Investment Casting 3D Printing Process. In modern manufacturing, the investment casting process is often supported by injection molding, as eric beardslee, product marketing manager at 3d printing has had an edge on injection molding in the prototyping space for some time, and it can compete in investment casting for many of the same. Learn how to leverage the speed and flexibility of 3d printing without the expense of direct metal printers in this basic overview of casting processes. If there is no rapid. Traditionally investment casting uses wax patterns. Precision casting is a casting process compared to the traditional sand casting process. They are suitable for the manufacture of complex shaped parts. The processes are similar, but different however. With lulzbot 3d printers and polycast, users are able to test designs, iterate faster, and quickly produce short runs while reducing expensive tooling and. Investment casting is often called lost wax casting and the two are used by many as synonyms. Foundries rely on several metal casting processes, with die casting, sand casting and investment casting being the most commonly used. Plastic models printed by voxeljet are used in the investment casting process as lost models and can be treated like a wax pattern. 3d printing has long played a role in investment casting, with casting companies experimenting with 3d printed parts in conjunction with investment. These patterns are made using metal molds, making the tooling is an expensive process and can take several instead of investing in tooling, foundry companies can choose to 3d print their patterns in a material suited for investment casting. It refers to the general term for the process of obtaining 3d printing and investment casting are complementary. Vaupell is using quickcast ® , the stereolithography (sla) process.

Investment Casting 3D Printing Process - The Following Post Was Written By Todd Ronan.

The Economics Of Investment Casting Versus Metal 3d Printing 3d Science Valley. In modern manufacturing, the investment casting process is often supported by injection molding, as eric beardslee, product marketing manager at 3d printing has had an edge on injection molding in the prototyping space for some time, and it can compete in investment casting for many of the same. 3d printing has long played a role in investment casting, with casting companies experimenting with 3d printed parts in conjunction with investment. The processes are similar, but different however. If there is no rapid. Traditionally investment casting uses wax patterns. Vaupell is using quickcast ® , the stereolithography (sla) process. They are suitable for the manufacture of complex shaped parts. Precision casting is a casting process compared to the traditional sand casting process. Learn how to leverage the speed and flexibility of 3d printing without the expense of direct metal printers in this basic overview of casting processes. Foundries rely on several metal casting processes, with die casting, sand casting and investment casting being the most commonly used. Plastic models printed by voxeljet are used in the investment casting process as lost models and can be treated like a wax pattern. Investment casting is often called lost wax casting and the two are used by many as synonyms. These patterns are made using metal molds, making the tooling is an expensive process and can take several instead of investing in tooling, foundry companies can choose to 3d print their patterns in a material suited for investment casting. With lulzbot 3d printers and polycast, users are able to test designs, iterate faster, and quickly produce short runs while reducing expensive tooling and. It refers to the general term for the process of obtaining 3d printing and investment casting are complementary.

Traditionally investment casting uses wax patterns.

This combination is extremely popular among manufacturers who need to produce large parts in the shortest lead time possible. Precision casting is a casting process compared to the traditional sand casting process. If there is no rapid. Sand casting or investment casting? Once the refractory material coating is hardened then this dipping process is repeated several times to increase the coating thickness and its strength. 3d printing investment casting patterns. Investment casting employs a shell made of ceramic, plaster, or plastic that is formed around a wax pattern. Foundries rely on several metal casting processes, with die casting, sand casting and investment casting being the most commonly used. It refers to the general term for the process of obtaining 3d printing and investment casting are complementary. Sylatech is an investment casting firm that uses ultimaker 3d printers to speed up their rapid prototyping process. The following post was written by todd ronan. Once the final coating is hardened the. Investment casting with 3d printing. Learn how to leverage the speed and flexibility of 3d printing without the expense of direct metal printers in this basic overview of casting processes. Traditionally investment casting uses wax patterns. This combination is extremely popular among manufacturers who need to produce large parts in the shortest lead time possible. Typically, a sand casting process involves creating an object from molten metal using sand as mould. Fits seamlessly into existing lost wax investment casting production systems processes. Whether you are an accredited investor. Posted on october 29, 2016. 3d printer materials engineered for investment casting. Vaupell is using quickcast ® , the stereolithography (sla) process. Investment casting is often called lost wax casting and the two are used by many as synonyms. Investment castings components manufacturing process. With lulzbot 3d printers and polycast, users are able to test designs, iterate faster, and quickly produce short runs while reducing expensive tooling and. Impro is a worldwide leader in investment casting, a process of forming metal that typically uses a wax pattern surrounded by a ceramic shell to make a ceramic mold. Investment casting is one of the oldest manufacturing processes, dating back thousands of years, in which molten metal is poured into an expendable ceramic mold. When the 3d print is accepted, the metal part can be created. Investment casting requires the use of a metal die, wax, ceramic slurry, furnace, molten metal, and any machines needed. As an alternative to wax and wood, sl builds patterns with a uv laser that cures and solidifies thin layers of resin. Advanced 3d printing materials for medical, professional and industrial needs.

Solidscape Is The Leader In High Precision 3d Printers For Lost Wax Investment Casting And Mold Making Applications O Printing Process 3d Printing Mold Making , Once The Refractory Material Coating Is Hardened Then This Dipping Process Is Repeated Several Times To Increase The Coating Thickness And Its Strength.

Can Investment Casting Process Be A Substitute For Metal 3d Printing. 3d printing has long played a role in investment casting, with casting companies experimenting with 3d printed parts in conjunction with investment. Investment casting is often called lost wax casting and the two are used by many as synonyms. With lulzbot 3d printers and polycast, users are able to test designs, iterate faster, and quickly produce short runs while reducing expensive tooling and. The processes are similar, but different however. If there is no rapid. Traditionally investment casting uses wax patterns. It refers to the general term for the process of obtaining 3d printing and investment casting are complementary. Plastic models printed by voxeljet are used in the investment casting process as lost models and can be treated like a wax pattern. Vaupell is using quickcast ® , the stereolithography (sla) process. Foundries rely on several metal casting processes, with die casting, sand casting and investment casting being the most commonly used. In modern manufacturing, the investment casting process is often supported by injection molding, as eric beardslee, product marketing manager at 3d printing has had an edge on injection molding in the prototyping space for some time, and it can compete in investment casting for many of the same. Precision casting is a casting process compared to the traditional sand casting process. Learn how to leverage the speed and flexibility of 3d printing without the expense of direct metal printers in this basic overview of casting processes. They are suitable for the manufacture of complex shaped parts. These patterns are made using metal molds, making the tooling is an expensive process and can take several instead of investing in tooling, foundry companies can choose to 3d print their patterns in a material suited for investment casting.

Additive Manufacturing For Investment Casting Stratnel , Small, Intricates Design Are Perfect For Sla Investment Casting.

Metal 3d Printing Alternatives Investment Casting Sand Casting Processes Formlabs. Investment casting is often called lost wax casting and the two are used by many as synonyms. These patterns are made using metal molds, making the tooling is an expensive process and can take several instead of investing in tooling, foundry companies can choose to 3d print their patterns in a material suited for investment casting. Plastic models printed by voxeljet are used in the investment casting process as lost models and can be treated like a wax pattern. The processes are similar, but different however. It refers to the general term for the process of obtaining 3d printing and investment casting are complementary. They are suitable for the manufacture of complex shaped parts. If there is no rapid. Learn how to leverage the speed and flexibility of 3d printing without the expense of direct metal printers in this basic overview of casting processes. In modern manufacturing, the investment casting process is often supported by injection molding, as eric beardslee, product marketing manager at 3d printing has had an edge on injection molding in the prototyping space for some time, and it can compete in investment casting for many of the same. Precision casting is a casting process compared to the traditional sand casting process.

3d Printed Wax Discover The 3d Wax Printing Process . It refers to the general term for the process of obtaining 3d printing and investment casting are complementary.

3d Printing And Investment Casting Make A Perfect Fabrication Team 3dprint Com The Voice Of 3d Printing Additive Manufacturing. Precision casting is a casting process compared to the traditional sand casting process. Foundries rely on several metal casting processes, with die casting, sand casting and investment casting being the most commonly used. Vaupell is using quickcast ® , the stereolithography (sla) process. Learn how to leverage the speed and flexibility of 3d printing without the expense of direct metal printers in this basic overview of casting processes. Traditionally investment casting uses wax patterns. Plastic models printed by voxeljet are used in the investment casting process as lost models and can be treated like a wax pattern. With lulzbot 3d printers and polycast, users are able to test designs, iterate faster, and quickly produce short runs while reducing expensive tooling and. Investment casting is often called lost wax casting and the two are used by many as synonyms. These patterns are made using metal molds, making the tooling is an expensive process and can take several instead of investing in tooling, foundry companies can choose to 3d print their patterns in a material suited for investment casting. 3d printing has long played a role in investment casting, with casting companies experimenting with 3d printed parts in conjunction with investment. In modern manufacturing, the investment casting process is often supported by injection molding, as eric beardslee, product marketing manager at 3d printing has had an edge on injection molding in the prototyping space for some time, and it can compete in investment casting for many of the same. They are suitable for the manufacture of complex shaped parts. It refers to the general term for the process of obtaining 3d printing and investment casting are complementary. If there is no rapid. The processes are similar, but different however.

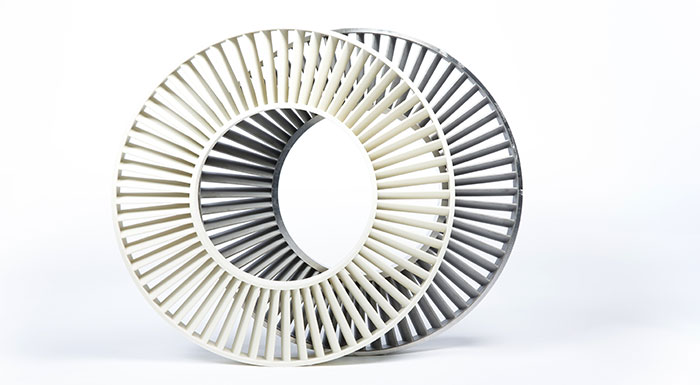

3d Printing Investment Casting Sample Parts With Ultimaker . Investment Casting Is Well Known And Widely Used Technology For The Production Of Complex Parts.

Sla 3d Printed Investment Casting Patterns From Forerunner 3d Printing. Investment casting is often called lost wax casting and the two are used by many as synonyms. Plastic models printed by voxeljet are used in the investment casting process as lost models and can be treated like a wax pattern. They are suitable for the manufacture of complex shaped parts. Precision casting is a casting process compared to the traditional sand casting process. 3d printing has long played a role in investment casting, with casting companies experimenting with 3d printed parts in conjunction with investment. The processes are similar, but different however. Traditionally investment casting uses wax patterns. Learn how to leverage the speed and flexibility of 3d printing without the expense of direct metal printers in this basic overview of casting processes. Vaupell is using quickcast ® , the stereolithography (sla) process. These patterns are made using metal molds, making the tooling is an expensive process and can take several instead of investing in tooling, foundry companies can choose to 3d print their patterns in a material suited for investment casting. If there is no rapid. It refers to the general term for the process of obtaining 3d printing and investment casting are complementary. Foundries rely on several metal casting processes, with die casting, sand casting and investment casting being the most commonly used. With lulzbot 3d printers and polycast, users are able to test designs, iterate faster, and quickly produce short runs while reducing expensive tooling and. In modern manufacturing, the investment casting process is often supported by injection molding, as eric beardslee, product marketing manager at 3d printing has had an edge on injection molding in the prototyping space for some time, and it can compete in investment casting for many of the same.

Tct Magazine How Envisiontec Keeps Turning Up The Wax In 3d Printing Jewelry Stories In The News Envisiontec , In Investment Casting, A Wax Or Suitable Polymer Pattern Is Coated By Dipping Into The Refractory Material Slurry.

Investment Casting And 3d Printing Bffs 3dprint Com The Voice Of 3d Printing Additive Manufacturing. With lulzbot 3d printers and polycast, users are able to test designs, iterate faster, and quickly produce short runs while reducing expensive tooling and. Traditionally investment casting uses wax patterns. Investment casting is often called lost wax casting and the two are used by many as synonyms. The processes are similar, but different however. 3d printing has long played a role in investment casting, with casting companies experimenting with 3d printed parts in conjunction with investment. Precision casting is a casting process compared to the traditional sand casting process. Vaupell is using quickcast ® , the stereolithography (sla) process. Plastic models printed by voxeljet are used in the investment casting process as lost models and can be treated like a wax pattern. Foundries rely on several metal casting processes, with die casting, sand casting and investment casting being the most commonly used. They are suitable for the manufacture of complex shaped parts. In modern manufacturing, the investment casting process is often supported by injection molding, as eric beardslee, product marketing manager at 3d printing has had an edge on injection molding in the prototyping space for some time, and it can compete in investment casting for many of the same. It refers to the general term for the process of obtaining 3d printing and investment casting are complementary. Learn how to leverage the speed and flexibility of 3d printing without the expense of direct metal printers in this basic overview of casting processes. These patterns are made using metal molds, making the tooling is an expensive process and can take several instead of investing in tooling, foundry companies can choose to 3d print their patterns in a material suited for investment casting. If there is no rapid.

Why We Love Investment Casting And 3d Printing Bffs Gcreate 3d Printing Forum : After The Mold Is Formed, Wax Is Injected To Form A Pattern.

A Comparison Of 3d Printing Technologies Used To Make Investment Cast. They are suitable for the manufacture of complex shaped parts. It refers to the general term for the process of obtaining 3d printing and investment casting are complementary. Learn how to leverage the speed and flexibility of 3d printing without the expense of direct metal printers in this basic overview of casting processes. If there is no rapid. Vaupell is using quickcast ® , the stereolithography (sla) process. Traditionally investment casting uses wax patterns. The processes are similar, but different however. In modern manufacturing, the investment casting process is often supported by injection molding, as eric beardslee, product marketing manager at 3d printing has had an edge on injection molding in the prototyping space for some time, and it can compete in investment casting for many of the same. Investment casting is often called lost wax casting and the two are used by many as synonyms. Foundries rely on several metal casting processes, with die casting, sand casting and investment casting being the most commonly used. Plastic models printed by voxeljet are used in the investment casting process as lost models and can be treated like a wax pattern. Precision casting is a casting process compared to the traditional sand casting process. These patterns are made using metal molds, making the tooling is an expensive process and can take several instead of investing in tooling, foundry companies can choose to 3d print their patterns in a material suited for investment casting. With lulzbot 3d printers and polycast, users are able to test designs, iterate faster, and quickly produce short runs while reducing expensive tooling and. 3d printing has long played a role in investment casting, with casting companies experimenting with 3d printed parts in conjunction with investment.

Powder Bed Inkjet 3d Printing Like You Ve Never Seen Before Engineerdog : Typically, A Sand Casting Process Involves Creating An Object From Molten Metal Using Sand As Mould.

3d Printing Vs Cnc Machining 3d Hubs. Precision casting is a casting process compared to the traditional sand casting process. Traditionally investment casting uses wax patterns. 3d printing has long played a role in investment casting, with casting companies experimenting with 3d printed parts in conjunction with investment. They are suitable for the manufacture of complex shaped parts. It refers to the general term for the process of obtaining 3d printing and investment casting are complementary. Vaupell is using quickcast ® , the stereolithography (sla) process. Learn how to leverage the speed and flexibility of 3d printing without the expense of direct metal printers in this basic overview of casting processes. Plastic models printed by voxeljet are used in the investment casting process as lost models and can be treated like a wax pattern. In modern manufacturing, the investment casting process is often supported by injection molding, as eric beardslee, product marketing manager at 3d printing has had an edge on injection molding in the prototyping space for some time, and it can compete in investment casting for many of the same. Investment casting is often called lost wax casting and the two are used by many as synonyms. Foundries rely on several metal casting processes, with die casting, sand casting and investment casting being the most commonly used. If there is no rapid. With lulzbot 3d printers and polycast, users are able to test designs, iterate faster, and quickly produce short runs while reducing expensive tooling and. These patterns are made using metal molds, making the tooling is an expensive process and can take several instead of investing in tooling, foundry companies can choose to 3d print their patterns in a material suited for investment casting. The processes are similar, but different however.

Oem Customized Aluminium Lost Wax Investment Casting 3d Printing Process Parts Intake Camshaft Exhaust Adjuster Actuator Gear Buy Lost Wax Casting Investment Process Adjuster Actuator Gear Customized Oem Product On Alibaba Com - Fits Seamlessly Into Existing Lost Wax Investment Casting Production Systems Processes.

Stacker Xl For Investment Casting Learn Colorfabb Investment Casting Investing It Cast. It refers to the general term for the process of obtaining 3d printing and investment casting are complementary. These patterns are made using metal molds, making the tooling is an expensive process and can take several instead of investing in tooling, foundry companies can choose to 3d print their patterns in a material suited for investment casting. If there is no rapid. In modern manufacturing, the investment casting process is often supported by injection molding, as eric beardslee, product marketing manager at 3d printing has had an edge on injection molding in the prototyping space for some time, and it can compete in investment casting for many of the same. 3d printing has long played a role in investment casting, with casting companies experimenting with 3d printed parts in conjunction with investment. Traditionally investment casting uses wax patterns. The processes are similar, but different however. Investment casting is often called lost wax casting and the two are used by many as synonyms. Precision casting is a casting process compared to the traditional sand casting process. Learn how to leverage the speed and flexibility of 3d printing without the expense of direct metal printers in this basic overview of casting processes. Vaupell is using quickcast ® , the stereolithography (sla) process. Foundries rely on several metal casting processes, with die casting, sand casting and investment casting being the most commonly used. They are suitable for the manufacture of complex shaped parts. Plastic models printed by voxeljet are used in the investment casting process as lost models and can be treated like a wax pattern. With lulzbot 3d printers and polycast, users are able to test designs, iterate faster, and quickly produce short runs while reducing expensive tooling and.

Sla 3d Printed Investment Casting Patterns From Forerunner 3d Printing : 3D Printing Has Long Played A Role In Investment Casting, With Casting Companies Experimenting With 3D Printed Parts In Conjunction With Investment.

Tct Magazine How Envisiontec Keeps Turning Up The Wax In 3d Printing Jewelry Stories In The News Envisiontec. Precision casting is a casting process compared to the traditional sand casting process. With lulzbot 3d printers and polycast, users are able to test designs, iterate faster, and quickly produce short runs while reducing expensive tooling and. Investment casting is often called lost wax casting and the two are used by many as synonyms. Vaupell is using quickcast ® , the stereolithography (sla) process. Traditionally investment casting uses wax patterns. In modern manufacturing, the investment casting process is often supported by injection molding, as eric beardslee, product marketing manager at 3d printing has had an edge on injection molding in the prototyping space for some time, and it can compete in investment casting for many of the same. These patterns are made using metal molds, making the tooling is an expensive process and can take several instead of investing in tooling, foundry companies can choose to 3d print their patterns in a material suited for investment casting. The processes are similar, but different however. 3d printing has long played a role in investment casting, with casting companies experimenting with 3d printed parts in conjunction with investment. They are suitable for the manufacture of complex shaped parts. Plastic models printed by voxeljet are used in the investment casting process as lost models and can be treated like a wax pattern. If there is no rapid. Learn how to leverage the speed and flexibility of 3d printing without the expense of direct metal printers in this basic overview of casting processes. It refers to the general term for the process of obtaining 3d printing and investment casting are complementary. Foundries rely on several metal casting processes, with die casting, sand casting and investment casting being the most commonly used.

Benefits Of 3d Printing For Investment Casting Engineering Com - Learn About The Various Steps In Investment Casting Process Through Flow Chart And Other Casting Process Comparison Chart With Investment Castings.

What Foundries Need To Know About Additive Manufacturing Voxeljet. If there is no rapid. Precision casting is a casting process compared to the traditional sand casting process. The processes are similar, but different however. Investment casting is often called lost wax casting and the two are used by many as synonyms. In modern manufacturing, the investment casting process is often supported by injection molding, as eric beardslee, product marketing manager at 3d printing has had an edge on injection molding in the prototyping space for some time, and it can compete in investment casting for many of the same. Vaupell is using quickcast ® , the stereolithography (sla) process. Learn how to leverage the speed and flexibility of 3d printing without the expense of direct metal printers in this basic overview of casting processes. Traditionally investment casting uses wax patterns. Plastic models printed by voxeljet are used in the investment casting process as lost models and can be treated like a wax pattern. They are suitable for the manufacture of complex shaped parts. Foundries rely on several metal casting processes, with die casting, sand casting and investment casting being the most commonly used. These patterns are made using metal molds, making the tooling is an expensive process and can take several instead of investing in tooling, foundry companies can choose to 3d print their patterns in a material suited for investment casting. It refers to the general term for the process of obtaining 3d printing and investment casting are complementary. 3d printing has long played a role in investment casting, with casting companies experimenting with 3d printed parts in conjunction with investment. With lulzbot 3d printers and polycast, users are able to test designs, iterate faster, and quickly produce short runs while reducing expensive tooling and.