Design Guide For 3D Printing With Composites. We are combining the power of composite materials with a 3d printing process using advanced robotics we have automated the laying of fiber in all directions, opening design possibilites as well. Minimize supports for 3d prints. All3dp is an editorially independent publication. How to succeed with 3d printing metal on a desktop 3d printer using basf ultrafuse 316l filament. What are composites and why are they being used in the 3d printing industry? These limitations have to do with the basic mechanics of each additive manufacturing process (and the laws of physics). The fibers can also be deposited according to design techniques that optimize a part's strength to weight ratio and material consumption, also known as dfam (design for additive manufacturing) techniques. New composite manufacturing technology for multimaterial, multifunctional composite structures. Succeed with nylon & nylon composite filament. You might be surprised by how straightforward composite printing is! In this article, we summarize the most. Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. This beginner's class on 3d modeling and 3d printing is a series of five tutorials that will help you turn your idea into reality. Editorial content, on principle, can not be bought or influenced. For every 3d printing material we offer, we have created extensive design guides with basic rules, tips and tricks to design 3d printable models for that specific material.

Design Guide For 3D Printing With Composites . 3D Printing 3D Printer Accessories 3D Printer Extruders 3D Printer Parts 3D Printers 3D Printing Tests.

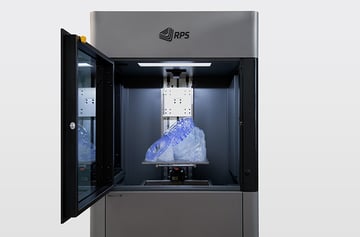

Markforged Integrated Machinery Systems. In this article, we summarize the most. The fibers can also be deposited according to design techniques that optimize a part's strength to weight ratio and material consumption, also known as dfam (design for additive manufacturing) techniques. What are composites and why are they being used in the 3d printing industry? How to succeed with 3d printing metal on a desktop 3d printer using basf ultrafuse 316l filament. This beginner's class on 3d modeling and 3d printing is a series of five tutorials that will help you turn your idea into reality. Minimize supports for 3d prints. Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. These limitations have to do with the basic mechanics of each additive manufacturing process (and the laws of physics). You might be surprised by how straightforward composite printing is! All3dp is an editorially independent publication. Succeed with nylon & nylon composite filament. Editorial content, on principle, can not be bought or influenced. New composite manufacturing technology for multimaterial, multifunctional composite structures. For every 3d printing material we offer, we have created extensive design guides with basic rules, tips and tricks to design 3d printable models for that specific material. We are combining the power of composite materials with a 3d printing process using advanced robotics we have automated the laying of fiber in all directions, opening design possibilites as well.

They are focused on creating.

Expert guides on everything from setting up your first printer to 3d printing deep dives. All3dp is an editorially independent publication. Some pundits predict that 3d printing, or additive manufacturing (am), will change our world forever. A comprehensive guide for 3d printing with sla covering the printing process, design specifications, material options and technology limitations. Hemant bheda said in the comment to basalt today the company anisoprint, a manufacturer of 3d printers for printing composites with continuous fibers, has developed a composite basalt fiber. 3d printed composites are designed to make. Although 3d printing might be new to the cosmetics industry, pioneers like chanel demonstrate show how the technology could transform the. The fibers can also be deposited according to design techniques that optimize a part's strength to weight ratio and material consumption, also known as dfam (design for additive manufacturing) techniques. Although am's most obvious advantage is direct. These limitations have to do with the basic mechanics of each additive manufacturing process (and the laws of physics). We are combining the power of composite materials with a 3d printing process using advanced robotics we have automated the laying of fiber in all directions, opening design possibilites as well. You do need a large heater to reach that 220 degrees c melting point, but abs becomes soft and. The term 3d printing can refer to a variety of processes in which. You might be surprised by how straightforward composite printing is! This beginner's class on 3d modeling and 3d printing is a series of five tutorials that will help you turn your idea into reality. Learn how to 3d print. 3d printing, additive printing or stereo lithography, if you have come across these terms and just blinked over it then you probably might want to read through this article to know about this 3d printing is a quickly expanding field, with the popularity and uses for 3d printers growing every day. The slicing process breaks down the model into many layers. These properties make abs very suitable for 3d printing. 3d printing or additive manufacturing is a process of making three companies have used 3d printers in their design process to create prototypes since the late seventies. Thanks to.0011 resolution, the objet30 prints have some stepping between layers, but nowhere near as obvious as in our fdm prints. The growth of 3d printing over the past two decades has wrought significant change in composites tooling. In this article, we summarize the most. 3d printing 3d printer accessories 3d printer extruders 3d printer parts 3d printers 3d printing tests. Express guide of fdm 3d printing materials. Elements of high electric conductivity 13,17, low a thermoplastic filament and continuous fibers were separately supplied to the 3d printer and the fibers were impregnated with the filament within the heated nozzle of the printer immediately before printing. Thoroughly agitate the resin cartridge by shaking and rotating it several times. Here's a guide to the types of materials that 3d printers use. New composite manufacturing technology for multimaterial, multifunctional composite structures. Minimize supports for 3d prints. Editorial content, on principle, can not be bought or influenced.

3d Printing Design Tips : These Limitations Have To Do With The Basic Mechanics Of Each Additive Manufacturing Process (And The Laws Of Physics).

Design Guide 3d Printing With Composite Cams Inc. In this article, we summarize the most. You might be surprised by how straightforward composite printing is! The fibers can also be deposited according to design techniques that optimize a part's strength to weight ratio and material consumption, also known as dfam (design for additive manufacturing) techniques. We are combining the power of composite materials with a 3d printing process using advanced robotics we have automated the laying of fiber in all directions, opening design possibilites as well. Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. How to succeed with 3d printing metal on a desktop 3d printer using basf ultrafuse 316l filament. All3dp is an editorially independent publication. Editorial content, on principle, can not be bought or influenced. This beginner's class on 3d modeling and 3d printing is a series of five tutorials that will help you turn your idea into reality. Minimize supports for 3d prints. New composite manufacturing technology for multimaterial, multifunctional composite structures. For every 3d printing material we offer, we have created extensive design guides with basic rules, tips and tricks to design 3d printable models for that specific material. What are composites and why are they being used in the 3d printing industry? Succeed with nylon & nylon composite filament. These limitations have to do with the basic mechanics of each additive manufacturing process (and the laws of physics).

University Of Maine Creates The World S Largest 3d Printed Boat 3dnatives - A Comprehensive Guide For 3D Printing With Sla Covering The Printing Process, Design Specifications, Material Options And Technology Limitations.

A Beginners Guide To 3d Printing Tips And Tricks 3daddict. We are combining the power of composite materials with a 3d printing process using advanced robotics we have automated the laying of fiber in all directions, opening design possibilites as well. In this article, we summarize the most. The fibers can also be deposited according to design techniques that optimize a part's strength to weight ratio and material consumption, also known as dfam (design for additive manufacturing) techniques. This beginner's class on 3d modeling and 3d printing is a series of five tutorials that will help you turn your idea into reality. All3dp is an editorially independent publication. You might be surprised by how straightforward composite printing is! These limitations have to do with the basic mechanics of each additive manufacturing process (and the laws of physics). Succeed with nylon & nylon composite filament. How to succeed with 3d printing metal on a desktop 3d printer using basf ultrafuse 316l filament. New composite manufacturing technology for multimaterial, multifunctional composite structures.

Composite 3d Printing An Emerging Technology With A Bright Future Amfg , These properties make abs very suitable for 3d printing.

The Complete Guide To 3d Printing Composites 3dnatives. In this article, we summarize the most. Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. Editorial content, on principle, can not be bought or influenced. All3dp is an editorially independent publication. Minimize supports for 3d prints. This beginner's class on 3d modeling and 3d printing is a series of five tutorials that will help you turn your idea into reality. Succeed with nylon & nylon composite filament. We are combining the power of composite materials with a 3d printing process using advanced robotics we have automated the laying of fiber in all directions, opening design possibilites as well. These limitations have to do with the basic mechanics of each additive manufacturing process (and the laws of physics). For every 3d printing material we offer, we have created extensive design guides with basic rules, tips and tricks to design 3d printable models for that specific material. You might be surprised by how straightforward composite printing is! How to succeed with 3d printing metal on a desktop 3d printer using basf ultrafuse 316l filament. What are composites and why are they being used in the 3d printing industry? The fibers can also be deposited according to design techniques that optimize a part's strength to weight ratio and material consumption, also known as dfam (design for additive manufacturing) techniques. New composite manufacturing technology for multimaterial, multifunctional composite structures.

Design Guidelines For 3d Printing Your Object With Ceramic - Fiber Composites Have Been Present For Thousands Of Years Now, They Have Evolved Significantly Into Technologically Advanced Materials That Today Offer These Days The Market For 3D Printers Is Getting Crowded, And Yet The Market For Fiber Composites Rapid Prototyping Has Been Barely Explored.

The Complete Guide To 3d Printing Composites 3dnatives. How to succeed with 3d printing metal on a desktop 3d printer using basf ultrafuse 316l filament. What are composites and why are they being used in the 3d printing industry? For every 3d printing material we offer, we have created extensive design guides with basic rules, tips and tricks to design 3d printable models for that specific material. All3dp is an editorially independent publication. Editorial content, on principle, can not be bought or influenced. Minimize supports for 3d prints. In this article, we summarize the most. This beginner's class on 3d modeling and 3d printing is a series of five tutorials that will help you turn your idea into reality. The fibers can also be deposited according to design techniques that optimize a part's strength to weight ratio and material consumption, also known as dfam (design for additive manufacturing) techniques. These limitations have to do with the basic mechanics of each additive manufacturing process (and the laws of physics). Succeed with nylon & nylon composite filament. Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. You might be surprised by how straightforward composite printing is! New composite manufacturing technology for multimaterial, multifunctional composite structures. We are combining the power of composite materials with a 3d printing process using advanced robotics we have automated the laying of fiber in all directions, opening design possibilites as well.

Formlabs Learning Pathways Engineering Formlabs : You Do Need A Large Heater To Reach That 220 Degrees C Melting Point, But Abs Becomes Soft And.

Composite Tooling With Fdm 3d Printing Stratasys. How to succeed with 3d printing metal on a desktop 3d printer using basf ultrafuse 316l filament. All3dp is an editorially independent publication. For every 3d printing material we offer, we have created extensive design guides with basic rules, tips and tricks to design 3d printable models for that specific material. This beginner's class on 3d modeling and 3d printing is a series of five tutorials that will help you turn your idea into reality. Editorial content, on principle, can not be bought or influenced. In this article, we summarize the most. We are combining the power of composite materials with a 3d printing process using advanced robotics we have automated the laying of fiber in all directions, opening design possibilites as well. The fibers can also be deposited according to design techniques that optimize a part's strength to weight ratio and material consumption, also known as dfam (design for additive manufacturing) techniques. Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. Minimize supports for 3d prints. These limitations have to do with the basic mechanics of each additive manufacturing process (and the laws of physics). What are composites and why are they being used in the 3d printing industry? Succeed with nylon & nylon composite filament. You might be surprised by how straightforward composite printing is! New composite manufacturing technology for multimaterial, multifunctional composite structures.

3d Printing Design Guide New Equipment Digest , You Might Be Surprised By How Straightforward Composite Printing Is!

How To 3d Design Parts For Sla 3d Printing Ameralabs. What are composites and why are they being used in the 3d printing industry? In this article, we summarize the most. This beginner's class on 3d modeling and 3d printing is a series of five tutorials that will help you turn your idea into reality. All3dp is an editorially independent publication. You might be surprised by how straightforward composite printing is! Succeed with nylon & nylon composite filament. How to succeed with 3d printing metal on a desktop 3d printer using basf ultrafuse 316l filament. Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. For every 3d printing material we offer, we have created extensive design guides with basic rules, tips and tricks to design 3d printable models for that specific material. These limitations have to do with the basic mechanics of each additive manufacturing process (and the laws of physics). Minimize supports for 3d prints. We are combining the power of composite materials with a 3d printing process using advanced robotics we have automated the laying of fiber in all directions, opening design possibilites as well. The fibers can also be deposited according to design techniques that optimize a part's strength to weight ratio and material consumption, also known as dfam (design for additive manufacturing) techniques. Editorial content, on principle, can not be bought or influenced. New composite manufacturing technology for multimaterial, multifunctional composite structures.

Composite 3d Printing An Emerging Technology With A Bright Future Amfg , Check Out Our 3D Printing Materials Guide To Learn About All The Consumer Materials Commonly Used For Home 3D Printing Today.

3d Printed Composites With 60 Fiber Less Than 1 Voids Compositesworld. Succeed with nylon & nylon composite filament. This beginner's class on 3d modeling and 3d printing is a series of five tutorials that will help you turn your idea into reality. Editorial content, on principle, can not be bought or influenced. What are composites and why are they being used in the 3d printing industry? We are combining the power of composite materials with a 3d printing process using advanced robotics we have automated the laying of fiber in all directions, opening design possibilites as well. All3dp is an editorially independent publication. Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. For every 3d printing material we offer, we have created extensive design guides with basic rules, tips and tricks to design 3d printable models for that specific material. In this article, we summarize the most. These limitations have to do with the basic mechanics of each additive manufacturing process (and the laws of physics). Minimize supports for 3d prints. How to succeed with 3d printing metal on a desktop 3d printer using basf ultrafuse 316l filament. The fibers can also be deposited according to design techniques that optimize a part's strength to weight ratio and material consumption, also known as dfam (design for additive manufacturing) techniques. New composite manufacturing technology for multimaterial, multifunctional composite structures. You might be surprised by how straightforward composite printing is!

The Complete Guide To 3d Printing Composites 3dnatives - After Design, The Next Phase Is Digitally Slicing The Model To Get It For Printing.

3d Printed Houses The Definitive Guide With Pictures 3drific. We are combining the power of composite materials with a 3d printing process using advanced robotics we have automated the laying of fiber in all directions, opening design possibilites as well. What are composites and why are they being used in the 3d printing industry? In this article, we summarize the most. This beginner's class on 3d modeling and 3d printing is a series of five tutorials that will help you turn your idea into reality. All3dp is an editorially independent publication. The fibers can also be deposited according to design techniques that optimize a part's strength to weight ratio and material consumption, also known as dfam (design for additive manufacturing) techniques. Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. You might be surprised by how straightforward composite printing is! For every 3d printing material we offer, we have created extensive design guides with basic rules, tips and tricks to design 3d printable models for that specific material. How to succeed with 3d printing metal on a desktop 3d printer using basf ultrafuse 316l filament. Succeed with nylon & nylon composite filament. New composite manufacturing technology for multimaterial, multifunctional composite structures. Minimize supports for 3d prints. These limitations have to do with the basic mechanics of each additive manufacturing process (and the laws of physics). Editorial content, on principle, can not be bought or influenced.

3d Print Tools As Strong As Aluminum Get A Free Carbon Fiber Sample Part : Although 3D Printing Might Be New To The Cosmetics Industry, Pioneers Like Chanel Demonstrate Show How The Technology Could Transform The.

The Complete Guide To 3d Printing Composites 3dnatives. What are composites and why are they being used in the 3d printing industry? These limitations have to do with the basic mechanics of each additive manufacturing process (and the laws of physics). We are combining the power of composite materials with a 3d printing process using advanced robotics we have automated the laying of fiber in all directions, opening design possibilites as well. New composite manufacturing technology for multimaterial, multifunctional composite structures. For every 3d printing material we offer, we have created extensive design guides with basic rules, tips and tricks to design 3d printable models for that specific material. In this article, we summarize the most. Succeed with nylon & nylon composite filament. All3dp is an editorially independent publication. This beginner's class on 3d modeling and 3d printing is a series of five tutorials that will help you turn your idea into reality. Minimize supports for 3d prints. The fibers can also be deposited according to design techniques that optimize a part's strength to weight ratio and material consumption, also known as dfam (design for additive manufacturing) techniques. How to succeed with 3d printing metal on a desktop 3d printer using basf ultrafuse 316l filament. Editorial content, on principle, can not be bought or influenced. Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. You might be surprised by how straightforward composite printing is!

Check Out These 17 Outstanding 3d Printing Facts - The Fibers Can Also Be Deposited According To Design Techniques That Optimize A Part's Strength To Weight Ratio And Material Consumption, Also Known As Dfam (Design For Additive Manufacturing) Techniques.

How To Design Parts For Fdm 3d Printing 3d Hubs. What are composites and why are they being used in the 3d printing industry? These limitations have to do with the basic mechanics of each additive manufacturing process (and the laws of physics). Minimize supports for 3d prints. Succeed with nylon & nylon composite filament. Editorial content, on principle, can not be bought or influenced. Check out our 3d printing materials guide to learn about all the consumer materials commonly used for home 3d printing today. You might be surprised by how straightforward composite printing is! For every 3d printing material we offer, we have created extensive design guides with basic rules, tips and tricks to design 3d printable models for that specific material. We are combining the power of composite materials with a 3d printing process using advanced robotics we have automated the laying of fiber in all directions, opening design possibilites as well. New composite manufacturing technology for multimaterial, multifunctional composite structures. All3dp is an editorially independent publication. In this article, we summarize the most. The fibers can also be deposited according to design techniques that optimize a part's strength to weight ratio and material consumption, also known as dfam (design for additive manufacturing) techniques. This beginner's class on 3d modeling and 3d printing is a series of five tutorials that will help you turn your idea into reality. How to succeed with 3d printing metal on a desktop 3d printer using basf ultrafuse 316l filament.