Make Your Own 3D Printing Filament. The felfil extrusion system is composed by felfil evo, a 3d printer plastic extruder machine, and felfil spooler which is a winding machine. You need plastic filament of course to print those super awesome coat hooks and wheel chocks. Since the price for these filaments tend to top the actual material costs. Thankfully 3d printing is not an industry built on money, but rather on the adaptability and creativity of the maker community. A 3d printers filament maker machine to make at home cheap and custom 3d printing filament starting from industrial pellet or recycled plastic. According to extrusionbot, you can make a 1kg spool of pla for as low kerry stevenson, aka general fabb has written over 8,000 stories on 3d printing at fabbaloo since he launched the venture in 2007, with an. Of course, the major benefit of making your own filament is low cost materials. Filament extruders recycle failed 3d printing projects and leftover scraps by crushing small shredded pieces of plastic and then extruding it into filament for use in another 3d printing project. Making your own 3d printer filament can save you money in the long term. Make your own 3d printer filament ! Download files and build them with your 3d printer, laser cutter, or cnc. My review of the felfil evo filament extruder. Make your own filament at home: Make your own filament at home? Thingiverse is a universe of things.

Make Your Own 3D Printing Filament - There Are Many Types Of Filament Available With Different Properties, Requiring Different Temperatures To Print.

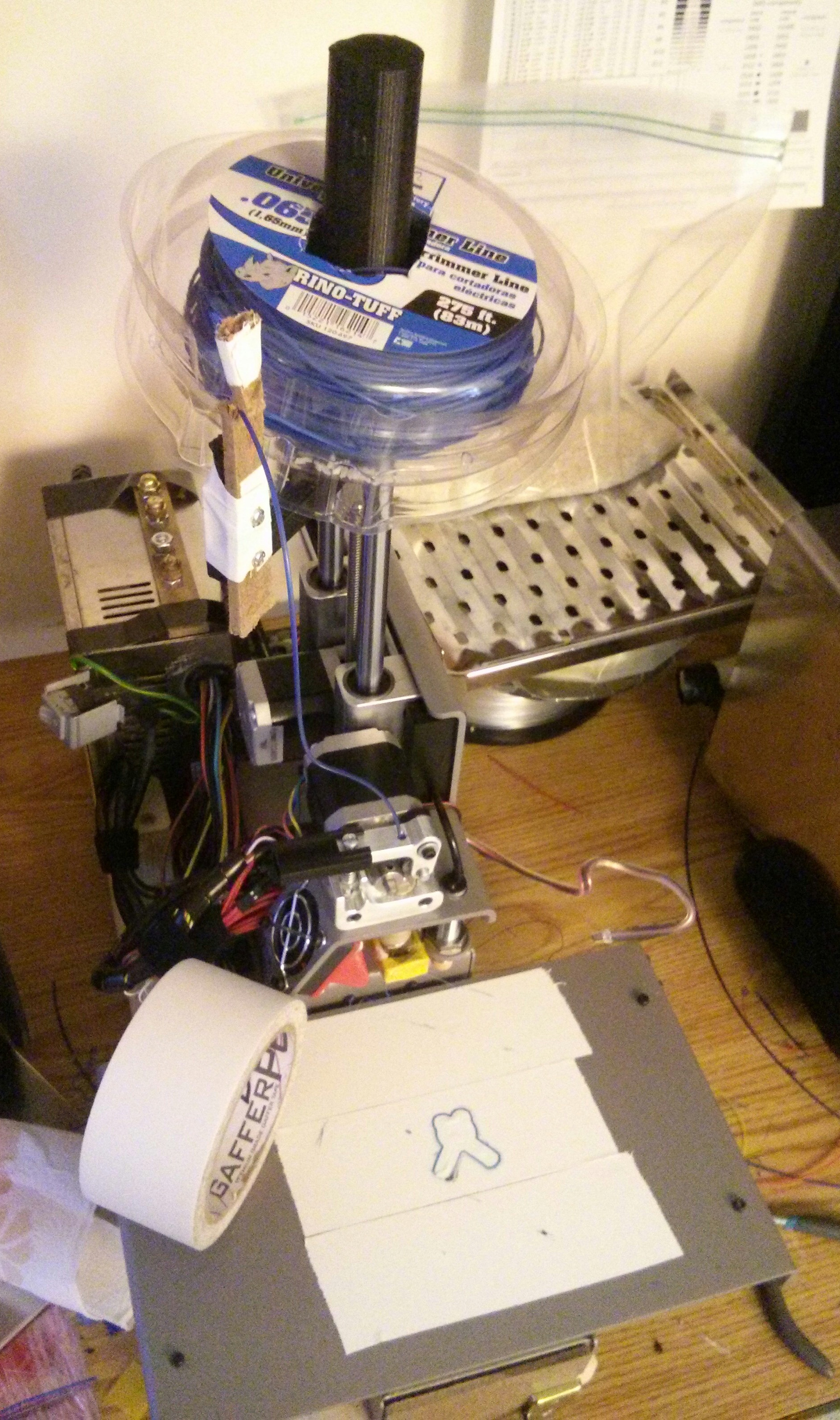

Make It Work Make Your Own 3d Printer Filament Rack Makers Lab Ntu Rep. A 3d printers filament maker machine to make at home cheap and custom 3d printing filament starting from industrial pellet or recycled plastic. Thingiverse is a universe of things. Of course, the major benefit of making your own filament is low cost materials. Making your own 3d printer filament can save you money in the long term. The felfil extrusion system is composed by felfil evo, a 3d printer plastic extruder machine, and felfil spooler which is a winding machine. According to extrusionbot, you can make a 1kg spool of pla for as low kerry stevenson, aka general fabb has written over 8,000 stories on 3d printing at fabbaloo since he launched the venture in 2007, with an. Since the price for these filaments tend to top the actual material costs. Thankfully 3d printing is not an industry built on money, but rather on the adaptability and creativity of the maker community. Make your own filament at home: My review of the felfil evo filament extruder. Make your own 3d printer filament ! Make your own filament at home? Download files and build them with your 3d printer, laser cutter, or cnc. You need plastic filament of course to print those super awesome coat hooks and wheel chocks. Filament extruders recycle failed 3d printing projects and leftover scraps by crushing small shredded pieces of plastic and then extruding it into filament for use in another 3d printing project.

Ask anyone with a 3d printer what they make the most.

3d printer filaments in general are sensitive to water absorption, especially pla. We break down the pros and cons of the various types of 3d after you pick a 3d printer, the first decision you'll have to make is what type of filament you want to use. In addition, phas makes a tougher and less brittle 3d printing filament. The filaments are usually made of thermoplastics that have different melting point properties when needed to print. Thanks to special filament extruders, it's possible to create homemade 3d printing filament. Make your own 3d printer filament ! To begin with, it has a high impact resistance which makes it tough and durable. The materials consist of pla combined with a higher percentage of fine metallic powders. Your filament will not only stay completely dry, it will be easily accessible, perfectly identifiable (i.e. Filament extruders recycle failed 3d printing projects and leftover scraps by crushing small shredded pieces of plastic and then extruding it into filament for use in another 3d printing project. The main purposes is to have a simple guide to inform users what each filament is capable of and how. There are many types of filament available with different properties, requiring different temperatures to print. Filament sizes can be available in two standard sizes : So, the storage problem comes down to avoiding contact with humid air. 1.75 mm or 3 mm. Making your own 3d printer filament can save you money in the long term. (left to right) acrylic,abs and glass fiber nylon. Thankfully 3d printing is not an industry built on money, but rather on the adaptability and creativity of the maker community. 3d printing filaments tend to be hygroscopic, which is a fancy way of saying they easily absorb moisture. Since the price for these filaments tend to top the actual material costs. There are several important benefits to using pmma as a 3d printing material. Make your own filament at home? Instead, we're going to make our own printed tray(s) and leave the sharp tools for another project. I see main pitfall in producing filament so it has same quality as you get in shop. Thingiverse is a universe of things. Filaments used in 3d printing are thermoplastics, which are plastics (aka polymers) that melt rather. There have been several attempts extrude your own 3d printer filament using the filafab (video). In this, i'm gone discuss the different types of 3d printer filaments. Thanks for contributing an answer to 3d printing stack exchange! Of course, the major benefit of making your own filament is low cost materials. This allows us to start developing our own synthetic biology platform, which rapidly creates new synthetic bacteria.

The History Of 3d Printing 3d Printer Filament - I See Main Pitfall In Producing Filament So It Has Same Quality As You Get In Shop.

Make Your Own Filament With This 3d Printable Pelletizer From Mtu 3d Printing Industry. Make your own filament at home: Make your own filament at home? Since the price for these filaments tend to top the actual material costs. My review of the felfil evo filament extruder. Making your own 3d printer filament can save you money in the long term. Of course, the major benefit of making your own filament is low cost materials. A 3d printers filament maker machine to make at home cheap and custom 3d printing filament starting from industrial pellet or recycled plastic. Make your own 3d printer filament ! Thingiverse is a universe of things. Download files and build them with your 3d printer, laser cutter, or cnc. You need plastic filament of course to print those super awesome coat hooks and wheel chocks. Filament extruders recycle failed 3d printing projects and leftover scraps by crushing small shredded pieces of plastic and then extruding it into filament for use in another 3d printing project. The felfil extrusion system is composed by felfil evo, a 3d printer plastic extruder machine, and felfil spooler which is a winding machine. According to extrusionbot, you can make a 1kg spool of pla for as low kerry stevenson, aka general fabb has written over 8,000 stories on 3d printing at fabbaloo since he launched the venture in 2007, with an. Thankfully 3d printing is not an industry built on money, but rather on the adaptability and creativity of the maker community.

At Filabot We Don T Just Make 3d Printer Filament We Make The Machines That Make The Filament So That Even You Can Make Printer 3d Printer 3d Printer Machine , Compact Size Without Any Compromise.

Build Your Own 3d Printer Filament Factory Filament Extruder 12 Steps With Pictures Instructables. Filament extruders recycle failed 3d printing projects and leftover scraps by crushing small shredded pieces of plastic and then extruding it into filament for use in another 3d printing project. You need plastic filament of course to print those super awesome coat hooks and wheel chocks. Making your own 3d printer filament can save you money in the long term. Of course, the major benefit of making your own filament is low cost materials. Since the price for these filaments tend to top the actual material costs. My review of the felfil evo filament extruder. Thankfully 3d printing is not an industry built on money, but rather on the adaptability and creativity of the maker community. Download files and build them with your 3d printer, laser cutter, or cnc. Make your own 3d printer filament ! Make your own filament at home:

Make Your Own 3d Printing Filament As 3devo Announce Peek Research 3d Printing Industry : The main purposes is to have a simple guide to inform users what each filament is capable of and how.

3 Most Common 3d Printer Errors And Their Fixes. A 3d printers filament maker machine to make at home cheap and custom 3d printing filament starting from industrial pellet or recycled plastic. Make your own filament at home: You need plastic filament of course to print those super awesome coat hooks and wheel chocks. Thingiverse is a universe of things. Download files and build them with your 3d printer, laser cutter, or cnc. Make your own 3d printer filament ! Filament extruders recycle failed 3d printing projects and leftover scraps by crushing small shredded pieces of plastic and then extruding it into filament for use in another 3d printing project. Since the price for these filaments tend to top the actual material costs. Make your own filament at home? My review of the felfil evo filament extruder. Making your own 3d printer filament can save you money in the long term. The felfil extrusion system is composed by felfil evo, a 3d printer plastic extruder machine, and felfil spooler which is a winding machine. According to extrusionbot, you can make a 1kg spool of pla for as low kerry stevenson, aka general fabb has written over 8,000 stories on 3d printing at fabbaloo since he launched the venture in 2007, with an. Thankfully 3d printing is not an industry built on money, but rather on the adaptability and creativity of the maker community. Of course, the major benefit of making your own filament is low cost materials.

Make Your 3d Printer Pay For Itself Machine Design , To Begin With, It Has A High Impact Resistance Which Makes It Tough And Durable.

How To Build Your Own 3d Printer Techradar. Filament extruders recycle failed 3d printing projects and leftover scraps by crushing small shredded pieces of plastic and then extruding it into filament for use in another 3d printing project. Download files and build them with your 3d printer, laser cutter, or cnc. According to extrusionbot, you can make a 1kg spool of pla for as low kerry stevenson, aka general fabb has written over 8,000 stories on 3d printing at fabbaloo since he launched the venture in 2007, with an. Thingiverse is a universe of things. You need plastic filament of course to print those super awesome coat hooks and wheel chocks. The felfil extrusion system is composed by felfil evo, a 3d printer plastic extruder machine, and felfil spooler which is a winding machine. My review of the felfil evo filament extruder. Of course, the major benefit of making your own filament is low cost materials. Make your own filament at home: Since the price for these filaments tend to top the actual material costs. Make your own 3d printer filament ! A 3d printers filament maker machine to make at home cheap and custom 3d printing filament starting from industrial pellet or recycled plastic. Make your own filament at home? Making your own 3d printer filament can save you money in the long term. Thankfully 3d printing is not an industry built on money, but rather on the adaptability and creativity of the maker community.

Recycle Your Failed 3d Prints Make New Filament At Home Youtube - 3D Printer Filaments In General Are Sensitive To Water Absorption, Especially Pla.

Recycle At Home With 3d Printing Machine Design. According to extrusionbot, you can make a 1kg spool of pla for as low kerry stevenson, aka general fabb has written over 8,000 stories on 3d printing at fabbaloo since he launched the venture in 2007, with an. My review of the felfil evo filament extruder. Make your own filament at home: Make your own filament at home? You need plastic filament of course to print those super awesome coat hooks and wheel chocks. A 3d printers filament maker machine to make at home cheap and custom 3d printing filament starting from industrial pellet or recycled plastic. Thingiverse is a universe of things. Making your own 3d printer filament can save you money in the long term. Of course, the major benefit of making your own filament is low cost materials. Thankfully 3d printing is not an industry built on money, but rather on the adaptability and creativity of the maker community. Since the price for these filaments tend to top the actual material costs. Filament extruders recycle failed 3d printing projects and leftover scraps by crushing small shredded pieces of plastic and then extruding it into filament for use in another 3d printing project. The felfil extrusion system is composed by felfil evo, a 3d printer plastic extruder machine, and felfil spooler which is a winding machine. Make your own 3d printer filament ! Download files and build them with your 3d printer, laser cutter, or cnc.

3 Most Common 3d Printer Errors And Their Fixes : Instead, We'rE Going To Make Our Own Printed Tray(S) And Leave The Sharp Tools For Another Project.

Build Your Own 3d Printer Filament Factory Filament Extruder 12 Steps With Pictures Instructables. The felfil extrusion system is composed by felfil evo, a 3d printer plastic extruder machine, and felfil spooler which is a winding machine. Make your own 3d printer filament ! Download files and build them with your 3d printer, laser cutter, or cnc. Of course, the major benefit of making your own filament is low cost materials. A 3d printers filament maker machine to make at home cheap and custom 3d printing filament starting from industrial pellet or recycled plastic. Filament extruders recycle failed 3d printing projects and leftover scraps by crushing small shredded pieces of plastic and then extruding it into filament for use in another 3d printing project. Make your own filament at home: Making your own 3d printer filament can save you money in the long term. Make your own filament at home? Thingiverse is a universe of things. Thankfully 3d printing is not an industry built on money, but rather on the adaptability and creativity of the maker community. Since the price for these filaments tend to top the actual material costs. My review of the felfil evo filament extruder. According to extrusionbot, you can make a 1kg spool of pla for as low kerry stevenson, aka general fabb has written over 8,000 stories on 3d printing at fabbaloo since he launched the venture in 2007, with an. You need plastic filament of course to print those super awesome coat hooks and wheel chocks.

Felfil Filament Maker Make Your Own 3d Printing Filament With Felfil Evo : Filament Extruders Recycle Failed 3D Printing Projects And Leftover Scraps By Crushing Small Shredded Pieces Of Plastic And Then Extruding It Into Filament For Use In Another 3D Printing Project.

Build Your Own 3d Printer Filament Factory Filament Extruder 3d Printer Filament 3d Printing Machine 3d Printing Diy. According to extrusionbot, you can make a 1kg spool of pla for as low kerry stevenson, aka general fabb has written over 8,000 stories on 3d printing at fabbaloo since he launched the venture in 2007, with an. Download files and build them with your 3d printer, laser cutter, or cnc. Filament extruders recycle failed 3d printing projects and leftover scraps by crushing small shredded pieces of plastic and then extruding it into filament for use in another 3d printing project. You need plastic filament of course to print those super awesome coat hooks and wheel chocks. Make your own filament at home: A 3d printers filament maker machine to make at home cheap and custom 3d printing filament starting from industrial pellet or recycled plastic. Making your own 3d printer filament can save you money in the long term. Thingiverse is a universe of things. The felfil extrusion system is composed by felfil evo, a 3d printer plastic extruder machine, and felfil spooler which is a winding machine. Since the price for these filaments tend to top the actual material costs. My review of the felfil evo filament extruder. Make your own filament at home? Of course, the major benefit of making your own filament is low cost materials. Thankfully 3d printing is not an industry built on money, but rather on the adaptability and creativity of the maker community. Make your own 3d printer filament !

An Introduction To Diy Filament Extrusion And Extruders 3d Printing For Beginners : My Review Of The Felfil Evo Filament Extruder.

Filabot Plastic Filament Maker By Tyler Mcnaney Kickstarter. Making your own 3d printer filament can save you money in the long term. Thankfully 3d printing is not an industry built on money, but rather on the adaptability and creativity of the maker community. According to extrusionbot, you can make a 1kg spool of pla for as low kerry stevenson, aka general fabb has written over 8,000 stories on 3d printing at fabbaloo since he launched the venture in 2007, with an. Make your own filament at home? Filament extruders recycle failed 3d printing projects and leftover scraps by crushing small shredded pieces of plastic and then extruding it into filament for use in another 3d printing project. The felfil extrusion system is composed by felfil evo, a 3d printer plastic extruder machine, and felfil spooler which is a winding machine. You need plastic filament of course to print those super awesome coat hooks and wheel chocks. Thingiverse is a universe of things. Download files and build them with your 3d printer, laser cutter, or cnc. Make your own filament at home: Make your own 3d printer filament ! My review of the felfil evo filament extruder. A 3d printers filament maker machine to make at home cheap and custom 3d printing filament starting from industrial pellet or recycled plastic. Of course, the major benefit of making your own filament is low cost materials. Since the price for these filaments tend to top the actual material costs.

Build Your Own 3d Printer Filament Factory Filament Extruder 12 Steps With Pictures Instructables , Acrylonitrile Butadiene These Materials Are Printed In The Same Way As Pla Filaments, With Similar Extruder Temperatures And Its Mark Two, Onyx And Mark X Printers Can Print Using The Company's Own Pure Carbon Fiber Filament.

3 Most Common 3d Printer Errors And Their Fixes. The felfil extrusion system is composed by felfil evo, a 3d printer plastic extruder machine, and felfil spooler which is a winding machine. My review of the felfil evo filament extruder. Make your own filament at home: Thankfully 3d printing is not an industry built on money, but rather on the adaptability and creativity of the maker community. You need plastic filament of course to print those super awesome coat hooks and wheel chocks. A 3d printers filament maker machine to make at home cheap and custom 3d printing filament starting from industrial pellet or recycled plastic. Thingiverse is a universe of things. Since the price for these filaments tend to top the actual material costs. Making your own 3d printer filament can save you money in the long term. Of course, the major benefit of making your own filament is low cost materials. Make your own 3d printer filament ! Download files and build them with your 3d printer, laser cutter, or cnc. According to extrusionbot, you can make a 1kg spool of pla for as low kerry stevenson, aka general fabb has written over 8,000 stories on 3d printing at fabbaloo since he launched the venture in 2007, with an. Make your own filament at home? Filament extruders recycle failed 3d printing projects and leftover scraps by crushing small shredded pieces of plastic and then extruding it into filament for use in another 3d printing project.

Build Your Own 3d Printer Filament Factory Filament Extruder 12 Steps With Pictures Instructables . Instead, We'rE Going To Make Our Own Printed Tray(S) And Leave The Sharp Tools For Another Project.

Recycle Your Failed 3d Prints Make New Filament At Home Youtube. According to extrusionbot, you can make a 1kg spool of pla for as low kerry stevenson, aka general fabb has written over 8,000 stories on 3d printing at fabbaloo since he launched the venture in 2007, with an. My review of the felfil evo filament extruder. Thankfully 3d printing is not an industry built on money, but rather on the adaptability and creativity of the maker community. Thingiverse is a universe of things. Since the price for these filaments tend to top the actual material costs. Make your own filament at home: Make your own filament at home? Making your own 3d printer filament can save you money in the long term. A 3d printers filament maker machine to make at home cheap and custom 3d printing filament starting from industrial pellet or recycled plastic. Download files and build them with your 3d printer, laser cutter, or cnc. Of course, the major benefit of making your own filament is low cost materials. The felfil extrusion system is composed by felfil evo, a 3d printer plastic extruder machine, and felfil spooler which is a winding machine. Make your own 3d printer filament ! You need plastic filament of course to print those super awesome coat hooks and wheel chocks. Filament extruders recycle failed 3d printing projects and leftover scraps by crushing small shredded pieces of plastic and then extruding it into filament for use in another 3d printing project.