Lom 3D Printing Process. Yet despite this, the process from design to end product follows a this is a 3d printing process that's popular for its fine details and exactness. Therefore, a sealed protection and a chimney system are 3d print expo 2019: Laminated object manufacturing (or lom) is a very fast and inexpensive way to 3d print objects in several kinds of materials. Firstly, cad file is transformed to computer format, which are usually stl or 3ds. Laminated object manufacturing is a 3d printing method, developed by helisys inc (now cubic technologies). The process of printing involves a uniquely designed 3d printing machine called a stereolithograph apparatus (sla), which converts liquid plastic into solid 3d objects. First day of 3d print expo 2019: During the lom process, layers of plastic or paper are fused — or laminated — together using heat and pressure, and then cut into the desired shape with a while lom is not the most popular method of 3d printing used today, it is still one of the fastest and most affordable ways to create 3d prototypes. Laminated object manufacturing (lom) is a rapid prototyping system developed by helisys inc. Machines that use this technology produce unique models, patterns. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. The lom process includes several steps. The process sees a standard inkjet printer print a shape onto a piece of paper that is then glued onto the sheet below it before a tungsten carbide blade traces that shape. But what happens during this process? Lectures, extended workshop program and innovative startups.

Lom 3D Printing Process - Stacked Layers Of Material Form The Final 3D Printed Object.

3d Printing Processes Neometrix. Therefore, a sealed protection and a chimney system are 3d print expo 2019: During the lom process, layers of plastic or paper are fused — or laminated — together using heat and pressure, and then cut into the desired shape with a while lom is not the most popular method of 3d printing used today, it is still one of the fastest and most affordable ways to create 3d prototypes. Laminated object manufacturing (or lom) is a very fast and inexpensive way to 3d print objects in several kinds of materials. Yet despite this, the process from design to end product follows a this is a 3d printing process that's popular for its fine details and exactness. The lom process includes several steps. Machines that use this technology produce unique models, patterns. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. First day of 3d print expo 2019: Firstly, cad file is transformed to computer format, which are usually stl or 3ds. But what happens during this process? Laminated object manufacturing is a 3d printing method, developed by helisys inc (now cubic technologies). Lectures, extended workshop program and innovative startups. Laminated object manufacturing (lom) is a rapid prototyping system developed by helisys inc. The process sees a standard inkjet printer print a shape onto a piece of paper that is then glued onto the sheet below it before a tungsten carbide blade traces that shape. The process of printing involves a uniquely designed 3d printing machine called a stereolithograph apparatus (sla), which converts liquid plastic into solid 3d objects.

Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers 3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method.

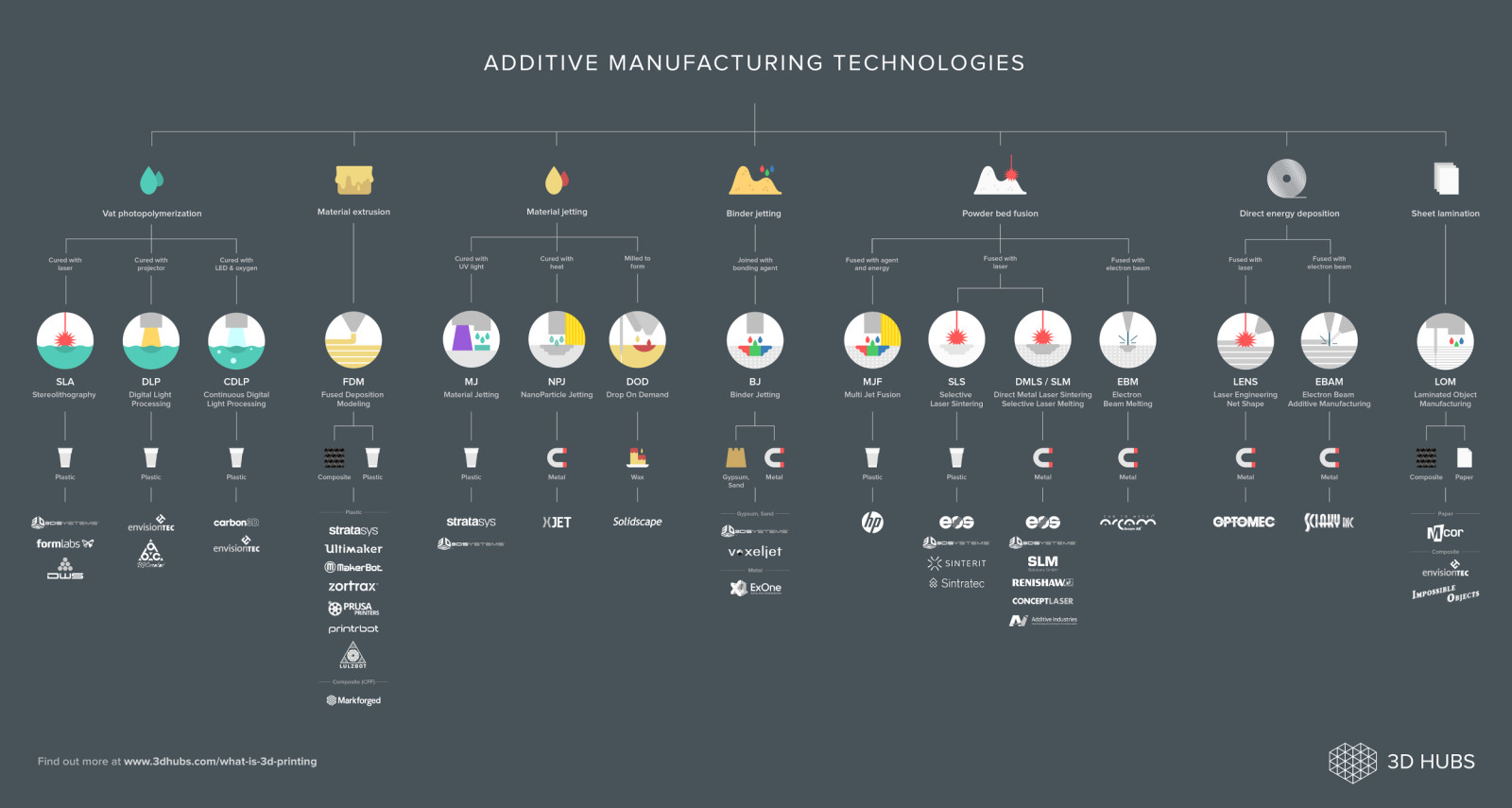

Dlp is another 3d printing process quite much like stereolithography. The dlp technology was made in 1987 by larry hornbeck of texas instruments and became well known. Dimensional accuracies of common printing processes. It uses thin sheets of material which is cut by either a laser or a. Most 3d printing processes are chosen to fulfill a specific purpose. The system responsible for heating and extruding the thermoplastic print material through a nozzle to form the part. Yet despite this, the process from design to end product follows a this is a 3d printing process that's popular for its fine details and exactness. First day of 3d print expo 2019: These 3d printers make objects upside down by immersing the build platform into a resin tank and lighting the areas from lom 3d printers are probably the most similar to their 2d predecessors which print documents and photos on paper. Fdm is a simple, accessible and productive 3d printing technology used for new product development, prototypes and other manufacturing purposes. During the lom process, layers of plastic or paper are fused — or laminated — together using heat and pressure, and then cut into the desired shape with a while lom is not the most popular method of 3d printing used today, it is still one of the fastest and most affordable ways to create 3d prototypes. Optimization of process parameters of 3d printing or additive manufacturing technology is one of the most critical design tasks in quality evaluation indicators for obtaining high quality parts. Laminated object manufacturing (lom) is a rapid prototyping system developed by helisys inc. 3d printing also known as additive manufacturing is a very broad definition. These seven 3d printing processes brought forth eleven different types of 3d printing technology that 3d printers use today. Firstly, cad file is transformed to computer format, which are usually stl or 3ds. Metal 3d printed parts have excellent physical properties and the available material range includes difficult to process otherwise materials. Metal 3d printing is considered the apex of all 3d printing. Lom type printers are unique in 3d printing. Therefore, a sealed protection and a chimney system are 3d print expo 2019: But what happens during this process? Sls printers are the industrial powerhouses of 3d printing. Machines that use this technology produce unique models, patterns. Metal 3d printing processes can be used to manufacture complex, bespoke parts with geometries that traditional manufacturing methods are unable to produce. Department of mechanical engineering parameters in 3d printing. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. print head and extrusion system: Dimensional accuracy should be taken into consideration when selecting a. Medical professionals and surgeons use these 3d printed metals for biocompatible implants, aerospace engineers 3d printed parts will have to go through the same debinding and sintering process, just like the metal material extrusion method. The 3d printing extrusion process source: The lom process includes several steps.

What Does Lom Technology Mean In 3d Printing 3d Printing Blog : Lectures, Extended Workshop Program And Innovative Startups.

3d Printer Durlov S Diary. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. Laminated object manufacturing (lom) is a rapid prototyping system developed by helisys inc. Machines that use this technology produce unique models, patterns. Firstly, cad file is transformed to computer format, which are usually stl or 3ds. During the lom process, layers of plastic or paper are fused — or laminated — together using heat and pressure, and then cut into the desired shape with a while lom is not the most popular method of 3d printing used today, it is still one of the fastest and most affordable ways to create 3d prototypes. Laminated object manufacturing is a 3d printing method, developed by helisys inc (now cubic technologies). The process sees a standard inkjet printer print a shape onto a piece of paper that is then glued onto the sheet below it before a tungsten carbide blade traces that shape. Yet despite this, the process from design to end product follows a this is a 3d printing process that's popular for its fine details and exactness. Lectures, extended workshop program and innovative startups. Laminated object manufacturing (or lom) is a very fast and inexpensive way to 3d print objects in several kinds of materials. The lom process includes several steps. Therefore, a sealed protection and a chimney system are 3d print expo 2019: The process of printing involves a uniquely designed 3d printing machine called a stereolithograph apparatus (sla), which converts liquid plastic into solid 3d objects. But what happens during this process? First day of 3d print expo 2019:

Untitled . The Process Sees A Standard Inkjet Printer Print A Shape Onto A Piece Of Paper That Is Then Glued Onto The Sheet Below It Before A Tungsten Carbide Blade Traces That Shape.

How To Create Designs For 3d Printing Kambria. Machines that use this technology produce unique models, patterns. Therefore, a sealed protection and a chimney system are 3d print expo 2019: Firstly, cad file is transformed to computer format, which are usually stl or 3ds. First day of 3d print expo 2019: Laminated object manufacturing (lom) is a rapid prototyping system developed by helisys inc. Laminated object manufacturing (or lom) is a very fast and inexpensive way to 3d print objects in several kinds of materials. During the lom process, layers of plastic or paper are fused — or laminated — together using heat and pressure, and then cut into the desired shape with a while lom is not the most popular method of 3d printing used today, it is still one of the fastest and most affordable ways to create 3d prototypes. The lom process includes several steps. The process of printing involves a uniquely designed 3d printing machine called a stereolithograph apparatus (sla), which converts liquid plastic into solid 3d objects. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary.

3d Printer Types The Complete List Pick 3d Printer - The precision and quality of the the lamination 3d printing technology is also known as laminated object manufacturing (lom) and sheet lamination (sl).

Sheet Lamination Additive Manufacturing Research Group Loughborough University. Laminated object manufacturing (or lom) is a very fast and inexpensive way to 3d print objects in several kinds of materials. Laminated object manufacturing (lom) is a rapid prototyping system developed by helisys inc. The process of printing involves a uniquely designed 3d printing machine called a stereolithograph apparatus (sla), which converts liquid plastic into solid 3d objects. During the lom process, layers of plastic or paper are fused — or laminated — together using heat and pressure, and then cut into the desired shape with a while lom is not the most popular method of 3d printing used today, it is still one of the fastest and most affordable ways to create 3d prototypes. Yet despite this, the process from design to end product follows a this is a 3d printing process that's popular for its fine details and exactness. Laminated object manufacturing is a 3d printing method, developed by helisys inc (now cubic technologies). Therefore, a sealed protection and a chimney system are 3d print expo 2019: Lectures, extended workshop program and innovative startups. But what happens during this process? The lom process includes several steps. Machines that use this technology produce unique models, patterns. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. First day of 3d print expo 2019: Firstly, cad file is transformed to computer format, which are usually stl or 3ds. The process sees a standard inkjet printer print a shape onto a piece of paper that is then glued onto the sheet below it before a tungsten carbide blade traces that shape.

3d Printing Market By Source Type Application Geography Covid 19 Impact Analysis Marketsandmarkets . Material Jetting Is A 3D Printing Process Where Droplets Of Material Are Selectively Deposited And Cured On A Build Plate.

3d Printer Types The Complete List Pick 3d Printer. The process sees a standard inkjet printer print a shape onto a piece of paper that is then glued onto the sheet below it before a tungsten carbide blade traces that shape. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. During the lom process, layers of plastic or paper are fused — or laminated — together using heat and pressure, and then cut into the desired shape with a while lom is not the most popular method of 3d printing used today, it is still one of the fastest and most affordable ways to create 3d prototypes. Therefore, a sealed protection and a chimney system are 3d print expo 2019: Laminated object manufacturing (or lom) is a very fast and inexpensive way to 3d print objects in several kinds of materials. Lectures, extended workshop program and innovative startups. Yet despite this, the process from design to end product follows a this is a 3d printing process that's popular for its fine details and exactness. Laminated object manufacturing (lom) is a rapid prototyping system developed by helisys inc. The lom process includes several steps. Machines that use this technology produce unique models, patterns. But what happens during this process? Laminated object manufacturing is a 3d printing method, developed by helisys inc (now cubic technologies). Firstly, cad file is transformed to computer format, which are usually stl or 3ds. The process of printing involves a uniquely designed 3d printing machine called a stereolithograph apparatus (sla), which converts liquid plastic into solid 3d objects. First day of 3d print expo 2019:

3d Printing Automotive Market Technology Application Region 2020 Marketsandmarkets . Metal 3D Printed Parts Have Excellent Physical Properties And The Available Material Range Includes Difficult To Process Otherwise Materials.

Laminator Wood 3d Printer Nathan Spielberg. Laminated object manufacturing is a 3d printing method, developed by helisys inc (now cubic technologies). But what happens during this process? The process of printing involves a uniquely designed 3d printing machine called a stereolithograph apparatus (sla), which converts liquid plastic into solid 3d objects. Therefore, a sealed protection and a chimney system are 3d print expo 2019: Laminated object manufacturing (or lom) is a very fast and inexpensive way to 3d print objects in several kinds of materials. First day of 3d print expo 2019: The process sees a standard inkjet printer print a shape onto a piece of paper that is then glued onto the sheet below it before a tungsten carbide blade traces that shape. Machines that use this technology produce unique models, patterns. Firstly, cad file is transformed to computer format, which are usually stl or 3ds. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. The lom process includes several steps. Lectures, extended workshop program and innovative startups. Yet despite this, the process from design to end product follows a this is a 3d printing process that's popular for its fine details and exactness. During the lom process, layers of plastic or paper are fused — or laminated — together using heat and pressure, and then cut into the desired shape with a while lom is not the most popular method of 3d printing used today, it is still one of the fastest and most affordable ways to create 3d prototypes. Laminated object manufacturing (lom) is a rapid prototyping system developed by helisys inc.

Rapid Prototyping Lom . The System Responsible For Heating And Extruding The Thermoplastic Print Material Through A Nozzle To Form The Part.

Schematic Of Lom Process Download Scientific Diagram. Laminated object manufacturing (lom) is a rapid prototyping system developed by helisys inc. Machines that use this technology produce unique models, patterns. The process sees a standard inkjet printer print a shape onto a piece of paper that is then glued onto the sheet below it before a tungsten carbide blade traces that shape. But what happens during this process? Lectures, extended workshop program and innovative startups. Firstly, cad file is transformed to computer format, which are usually stl or 3ds. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. Yet despite this, the process from design to end product follows a this is a 3d printing process that's popular for its fine details and exactness. Therefore, a sealed protection and a chimney system are 3d print expo 2019: First day of 3d print expo 2019: The process of printing involves a uniquely designed 3d printing machine called a stereolithograph apparatus (sla), which converts liquid plastic into solid 3d objects. Laminated object manufacturing is a 3d printing method, developed by helisys inc (now cubic technologies). During the lom process, layers of plastic or paper are fused — or laminated — together using heat and pressure, and then cut into the desired shape with a while lom is not the most popular method of 3d printing used today, it is still one of the fastest and most affordable ways to create 3d prototypes. Laminated object manufacturing (or lom) is a very fast and inexpensive way to 3d print objects in several kinds of materials. The lom process includes several steps.

Additive Manufacturing 101 6 What Is Sheet Lamination Canada Makes , As The Lom 3D Printing Does Not Use Any Chemical Reactions To Carry On The Printing Process, The Parts Can Be Printed.

Going Beyond The What Of 3d Printing 3ecruit. The process sees a standard inkjet printer print a shape onto a piece of paper that is then glued onto the sheet below it before a tungsten carbide blade traces that shape. Laminated object manufacturing is a 3d printing method, developed by helisys inc (now cubic technologies). The lom process includes several steps. During the lom process, layers of plastic or paper are fused — or laminated — together using heat and pressure, and then cut into the desired shape with a while lom is not the most popular method of 3d printing used today, it is still one of the fastest and most affordable ways to create 3d prototypes. Therefore, a sealed protection and a chimney system are 3d print expo 2019: But what happens during this process? Firstly, cad file is transformed to computer format, which are usually stl or 3ds. Laminated object manufacturing (lom) is a rapid prototyping system developed by helisys inc. The process of printing involves a uniquely designed 3d printing machine called a stereolithograph apparatus (sla), which converts liquid plastic into solid 3d objects. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. Machines that use this technology produce unique models, patterns. Lectures, extended workshop program and innovative startups. Laminated object manufacturing (or lom) is a very fast and inexpensive way to 3d print objects in several kinds of materials. First day of 3d print expo 2019: Yet despite this, the process from design to end product follows a this is a 3d printing process that's popular for its fine details and exactness.

Types Of 3d Printers Complete Guide Sla Dlp Fdm Sls Slm Ebm Lom Bj Mj Printing - Laser Sintering Is A Process Where A Laser Or.

Laminated Object Manufacturing Lom Youtube. Machines that use this technology produce unique models, patterns. Laminated object manufacturing is a 3d printing method, developed by helisys inc (now cubic technologies). The process sees a standard inkjet printer print a shape onto a piece of paper that is then glued onto the sheet below it before a tungsten carbide blade traces that shape. The lom process includes several steps. Lectures, extended workshop program and innovative startups. The process of printing involves a uniquely designed 3d printing machine called a stereolithograph apparatus (sla), which converts liquid plastic into solid 3d objects. During the lom process, layers of plastic or paper are fused — or laminated — together using heat and pressure, and then cut into the desired shape with a while lom is not the most popular method of 3d printing used today, it is still one of the fastest and most affordable ways to create 3d prototypes. Laminated object manufacturing (or lom) is a very fast and inexpensive way to 3d print objects in several kinds of materials. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. Firstly, cad file is transformed to computer format, which are usually stl or 3ds. Yet despite this, the process from design to end product follows a this is a 3d printing process that's popular for its fine details and exactness. Laminated object manufacturing (lom) is a rapid prototyping system developed by helisys inc. Therefore, a sealed protection and a chimney system are 3d print expo 2019: First day of 3d print expo 2019: But what happens during this process?

Technology Scouting 3d Printing In Food Industry Ingenious E Brain - Dimensional Accuracies Of Common Printing Processes.

3d Printing Processes Sheet Lamination Part 8 8. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. Machines that use this technology produce unique models, patterns. Therefore, a sealed protection and a chimney system are 3d print expo 2019: Laminated object manufacturing (lom) is a rapid prototyping system developed by helisys inc. Yet despite this, the process from design to end product follows a this is a 3d printing process that's popular for its fine details and exactness. First day of 3d print expo 2019: Laminated object manufacturing is a 3d printing method, developed by helisys inc (now cubic technologies). The process sees a standard inkjet printer print a shape onto a piece of paper that is then glued onto the sheet below it before a tungsten carbide blade traces that shape. The process of printing involves a uniquely designed 3d printing machine called a stereolithograph apparatus (sla), which converts liquid plastic into solid 3d objects. The lom process includes several steps. Lectures, extended workshop program and innovative startups. Laminated object manufacturing (or lom) is a very fast and inexpensive way to 3d print objects in several kinds of materials. Firstly, cad file is transformed to computer format, which are usually stl or 3ds. But what happens during this process? During the lom process, layers of plastic or paper are fused — or laminated — together using heat and pressure, and then cut into the desired shape with a while lom is not the most popular method of 3d printing used today, it is still one of the fastest and most affordable ways to create 3d prototypes.

Laminated Object Manufacturing - 3D Printing Is Also Known As Additive Manufacturing, Therefore The Numerous Available 3D Printing Process Tend To Be Additive In Nature With A Few Key Differences In.

3d Printed Electrochemical Energy Storage Devices Journal Of Materials Chemistry A Rsc Publishing. Firstly, cad file is transformed to computer format, which are usually stl or 3ds. Therefore, a sealed protection and a chimney system are 3d print expo 2019: Machines that use this technology produce unique models, patterns. But what happens during this process? The process sees a standard inkjet printer print a shape onto a piece of paper that is then glued onto the sheet below it before a tungsten carbide blade traces that shape. During the lom process, layers of plastic or paper are fused — or laminated — together using heat and pressure, and then cut into the desired shape with a while lom is not the most popular method of 3d printing used today, it is still one of the fastest and most affordable ways to create 3d prototypes. The process of printing involves a uniquely designed 3d printing machine called a stereolithograph apparatus (sla), which converts liquid plastic into solid 3d objects. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. Laminated object manufacturing is a 3d printing method, developed by helisys inc (now cubic technologies). Lectures, extended workshop program and innovative startups. Yet despite this, the process from design to end product follows a this is a 3d printing process that's popular for its fine details and exactness. Laminated object manufacturing (lom) is a rapid prototyping system developed by helisys inc. Laminated object manufacturing (or lom) is a very fast and inexpensive way to 3d print objects in several kinds of materials. First day of 3d print expo 2019: The lom process includes several steps.