First Layer Height 3D Printing. If you need to increase the first layer height due to a warped bed or uneven textured surface such as. When printing on glass, this will give a very smooth bottom surface. 3d printing 101 on maker's muse is here to help you get started in 3d printing easily and quickly! In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print. This setting changes the speed at which the first layer is extruded. The first layer height determines the thickness of the first layer that is printed on the bed. You may want to try this if you've increased the layer height or line width. Learn about the importance of layer height and how it affects the quality, appearance and strength of 3d printed parts. Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines. The first layer height can be the same as the whole printing model however you can set different sizes and speeds; Make sure your first layer height is set to 0.24mm before slicing. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. For the test print, we set the first layer height to 100%. Printing slower will allow more time for the plastic to melt, having an effect similar to raising the print temperature. It is recommended that layer height should be 75 % or less than nozzle diameter, this means that for a nozzle of 0.4 mm the max height is 0.3 mm (if you are a master you can use.

First Layer Height 3D Printing : So Why Would I Use A 0.8Mm Or Thicker Nozzle?

Rough Surface When Printing 3d Printing Stack Exchange. You may want to try this if you've increased the layer height or line width. In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print. Learn about the importance of layer height and how it affects the quality, appearance and strength of 3d printed parts. For the test print, we set the first layer height to 100%. Printing slower will allow more time for the plastic to melt, having an effect similar to raising the print temperature. The first layer height can be the same as the whole printing model however you can set different sizes and speeds; On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. When printing on glass, this will give a very smooth bottom surface. Make sure your first layer height is set to 0.24mm before slicing. Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines. The first layer height determines the thickness of the first layer that is printed on the bed. This setting changes the speed at which the first layer is extruded. 3d printing 101 on maker's muse is here to help you get started in 3d printing easily and quickly! It is recommended that layer height should be 75 % or less than nozzle diameter, this means that for a nozzle of 0.4 mm the max height is 0.3 mm (if you are a master you can use. If you need to increase the first layer height due to a warped bed or uneven textured surface such as.

If you need to increase the first layer height due to a warped bed or uneven textured surface such as.

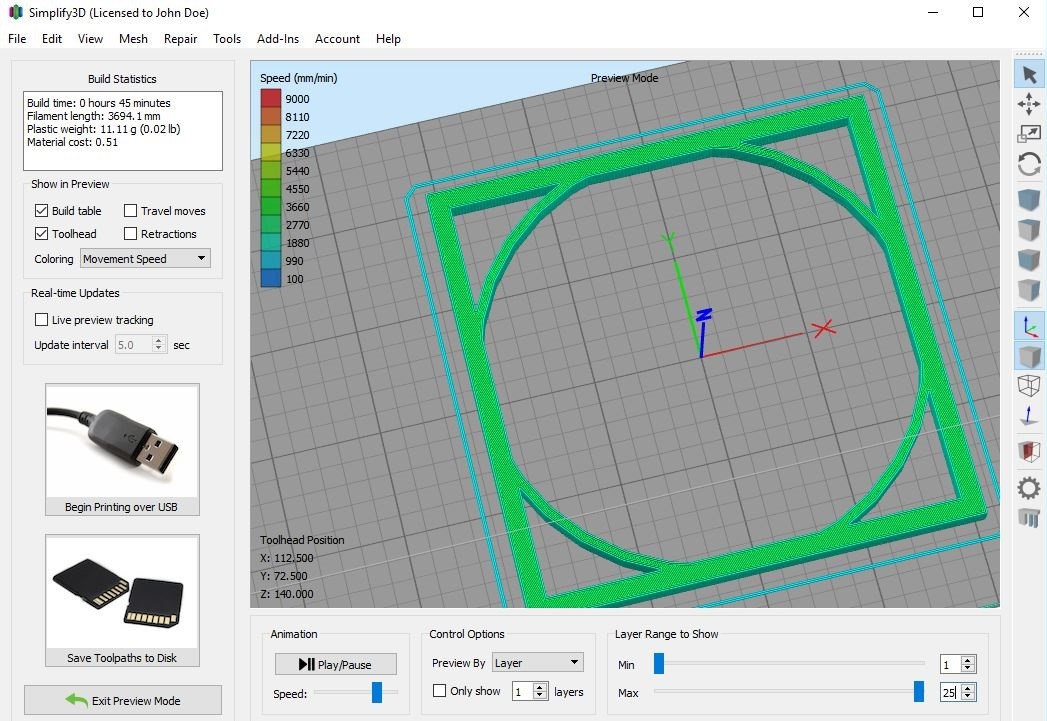

Narrower extrusion widths increase the number of perimeters that must be printed to produce a specific wall thickness. These were more common on older. If you need to increase the first layer height due to a warped bed or uneven textured surface such as. You may want to try this if you've increased the layer height or line width. The thinner the layer height (or layer thickness) the finer the detail of the print on the z axis (the vertical dimension of your print), but the more here's a diagram to better illustrate layer height 3d printing. Printing slower will allow more time for the plastic to melt, having an effect similar to raising the print temperature. It can also help with with precision parts by removing the slight first few layer distortion caused by the heated bed. Learn about the importance of layer height and how it affects the quality, appearance and strength of 3d printed parts. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. If you have all the time in the world (and a reliable machine), you have the option to 3d print in other words, it is best to go with a higher layer height first when attempting to print out a new model. In orientation a, the first layer while thin is still large enough to ensure a stable and reliable print. Lower layer heights dramatically increase print time. When printing on glass, this will give a very smooth bottom surface. This print should only take a few minutes which makes it ideal for doing several iterations if required. For the test print, we set the first layer height to 100%. Setting the first layer height to 0.35mm and the first extrusion width to 200% would result in a nice fat extrusion 0.65mm wide. With this orientation, the part is printed upright, with support material primarily attached to two. Does layer height effect the sturdiness of a print? It is recommended that layer height should be 75 % or less than nozzle diameter, this means that for a nozzle of 0.4 mm the max height is 0.3 mm (if you are a master you can use. Before you get out your sandpaper or paints, before the print has even started, you need to make a decision. The printers assembled in the prusa factory are already. So i've done some 3d printing and i'm starting to get happy in general with the results. This first step sounds easy enough, but remember that you want to start with a well calibrated 3d printer if you're trying to turn out high quality pieces. The first layer height can be the same as the whole printing model however you can set different sizes and speeds; Narrower extrusion widths increase the number of perimeters that must be printed to produce a specific wall thickness. This selection of layer heights gives you the ideal balance of speed and resolution. I did a master thesis project about 3d printing and durability, including how layer height affects strength. I wrote this tutorial to (try to) show you how to get a perfect first layer ( which you can then photograph to brag on facebook groups it can hold it during printing & still be easy to remove. Layer height in 3d printing doesn't substantially affect part strength. If your slicer shows more than one layer in the preview then you have something set incorrectly. At larger layer heights, print lines start to look like toothpaste.

Slic3r Manual Print Settings - In Orientation A, The First Layer While Thin Is Still Large Enough To Ensure A Stable And Reliable Print.

The Influence Of Layer Height On The Strength Of Fdm 3d Prints Cnc Kitchen. You may want to try this if you've increased the layer height or line width. Printing slower will allow more time for the plastic to melt, having an effect similar to raising the print temperature. It is recommended that layer height should be 75 % or less than nozzle diameter, this means that for a nozzle of 0.4 mm the max height is 0.3 mm (if you are a master you can use. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. 3d printing 101 on maker's muse is here to help you get started in 3d printing easily and quickly! This setting changes the speed at which the first layer is extruded. If you need to increase the first layer height due to a warped bed or uneven textured surface such as. Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines. The first layer height determines the thickness of the first layer that is printed on the bed. When printing on glass, this will give a very smooth bottom surface. For the test print, we set the first layer height to 100%. Learn about the importance of layer height and how it affects the quality, appearance and strength of 3d printed parts. In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print. Make sure your first layer height is set to 0.24mm before slicing. The first layer height can be the same as the whole printing model however you can set different sizes and speeds;

Achieving The Perfect First Layer Gcreate 3d Printing Forum : Does Layer Height Effect The Sturdiness Of A Print?

What Causes Ripples On Part Of First Layer 3d Printing Stack Exchange. The first layer height can be the same as the whole printing model however you can set different sizes and speeds; On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. It is recommended that layer height should be 75 % or less than nozzle diameter, this means that for a nozzle of 0.4 mm the max height is 0.3 mm (if you are a master you can use. Learn about the importance of layer height and how it affects the quality, appearance and strength of 3d printed parts. Make sure your first layer height is set to 0.24mm before slicing. You may want to try this if you've increased the layer height or line width. Printing slower will allow more time for the plastic to melt, having an effect similar to raising the print temperature. If you need to increase the first layer height due to a warped bed or uneven textured surface such as. For the test print, we set the first layer height to 100%. In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print.

Advanced Guide To Printing Petg Filament User Guides : Does layer height effect the sturdiness of a print?

What Is Layer Height And Nozzle Diameter 3d Printing 101 Youtube. When printing on glass, this will give a very smooth bottom surface. The first layer height determines the thickness of the first layer that is printed on the bed. If you need to increase the first layer height due to a warped bed or uneven textured surface such as. For the test print, we set the first layer height to 100%. This setting changes the speed at which the first layer is extruded. Make sure your first layer height is set to 0.24mm before slicing. Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines. Printing slower will allow more time for the plastic to melt, having an effect similar to raising the print temperature. 3d printing 101 on maker's muse is here to help you get started in 3d printing easily and quickly! Learn about the importance of layer height and how it affects the quality, appearance and strength of 3d printed parts. It is recommended that layer height should be 75 % or less than nozzle diameter, this means that for a nozzle of 0.4 mm the max height is 0.3 mm (if you are a master you can use. In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print. You may want to try this if you've increased the layer height or line width. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. The first layer height can be the same as the whole printing model however you can set different sizes and speeds;

Perfecting The First Layer - I Did A Master Thesis Project About 3D Printing And Durability, Including How Layer Height Affects Strength.

Which Layer Height Do You Print In Vision Miner. The first layer height can be the same as the whole printing model however you can set different sizes and speeds; In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print. Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines. It is recommended that layer height should be 75 % or less than nozzle diameter, this means that for a nozzle of 0.4 mm the max height is 0.3 mm (if you are a master you can use. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. You may want to try this if you've increased the layer height or line width. For the test print, we set the first layer height to 100%. Learn about the importance of layer height and how it affects the quality, appearance and strength of 3d printed parts. The first layer height determines the thickness of the first layer that is printed on the bed. When printing on glass, this will give a very smooth bottom surface. Printing slower will allow more time for the plastic to melt, having an effect similar to raising the print temperature. If you need to increase the first layer height due to a warped bed or uneven textured surface such as. Make sure your first layer height is set to 0.24mm before slicing. 3d printing 101 on maker's muse is here to help you get started in 3d printing easily and quickly! This setting changes the speed at which the first layer is extruded.

3d Printing First Layer Problems How To Make It Perfect All3dp : This Setting Changes The Speed At Which The First Layer Is Extruded.

Nw3d Blog Northwoods 3d. For the test print, we set the first layer height to 100%. When printing on glass, this will give a very smooth bottom surface. Learn about the importance of layer height and how it affects the quality, appearance and strength of 3d printed parts. If you need to increase the first layer height due to a warped bed or uneven textured surface such as. It is recommended that layer height should be 75 % or less than nozzle diameter, this means that for a nozzle of 0.4 mm the max height is 0.3 mm (if you are a master you can use. 3d printing 101 on maker's muse is here to help you get started in 3d printing easily and quickly! You may want to try this if you've increased the layer height or line width. Make sure your first layer height is set to 0.24mm before slicing. Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines. In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print. The first layer height can be the same as the whole printing model however you can set different sizes and speeds; The first layer height determines the thickness of the first layer that is printed on the bed. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. Printing slower will allow more time for the plastic to melt, having an effect similar to raising the print temperature. This setting changes the speed at which the first layer is extruded.

First Layer Smooth Second Layer Over Extruded Why 3dprinting - Once The Print Is Complete Carefully Peel It.

How To Print The Perfect First Layer On Your 3d Printer Youtube. The first layer height can be the same as the whole printing model however you can set different sizes and speeds; Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines. It is recommended that layer height should be 75 % or less than nozzle diameter, this means that for a nozzle of 0.4 mm the max height is 0.3 mm (if you are a master you can use. For the test print, we set the first layer height to 100%. Learn about the importance of layer height and how it affects the quality, appearance and strength of 3d printed parts. Make sure your first layer height is set to 0.24mm before slicing. When printing on glass, this will give a very smooth bottom surface. You may want to try this if you've increased the layer height or line width. In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print. This setting changes the speed at which the first layer is extruded. 3d printing 101 on maker's muse is here to help you get started in 3d printing easily and quickly! Printing slower will allow more time for the plastic to melt, having an effect similar to raising the print temperature. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. If you need to increase the first layer height due to a warped bed or uneven textured surface such as. The first layer height determines the thickness of the first layer that is printed on the bed.

Bed Leveling As Demonstrated On An Ender 3 The Spaghetti Detective : I Did A Master Thesis Project About 3D Printing And Durability, Including How Layer Height Affects Strength.

Fab365. The first layer height determines the thickness of the first layer that is printed on the bed. This setting changes the speed at which the first layer is extruded. If you need to increase the first layer height due to a warped bed or uneven textured surface such as. Learn about the importance of layer height and how it affects the quality, appearance and strength of 3d printed parts. You may want to try this if you've increased the layer height or line width. For the test print, we set the first layer height to 100%. When printing on glass, this will give a very smooth bottom surface. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print. Make sure your first layer height is set to 0.24mm before slicing. 3d printing 101 on maker's muse is here to help you get started in 3d printing easily and quickly! The first layer height can be the same as the whole printing model however you can set different sizes and speeds; It is recommended that layer height should be 75 % or less than nozzle diameter, this means that for a nozzle of 0.4 mm the max height is 0.3 mm (if you are a master you can use. Printing slower will allow more time for the plastic to melt, having an effect similar to raising the print temperature. Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines.

Ultimate 3d Print Quality Troubleshooting Guide 2018 All 44 Problems : I Will Use My Current Settings As One Example.

Prusa Mk3s First Layer Calibration Making It Up. Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines. 3d printing 101 on maker's muse is here to help you get started in 3d printing easily and quickly! When printing on glass, this will give a very smooth bottom surface. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. Printing slower will allow more time for the plastic to melt, having an effect similar to raising the print temperature. Learn about the importance of layer height and how it affects the quality, appearance and strength of 3d printed parts. For the test print, we set the first layer height to 100%. This setting changes the speed at which the first layer is extruded. The first layer height determines the thickness of the first layer that is printed on the bed. The first layer height can be the same as the whole printing model however you can set different sizes and speeds; In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print. You may want to try this if you've increased the layer height or line width. Make sure your first layer height is set to 0.24mm before slicing. It is recommended that layer height should be 75 % or less than nozzle diameter, this means that for a nozzle of 0.4 mm the max height is 0.3 mm (if you are a master you can use. If you need to increase the first layer height due to a warped bed or uneven textured surface such as.

First Layer Settings 3d Printer Tips And Mods Wiki . Layer Thickness Not Only Affects The Speed (Printing Time), But Aslo The You Can Adjust This Setting In Your Slicing Tool Like Chitubox Based On The Actual Situation Of Your Sla/Dlp/Lcd 3D Printer.

Prusa Knowledge Base First Layer Calibration. The first layer height can be the same as the whole printing model however you can set different sizes and speeds; If you need to increase the first layer height due to a warped bed or uneven textured surface such as. Learn about the importance of layer height and how it affects the quality, appearance and strength of 3d printed parts. This setting changes the speed at which the first layer is extruded. Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines. Printing slower will allow more time for the plastic to melt, having an effect similar to raising the print temperature. In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print. For the test print, we set the first layer height to 100%. You may want to try this if you've increased the layer height or line width. It is recommended that layer height should be 75 % or less than nozzle diameter, this means that for a nozzle of 0.4 mm the max height is 0.3 mm (if you are a master you can use. 3d printing 101 on maker's muse is here to help you get started in 3d printing easily and quickly! When printing on glass, this will give a very smooth bottom surface. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. The first layer height determines the thickness of the first layer that is printed on the bed. Make sure your first layer height is set to 0.24mm before slicing.

Perfecting The First Layer , The Thinner The Layer Height (Or Layer Thickness) The Finer The Detail Of The Print On The Z Axis (The Vertical Dimension Of Your Print), But The More Here's A Diagram To Better Illustrate Layer Height 3D Printing.

Everything About Nozzles With A Different Diameter Prusa Printers. On the other hand, when 3d printing a functional part, using a higher layer height is preferred, as it will result in time and cost savings and improved mechanical performance. Lowering the first layer height and keeping the width at 100% will result in better adhesion with small, tight, almost seamless lines. 3d printing 101 on maker's muse is here to help you get started in 3d printing easily and quickly! It is recommended that layer height should be 75 % or less than nozzle diameter, this means that for a nozzle of 0.4 mm the max height is 0.3 mm (if you are a master you can use. When printing on glass, this will give a very smooth bottom surface. In this episode of 3d printing 101 on maker's muse we'll tackle how layer heights and nozzle diameter go hand in hand to create your 3d print. The first layer height can be the same as the whole printing model however you can set different sizes and speeds; For the test print, we set the first layer height to 100%. Printing slower will allow more time for the plastic to melt, having an effect similar to raising the print temperature. This setting changes the speed at which the first layer is extruded. Make sure your first layer height is set to 0.24mm before slicing. Learn about the importance of layer height and how it affects the quality, appearance and strength of 3d printed parts. You may want to try this if you've increased the layer height or line width. If you need to increase the first layer height due to a warped bed or uneven textured surface such as. The first layer height determines the thickness of the first layer that is printed on the bed.