Infill Ratio 3D Printing. Besides the actual printing process, infill will affect the strength or feel of the final product. Infill provides the 3d print with internal support as the printer builds each layer. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. What is infill in 3d printing? Best infill for strength vs material used. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. All3dp is an editorially independent publication. This shape is the most efficient infill and fastest to print, the goto infill for most things. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. Editorial content, on principle, can not be bought or influenced.

Infill Ratio 3D Printing : All3Dp Is An Editorially Independent Publication.

How Do Layer Height Infill Settings Impact 3d Print Strength 3d Matter. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. Best infill for strength vs material used. The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. All3dp is an editorially independent publication. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. This shape is the most efficient infill and fastest to print, the goto infill for most things. What is infill in 3d printing? Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with. Editorial content, on principle, can not be bought or influenced. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Besides the actual printing process, infill will affect the strength or feel of the final product. The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. Infill provides the 3d print with internal support as the printer builds each layer.

The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio.

Properties would include wall thickness, filament type, infill. Rectilinear is quick and does the job, kind of the median setting. This is because geometry matters to cells! The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Infill with increased strength for the lowest weight. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Best infill for strength vs material used. Consider a print with low infill that is going to be drilled and then screwed to another surface. 3d printing stack exchange is a question and answer site for 3d printing enthusiasts. What is infill in 3d printing? This blog will teach you the basics for understanding 3d printer extrusion, how we developed the calculator and why it can be very useful for you. Choosing the slic3r infill pattern for your bioprint can be tricky and confusing. Properties would include wall thickness, filament type, infill. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. The print speed calculator has been developed to help you choose the right setting based on our experimental values. Properties would include wall thickness, filament type, infill density, and infill type. The mechanical properties would reflect the way a 3d printer creates a smooth shell of a part with lightweight but weaker core structure. 3d printing layer height and its effect on part strenght and print speed. Infill provides the 3d print with internal support as the printer builds each layer. Firstly, i am unclear on how hexagonal infill is stronger than, say, diamond pattern. Learn how to optimize these features for your 3d printed part. Infill ratio describes the percentage of plastic filling the inside of your 3d print, under the outer layer. Editorial content, on principle, can not be bought or influenced. For those unfamiliar, shells are the outer layers of a print which make the walls of an object, prior to the various infill levels being printed within. They understand the substrates surrounding them and. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Can anyone explain how the different shape causes the structure to be stronger? Low infill saves the material and speeds up the layer height has a huge impact on the quality of 3d prints. Additive manufacturing technologies allow users to adjust the infill of a printed object, which represents the interior structure of a 3d printed object 55. Say it 5 times fast!

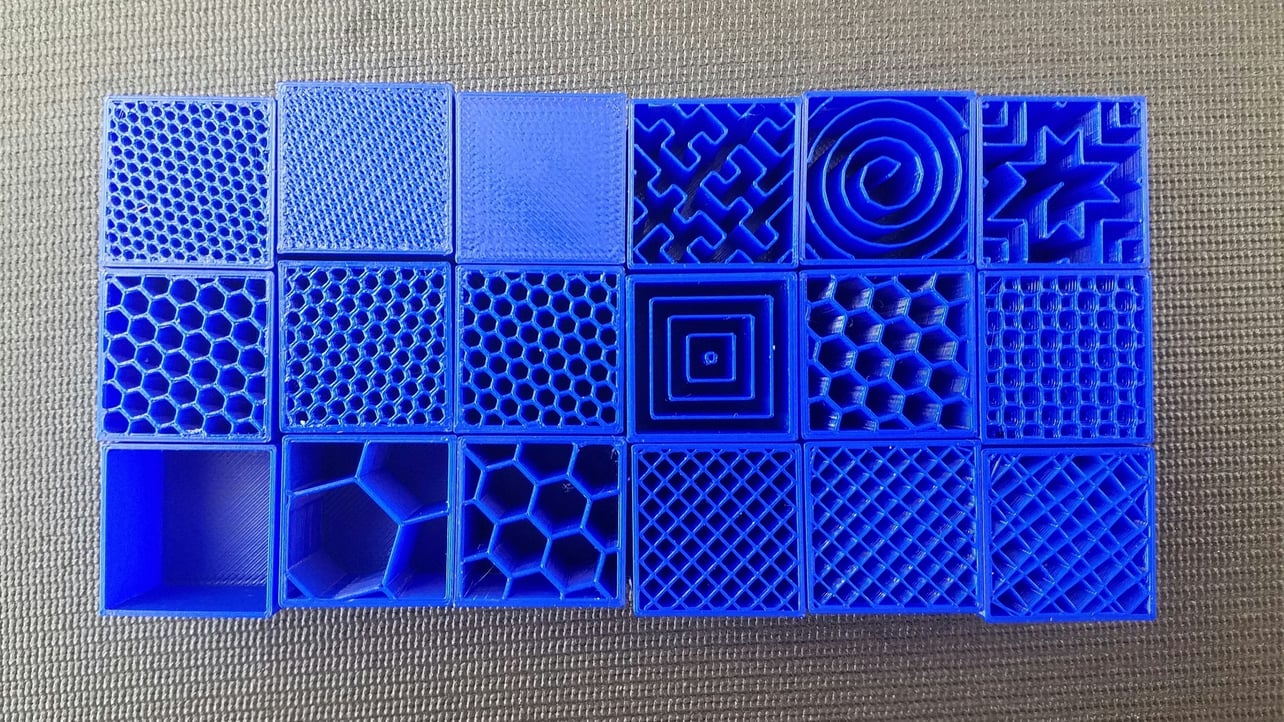

3d Printable Infill Density Reference Display By Joseph Bozarth : Learn How To Optimize These Features For Your 3D Printed Part.

How Do Layer Height Infill Settings Impact 3d Print Strength 3d Matter. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. This shape is the most efficient infill and fastest to print, the goto infill for most things. What is infill in 3d printing? We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Besides the actual printing process, infill will affect the strength or feel of the final product. The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. Best infill for strength vs material used. Editorial content, on principle, can not be bought or influenced. All3dp is an editorially independent publication. The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. Infill provides the 3d print with internal support as the printer builds each layer. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with.

3d Printing Infill Archives Perfect 3d Printing Filament , Download Files And Build Them With Your 3D Printer, Laser Cutter, Or Cnc.

How To Choose An Infill For Your 3d Prints. Infill provides the 3d print with internal support as the printer builds each layer. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. Best infill for strength vs material used. The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Besides the actual printing process, infill will affect the strength or feel of the final product. This shape is the most efficient infill and fastest to print, the goto infill for most things. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill.

Infill Pattern Basics Simplify3d Youtube - The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing.

How Do Layer Height Infill Settings Impact 3d Print Strength 3d Matter. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. This shape is the most efficient infill and fastest to print, the goto infill for most things. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Besides the actual printing process, infill will affect the strength or feel of the final product. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. What is infill in 3d printing? The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. All3dp is an editorially independent publication. Best infill for strength vs material used. Infill provides the 3d print with internal support as the printer builds each layer. Editorial content, on principle, can not be bought or influenced. The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with.

What Is The Influence Of Infill Layer Height And Infill Pattern On My 3d Prints 3dprinteros . Say It 5 Times Fast!

The Importance Of The Type Of Infill In 3d Printing. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. What is infill in 3d printing? Best infill for strength vs material used. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with. This shape is the most efficient infill and fastest to print, the goto infill for most things. The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. All3dp is an editorially independent publication. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. Editorial content, on principle, can not be bought or influenced. Infill provides the 3d print with internal support as the printer builds each layer. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Besides the actual printing process, infill will affect the strength or feel of the final product.

What Infill Settings Should I Use For My Fdm 3d Print Sd3d Printing : What Is Infill In 3D Printing?

3d Printing Infill The Basics Simply Explained All3dp. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. Infill provides the 3d print with internal support as the printer builds each layer. Editorial content, on principle, can not be bought or influenced. Besides the actual printing process, infill will affect the strength or feel of the final product. What is infill in 3d printing? When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Best infill for strength vs material used. The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with. All3dp is an editorially independent publication. This shape is the most efficient infill and fastest to print, the goto infill for most things. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing.

Pdf Study Of Infill Print Design On Production Cost Time Of 3d Printed Abs Parts , I Want To Be Able To Have A Print Be Very Bottom Heavy And Have Like Say 50% Infill At The Bottom But Drop Down To If You Increase The Infill Ratio Every Layer (Or Every Few Layers), There Will Be Tighter Spacing And Lines Won't.

Effect Of Infill Patterns On The Mechanical Performance Of Lightweight 3d Printed Cellular Pla Parts Sciencedirect. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. Besides the actual printing process, infill will affect the strength or feel of the final product. What is infill in 3d printing? .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. Editorial content, on principle, can not be bought or influenced. The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. This shape is the most efficient infill and fastest to print, the goto infill for most things. Infill provides the 3d print with internal support as the printer builds each layer. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with. Best infill for strength vs material used. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. All3dp is an editorially independent publication.

Z Suite 2 Print Preparation Guide Zortrax Support Center - I Want To Be Able To Have A Print Be Very Bottom Heavy And Have Like Say 50% Infill At The Bottom But Drop Down To If You Increase The Infill Ratio Every Layer (Or Every Few Layers), There Will Be Tighter Spacing And Lines Won't.

Bridging Over Honeycomb Infill Ruining Prints 3dprinting. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with. Besides the actual printing process, infill will affect the strength or feel of the final product. Editorial content, on principle, can not be bought or influenced. All3dp is an editorially independent publication. The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. What is infill in 3d printing? Infill provides the 3d print with internal support as the printer builds each layer. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. Best infill for strength vs material used. This shape is the most efficient infill and fastest to print, the goto infill for most things.

Slic3r Manual Print Settings : The Ratio Of Infilled Space To Your Model's Internal Volume Is Called Infill Percentage In 3D Printing.

Infill With Modulated Stiffness For 3d Printing More Elastic Infill Is Download Scientific Diagram. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. What is infill in 3d printing? All3dp is an editorially independent publication. The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. Best infill for strength vs material used. Besides the actual printing process, infill will affect the strength or feel of the final product. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. This shape is the most efficient infill and fastest to print, the goto infill for most things. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with. Infill provides the 3d print with internal support as the printer builds each layer. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. Editorial content, on principle, can not be bought or influenced.

Infill Pattern Basics Simplify3d Youtube : Triangular Infill Is The Strongest Infill Pattern Because Triangles Are The Strongest Shape.

3d Printing Settings Impacting Part Strength. Infill provides the 3d print with internal support as the printer builds each layer. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Editorial content, on principle, can not be bought or influenced. Best infill for strength vs material used. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with. The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. Besides the actual printing process, infill will affect the strength or feel of the final product. We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. This shape is the most efficient infill and fastest to print, the goto infill for most things. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. All3dp is an editorially independent publication. What is infill in 3d printing? The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing.

3d Printable Infill Density Reference Display By Joseph Bozarth : When It Comes To 3D Printing, Infill Is A Very Important Factor To A Print's Strength, Structure, And Weight.

What Is The Influence Of Infill Layer Height And Infill Pattern On My 3d Prints 3dprinteros. When it comes to 3d printing, infill is a very important factor to a print's strength, structure, and weight. The infill in 3d printing can be carried out with it's set during the preparation of a part for printing. Infill provides the 3d print with internal support as the printer builds each layer. Best infill for strength vs material used. The infill the amount of material that occupies the internal part of weight and a very efficient printing time, which transforms into parts with a good resistance / cost ratio. This shape is the most efficient infill and fastest to print, the goto infill for most things. Besides the actual printing process, infill will affect the strength or feel of the final product. Once you know what your print is going to be used for, you should have a general idea of the pattern and percentage that you. Editorial content, on principle, can not be bought or influenced. .of infill in 3d printing meta_description => in this post we talk about how the infill can affect the infill percentage in 3d printing. What is infill in 3d printing? We'll then cover any troubleshooting with infill related problems and how to compensate when using low or no infill. Sometimes parts were gotten stronger with minimal infill but good wall thickness than parts with. The ratio of infilled space to your model's internal volume is called infill percentage in 3d printing. All3dp is an editorially independent publication.