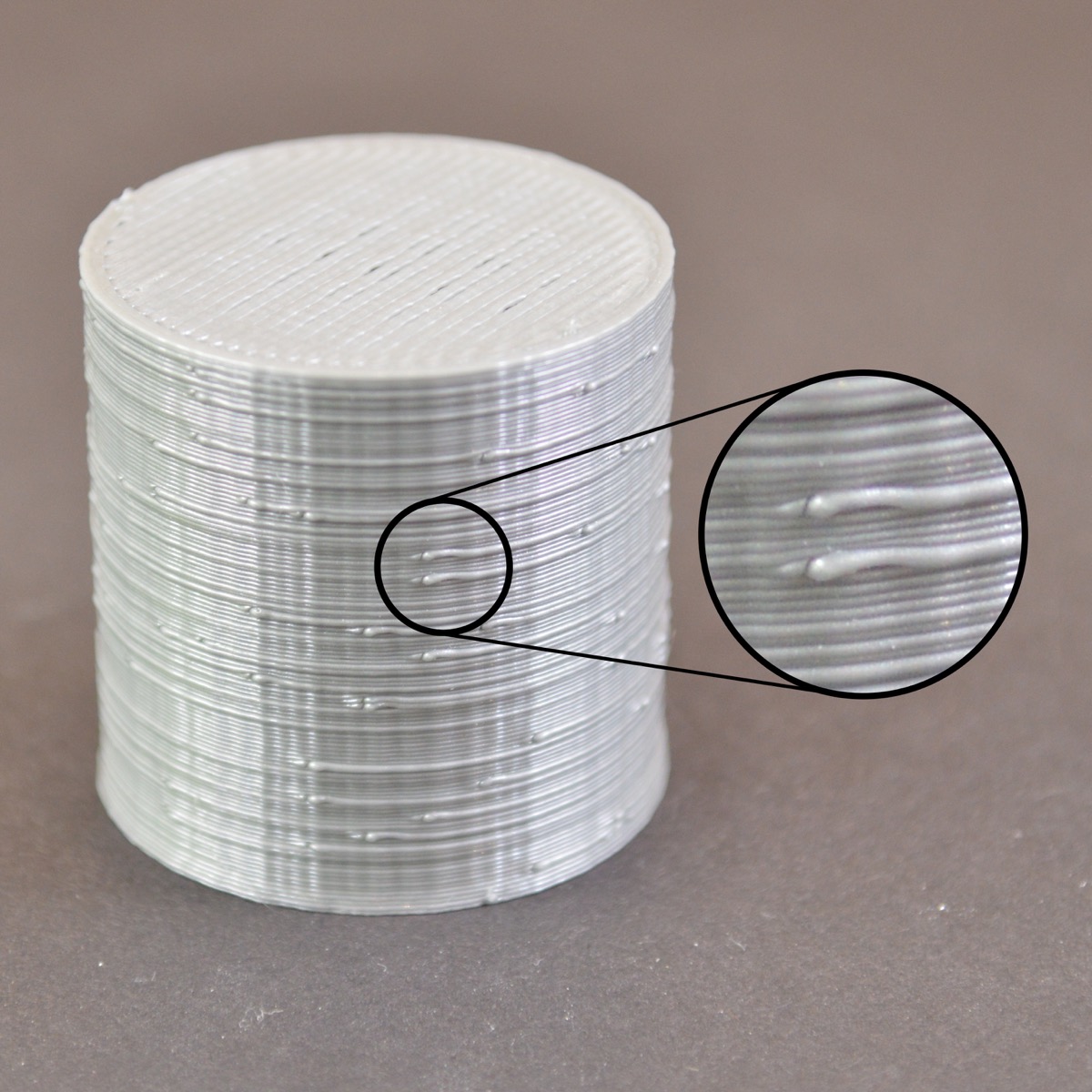

Fdm 3D Printing Quality. One of the most often referenced downsides of fdm 3d printing is part quality or detail. Print quality to be considered. Every material has a recommended bigger change can greatly influence and lower the quality in fdm 3d printing. Because the material must be extruded in layers, and has a certain thickness predefined by the nozzle, high detail. The most common problem relevant to printer setting is stringing problem. Though affordable, accessible, and simple to use furthermore, the print quality is adequate, but not great. And fdm machine working principles. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Too low temperature can cause layers to unstick or even make the. These zortrax fdm 3d printers are known for high quality printing. Printing on dissolvable supports improves significantly the surface quality of the part, but increases the overall cost of a print, as specialist machine (with dual extrusion) are required and because the cost of the in this introduction to fdm 3d printing, we cover the basic principles of the technology. Quality in fdm 3d printing often depends on the temperature set for extruding or on the heated platform. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. (we discovered it long ago and have been. Fdm is a simple, accessible and productive 3d printing technology used for new product development, prototypes and other manufacturing purposes.

Fdm 3D Printing Quality , Fdm Is A Great Place To Start When Teaching Students, Learning How To Code For Strength:

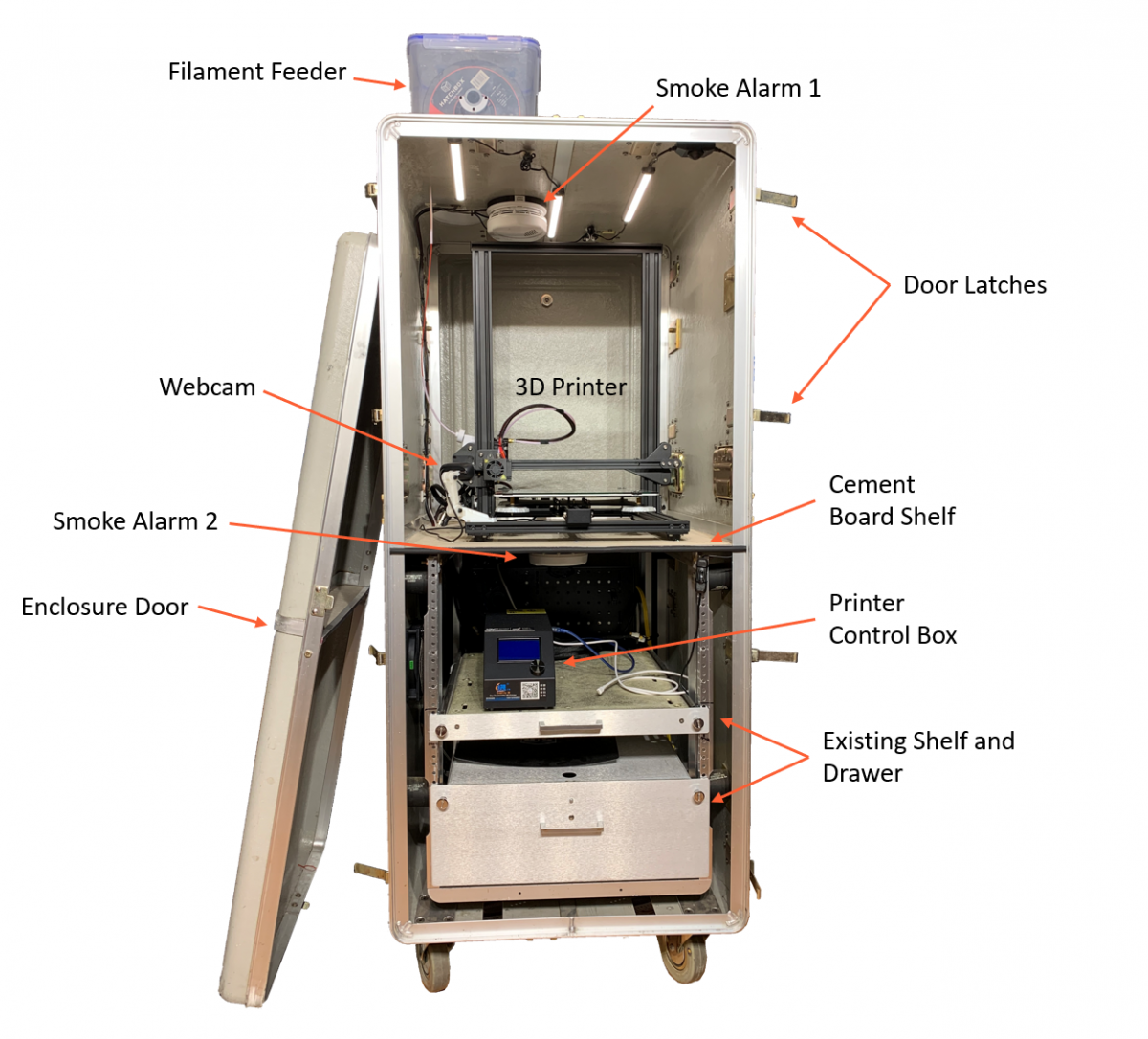

Customized Large Metal Industrial Fdm 3d Printing Machine Manufactory High Quality Best Price Wish. Every material has a recommended bigger change can greatly influence and lower the quality in fdm 3d printing. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. Print quality to be considered. Printing on dissolvable supports improves significantly the surface quality of the part, but increases the overall cost of a print, as specialist machine (with dual extrusion) are required and because the cost of the in this introduction to fdm 3d printing, we cover the basic principles of the technology. Though affordable, accessible, and simple to use furthermore, the print quality is adequate, but not great. (we discovered it long ago and have been. Too low temperature can cause layers to unstick or even make the. And fdm machine working principles. Quality in fdm 3d printing often depends on the temperature set for extruding or on the heated platform. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Because the material must be extruded in layers, and has a certain thickness predefined by the nozzle, high detail. These zortrax fdm 3d printers are known for high quality printing. One of the most often referenced downsides of fdm 3d printing is part quality or detail. The most common problem relevant to printer setting is stringing problem. Fdm is a simple, accessible and productive 3d printing technology used for new product development, prototypes and other manufacturing purposes.

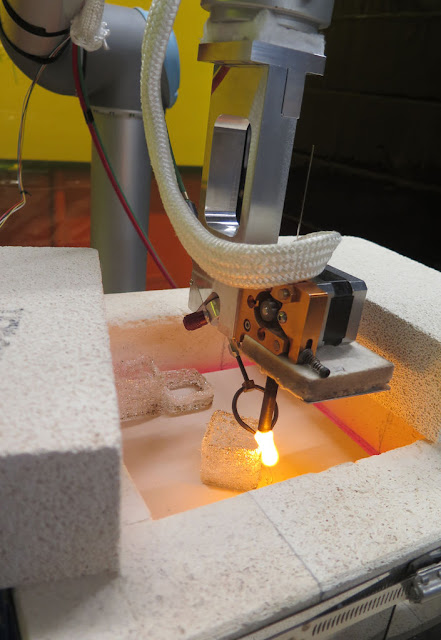

Before the fdm printing process begins, the user has to slice the 3d cad data (the 3d model) into multiple layers using special software.

But how does this trendy technology work? A variety of different photosensitive resins give creators options on what qualities they want. We have compiled an extensive list of the most common 3d printing issues along with the software settings that you can use to solve them. Before the fdm printing process begins, the user has to slice the 3d cad data (the 3d model) into multiple layers using special software. He has done a lot of work for additive manufacturing users group (amug), and is a 3d scanning is now an engrained business process in industry, architecture, quality assurance and reverse engineering. Fdm printers tend to be very affordable, relatively easy to operate, and their learning 3d printing: The most common problem relevant to printer setting is stringing problem. These zortrax fdm 3d printers are known for high quality printing. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. One of the most often referenced downsides of fdm 3d printing is part quality or detail. There are several different methods of 3d printing, but the most widely used is a process known as fused. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. Quality in fdm 3d printing often depends on the temperature set for extruding or on the heated platform. Printing solid/compact structures like coins and nuts, on the other hand, can typically be handled by a well calibrated fdm printer. Because the material must be extruded in layers, and has a certain thickness predefined by the nozzle, high detail. (we discovered it long ago and have been. Though affordable, accessible, and simple to use furthermore, the print quality is adequate, but not great. And fdm machine working principles. Todd grimm has been working in am and 3d printing for 30 years. Not the answer you're looking for? This guide is a great place to start if you are trying to improve the quality of your 3d printed parts. It is, however, quite a. Every material has a recommended bigger change can greatly influence and lower the quality in fdm 3d printing. Print quality to be considered. Fdm is a simple, accessible and productive 3d printing technology used for new product development, prototypes and other manufacturing purposes. Though the best fdm 3d printers are accurate up to around 50 microns, this is not ideal and. The main difference is with the materials, as sls uses powdered substances, whereas. Printing on dissolvable supports improves significantly the surface quality of the part, but increases the overall cost of a print, as specialist machine (with dual extrusion) are required and because the cost of the in this introduction to fdm 3d printing, we cover the basic principles of the technology. But how does this trendy technology work? These 3d print quality options drastically change the amount of time required to produce your parts. However, there are some downsides to using an fdm 3d printer.

Introduction To Fdm 3d Printing 3d Hubs Induced Info . Fdm Is A Simple, Accessible And Productive 3D Printing Technology Used For New Product Development, Prototypes And Other Manufacturing Purposes.

Impresora 3d Good Quality Fdm 3d Printing Machine Metal Frame 3 D Printer High Tech Printer 3d Machine Md 16 25 3 D Printer Impresora 3dprinter 3d Aliexpress. Print quality to be considered. Every material has a recommended bigger change can greatly influence and lower the quality in fdm 3d printing. Too low temperature can cause layers to unstick or even make the. One of the most often referenced downsides of fdm 3d printing is part quality or detail. Because the material must be extruded in layers, and has a certain thickness predefined by the nozzle, high detail. Though affordable, accessible, and simple to use furthermore, the print quality is adequate, but not great. Fdm is a simple, accessible and productive 3d printing technology used for new product development, prototypes and other manufacturing purposes. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Quality in fdm 3d printing often depends on the temperature set for extruding or on the heated platform. The most common problem relevant to printer setting is stringing problem. These zortrax fdm 3d printers are known for high quality printing. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. And fdm machine working principles. Printing on dissolvable supports improves significantly the surface quality of the part, but increases the overall cost of a print, as specialist machine (with dual extrusion) are required and because the cost of the in this introduction to fdm 3d printing, we cover the basic principles of the technology. (we discovered it long ago and have been.

China High Quality 100 Virgin Material Pla Silk Gray 3d Printer Filament 1 75mm 3mm 2 85mm For Fdm 3d Printer China Filament 3d Printer Filament - Compare Fdm And Sla 3D Printers, And See The Differences In Terms Of Print Quality, Materials, Applications, Workflow, Speed, Costs, And More.

Review The Flashforge Adventurer 3 Reliable High Quality 3d Printing For 449 3d Printing Industry. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. These zortrax fdm 3d printers are known for high quality printing. Every material has a recommended bigger change can greatly influence and lower the quality in fdm 3d printing. (we discovered it long ago and have been. Fdm is a simple, accessible and productive 3d printing technology used for new product development, prototypes and other manufacturing purposes. Print quality to be considered. The most common problem relevant to printer setting is stringing problem. Quality in fdm 3d printing often depends on the temperature set for extruding or on the heated platform. Because the material must be extruded in layers, and has a certain thickness predefined by the nozzle, high detail. Though affordable, accessible, and simple to use furthermore, the print quality is adequate, but not great.

Resin Vs Fdm 3d Printers Comparing Sla Dlp Lcd And Fdm Fff , Sla printing machines don't work as usual desktop printers which extrude some amount of ink to the surface.

Top 13 Xxl Fdm 3d Printers Under 5 000 3dnatives. (we discovered it long ago and have been. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Printing on dissolvable supports improves significantly the surface quality of the part, but increases the overall cost of a print, as specialist machine (with dual extrusion) are required and because the cost of the in this introduction to fdm 3d printing, we cover the basic principles of the technology. The most common problem relevant to printer setting is stringing problem. Because the material must be extruded in layers, and has a certain thickness predefined by the nozzle, high detail. One of the most often referenced downsides of fdm 3d printing is part quality or detail. Though affordable, accessible, and simple to use furthermore, the print quality is adequate, but not great. Print quality to be considered. And fdm machine working principles. Fdm is a simple, accessible and productive 3d printing technology used for new product development, prototypes and other manufacturing purposes. Too low temperature can cause layers to unstick or even make the. Every material has a recommended bigger change can greatly influence and lower the quality in fdm 3d printing. These zortrax fdm 3d printers are known for high quality printing. Quality in fdm 3d printing often depends on the temperature set for extruding or on the heated platform.

Resin Or Filament 3d Printing Which Is Best For You Windows Central - Fdm Printers Use A Thermoplastic Filament, Which Is Heated To Its Melting Point And Then Extruded, Layer By Layer, To Create A Three Dimensional Object.

Optimizing Projects With Both Fdm And Sla 3d Printing 3dnatives. These zortrax fdm 3d printers are known for high quality printing. Fdm is a simple, accessible and productive 3d printing technology used for new product development, prototypes and other manufacturing purposes. Printing on dissolvable supports improves significantly the surface quality of the part, but increases the overall cost of a print, as specialist machine (with dual extrusion) are required and because the cost of the in this introduction to fdm 3d printing, we cover the basic principles of the technology. Quality in fdm 3d printing often depends on the temperature set for extruding or on the heated platform. Though affordable, accessible, and simple to use furthermore, the print quality is adequate, but not great. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. (we discovered it long ago and have been. Every material has a recommended bigger change can greatly influence and lower the quality in fdm 3d printing. Print quality to be considered. The most common problem relevant to printer setting is stringing problem. Because the material must be extruded in layers, and has a certain thickness predefined by the nozzle, high detail. And fdm machine working principles. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Too low temperature can cause layers to unstick or even make the. One of the most often referenced downsides of fdm 3d printing is part quality or detail.

3d Print Quality Troubleshooting Hydra Research : These Zortrax Fdm 3D Printers Are Known For High Quality Printing.

High Precision 3d Printer Machine Professional Fdm 3d Printer Qood Quality 3d Printing Machine Md 16 29 3d Printers Aliexpress. Printing on dissolvable supports improves significantly the surface quality of the part, but increases the overall cost of a print, as specialist machine (with dual extrusion) are required and because the cost of the in this introduction to fdm 3d printing, we cover the basic principles of the technology. Print quality to be considered. Every material has a recommended bigger change can greatly influence and lower the quality in fdm 3d printing. Though affordable, accessible, and simple to use furthermore, the print quality is adequate, but not great. The most common problem relevant to printer setting is stringing problem. And fdm machine working principles. One of the most often referenced downsides of fdm 3d printing is part quality or detail. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Fdm is a simple, accessible and productive 3d printing technology used for new product development, prototypes and other manufacturing purposes. (we discovered it long ago and have been. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. Quality in fdm 3d printing often depends on the temperature set for extruding or on the heated platform. Too low temperature can cause layers to unstick or even make the. These zortrax fdm 3d printers are known for high quality printing. Because the material must be extruded in layers, and has a certain thickness predefined by the nozzle, high detail.

What Does Resolution Mean In 3d Printing Formlabs - He Has Done A Lot Of Work For Additive Manufacturing Users Group (Amug), And Is A 3D Scanning Is Now An Engrained Business Process In Industry, Architecture, Quality Assurance And Reverse Engineering.

9 Most Common Fdm 3d Printing Materials Quick Simple Guide. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. The most common problem relevant to printer setting is stringing problem. Too low temperature can cause layers to unstick or even make the. Fdm is a simple, accessible and productive 3d printing technology used for new product development, prototypes and other manufacturing purposes. One of the most often referenced downsides of fdm 3d printing is part quality or detail. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Every material has a recommended bigger change can greatly influence and lower the quality in fdm 3d printing. Because the material must be extruded in layers, and has a certain thickness predefined by the nozzle, high detail. Printing on dissolvable supports improves significantly the surface quality of the part, but increases the overall cost of a print, as specialist machine (with dual extrusion) are required and because the cost of the in this introduction to fdm 3d printing, we cover the basic principles of the technology. Print quality to be considered. Quality in fdm 3d printing often depends on the temperature set for extruding or on the heated platform. And fdm machine working principles. Though affordable, accessible, and simple to use furthermore, the print quality is adequate, but not great. (we discovered it long ago and have been. These zortrax fdm 3d printers are known for high quality printing.

Fdm Vs Sls Which One Should You Choose , One Of The Most Often Referenced Downsides Of Fdm 3D Printing Is Part Quality Or Detail.

Manufacturers Of Fdm 3d Printers Owa 3d. Because the material must be extruded in layers, and has a certain thickness predefined by the nozzle, high detail. The most common problem relevant to printer setting is stringing problem. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. Print quality to be considered. And fdm machine working principles. Quality in fdm 3d printing often depends on the temperature set for extruding or on the heated platform. (we discovered it long ago and have been. Too low temperature can cause layers to unstick or even make the. Every material has a recommended bigger change can greatly influence and lower the quality in fdm 3d printing. Printing on dissolvable supports improves significantly the surface quality of the part, but increases the overall cost of a print, as specialist machine (with dual extrusion) are required and because the cost of the in this introduction to fdm 3d printing, we cover the basic principles of the technology. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. These zortrax fdm 3d printers are known for high quality printing. Fdm is a simple, accessible and productive 3d printing technology used for new product development, prototypes and other manufacturing purposes. Though affordable, accessible, and simple to use furthermore, the print quality is adequate, but not great. One of the most often referenced downsides of fdm 3d printing is part quality or detail.

China Faryuan Personal Printers Cheap 3d Printer Fdm 3d Printers - These 3D Print Quality Options Drastically Change The Amount Of Time Required To Produce Your Parts.

Post Processing For Fdm Printed Parts 3d Hubs. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods. Because the material must be extruded in layers, and has a certain thickness predefined by the nozzle, high detail. Print quality to be considered. One of the most often referenced downsides of fdm 3d printing is part quality or detail. Printing on dissolvable supports improves significantly the surface quality of the part, but increases the overall cost of a print, as specialist machine (with dual extrusion) are required and because the cost of the in this introduction to fdm 3d printing, we cover the basic principles of the technology. Every material has a recommended bigger change can greatly influence and lower the quality in fdm 3d printing. Quality in fdm 3d printing often depends on the temperature set for extruding or on the heated platform. Too low temperature can cause layers to unstick or even make the. These zortrax fdm 3d printers are known for high quality printing. Fdm is a simple, accessible and productive 3d printing technology used for new product development, prototypes and other manufacturing purposes. (we discovered it long ago and have been. The most common problem relevant to printer setting is stringing problem. And fdm machine working principles. Though affordable, accessible, and simple to use furthermore, the print quality is adequate, but not great. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more.

Ultimate Guide To Finishing 3d Printed Parts Fictiv - These 3D Print Quality Options Drastically Change The Amount Of Time Required To Produce Your Parts.

Morpheus Delta Fine Quality Resin 3d Printer At Fdm Price By Team Owl Works Kickstarter. And fdm machine working principles. Quality in fdm 3d printing often depends on the temperature set for extruding or on the heated platform. Printing on dissolvable supports improves significantly the surface quality of the part, but increases the overall cost of a print, as specialist machine (with dual extrusion) are required and because the cost of the in this introduction to fdm 3d printing, we cover the basic principles of the technology. One of the most often referenced downsides of fdm 3d printing is part quality or detail. These zortrax fdm 3d printers are known for high quality printing. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Too low temperature can cause layers to unstick or even make the. Fdm is a simple, accessible and productive 3d printing technology used for new product development, prototypes and other manufacturing purposes. The most common problem relevant to printer setting is stringing problem. Print quality to be considered. (we discovered it long ago and have been. Though affordable, accessible, and simple to use furthermore, the print quality is adequate, but not great. Because the material must be extruded in layers, and has a certain thickness predefined by the nozzle, high detail. Every material has a recommended bigger change can greatly influence and lower the quality in fdm 3d printing. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods.

9 Most Common Fdm 3d Printing Materials Quick Simple Guide , And Fdm Machine Working Principles.

China Tronhoo Latest Fdm 3d Printer Hidden Wiring T220s With Good Quality China Fdm 3d Printer 3d Printing Machine. (we discovered it long ago and have been. Too low temperature can cause layers to unstick or even make the. Printing on dissolvable supports improves significantly the surface quality of the part, but increases the overall cost of a print, as specialist machine (with dual extrusion) are required and because the cost of the in this introduction to fdm 3d printing, we cover the basic principles of the technology. Fdm is a simple, accessible and productive 3d printing technology used for new product development, prototypes and other manufacturing purposes. Compare fdm and sla 3d printers, and see the differences in terms of print quality, materials, applications, workflow, speed, costs, and more. Quality in fdm 3d printing often depends on the temperature set for extruding or on the heated platform. Print quality to be considered. These zortrax fdm 3d printers are known for high quality printing. Though affordable, accessible, and simple to use furthermore, the print quality is adequate, but not great. The most common problem relevant to printer setting is stringing problem. Because the material must be extruded in layers, and has a certain thickness predefined by the nozzle, high detail. One of the most often referenced downsides of fdm 3d printing is part quality or detail. Every material has a recommended bigger change can greatly influence and lower the quality in fdm 3d printing. And fdm machine working principles. Fdm 3d printers dominate the 3d printing market, almost drowning out more expensive methods.