Fdm 3D Printing Applications. Fdm is the most widely used 3d printing technology: Applications fdm vs sla vs sls 0:55 dimensions & tolerances 2:03 material properties 3:55 visual characteristics #applications #fdm. Another downside of the layers in fdm printing is that they create and inherent weak point in the print where each layer is joined, making prints less sturdy and unsuitable for certain applications. These 3d printing processes are the same, but we will use fdm in this article. Fdm 3d printing technology builds durable and functional prototypes that can withstand rigorous testing. Fused filament fabrication (fff), also known under the trademarked term fused deposition modeling (fdm), sometimes also called filament freeform fabrication. Fused deposition modeling is sometimes called fused filament fabrication, or fff. Welcome to fdm 3d printing. The fact that it can be 3d printed on an. Fdm technology uses thermoplastics found in traditional manufacturing processes and are ideal for applications that demand tight tolerances, toughness, and environmental stability. We 3d print and design plastic parts for every application within our possibilities. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. 0:01 choose your 3d printer: 4 001 просмотр 4 тыс. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods.

Fdm 3D Printing Applications , Fdm Technology Uses Thermoplastics Found In Traditional Manufacturing Processes And Are Ideal For Applications That Demand Tight Tolerances, Toughness, And Environmental Stability.

The State Of 3d Printing 2018. Another downside of the layers in fdm printing is that they create and inherent weak point in the print where each layer is joined, making prints less sturdy and unsuitable for certain applications. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Welcome to fdm 3d printing. Fused deposition modeling is sometimes called fused filament fabrication, or fff. 0:01 choose your 3d printer: Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. Fdm is the most widely used 3d printing technology: Fdm technology uses thermoplastics found in traditional manufacturing processes and are ideal for applications that demand tight tolerances, toughness, and environmental stability. The fact that it can be 3d printed on an. Applications fdm vs sla vs sls 0:55 dimensions & tolerances 2:03 material properties 3:55 visual characteristics #applications #fdm. Fused filament fabrication (fff), also known under the trademarked term fused deposition modeling (fdm), sometimes also called filament freeform fabrication. These 3d printing processes are the same, but we will use fdm in this article. 4 001 просмотр 4 тыс. Fdm 3d printing technology builds durable and functional prototypes that can withstand rigorous testing. We 3d print and design plastic parts for every application within our possibilities.

We 3d print and design plastic parts for every application within our possibilities.

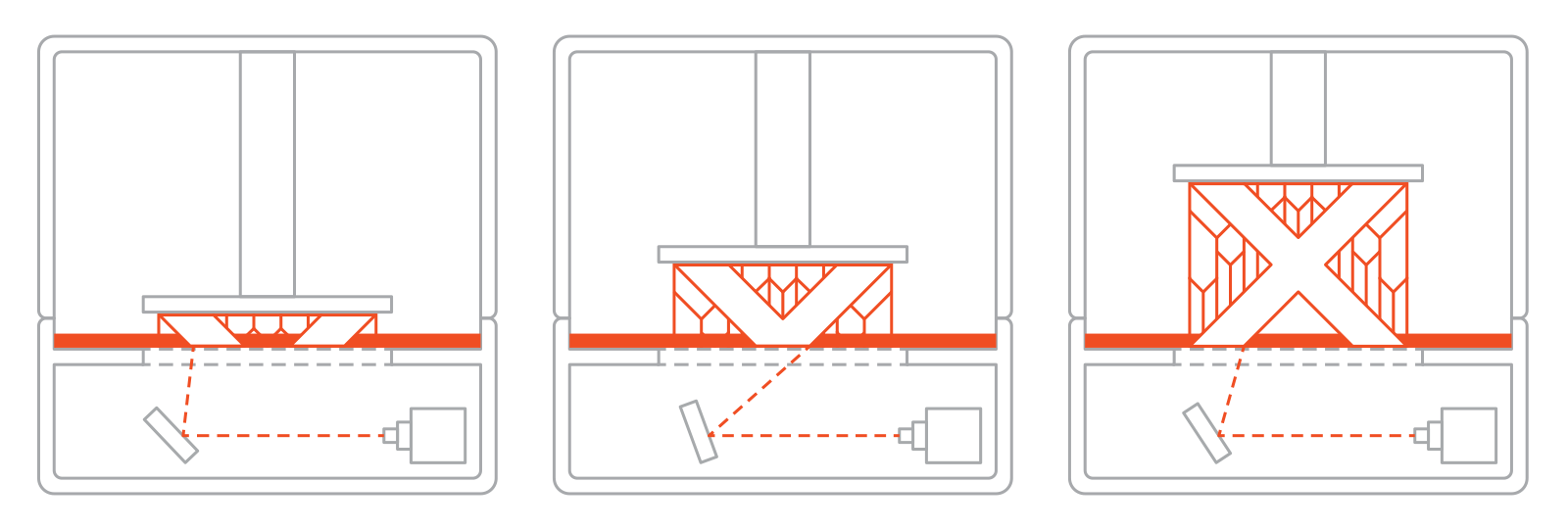

Fdm printers are equipped with a nozzle (or nozzles) that melt and. Fused filament fabrication (fff), also known under the trademarked term fused deposition modeling (fdm), sometimes also called filament freeform fabrication. .(fdm) 3d printing technology through the power of a very flexible modeling workflow in. Jgaurora 3d desktop fdm printer, alunar high resolution desktop fdm 3d printer, original prusa i3 mk2 at the time of writing, some applications of bj 3d printing include rapid prototyping, and various uses in the aerospace, automotive, and medical industries. International congress on 3d printing (additive manufacturing) technologies and digital industry. Rapid prototyping (rp) is a group of 3d printing techniques aiming design verification, visualization, and kinematic functionality testing, which. 3d printing applications cover various sectors from education to industry, and the whole value chain from prototypes to spare part management. We 3d print and design plastic parts for every application within our possibilities. Robotic arms are most commonly known for assembling components on industrial production lines, especially in large automotive plants. These 3d printing processes are the same, but we will use fdm in this article. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Fdm printers are equipped with a nozzle (or nozzles) that melt and. In recent years, 3d printing has developed significantly and can now perform crucial roles in many applications, with the most important being manufacturing, medicine, architecture, custom art and design. The fact that it can be 3d printed on an. Learn how to 3d print. Fdm printers use a thermoplastic filament, which is heated to its melting point and then extruded, layer by layer, to create a three dimensional object. \ plm product as application engineer in several companies, matteo crocetti joined autodesk in 2013 as a technical sales emea focused on 0:01 choose your 3d printer: Fdm, also known as fff (fused filament fabrication), can build just about any geometry you have in ideal applications for fdm. How fdm printers produce objects? Fdm printers tend to be very affordable, relatively easy to operate, and their materials are widely available. While prototyping currently remains the main application of 3d printing in the automotive industry, companies are increasingly finding other use. Fdm is the most widely used 3d printing technology: Fdm 3d printing technology builds durable and functional prototypes that can withstand rigorous testing. Fdm technology uses thermoplastics found in traditional manufacturing processes and are ideal for applications that demand tight tolerances, toughness, and environmental stability. Fdm printed objects can be used for a variety of purposes, and improved filaments continue to make them more durable. Fused deposition modeling is sometimes called fused filament fabrication, or fff. 3d printing or additive manufacturing is a process of making three adoption of 3d printing has reached critical mass as those who have yet to integrate additive manufacturing fdm works using a plastic filament which is unwound from a spool and is supplied to an extrusion. Fdm is a 3d printing technology in which a thermoplastic material is extruded layer by layer to build durable parts. There are several different methods of 3d printing, but the most widely used is a process known as fused deposition modeling (fdm). With 3d printing (fdm), airbus has been able to produce components with complex features like lattice structures, without any additional manufacturing cost.

3d Printing In Pharmaceutical And Medical Applications Recent Achievements And Challenges Springerlink , Fdm 3D Printing With Robotic Arms.

Polymers Free Full Text Fdm 3d Printing Of Polymers Containing Natural Fillers A Review Of Their Mechanical Properties Html. We 3d print and design plastic parts for every application within our possibilities. Fdm is the most widely used 3d printing technology: Fdm technology uses thermoplastics found in traditional manufacturing processes and are ideal for applications that demand tight tolerances, toughness, and environmental stability. Fused deposition modeling is sometimes called fused filament fabrication, or fff. These 3d printing processes are the same, but we will use fdm in this article. Fused filament fabrication (fff), also known under the trademarked term fused deposition modeling (fdm), sometimes also called filament freeform fabrication. 0:01 choose your 3d printer: The fact that it can be 3d printed on an. Fdm 3d printing technology builds durable and functional prototypes that can withstand rigorous testing. Welcome to fdm 3d printing. Applications fdm vs sla vs sls 0:55 dimensions & tolerances 2:03 material properties 3:55 visual characteristics #applications #fdm. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. 4 001 просмотр 4 тыс. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Another downside of the layers in fdm printing is that they create and inherent weak point in the print where each layer is joined, making prints less sturdy and unsuitable for certain applications.

Fused Deposition Modeling Fdm 3d Printing Technology How It Works - 0:01 Choose Your 3D Printer:

3d Printing Market Size Share Trend Growth And Forecast To 2022. 0:01 choose your 3d printer: Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. Fused filament fabrication (fff), also known under the trademarked term fused deposition modeling (fdm), sometimes also called filament freeform fabrication. Fdm is the most widely used 3d printing technology: Fdm technology uses thermoplastics found in traditional manufacturing processes and are ideal for applications that demand tight tolerances, toughness, and environmental stability. 4 001 просмотр 4 тыс. Welcome to fdm 3d printing. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. We 3d print and design plastic parts for every application within our possibilities. Fdm 3d printing technology builds durable and functional prototypes that can withstand rigorous testing.

Real World Applications Of 3d Printing By Autodesk University Autodesk University Medium : 0:01 choose your 3d printer:

Paek Filaments In 3d Printing. 0:01 choose your 3d printer: Fused deposition modeling is sometimes called fused filament fabrication, or fff. 4 001 просмотр 4 тыс. Fdm 3d printing technology builds durable and functional prototypes that can withstand rigorous testing. Welcome to fdm 3d printing. Fdm is the most widely used 3d printing technology: Fdm technology uses thermoplastics found in traditional manufacturing processes and are ideal for applications that demand tight tolerances, toughness, and environmental stability. We 3d print and design plastic parts for every application within our possibilities. The fact that it can be 3d printed on an. Fused filament fabrication (fff), also known under the trademarked term fused deposition modeling (fdm), sometimes also called filament freeform fabrication. These 3d printing processes are the same, but we will use fdm in this article. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. Another downside of the layers in fdm printing is that they create and inherent weak point in the print where each layer is joined, making prints less sturdy and unsuitable for certain applications. Applications fdm vs sla vs sls 0:55 dimensions & tolerances 2:03 material properties 3:55 visual characteristics #applications #fdm. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more.

Sterile 3d Printing For Medical Applications And Sterile Outcomes : We 3D Print And Design Plastic Parts For Every Application Within Our Possibilities.

3d Printing By Fused Deposition Modeling Fdm Of A Swellable Erodible Capsular Device For Oral Pulsatile Release Of Drugs Sciencedirect. 4 001 просмотр 4 тыс. Another downside of the layers in fdm printing is that they create and inherent weak point in the print where each layer is joined, making prints less sturdy and unsuitable for certain applications. Fused deposition modeling is sometimes called fused filament fabrication, or fff. Fdm technology uses thermoplastics found in traditional manufacturing processes and are ideal for applications that demand tight tolerances, toughness, and environmental stability. The fact that it can be 3d printed on an. Fdm 3d printing technology builds durable and functional prototypes that can withstand rigorous testing. 0:01 choose your 3d printer: Applications fdm vs sla vs sls 0:55 dimensions & tolerances 2:03 material properties 3:55 visual characteristics #applications #fdm. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. Welcome to fdm 3d printing. Fused filament fabrication (fff), also known under the trademarked term fused deposition modeling (fdm), sometimes also called filament freeform fabrication. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. These 3d printing processes are the same, but we will use fdm in this article. Fdm is the most widely used 3d printing technology: We 3d print and design plastic parts for every application within our possibilities.

3d Printing With Fdm Technology Rapid Model - 3Dnatives Is The Largest International Online Media Platform On 3D Printing And Its Applications.

Overview Fff Fdm 3d Printing Applications. Welcome to fdm 3d printing. Another downside of the layers in fdm printing is that they create and inherent weak point in the print where each layer is joined, making prints less sturdy and unsuitable for certain applications. The fact that it can be 3d printed on an. Fdm 3d printing technology builds durable and functional prototypes that can withstand rigorous testing. Applications fdm vs sla vs sls 0:55 dimensions & tolerances 2:03 material properties 3:55 visual characteristics #applications #fdm. 0:01 choose your 3d printer: 4 001 просмотр 4 тыс. Fdm is the most widely used 3d printing technology: These 3d printing processes are the same, but we will use fdm in this article. We 3d print and design plastic parts for every application within our possibilities. Fused filament fabrication (fff), also known under the trademarked term fused deposition modeling (fdm), sometimes also called filament freeform fabrication. Fused deposition modeling is sometimes called fused filament fabrication, or fff. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. Fdm technology uses thermoplastics found in traditional manufacturing processes and are ideal for applications that demand tight tolerances, toughness, and environmental stability. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more.

Paek Filaments In 3d Printing . There Are Several Different Methods Of 3D Printing, But The Most Widely Used Is A Process Known As Fused Deposition Modeling (Fdm).

Revealing Interactions Of Layered Polymeric Materials At Solid Liquid Interface For Building Solvent Compatibility Charts For 3d Printing Applications Scientific Reports. We 3d print and design plastic parts for every application within our possibilities. 0:01 choose your 3d printer: The fact that it can be 3d printed on an. Fdm 3d printing technology builds durable and functional prototypes that can withstand rigorous testing. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. 4 001 просмотр 4 тыс. Fdm technology uses thermoplastics found in traditional manufacturing processes and are ideal for applications that demand tight tolerances, toughness, and environmental stability. Another downside of the layers in fdm printing is that they create and inherent weak point in the print where each layer is joined, making prints less sturdy and unsuitable for certain applications. Fused deposition modeling is sometimes called fused filament fabrication, or fff. Fdm is the most widely used 3d printing technology: Applications fdm vs sla vs sls 0:55 dimensions & tolerances 2:03 material properties 3:55 visual characteristics #applications #fdm. Fused filament fabrication (fff), also known under the trademarked term fused deposition modeling (fdm), sometimes also called filament freeform fabrication. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. These 3d printing processes are the same, but we will use fdm in this article. Welcome to fdm 3d printing.

Recent Advances On 3d Printing Graphene Based Composites Sciencedirect . We 3D Print And Design Plastic Parts For Every Application Within Our Possibilities.

The Mechatronic Structure Of An Fdm 3d Printer With Inevitable Download Scientific Diagram. Applications fdm vs sla vs sls 0:55 dimensions & tolerances 2:03 material properties 3:55 visual characteristics #applications #fdm. The fact that it can be 3d printed on an. Fdm is the most widely used 3d printing technology: Another downside of the layers in fdm printing is that they create and inherent weak point in the print where each layer is joined, making prints less sturdy and unsuitable for certain applications. Fused deposition modeling is sometimes called fused filament fabrication, or fff. We 3d print and design plastic parts for every application within our possibilities. These 3d printing processes are the same, but we will use fdm in this article. 0:01 choose your 3d printer: Welcome to fdm 3d printing. Fused filament fabrication (fff), also known under the trademarked term fused deposition modeling (fdm), sometimes also called filament freeform fabrication. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. 4 001 просмотр 4 тыс. Fdm 3d printing technology builds durable and functional prototypes that can withstand rigorous testing. Fdm technology uses thermoplastics found in traditional manufacturing processes and are ideal for applications that demand tight tolerances, toughness, and environmental stability. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more.

Medical 3d Printing Applications For Prosthetics Implants More . International Congress On 3D Printing (Additive Manufacturing) Technologies And Digital Industry.

Fdm 3d Printing Materials And Their Uses In High Stress Applications Youtube. 4 001 просмотр 4 тыс. Another downside of the layers in fdm printing is that they create and inherent weak point in the print where each layer is joined, making prints less sturdy and unsuitable for certain applications. The fact that it can be 3d printed on an. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Fdm 3d printing technology builds durable and functional prototypes that can withstand rigorous testing. Fdm technology uses thermoplastics found in traditional manufacturing processes and are ideal for applications that demand tight tolerances, toughness, and environmental stability. Fused deposition modeling is sometimes called fused filament fabrication, or fff. Welcome to fdm 3d printing. Fused filament fabrication (fff), also known under the trademarked term fused deposition modeling (fdm), sometimes also called filament freeform fabrication. Fdm is the most widely used 3d printing technology: These 3d printing processes are the same, but we will use fdm in this article. 0:01 choose your 3d printer: We 3d print and design plastic parts for every application within our possibilities. Applications fdm vs sla vs sls 0:55 dimensions & tolerances 2:03 material properties 3:55 visual characteristics #applications #fdm. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods.

Fdm 3d Printing Fused Deposition Modeling 3d Printing Service In India Think3d - Fdm 3D Printers Dominate The 3D Printing Market, Almost Drowning Out More Expensive Methods.

Fdm Fused Deposition Modeling Or Fff Pjp Lpd. We 3d print and design plastic parts for every application within our possibilities. The fact that it can be 3d printed on an. Fused filament fabrication (fff), also known under the trademarked term fused deposition modeling (fdm), sometimes also called filament freeform fabrication. 4 001 просмотр 4 тыс. Fdm technology uses thermoplastics found in traditional manufacturing processes and are ideal for applications that demand tight tolerances, toughness, and environmental stability. 0:01 choose your 3d printer: Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. These 3d printing processes are the same, but we will use fdm in this article. Fdm 3d printing technology builds durable and functional prototypes that can withstand rigorous testing. Applications fdm vs sla vs sls 0:55 dimensions & tolerances 2:03 material properties 3:55 visual characteristics #applications #fdm. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. Welcome to fdm 3d printing. Another downside of the layers in fdm printing is that they create and inherent weak point in the print where each layer is joined, making prints less sturdy and unsuitable for certain applications. Fused deposition modeling is sometimes called fused filament fabrication, or fff. Fdm is the most widely used 3d printing technology:

Printing Temperature Properties And Applications Of Different Download Table : Fdm Is The Most Widely Used 3D Printing Technology:

Everything You Need To Know About 3d Printing. The fact that it can be 3d printed on an. Fdm 3d printing technology builds durable and functional prototypes that can withstand rigorous testing. These 3d printing processes are the same, but we will use fdm in this article. 0:01 choose your 3d printer: Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Fused deposition modeling is sometimes called fused filament fabrication, or fff. Fused filament fabrication (fff), also known under the trademarked term fused deposition modeling (fdm), sometimes also called filament freeform fabrication. Welcome to fdm 3d printing. Fdm is the most widely used 3d printing technology: Fdm technology uses thermoplastics found in traditional manufacturing processes and are ideal for applications that demand tight tolerances, toughness, and environmental stability. Applications fdm vs sla vs sls 0:55 dimensions & tolerances 2:03 material properties 3:55 visual characteristics #applications #fdm. 4 001 просмотр 4 тыс. We 3d print and design plastic parts for every application within our possibilities. Another downside of the layers in fdm printing is that they create and inherent weak point in the print where each layer is joined, making prints less sturdy and unsuitable for certain applications. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods.