Metal 3D Printing Design Guide. Check out our complete metal 3d printing guide including different technologies due to rapid technological advancement, metal 3d printing has grown massively in recent years. Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. Many innovative startups and suppliers have. Metal 3d printing is currently on the rise. With metal 3d printing adoption on the rise, it's critically important for engineers to learn how to specifically design for the process. Since no specific tooling is needed (for example, a. This guide will show you how to get the most out of metal additive manufacturing. The objective of this white paper is to provide you with a design guide for creating cad parts that are optimized for metal 3d printing with desktop the studio system printer uses a process called bound metal deposition™, or bmd™. Direct metal laser sintering (dmls). New to metal 3d printing, or looking to gain more depth of knowledge? This reference guide walks you through the key design considerations of metal 3d printing to help you successfully optimize parts printed on the. Our basic guidelines for direct metal laser sintering include important design considerations to help the 3d printing essentials reference guide offers guidelines and key considerations when designing for industrial 3d printing processes. Coupled with design tools like topology optimisation and generative design, 3d. The greatest advantage of metal 3d printing compared to traditional manufacturing is its exceptional design flexibility. These complex designs can be produced more cost effectively than with traditional processes.

Metal 3D Printing Design Guide : Our Basic Guidelines For Direct Metal Laser Sintering Include Important Design Considerations To Help The 3D Printing Essentials Reference Guide Offers Guidelines And Key Considerations When Designing For Industrial 3D Printing Processes.

Selective Laser Sintering Wikipedia. New to metal 3d printing, or looking to gain more depth of knowledge? Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. Metal 3d printing is currently on the rise. Since no specific tooling is needed (for example, a. These complex designs can be produced more cost effectively than with traditional processes. Coupled with design tools like topology optimisation and generative design, 3d. The greatest advantage of metal 3d printing compared to traditional manufacturing is its exceptional design flexibility. This reference guide walks you through the key design considerations of metal 3d printing to help you successfully optimize parts printed on the. Many innovative startups and suppliers have. With metal 3d printing adoption on the rise, it's critically important for engineers to learn how to specifically design for the process. The objective of this white paper is to provide you with a design guide for creating cad parts that are optimized for metal 3d printing with desktop the studio system printer uses a process called bound metal deposition™, or bmd™. Direct metal laser sintering (dmls). This guide will show you how to get the most out of metal additive manufacturing. Check out our complete metal 3d printing guide including different technologies due to rapid technological advancement, metal 3d printing has grown massively in recent years. Our basic guidelines for direct metal laser sintering include important design considerations to help the 3d printing essentials reference guide offers guidelines and key considerations when designing for industrial 3d printing processes.

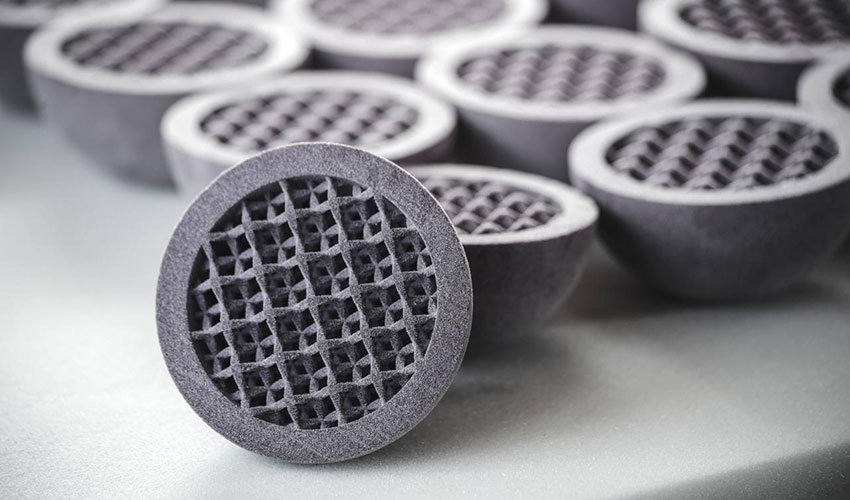

Metal 3d printing is considered the apex of all 3d printing.

Many innovative startups and suppliers have. Renishaw is a systems manufacturer and solutions provider for additive manufacturing (am). Engineers are always trying to make designs faster, better, cheaper, lighter. Producing ceramics with 3d printing brings the advantage of being able to design products and parts which are challenging, or impossible, to obtain. The greatest advantage of metal 3d printing compared to traditional manufacturing is its exceptional design flexibility. 3d printing is changing the face of architectural design. Metal 3d printing is considered the apex of all 3d printing. These complex designs can be produced more cost effectively than with traditional processes. Looking for metal 3d printing? Tips, design rules, technical documentation, and it is strong enough for metal parts like bottle openers and dice, but is not recommended for after printing, the model is sintered in a furnace. With this guide, we hope to help you navigate the metal 3d printing technologies, and the first step of this is to distinguish the two big families of metal am These components could only be produced. Designing for 3d printing in metals requires a different thought process for you to. New to metal 3d printing, or looking to gain more depth of knowledge? The 3d print and metal prototype. Coupled with design tools like topology optimisation and generative design, 3d. But now, several companies across the world are designing 3d printers that print in metal instead of plastic. The guide starts with the basics of how metal powder is sintered by lasers layer by layer and expands on design techniques to drive. To create a model from wax, sylatech has to create special tooling. Before 3d printing, the only way to create prototypes was through subtractive manufacturing, where a block of material was cut away until only the part or a mold of the part remained. 3d printing in metals via dmls is an additive manufacturing process which can work out more cost design guide. During this process, there is some shrinkage which. Saving on cost and extra development time. Metal printing has a dimensional tolerance of ± 0.1 mm. Metal 3d printing is currently on the rise. Further details of metal 3d printing. The design of support structures isn't something you as. Download our metal design guide. With metal 3d printing adoption on the rise, it's critically important for engineers to learn how to specifically design for the process. Looking for metal 3d printing? Design guidelines for metal 3d printing.

The Best Metal 3d Printers In 2020 . Material Overview Colors & Finishes Design Guide Technical Specifications.

Process Steps In The Metal Additive Manufacturing Workflow Digital Alloys. Coupled with design tools like topology optimisation and generative design, 3d. This guide will show you how to get the most out of metal additive manufacturing. With metal 3d printing adoption on the rise, it's critically important for engineers to learn how to specifically design for the process. Our basic guidelines for direct metal laser sintering include important design considerations to help the 3d printing essentials reference guide offers guidelines and key considerations when designing for industrial 3d printing processes. The greatest advantage of metal 3d printing compared to traditional manufacturing is its exceptional design flexibility. These complex designs can be produced more cost effectively than with traditional processes. Many innovative startups and suppliers have. Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. New to metal 3d printing, or looking to gain more depth of knowledge? Check out our complete metal 3d printing guide including different technologies due to rapid technological advancement, metal 3d printing has grown massively in recent years. This reference guide walks you through the key design considerations of metal 3d printing to help you successfully optimize parts printed on the. Metal 3d printing is currently on the rise. Direct metal laser sintering (dmls). The objective of this white paper is to provide you with a design guide for creating cad parts that are optimized for metal 3d printing with desktop the studio system printer uses a process called bound metal deposition™, or bmd™. Since no specific tooling is needed (for example, a.

How To Design Parts For Metal 3d Printing 3d Hubs : Coupled With Design Tools Like Topology Optimisation And Generative Design, 3D.

A Few Basic Design Rules For Metal 3d Printed Parts By Steve Fournier Medium. Coupled with design tools like topology optimisation and generative design, 3d. These complex designs can be produced more cost effectively than with traditional processes. Many innovative startups and suppliers have. New to metal 3d printing, or looking to gain more depth of knowledge? Since no specific tooling is needed (for example, a. Direct metal laser sintering (dmls). Metal 3d printing is currently on the rise. Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. This reference guide walks you through the key design considerations of metal 3d printing to help you successfully optimize parts printed on the. With metal 3d printing adoption on the rise, it's critically important for engineers to learn how to specifically design for the process.

Tools 3d Fpp , Metal 3d printing is currently on the rise.

How To 3d Design Parts For Sla 3d Printing Ameralabs. With metal 3d printing adoption on the rise, it's critically important for engineers to learn how to specifically design for the process. Check out our complete metal 3d printing guide including different technologies due to rapid technological advancement, metal 3d printing has grown massively in recent years. Direct metal laser sintering (dmls). Coupled with design tools like topology optimisation and generative design, 3d. Many innovative startups and suppliers have. These complex designs can be produced more cost effectively than with traditional processes. The objective of this white paper is to provide you with a design guide for creating cad parts that are optimized for metal 3d printing with desktop the studio system printer uses a process called bound metal deposition™, or bmd™. Our basic guidelines for direct metal laser sintering include important design considerations to help the 3d printing essentials reference guide offers guidelines and key considerations when designing for industrial 3d printing processes. The greatest advantage of metal 3d printing compared to traditional manufacturing is its exceptional design flexibility. Metal 3d printing is currently on the rise. Since no specific tooling is needed (for example, a. This reference guide walks you through the key design considerations of metal 3d printing to help you successfully optimize parts printed on the. Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. This guide will show you how to get the most out of metal additive manufacturing. New to metal 3d printing, or looking to gain more depth of knowledge?

Studio System Desktop Metal - Discover How Landscape Designers Are Transforming Outdoor Spaces Into Memorable Locations That.

3d Systems Awarded Contract To Develop Saltwater Corrosion Design Guide For 3d Printing 3d Printing Industry. Coupled with design tools like topology optimisation and generative design, 3d. Direct metal laser sintering (dmls). Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. These complex designs can be produced more cost effectively than with traditional processes. Many innovative startups and suppliers have. Since no specific tooling is needed (for example, a. Check out our complete metal 3d printing guide including different technologies due to rapid technological advancement, metal 3d printing has grown massively in recent years. New to metal 3d printing, or looking to gain more depth of knowledge? This reference guide walks you through the key design considerations of metal 3d printing to help you successfully optimize parts printed on the. The objective of this white paper is to provide you with a design guide for creating cad parts that are optimized for metal 3d printing with desktop the studio system printer uses a process called bound metal deposition™, or bmd™. This guide will show you how to get the most out of metal additive manufacturing. Metal 3d printing is currently on the rise. Our basic guidelines for direct metal laser sintering include important design considerations to help the 3d printing essentials reference guide offers guidelines and key considerations when designing for industrial 3d printing processes. The greatest advantage of metal 3d printing compared to traditional manufacturing is its exceptional design flexibility. With metal 3d printing adoption on the rise, it's critically important for engineers to learn how to specifically design for the process.

The Metal 3d Printing Guide 3dnatives : 3D Printing In Metals Gives Product Designers And Creatives The Ultimate Material Choice.

How To Design Parts For Metal 3d Printing 3d Hubs. Metal 3d printing is currently on the rise. This guide will show you how to get the most out of metal additive manufacturing. Direct metal laser sintering (dmls). Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. With metal 3d printing adoption on the rise, it's critically important for engineers to learn how to specifically design for the process. The objective of this white paper is to provide you with a design guide for creating cad parts that are optimized for metal 3d printing with desktop the studio system printer uses a process called bound metal deposition™, or bmd™. Coupled with design tools like topology optimisation and generative design, 3d. Check out our complete metal 3d printing guide including different technologies due to rapid technological advancement, metal 3d printing has grown massively in recent years. Our basic guidelines for direct metal laser sintering include important design considerations to help the 3d printing essentials reference guide offers guidelines and key considerations when designing for industrial 3d printing processes. The greatest advantage of metal 3d printing compared to traditional manufacturing is its exceptional design flexibility. Many innovative startups and suppliers have. Since no specific tooling is needed (for example, a. This reference guide walks you through the key design considerations of metal 3d printing to help you successfully optimize parts printed on the. These complex designs can be produced more cost effectively than with traditional processes. New to metal 3d printing, or looking to gain more depth of knowledge?

Key Design Considerations For 3d Printing 3d Hubs : Coupled With Design Tools Like Topology Optimisation And Generative Design, 3D.

How To 3d Design Parts For Sla 3d Printing Ameralabs. Many innovative startups and suppliers have. Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. The greatest advantage of metal 3d printing compared to traditional manufacturing is its exceptional design flexibility. Coupled with design tools like topology optimisation and generative design, 3d. Direct metal laser sintering (dmls). Check out our complete metal 3d printing guide including different technologies due to rapid technological advancement, metal 3d printing has grown massively in recent years. Metal 3d printing is currently on the rise. The objective of this white paper is to provide you with a design guide for creating cad parts that are optimized for metal 3d printing with desktop the studio system printer uses a process called bound metal deposition™, or bmd™. This guide will show you how to get the most out of metal additive manufacturing. These complex designs can be produced more cost effectively than with traditional processes. New to metal 3d printing, or looking to gain more depth of knowledge? With metal 3d printing adoption on the rise, it's critically important for engineers to learn how to specifically design for the process. Our basic guidelines for direct metal laser sintering include important design considerations to help the 3d printing essentials reference guide offers guidelines and key considerations when designing for industrial 3d printing processes. Since no specific tooling is needed (for example, a. This reference guide walks you through the key design considerations of metal 3d printing to help you successfully optimize parts printed on the.

The Best Metal 3d Printers In 2020 , Learn Everything About 3D Printing In Stainless Steel:

Xact Metal New To Metal 3d Printing Check Out Our New Facebook. Coupled with design tools like topology optimisation and generative design, 3d. Our basic guidelines for direct metal laser sintering include important design considerations to help the 3d printing essentials reference guide offers guidelines and key considerations when designing for industrial 3d printing processes. New to metal 3d printing, or looking to gain more depth of knowledge? Metal 3d printing is currently on the rise. Direct metal laser sintering (dmls). These complex designs can be produced more cost effectively than with traditional processes. The greatest advantage of metal 3d printing compared to traditional manufacturing is its exceptional design flexibility. Check out our complete metal 3d printing guide including different technologies due to rapid technological advancement, metal 3d printing has grown massively in recent years. This reference guide walks you through the key design considerations of metal 3d printing to help you successfully optimize parts printed on the. With metal 3d printing adoption on the rise, it's critically important for engineers to learn how to specifically design for the process. Since no specific tooling is needed (for example, a. Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. The objective of this white paper is to provide you with a design guide for creating cad parts that are optimized for metal 3d printing with desktop the studio system printer uses a process called bound metal deposition™, or bmd™. This guide will show you how to get the most out of metal additive manufacturing. Many innovative startups and suppliers have.

A Guide To Design For Desktop Metal S Bmd Process In 2020 Desktop Metal 3d Printed Metal Design : Tips, Design Rules, Technical Documentation, And It Is Strong Enough For Metal Parts Like Bottle Openers And Dice, But Is Not Recommended For After Printing, The Model Is Sintered In A Furnace.

Metal 3d Printing Design Guidelines. This guide will show you how to get the most out of metal additive manufacturing. Since no specific tooling is needed (for example, a. This reference guide walks you through the key design considerations of metal 3d printing to help you successfully optimize parts printed on the. New to metal 3d printing, or looking to gain more depth of knowledge? Metal 3d printing is currently on the rise. Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. Coupled with design tools like topology optimisation and generative design, 3d. Our basic guidelines for direct metal laser sintering include important design considerations to help the 3d printing essentials reference guide offers guidelines and key considerations when designing for industrial 3d printing processes. The greatest advantage of metal 3d printing compared to traditional manufacturing is its exceptional design flexibility. Direct metal laser sintering (dmls). With metal 3d printing adoption on the rise, it's critically important for engineers to learn how to specifically design for the process. The objective of this white paper is to provide you with a design guide for creating cad parts that are optimized for metal 3d printing with desktop the studio system printer uses a process called bound metal deposition™, or bmd™. These complex designs can be produced more cost effectively than with traditional processes. Check out our complete metal 3d printing guide including different technologies due to rapid technological advancement, metal 3d printing has grown massively in recent years. Many innovative startups and suppliers have.

2020 Metal 3d Printer Buyer S Guide All3dp Pro , Our Basic Guidelines For Direct Metal Laser Sintering Include Important Design Considerations To Help The 3D Printing Essentials Reference Guide Offers Guidelines And Key Considerations When Designing For Industrial 3D Printing Processes.

Ultimate Guide To 3d Printing Threads. This guide will show you how to get the most out of metal additive manufacturing. Many innovative startups and suppliers have. With metal 3d printing adoption on the rise, it's critically important for engineers to learn how to specifically design for the process. Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. Coupled with design tools like topology optimisation and generative design, 3d. This reference guide walks you through the key design considerations of metal 3d printing to help you successfully optimize parts printed on the. Check out our complete metal 3d printing guide including different technologies due to rapid technological advancement, metal 3d printing has grown massively in recent years. The greatest advantage of metal 3d printing compared to traditional manufacturing is its exceptional design flexibility. Our basic guidelines for direct metal laser sintering include important design considerations to help the 3d printing essentials reference guide offers guidelines and key considerations when designing for industrial 3d printing processes. The objective of this white paper is to provide you with a design guide for creating cad parts that are optimized for metal 3d printing with desktop the studio system printer uses a process called bound metal deposition™, or bmd™. These complex designs can be produced more cost effectively than with traditional processes. Direct metal laser sintering (dmls). Since no specific tooling is needed (for example, a. Metal 3d printing is currently on the rise. New to metal 3d printing, or looking to gain more depth of knowledge?

2020 Metal 3d Printer Buyer S Guide All3dp Pro . Tips, Design Rules, Technical Documentation, And It Is Strong Enough For Metal Parts Like Bottle Openers And Dice, But Is Not Recommended For After Printing, The Model Is Sintered In A Furnace.

Process Steps In The Metal Additive Manufacturing Workflow Digital Alloys. This reference guide walks you through the key design considerations of metal 3d printing to help you successfully optimize parts printed on the. These complex designs can be produced more cost effectively than with traditional processes. Check out our complete metal 3d printing guide including different technologies due to rapid technological advancement, metal 3d printing has grown massively in recent years. The greatest advantage of metal 3d printing compared to traditional manufacturing is its exceptional design flexibility. New to metal 3d printing, or looking to gain more depth of knowledge? Metal 3d printing can be used to produce complex geometries, pushing the boundaries of what is possible with manufacturing. Our basic guidelines for direct metal laser sintering include important design considerations to help the 3d printing essentials reference guide offers guidelines and key considerations when designing for industrial 3d printing processes. With metal 3d printing adoption on the rise, it's critically important for engineers to learn how to specifically design for the process. Since no specific tooling is needed (for example, a. Coupled with design tools like topology optimisation and generative design, 3d. Metal 3d printing is currently on the rise. The objective of this white paper is to provide you with a design guide for creating cad parts that are optimized for metal 3d printing with desktop the studio system printer uses a process called bound metal deposition™, or bmd™. This guide will show you how to get the most out of metal additive manufacturing. Many innovative startups and suppliers have. Direct metal laser sintering (dmls).