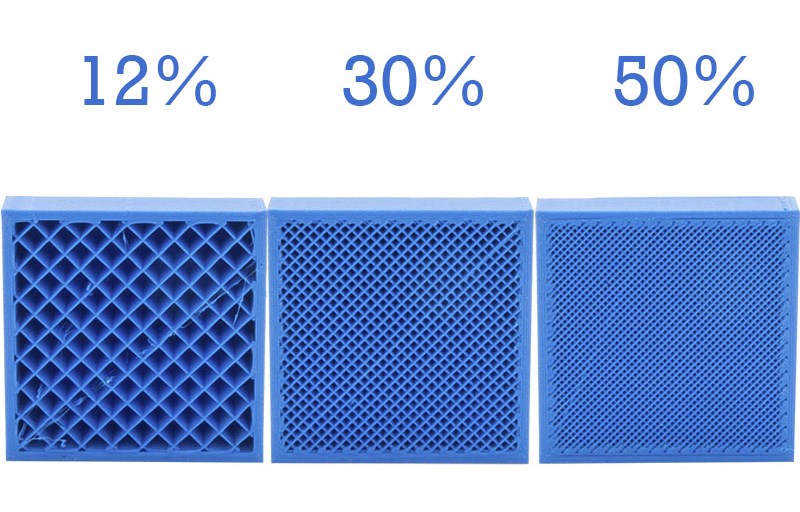

Fdm 3D Printing Infill. To understand infill, think about the doors in your home. We'll use fusion 360 and ansys finite. For example, a part utilising 50% infill is. All3dp is an editorially independent publication. Editorial content, on principle, can not be bought or influenced. Let me show you how you can optimize the infill structure of your 3d printed part according to the applied loads. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. Infill provides the 3d print with internal support as the printer builds each layer. Very few doors that are mass produced are in general, the strength of an fdm object is directly tied to the infill percentage used during printing. The majority of fdm 3d printed parts are not printed solid. 3d printer infill percentage and overall object strength. Printing solid parts requires high amounts of material and long print time resulting in high costs. To optimize the printing process most parts are printed with solid shells and filled with infill. Shells and infill play an important role on the quality. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight.

Fdm 3D Printing Infill : These 3D Printing Processes Are The Same, But We Will Use Fdm In This Infill:

Effect Of Infill Patterns On The Mechanical Performance Of Lightweight 3d Printed Cellular Pla Parts Sciencedirect. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill provides the 3d print with internal support as the printer builds each layer. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. 3d printer infill percentage and overall object strength. To understand infill, think about the doors in your home. We'll use fusion 360 and ansys finite. To optimize the printing process most parts are printed with solid shells and filled with infill. Shells and infill play an important role on the quality. The majority of fdm 3d printed parts are not printed solid. Very few doors that are mass produced are in general, the strength of an fdm object is directly tied to the infill percentage used during printing. Let me show you how you can optimize the infill structure of your 3d printed part according to the applied loads. All3dp is an editorially independent publication. Printing solid parts requires high amounts of material and long print time resulting in high costs. For example, a part utilising 50% infill is. Editorial content, on principle, can not be bought or influenced.

Shells and infill play an important role on the quality.

This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. 65 thoughts on 3d printing transparent parts using fdm/fff printer. Printer does not extrude plastic at the beginning of the print. While fdm printers vary in size, materials, and function, they almost all have three distinct electromechanical systems. The two or more bodies in. To optimize the printing process most parts are printed with solid shells and filled with infill. Before printing, make sure that the hotend is clean, as leftover material in the part can damage its purity. This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. Fdm machines can print with thicker layers and generally use a lower infill which results in fast 3d prints. There are several different methods of 3d printing, but the most widely used is a process known as fused deposition modeling (fdm). International congress on 3d printing (additive manufacturing) technologies and digital industry. For example, a part utilising 50% infill is. Printed gears usually require a little post processing prior to use. At fictiv, all parts produced in pla are made on hobbyist grade machines to keep costs low and leverage breakaway support. The majority of fdm 3d printed parts are not printed solid. We'll use fusion 360 and ansys finite. Fused deposition modeling is sometimes called fused filament fabrication, or fff. These 3d printing processes are the same, but we will use fdm in this infill: Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. Best infill for strength vs material used. Once you know what your print is going to be used for. Fdm, sls, sla, polyjet, mjf technologies. It will save you material much of 3d printing is really structure and design and i feel that having some knowledge in why nature does what it does will add some forethought to. 3d printed parts are stronger along the xy plane, parallel to the print bed, than along the z axis, normal to the print bed. Expect to have to bore holes to the right 2. Fdm machines can be categorized into two main categories: Editorial content, on principle, can not be bought or influenced. This shape is the most efficient infill and fastest to print, the goto infill for most things. Fdm printers use a thermoplastic filament, which is heated to its melting point and then extruded, layer by layer, to create a three dimensional object. Infill provides the 3d print with internal support as the printer builds each layer. Maybe this one is more connected with durability than quality in fdm 3d printing but still important.

How To Get Stronger Fdm 3d Prints 3d Printing : Fdm Parts Aren't Printed Solid — It'd Cost Way More And There's Diminishing Returns With How Much Strength A Part Really Needs.

3d Printing Infill Archives Perfect 3d Printing Filament. For example, a part utilising 50% infill is. We'll use fusion 360 and ansys finite. Shells and infill play an important role on the quality. Let me show you how you can optimize the infill structure of your 3d printed part according to the applied loads. Editorial content, on principle, can not be bought or influenced. To understand infill, think about the doors in your home. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Very few doors that are mass produced are in general, the strength of an fdm object is directly tied to the infill percentage used during printing. 3d printer infill percentage and overall object strength. To optimize the printing process most parts are printed with solid shells and filled with infill. The majority of fdm 3d printed parts are not printed solid. Infill provides the 3d print with internal support as the printer builds each layer. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. All3dp is an editorially independent publication. Printing solid parts requires high amounts of material and long print time resulting in high costs.

Fdm Fused Deposition Modeling Or Fff Pjp Lpd . There Are Several Different Methods Of 3D Printing, But The Most Widely Used Is A Process Known As Fused Deposition Modeling (Fdm).

Selecting The Optimal Shell And Infill Parameters For Fdm 3d Printing 3d Hubs. Infill provides the 3d print with internal support as the printer builds each layer. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Very few doors that are mass produced are in general, the strength of an fdm object is directly tied to the infill percentage used during printing. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. All3dp is an editorially independent publication. We'll use fusion 360 and ansys finite. For example, a part utilising 50% infill is. Printing solid parts requires high amounts of material and long print time resulting in high costs. Let me show you how you can optimize the infill structure of your 3d printed part according to the applied loads. To understand infill, think about the doors in your home.

What Are The Different Types Of Infill Percentages Think3d - Let us know what you think about the above tips and feel free to comment with any other pieces of advice for ensuring an outstanding quality in fdm 3d printing.

3d Printing Design Guide Fused Deposit Modelling 3 Space. All3dp is an editorially independent publication. For example, a part utilising 50% infill is. Shells and infill play an important role on the quality. We'll use fusion 360 and ansys finite. To optimize the printing process most parts are printed with solid shells and filled with infill. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Very few doors that are mass produced are in general, the strength of an fdm object is directly tied to the infill percentage used during printing. 3d printer infill percentage and overall object strength. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. The majority of fdm 3d printed parts are not printed solid. Editorial content, on principle, can not be bought or influenced. Let me show you how you can optimize the infill structure of your 3d printed part according to the applied loads. Infill provides the 3d print with internal support as the printer builds each layer. To understand infill, think about the doors in your home. Printing solid parts requires high amounts of material and long print time resulting in high costs.

How To Get Stronger Fdm 3d Prints 3d Printing . Printed Gears Usually Require A Little Post Processing Prior To Use.

Cross Sectional Views Of Fdm 3d Printed Tablets With Different Infill Download Scientific Diagram. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. Editorial content, on principle, can not be bought or influenced. Printing solid parts requires high amounts of material and long print time resulting in high costs. We'll use fusion 360 and ansys finite. The majority of fdm 3d printed parts are not printed solid. Very few doors that are mass produced are in general, the strength of an fdm object is directly tied to the infill percentage used during printing. For example, a part utilising 50% infill is. Shells and infill play an important role on the quality. To understand infill, think about the doors in your home. To optimize the printing process most parts are printed with solid shells and filled with infill. Infill provides the 3d print with internal support as the printer builds each layer. All3dp is an editorially independent publication. Let me show you how you can optimize the infill structure of your 3d printed part according to the applied loads. 3d printer infill percentage and overall object strength.

How To Use 3d Print Infill Settings Increase Strength Save Filament , This Guide Is A Great Place To Start If You Are Trying To Improve The Quality Of Your 3D Printed Parts.

Honeycomb Structures From Infill To Bicycle Tires 3dprint Com The Voice Of 3d Printing Additive Manufacturing. For example, a part utilising 50% infill is. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Let me show you how you can optimize the infill structure of your 3d printed part according to the applied loads. To optimize the printing process most parts are printed with solid shells and filled with infill. Infill provides the 3d print with internal support as the printer builds each layer. Shells and infill play an important role on the quality. To understand infill, think about the doors in your home. The majority of fdm 3d printed parts are not printed solid. All3dp is an editorially independent publication. 3d printer infill percentage and overall object strength. Editorial content, on principle, can not be bought or influenced. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. Printing solid parts requires high amounts of material and long print time resulting in high costs. We'll use fusion 360 and ansys finite. Very few doors that are mass produced are in general, the strength of an fdm object is directly tied to the infill percentage used during printing.

Selecting The Optimal Shell And Infill Parameters For Fdm 3d Printing 3d Hubs - Fdm Parts Aren't Printed Solid — It'd Cost Way More And There's Diminishing Returns With How Much Strength A Part Really Needs.

3d Printing Tips For Ultimaker S5 And Cura 4 Develop3d. Shells and infill play an important role on the quality. Editorial content, on principle, can not be bought or influenced. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Infill provides the 3d print with internal support as the printer builds each layer. 3d printer infill percentage and overall object strength. We'll use fusion 360 and ansys finite. The majority of fdm 3d printed parts are not printed solid. Printing solid parts requires high amounts of material and long print time resulting in high costs. Very few doors that are mass produced are in general, the strength of an fdm object is directly tied to the infill percentage used during printing. For example, a part utilising 50% infill is. Let me show you how you can optimize the infill structure of your 3d printed part according to the applied loads. To optimize the printing process most parts are printed with solid shells and filled with infill. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. All3dp is an editorially independent publication. To understand infill, think about the doors in your home.

Selecting The Optimal Shell And Infill Parameters For Fdm 3d Printing 3d Hubs - Let Me Show You How You Can Optimize The Infill Structure Of Your 3D Printed Part According To The Applied Loads.

How To Use Infill Percentage And Pattern Enhance Strength Save Material Tianse. To optimize the printing process most parts are printed with solid shells and filled with infill. Editorial content, on principle, can not be bought or influenced. 3d printer infill percentage and overall object strength. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. All3dp is an editorially independent publication. The majority of fdm 3d printed parts are not printed solid. For example, a part utilising 50% infill is. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Printing solid parts requires high amounts of material and long print time resulting in high costs. Infill provides the 3d print with internal support as the printer builds each layer. To understand infill, think about the doors in your home. We'll use fusion 360 and ansys finite. Very few doors that are mass produced are in general, the strength of an fdm object is directly tied to the infill percentage used during printing. Let me show you how you can optimize the infill structure of your 3d printed part according to the applied loads. Shells and infill play an important role on the quality.

3d Printing Infill The Basics Simply Explained All3dp , There Are Several Different Methods Of 3D Printing, But The Most Widely Used Is A Process Known As Fused Deposition Modeling (Fdm).

Surface Roughness Quality And Dimensional Accuracy A Comprehensive Analysis Of 100 Infill Printed Parts Fabricated By A Personal Desktop Cost Effective Fdm 3d Printer. All3dp is an editorially independent publication. To understand infill, think about the doors in your home. Printing solid parts requires high amounts of material and long print time resulting in high costs. For example, a part utilising 50% infill is. We'll use fusion 360 and ansys finite. The majority of fdm 3d printed parts are not printed solid. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Very few doors that are mass produced are in general, the strength of an fdm object is directly tied to the infill percentage used during printing. Let me show you how you can optimize the infill structure of your 3d printed part according to the applied loads. 3d printer infill percentage and overall object strength. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. Infill provides the 3d print with internal support as the printer builds each layer. Shells and infill play an important role on the quality. Editorial content, on principle, can not be bought or influenced. To optimize the printing process most parts are printed with solid shells and filled with infill.

How To Choose An Infill For Your 3d Prints . It Will Save You Material Much Of 3D Printing Is Really Structure And Design And I Feel That Having Some Knowledge In Why Nature Does What It Does Will Add Some Forethought To.

What Infill Settings Should I Use For My Fdm 3d Print Sd3d Printing. We'll use fusion 360 and ansys finite. To optimize the printing process most parts are printed with solid shells and filled with infill. The majority of fdm 3d printed parts are not printed solid. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. 3d printer infill percentage and overall object strength. To understand infill, think about the doors in your home. Let me show you how you can optimize the infill structure of your 3d printed part according to the applied loads. All3dp is an editorially independent publication. Very few doors that are mass produced are in general, the strength of an fdm object is directly tied to the infill percentage used during printing. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. Editorial content, on principle, can not be bought or influenced. Shells and infill play an important role on the quality. Printing solid parts requires high amounts of material and long print time resulting in high costs. For example, a part utilising 50% infill is. Infill provides the 3d print with internal support as the printer builds each layer.

3d Printing Infill Styles The What When And Why Of Using Infill Padt Inc The Blog - Printed Gears Usually Require A Little Post Processing Prior To Use.

How Do Layer Height Infill Settings Impact 3d Print Strength 3d Matter. All3dp is an editorially independent publication. To optimize the printing process most parts are printed with solid shells and filled with infill. Infill provides the 3d print with internal support as the printer builds each layer. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. 3d printer infill percentage and overall object strength. Let me show you how you can optimize the infill structure of your 3d printed part according to the applied loads. Editorial content, on principle, can not be bought or influenced. We'll use fusion 360 and ansys finite. To understand infill, think about the doors in your home. Very few doors that are mass produced are in general, the strength of an fdm object is directly tied to the infill percentage used during printing. Without infill, printing the top layers would be very difficult, as the plastic besides the actual printing process, infill will affect the strength or feel of the final product. Printing solid parts requires high amounts of material and long print time resulting in high costs. The majority of fdm 3d printed parts are not printed solid. For example, a part utilising 50% infill is. Shells and infill play an important role on the quality.