Inkjet 3D Printing Process. Different sff technologies use different types. Printing instructions in each layer are generated from a 3d mechanical model for your product, just as is done with popular fused deposition modeling (fdm) systems. Let's walk through the printing process to see just what happens. Continuous inkjet printing is an established technology that has been around for 150 years. Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper and plastic substrates. Whereas direct metal laser sintering/selective inkjet is probably the most exciting area in metal 3d printing at the moment. There are new companies and new technologies being commercialized. Inkjet metal 3d printing processes make some of the most production ready parts in the world. The inkjet printing process, as implemented by solidscape inc., begins with the build material (thermoplastic) and support material (wax) being held in a melted state inside two heated reservoirs. Inkjet printers shoot miniscule droplets of ink onto paper to create a seemingly fluid stroke. This is done by adding one or more layers of white ink to the regular printing process. It was first commercially used as a rapid prototyping method in the. Adding a subtle 3d effect is an easy way to make a print stand out. Layers of material in the 3d inkjet printing process. Inkjet printers are the most commonly used type of printer.

Inkjet 3D Printing Process . Here 3D Printers Based On.

Mas 865 2018 How To Make Something That Makes Almost Anything. Layers of material in the 3d inkjet printing process. Printing instructions in each layer are generated from a 3d mechanical model for your product, just as is done with popular fused deposition modeling (fdm) systems. Different sff technologies use different types. This is done by adding one or more layers of white ink to the regular printing process. Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper and plastic substrates. It was first commercially used as a rapid prototyping method in the. Continuous inkjet printing is an established technology that has been around for 150 years. Let's walk through the printing process to see just what happens. Inkjet printers are the most commonly used type of printer. The inkjet printing process, as implemented by solidscape inc., begins with the build material (thermoplastic) and support material (wax) being held in a melted state inside two heated reservoirs. There are new companies and new technologies being commercialized. Whereas direct metal laser sintering/selective inkjet is probably the most exciting area in metal 3d printing at the moment. Inkjet printers shoot miniscule droplets of ink onto paper to create a seemingly fluid stroke. Inkjet metal 3d printing processes make some of the most production ready parts in the world. Adding a subtle 3d effect is an easy way to make a print stand out.

Let's walk through the printing process to see just what happens.

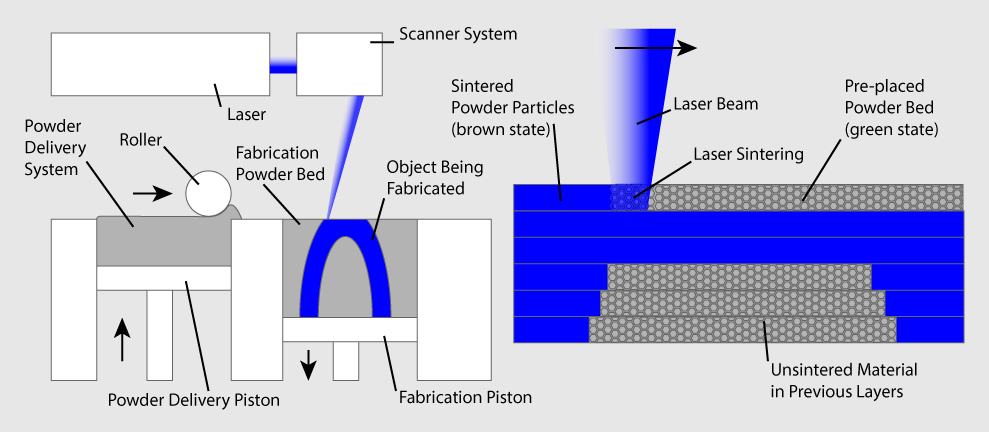

Different sff technologies use different types. Let's walk through the printing process to see just what happens. Inkjet printers are the most commonly used type of printer. The final attributes of the printed tablets were clearly. Learn how to 3d print. Inkjet printing — using special inks (resins and binders) it's possible to build up a 3d model using a device that's very similar to a home or office inkjet printer. The sla 3d printing process first appeared in the early 1970s, when japanese researcher dr. Industrial material jetting and sla printers, for example, are able to produce parts down to ± 0.01 metal 3d printed parts for critical applications are often finished via cnc machining or another process after printing, to improve their tolerances and. In 10, gong et al. Different sff technologies use different types. Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper and plastic substrates. Layers of material in the 3d inkjet printing process. In this process, material is applied in droplets through a small diameter nozzle, similar to the way a common inkjet paper printer works, but it is applied. Layer upon layer of resin and binder are added until an object is created. This is done by adding one or more layers of white ink to the regular printing process. A uv inkjet printer propels tiny droplets of ink onto paper, plastic, glass, metal and other substrates in order to form an image through the use of an ink delivery system, also known as a print head. It starts from creation of 3d model in cad program, special piece of software home 3d printers usually use additive manufacturing(am) processes and not stereolithography to produce 3d objects. This is the only 3d printing process that allows for custom colors. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. Inkjet printers shoot miniscule droplets of ink onto paper to create a seemingly fluid stroke. Here 3d printers based on. Here lies the importance of inkjet dyes. Adding a subtle 3d effect is an easy way to make a print stand out. Each of these builds objects in successive layers that are typically about also increasingly being used in traditional metal casting processes are 3d printed substitutes for 'lost wax' patterns. Jetting is somewhat similar to sla, except instead of using a vat of liquid, it sprays a jet of reactive polymer onto a base, and then it's most similar to modern inkjet printer, except jetting tends to use advanced polymers with unique properties. There are new companies and new technologies being commercialized. During this step, the supports and. The process of 3d printing begins by making a graphic model of the object to be printed. 3d printing encompasses a wide range of additive manufacturing technologies. The inkjet printing process, as implemented by solidscape inc., begins with the build material (thermoplastic) and support material (wax) being held in a melted state inside two heated reservoirs. This is a vital step as a 3d printer cannot conceptualize a 3d model in the.

Mas 865 2018 How To Make Something That Makes Almost Anything : It Starts From Creation Of 3D Model In Cad Program, Special Piece Of Software Home 3D Printers Usually Use Additive Manufacturing(Am) Processes And Not Stereolithography To Produce 3D Objects.

History Of 3d Printing 3d Printers Are Older Than You Think. Adding a subtle 3d effect is an easy way to make a print stand out. Inkjet printers are the most commonly used type of printer. Inkjet printers shoot miniscule droplets of ink onto paper to create a seemingly fluid stroke. It was first commercially used as a rapid prototyping method in the. Continuous inkjet printing is an established technology that has been around for 150 years. Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper and plastic substrates. This is done by adding one or more layers of white ink to the regular printing process. Printing instructions in each layer are generated from a 3d mechanical model for your product, just as is done with popular fused deposition modeling (fdm) systems. The inkjet printing process, as implemented by solidscape inc., begins with the build material (thermoplastic) and support material (wax) being held in a melted state inside two heated reservoirs. Different sff technologies use different types. Layers of material in the 3d inkjet printing process. Let's walk through the printing process to see just what happens. Inkjet metal 3d printing processes make some of the most production ready parts in the world. There are new companies and new technologies being commercialized. Whereas direct metal laser sintering/selective inkjet is probably the most exciting area in metal 3d printing at the moment.

What Is D Shape D Shape - A Uv Inkjet Printer Uses A Uv Digital Printing Process To Apply A 2D Digital Image To A 3D Object.

Freeform Micropatterning Of Living Cells Into Cell Culture Medium Using Direct Inkjet Printing Scientific Reports. Different sff technologies use different types. This is done by adding one or more layers of white ink to the regular printing process. Whereas direct metal laser sintering/selective inkjet is probably the most exciting area in metal 3d printing at the moment. Inkjet metal 3d printing processes make some of the most production ready parts in the world. Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper and plastic substrates. Let's walk through the printing process to see just what happens. Layers of material in the 3d inkjet printing process. There are new companies and new technologies being commercialized. Inkjet printers are the most commonly used type of printer. Inkjet printers shoot miniscule droplets of ink onto paper to create a seemingly fluid stroke.

3d Printing Technologies Recent Development And Emerging Applications In Various Drug Delivery Systems Springerlink . It starts from creation of 3d model in cad program, special piece of software home 3d printers usually use additive manufacturing(am) processes and not stereolithography to produce 3d objects.

3d Printing Additive Make. Inkjet metal 3d printing processes make some of the most production ready parts in the world. It was first commercially used as a rapid prototyping method in the. Whereas direct metal laser sintering/selective inkjet is probably the most exciting area in metal 3d printing at the moment. This is done by adding one or more layers of white ink to the regular printing process. Adding a subtle 3d effect is an easy way to make a print stand out. Continuous inkjet printing is an established technology that has been around for 150 years. Layers of material in the 3d inkjet printing process. The inkjet printing process, as implemented by solidscape inc., begins with the build material (thermoplastic) and support material (wax) being held in a melted state inside two heated reservoirs. Let's walk through the printing process to see just what happens. Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper and plastic substrates. Inkjet printers are the most commonly used type of printer. There are new companies and new technologies being commercialized. Inkjet printers shoot miniscule droplets of ink onto paper to create a seemingly fluid stroke. Different sff technologies use different types. Printing instructions in each layer are generated from a 3d mechanical model for your product, just as is done with popular fused deposition modeling (fdm) systems.

3d Printed Microfluidic Devices Enablers And Barriers Lab On A Chip Rsc Publishing , 3D Printing Encompasses A Wide Range Of Additive Manufacturing Technologies.

The Intersection Of Inkjet And 3d Printing Inkjet Insight. Whereas direct metal laser sintering/selective inkjet is probably the most exciting area in metal 3d printing at the moment. Inkjet printers shoot miniscule droplets of ink onto paper to create a seemingly fluid stroke. It was first commercially used as a rapid prototyping method in the. Continuous inkjet printing is an established technology that has been around for 150 years. This is done by adding one or more layers of white ink to the regular printing process. Adding a subtle 3d effect is an easy way to make a print stand out. Let's walk through the printing process to see just what happens. Inkjet metal 3d printing processes make some of the most production ready parts in the world. Different sff technologies use different types. Inkjet printers are the most commonly used type of printer. Printing instructions in each layer are generated from a 3d mechanical model for your product, just as is done with popular fused deposition modeling (fdm) systems. Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper and plastic substrates. Layers of material in the 3d inkjet printing process. The inkjet printing process, as implemented by solidscape inc., begins with the build material (thermoplastic) and support material (wax) being held in a melted state inside two heated reservoirs. There are new companies and new technologies being commercialized.

3d Printing Market By Source Type Application Geography Covid 19 Impact Analysis Marketsandmarkets . Here 3D Printers Based On.

Continuous Inkjet Printer Systems Ink Droplets Are Constantly Ejected Download Scientific Diagram. Adding a subtle 3d effect is an easy way to make a print stand out. Layers of material in the 3d inkjet printing process. Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper and plastic substrates. It was first commercially used as a rapid prototyping method in the. Inkjet printers are the most commonly used type of printer. The inkjet printing process, as implemented by solidscape inc., begins with the build material (thermoplastic) and support material (wax) being held in a melted state inside two heated reservoirs. Printing instructions in each layer are generated from a 3d mechanical model for your product, just as is done with popular fused deposition modeling (fdm) systems. Inkjet printers shoot miniscule droplets of ink onto paper to create a seemingly fluid stroke. This is done by adding one or more layers of white ink to the regular printing process. Let's walk through the printing process to see just what happens. Different sff technologies use different types. Inkjet metal 3d printing processes make some of the most production ready parts in the world. Whereas direct metal laser sintering/selective inkjet is probably the most exciting area in metal 3d printing at the moment. Continuous inkjet printing is an established technology that has been around for 150 years. There are new companies and new technologies being commercialized.

The Types Of 3d Printing Technology In 2020 All3dp - It Starts From Creation Of 3D Model In Cad Program, Special Piece Of Software Home 3D Printers Usually Use Additive Manufacturing(Am) Processes And Not Stereolithography To Produce 3D Objects.

Binder Jetting In 3d Printing. There are new companies and new technologies being commercialized. It was first commercially used as a rapid prototyping method in the. The inkjet printing process, as implemented by solidscape inc., begins with the build material (thermoplastic) and support material (wax) being held in a melted state inside two heated reservoirs. This is done by adding one or more layers of white ink to the regular printing process. Layers of material in the 3d inkjet printing process. Different sff technologies use different types. Inkjet printers are the most commonly used type of printer. Printing instructions in each layer are generated from a 3d mechanical model for your product, just as is done with popular fused deposition modeling (fdm) systems. Continuous inkjet printing is an established technology that has been around for 150 years. Let's walk through the printing process to see just what happens. Adding a subtle 3d effect is an easy way to make a print stand out. Inkjet metal 3d printing processes make some of the most production ready parts in the world. Inkjet printers shoot miniscule droplets of ink onto paper to create a seemingly fluid stroke. Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper and plastic substrates. Whereas direct metal laser sintering/selective inkjet is probably the most exciting area in metal 3d printing at the moment.

The Schematic Images Of A I3dp P And B I3dp L Printer Based Inkjet Download Scientific Diagram , Continuous Inkjet Printing Is An Established Technology That Has Been Around For 150 Years.

Schematic Illustration Of The Inkjet 3d Printing Process Download Scientific Diagram. Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper and plastic substrates. Different sff technologies use different types. Whereas direct metal laser sintering/selective inkjet is probably the most exciting area in metal 3d printing at the moment. This is done by adding one or more layers of white ink to the regular printing process. It was first commercially used as a rapid prototyping method in the. Layers of material in the 3d inkjet printing process. Continuous inkjet printing is an established technology that has been around for 150 years. Inkjet printers are the most commonly used type of printer. Inkjet printers shoot miniscule droplets of ink onto paper to create a seemingly fluid stroke. Let's walk through the printing process to see just what happens. Inkjet metal 3d printing processes make some of the most production ready parts in the world. Adding a subtle 3d effect is an easy way to make a print stand out. There are new companies and new technologies being commercialized. Printing instructions in each layer are generated from a 3d mechanical model for your product, just as is done with popular fused deposition modeling (fdm) systems. The inkjet printing process, as implemented by solidscape inc., begins with the build material (thermoplastic) and support material (wax) being held in a melted state inside two heated reservoirs.

Bioengineering Free Full Text 3d Printing Of Organs On Chips Html . A Uv Inkjet Printer Uses A Uv Digital Printing Process To Apply A 2D Digital Image To A 3D Object.

3d Printing Additive Make. Inkjet printers shoot miniscule droplets of ink onto paper to create a seemingly fluid stroke. This is done by adding one or more layers of white ink to the regular printing process. Different sff technologies use different types. Inkjet printers are the most commonly used type of printer. It was first commercially used as a rapid prototyping method in the. Whereas direct metal laser sintering/selective inkjet is probably the most exciting area in metal 3d printing at the moment. There are new companies and new technologies being commercialized. Inkjet metal 3d printing processes make some of the most production ready parts in the world. Continuous inkjet printing is an established technology that has been around for 150 years. Layers of material in the 3d inkjet printing process. Printing instructions in each layer are generated from a 3d mechanical model for your product, just as is done with popular fused deposition modeling (fdm) systems. Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper and plastic substrates. The inkjet printing process, as implemented by solidscape inc., begins with the build material (thermoplastic) and support material (wax) being held in a melted state inside two heated reservoirs. Let's walk through the printing process to see just what happens. Adding a subtle 3d effect is an easy way to make a print stand out.

3d Bioprinting Bioink Selection Guide Sigma Aldrich , Layers Of Material In The 3D Inkjet Printing Process.

Schematic Illustration Of The Inkjet 3d Printing Process Download Scientific Diagram. Adding a subtle 3d effect is an easy way to make a print stand out. There are new companies and new technologies being commercialized. Whereas direct metal laser sintering/selective inkjet is probably the most exciting area in metal 3d printing at the moment. Layers of material in the 3d inkjet printing process. Continuous inkjet printing is an established technology that has been around for 150 years. Inkjet printers shoot miniscule droplets of ink onto paper to create a seemingly fluid stroke. Inkjet metal 3d printing processes make some of the most production ready parts in the world. Different sff technologies use different types. Inkjet printers are the most commonly used type of printer. Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper and plastic substrates. Printing instructions in each layer are generated from a 3d mechanical model for your product, just as is done with popular fused deposition modeling (fdm) systems. The inkjet printing process, as implemented by solidscape inc., begins with the build material (thermoplastic) and support material (wax) being held in a melted state inside two heated reservoirs. This is done by adding one or more layers of white ink to the regular printing process. It was first commercially used as a rapid prototyping method in the. Let's walk through the printing process to see just what happens.

Sla Vs Polyjet What You Need To Know Cadimensions , In 10, Gong Et Al.

3d Printing How It Works Types Applications Services. Different sff technologies use different types. Whereas direct metal laser sintering/selective inkjet is probably the most exciting area in metal 3d printing at the moment. This is done by adding one or more layers of white ink to the regular printing process. Inkjet printers shoot miniscule droplets of ink onto paper to create a seemingly fluid stroke. Inkjet metal 3d printing processes make some of the most production ready parts in the world. Adding a subtle 3d effect is an easy way to make a print stand out. It was first commercially used as a rapid prototyping method in the. Continuous inkjet printing is an established technology that has been around for 150 years. Let's walk through the printing process to see just what happens. Inkjet printers are the most commonly used type of printer. The inkjet printing process, as implemented by solidscape inc., begins with the build material (thermoplastic) and support material (wax) being held in a melted state inside two heated reservoirs. Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper and plastic substrates. There are new companies and new technologies being commercialized. Layers of material in the 3d inkjet printing process. Printing instructions in each layer are generated from a 3d mechanical model for your product, just as is done with popular fused deposition modeling (fdm) systems.