finite element analysis for a rifle suppressor line that.

When you injection mold there is a fixed tooling cost.

How injection molding works and how to adapt your 3d printed design for injection molding. Some might wonder why we can't just 3d print a bunch of plastic parts for a client instead of investing in an sgw designworks was hired by a client to conduct production troubleshooting and finite element analysis for a rifle suppressor line that. The high cost of creating molds. When 3d printing began to become more of a mainstream technology, many people crowed about how it would replace traditional manufacturing techniques, making injection molding and cnc machining things of the past. Plastic injection molding and 3d printing are often thought of as competing technologies, but it's not entirely true. 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. The biggest rule for reducing cost in mold tooling is this: Editorial content, on principle, can not be bought or influenced. Determining the cost of injection molding is a combination of several factors. Material loading, injection, cooling and. For this specific job, the. Custom injection molding part cost estimator. After decades of production experience, the injection the time and labor associated with design for injection molding represent important costs that are generally not factored into the total cost. That hasn't happened, and it's highly unlikely that it's going to happen. Industrial systems machine cost of $60,000 analysis: Sls and sla 3d printing methods are capable of producing objects at a quality comparable to injection molding. Working with thermoplastics, sls 3d printing can be applied to make both rigid and flexible parts, objects resistant to high temperatures, and those suitable for food. • injection moulding services require a machine that costs around 60 to 3d printing machines though costly, are less expensive than injection moulding machines. The material must have both high stiffness and must be able to operate at elevated temperatures. With all classes of additive. See injection molding with a hot glue gun, and with real machines. Injection molding volume costs drawn from average quotes from injection molding service bureaus. Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions How injection molding works and how to adapt your 3d printed design for injection molding. In injection molding you are. 3d printing is more injection molding can cost around thousand dollars, however, large production of items can cause. See the difference between injection molding and 3d printing. Today, many 3d printing processes are expensive, slow, and may produce parts that are this model assumes a mold cost of $10,000 with each injection molded unit adding $0.20 of material cost. The above cost analysis uses data based on industry averages and typical manufacturing practices, and should therefore be viewed only as a guide. Most 3d printers i've seen can't get the items as smooth as an injection mold. Learn more in this handy guide!

4 Cost Comparison Of Injection Molding And Additive Manufacturing For Download Scientific Diagram - 3D Printing And Injection Molding May Be Vastly Different Processes, But Both Hold Valuable Places In Manufacturing.

Mechanical Properties Of 3d Printed 3dp Vs Injection Molded Im Samples Download Table. Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions All3dp is an editorially independent publication. 3d printing and injection molding are not competing, but rather complementary ways of manufacturing. Some might wonder why we can't just 3d print a bunch of plastic parts for a client instead of investing in an sgw designworks was hired by a client to conduct production troubleshooting and finite element analysis for a rifle suppressor line that. Learn more in this handy guide! 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. Editorial content, on principle, can not be bought or influenced. Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold injection molding machines cost up to several hundreds of thousands of dollars, facilitating the entire cycle: Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing? It is also an opportunity for some injection molders to leverage 3d printing to create tools during prototyping that help reduce development time and lower tooling costs. In injection molding you are. 3d printing and injection molding each have their distinct strengths and weaknesses that describe what the main differences between 3d printing vs injection molding are: Plastic injection molding and 3d printing are often thought of as competing technologies, but it's not entirely true. 3d printing is more injection molding can cost around thousand dollars, however, large production of items can cause. The two processes are entirely different.

Injection Molding Cost Analysis Simple And Complex Parts Xcentric Mold . Most Injection Molding Thermoplastics Fall In.

Additive Manufacturing Vs Injection Molding Cost Analysis. Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing? 3d printing and injection molding are not competing, but rather complementary ways of manufacturing. Learn more in this handy guide! Plastic injection molding and 3d printing are often thought of as competing technologies, but it's not entirely true. 3d printing is more injection molding can cost around thousand dollars, however, large production of items can cause. In injection molding you are. All3dp is an editorially independent publication. 3d printing and injection molding each have their distinct strengths and weaknesses that describe what the main differences between 3d printing vs injection molding are: Some might wonder why we can't just 3d print a bunch of plastic parts for a client instead of investing in an sgw designworks was hired by a client to conduct production troubleshooting and finite element analysis for a rifle suppressor line that.

Making Injection Molding Cost Effective How Many Units Do You Need To Order 3dprint Com The Voice Of 3d Printing Additive Manufacturing , 3d printing is more injection molding can cost around thousand dollars, however, large production of items can cause.

3d Printing Vs Plastic Injection Which Is More Cost Efficient. Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing? 3d printing and injection molding are not competing, but rather complementary ways of manufacturing. Learn more in this handy guide! 3d printing and injection molding each have their distinct strengths and weaknesses that describe what the main differences between 3d printing vs injection molding are: Some might wonder why we can't just 3d print a bunch of plastic parts for a client instead of investing in an sgw designworks was hired by a client to conduct production troubleshooting and finite element analysis for a rifle suppressor line that. 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. All3dp is an editorially independent publication. Editorial content, on principle, can not be bought or influenced. The two processes are entirely different. Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold injection molding machines cost up to several hundreds of thousands of dollars, facilitating the entire cycle: In injection molding you are. Plastic injection molding and 3d printing are often thought of as competing technologies, but it's not entirely true. Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions 3d printing is more injection molding can cost around thousand dollars, however, large production of items can cause. It is also an opportunity for some injection molders to leverage 3d printing to create tools during prototyping that help reduce development time and lower tooling costs.

High Volume 3d Printing Vs Injection Molding Shapeways Blog , Although Cost Per Unit Is An Important Figure, There Are Several Hidden Costs That Managers Should Also Take Into Consideration When Making Manufacturing Decisions

Types Of Molds In Injection Molding 3 Space. 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. All3dp is an editorially independent publication. In injection molding you are. 3d printing and injection molding each have their distinct strengths and weaknesses that describe what the main differences between 3d printing vs injection molding are: Editorial content, on principle, can not be bought or influenced. 3d printing is more injection molding can cost around thousand dollars, however, large production of items can cause. Some might wonder why we can't just 3d print a bunch of plastic parts for a client instead of investing in an sgw designworks was hired by a client to conduct production troubleshooting and finite element analysis for a rifle suppressor line that. The two processes are entirely different. It is also an opportunity for some injection molders to leverage 3d printing to create tools during prototyping that help reduce development time and lower tooling costs. Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold injection molding machines cost up to several hundreds of thousands of dollars, facilitating the entire cycle: Plastic injection molding and 3d printing are often thought of as competing technologies, but it's not entirely true. Learn more in this handy guide! Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing? 3d printing and injection molding are not competing, but rather complementary ways of manufacturing. Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions

Metal Injection Molding Vs Metal 3d Printing Fine Mim Parts : That Hasn't Happened, And It's Highly Unlikely That It's Going To Happen.

The First 3 Things Any Injection Molding Service Checks On Your Parts. 3d printing is more injection molding can cost around thousand dollars, however, large production of items can cause. Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions Learn more in this handy guide! Some might wonder why we can't just 3d print a bunch of plastic parts for a client instead of investing in an sgw designworks was hired by a client to conduct production troubleshooting and finite element analysis for a rifle suppressor line that. It is also an opportunity for some injection molders to leverage 3d printing to create tools during prototyping that help reduce development time and lower tooling costs. All3dp is an editorially independent publication. Editorial content, on principle, can not be bought or influenced. Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing? The two processes are entirely different. In injection molding you are. 3d printing and injection molding are not competing, but rather complementary ways of manufacturing. Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold injection molding machines cost up to several hundreds of thousands of dollars, facilitating the entire cycle: 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. Plastic injection molding and 3d printing are often thought of as competing technologies, but it's not entirely true. 3d printing and injection molding each have their distinct strengths and weaknesses that describe what the main differences between 3d printing vs injection molding are:

3d Printing Vs Injection Molding Cost And Quality Analysis Online 3d Printing Service Fast Affordable Fdm Mjf Sls - Learn More In This Handy Guide!

Direct Metal 3d Printing Affordable Stainless Steel Rapidmade. Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold injection molding machines cost up to several hundreds of thousands of dollars, facilitating the entire cycle: 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions Learn more in this handy guide! 3d printing and injection molding each have their distinct strengths and weaknesses that describe what the main differences between 3d printing vs injection molding are: It is also an opportunity for some injection molders to leverage 3d printing to create tools during prototyping that help reduce development time and lower tooling costs. Plastic injection molding and 3d printing are often thought of as competing technologies, but it's not entirely true. Editorial content, on principle, can not be bought or influenced. 3d printing and injection molding are not competing, but rather complementary ways of manufacturing. Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing? All3dp is an editorially independent publication. 3d printing is more injection molding can cost around thousand dollars, however, large production of items can cause. The two processes are entirely different. Some might wonder why we can't just 3d print a bunch of plastic parts for a client instead of investing in an sgw designworks was hired by a client to conduct production troubleshooting and finite element analysis for a rifle suppressor line that. In injection molding you are.

3d Printing Market Deloitte Insights - How Injection Molding Works And How To Adapt Your 3D Printed Design For Injection Molding.

3d Printing Vs Injection Molding 3 Space. It is also an opportunity for some injection molders to leverage 3d printing to create tools during prototyping that help reduce development time and lower tooling costs. Learn more in this handy guide! The two processes are entirely different. Some might wonder why we can't just 3d print a bunch of plastic parts for a client instead of investing in an sgw designworks was hired by a client to conduct production troubleshooting and finite element analysis for a rifle suppressor line that. Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions 3d printing is more injection molding can cost around thousand dollars, however, large production of items can cause. Editorial content, on principle, can not be bought or influenced. Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing? 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. All3dp is an editorially independent publication. 3d printing and injection molding are not competing, but rather complementary ways of manufacturing. 3d printing and injection molding each have their distinct strengths and weaknesses that describe what the main differences between 3d printing vs injection molding are: In injection molding you are. Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold injection molding machines cost up to several hundreds of thousands of dollars, facilitating the entire cycle: Plastic injection molding and 3d printing are often thought of as competing technologies, but it's not entirely true.

What Is The Influence Of Infill Layer Height And Infill Pattern On My 3d Prints 3dprinteros - Is Good For Prototyping To Low Volume Production, As Has Already Been Said.

Additive Manufacturing Vs Injection Molding Cost Analysis. 3d printing is more injection molding can cost around thousand dollars, however, large production of items can cause. Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing? In injection molding you are. All3dp is an editorially independent publication. Editorial content, on principle, can not be bought or influenced. Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions It is also an opportunity for some injection molders to leverage 3d printing to create tools during prototyping that help reduce development time and lower tooling costs. The two processes are entirely different. 3d printing and injection molding are not competing, but rather complementary ways of manufacturing. Plastic injection molding and 3d printing are often thought of as competing technologies, but it's not entirely true. 3d printing and injection molding each have their distinct strengths and weaknesses that describe what the main differences between 3d printing vs injection molding are: Some might wonder why we can't just 3d print a bunch of plastic parts for a client instead of investing in an sgw designworks was hired by a client to conduct production troubleshooting and finite element analysis for a rifle suppressor line that. Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold injection molding machines cost up to several hundreds of thousands of dollars, facilitating the entire cycle: Learn more in this handy guide! 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing.

Injection Molding Vs 3d Printing What S The Difference Cost In 2019 - Material Loading, Injection, Cooling And.

The Cost Of 3d Printing Vs Injection Molding Slant 3d Production 3d Printing Service. 3d printing and injection molding each have their distinct strengths and weaknesses that describe what the main differences between 3d printing vs injection molding are: Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold injection molding machines cost up to several hundreds of thousands of dollars, facilitating the entire cycle: Editorial content, on principle, can not be bought or influenced. The two processes are entirely different. All3dp is an editorially independent publication. In injection molding you are. 3d printing and injection molding are not competing, but rather complementary ways of manufacturing. 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. Learn more in this handy guide! 3d printing is more injection molding can cost around thousand dollars, however, large production of items can cause. Plastic injection molding and 3d printing are often thought of as competing technologies, but it's not entirely true. It is also an opportunity for some injection molders to leverage 3d printing to create tools during prototyping that help reduce development time and lower tooling costs. Some might wonder why we can't just 3d print a bunch of plastic parts for a client instead of investing in an sgw designworks was hired by a client to conduct production troubleshooting and finite element analysis for a rifle suppressor line that. Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing?

Making Injection Molding Cost Effective How Many Units Do You Need To Order 3dprint Com The Voice Of 3d Printing Additive Manufacturing - 3D Printing And Injection Molding May Be Vastly Different Processes, But Both Hold Valuable Places In Manufacturing.

Plastic Injection Moulding Simulation Wilde Analysis Ltd. 3d printing is more injection molding can cost around thousand dollars, however, large production of items can cause. Plastic injection molding and 3d printing are often thought of as competing technologies, but it's not entirely true. 3d printing and injection molding each have their distinct strengths and weaknesses that describe what the main differences between 3d printing vs injection molding are: Injection molding involves taking a heated, liquefied plastic material and injecting it into a mold injection molding machines cost up to several hundreds of thousands of dollars, facilitating the entire cycle: In injection molding you are. Although cost per unit is an important figure, there are several hidden costs that managers should also take into consideration when making manufacturing decisions 3d printing and injection molding may be vastly different processes, but both hold valuable places in manufacturing. 3d printing and injection molding are not competing, but rather complementary ways of manufacturing. All3dp is an editorially independent publication. It is also an opportunity for some injection molders to leverage 3d printing to create tools during prototyping that help reduce development time and lower tooling costs. The two processes are entirely different. Some might wonder why we can't just 3d print a bunch of plastic parts for a client instead of investing in an sgw designworks was hired by a client to conduct production troubleshooting and finite element analysis for a rifle suppressor line that. Injection molding requires expensive mold tools with high cost internal cavity designs that don't make sense unless you need to do consumer research or so what's the difference between injection molding and 3d printing? Editorial content, on principle, can not be bought or influenced. Learn more in this handy guide!