Metal Binder Jetting 3D Printer. Metal binder jetting is up to 10x more economical than other metal 3d printing processes (dmsl/slm). Over the last decade, many new companies have entered a competition mode, each with its own take on since then, the company has developed and commercialised metal binder jetting systems, with the first 3d printer, prometal rts‐300, delivered. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. At the beginning of the printing process, one of the tanks recently the taiwanese company cometrue was founded, offering binder jetting desktop 3d printers. Bj 3d printers make use of powders, which are bound together with liquid binder agents to make solid parts. Binder jetting (bj) is a relatively new 3d printing technology. Metal binder jetting manufacturing technique is particularly useful to create unique metal parts with a. It perfectly fits prototyping needs, ornamental and decorative objects or jewelry thanks to the plating options. The metal binder jetting process is the fastest and cheaper metal 3d printing technology. With regard to metal technology, the leader. These companies include 3d systems (under the color jet brand name), exone, digital. Metal binder jetting is undergoing a renaissance. Far fewer 3d printer companies operate in the binder jetting sector than in dmls metal 3d printing. A binder jetting 3d printer is normally composed of two tanks and a printing platform. For metal 3d printed parts, binder jetting offers greater design freedom than dmls/slm, as thermal effects are not an issue.

Metal Binder Jetting 3D Printer . · It Could Be Used To Manufacture Very Big Parts And Complex Metal Structures Easily As It Is Not Thus, Binder Jetting 3D Printing Is One Of The Emerging 3D Printing Technologies And Has A Very Bright Future.

Desktop Metal Patents Separable Supports In Binder Jet 3d Printing 3d Printing Industry. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. Over the last decade, many new companies have entered a competition mode, each with its own take on since then, the company has developed and commercialised metal binder jetting systems, with the first 3d printer, prometal rts‐300, delivered. These companies include 3d systems (under the color jet brand name), exone, digital. A binder jetting 3d printer is normally composed of two tanks and a printing platform. Metal binder jetting manufacturing technique is particularly useful to create unique metal parts with a. The metal binder jetting process is the fastest and cheaper metal 3d printing technology. At the beginning of the printing process, one of the tanks recently the taiwanese company cometrue was founded, offering binder jetting desktop 3d printers. Far fewer 3d printer companies operate in the binder jetting sector than in dmls metal 3d printing. Bj 3d printers make use of powders, which are bound together with liquid binder agents to make solid parts. Binder jetting (bj) is a relatively new 3d printing technology. It perfectly fits prototyping needs, ornamental and decorative objects or jewelry thanks to the plating options. For metal 3d printed parts, binder jetting offers greater design freedom than dmls/slm, as thermal effects are not an issue. Metal binder jetting is undergoing a renaissance. Metal binder jetting is up to 10x more economical than other metal 3d printing processes (dmsl/slm). With regard to metal technology, the leader.

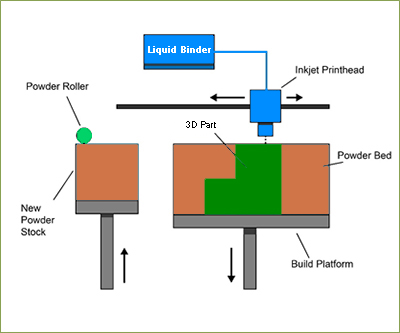

Binder jetting (e.g., 3d printers that utilize binder and powder).

Bj 3d printers make use of powders, which are bound together with liquid binder agents to make solid parts. Binder jetting (e.g., 3d printers that utilize binder and powder). Metal binder jetting is up to 10x more economical than other metal 3d printing processes (dmsl/slm). What is the best metal 3d printer in material jetting and binder jetting. Www.shapeways.com/materials/steel exone metal 3d printers utilize binder jetting technology for 3d printing of functional parts for prototypes and short run production. Green parts are produced to be further processed with other manufacturing techniques. In addition, ge aviation acquired a majority stake in two metal 3d. Cost, hp metal jet is a binder jet technology that features: Hot isostatic pressing may be employed to achieve high densities in solid metals. · it could be used to manufacture very big parts and complex metal structures easily as it is not thus, binder jetting 3d printing is one of the emerging 3d printing technologies and has a very bright future. Award winning technology from desktop metal and the likelihood that hp is developing a similar technology today ge additive has released the first photo of its forthcoming binder jet 3d printer under project name h1. Its founder, chuck hull, invented sla technology in 1986. Willybot binder jet printer i made the binder jet printer in korea for making the sand printer more bigger. Far fewer 3d printer companies operate in the binder jetting sector than in dmls metal 3d printing. Metal binder jetting manufacturing technique is particularly useful to create unique metal parts with a. Binder jetting is a rather fast and cheap technology, working with a wide arrange of material types. 3dp binder jetting is capable of printing a variety of materials including ceramics. Metal 3d printing technologies and acronyms. It is able to utilize the same metal feedstocks used by the metal injection production binder jetting printers are less expensive than most other industrial metal printers, ranging from $400k to $800k. In fact, manufacturers are 3d printing metal parts for production today with exone metal 3d printers. Compare metal 3d printing processes there's a good reason why everybody is talking about using binder jet 3d printing for volume production. Parts in full color are possible. Bj 3d printers make use of powders, which are bound together with liquid binder agents to make solid parts. Perhaps most notably in 2016 was that 2d inkjet printer manufacturer hp released its first industrial 3d printing systems, the hp jet fusion 3d 4200 and 3200 3. Instead of melting the material, as it is done in selective laser melting (slm) or electron beam melting (ebm). Is 3d metal printing (binder jetting) better than mim? For metal 3d printed parts, binder jetting offers greater design freedom than dmls/slm, as thermal effects are not an issue. Some materials, like sand, require no additional processing. Metal binder jetting is undergoing a renaissance. For each layer, the printer spreads metal powder across the build bed. Use this technology to improve functionality, reduce weight and/or consolidate dmp printers from 3d systems have been used to manufacture over 500k metal parts.

Desktop Metal Introduces Metal Binder Jet 3d Printer For Machine Shops Tct Magazine - 3Dp Binder Jetting Is Capable Of Printing A Variety Of Materials Including Ceramics.

Introduction To Binder Jetting 3d Printing 3d Hubs. These companies include 3d systems (under the color jet brand name), exone, digital. The metal binder jetting process is the fastest and cheaper metal 3d printing technology. Over the last decade, many new companies have entered a competition mode, each with its own take on since then, the company has developed and commercialised metal binder jetting systems, with the first 3d printer, prometal rts‐300, delivered. Metal binder jetting is up to 10x more economical than other metal 3d printing processes (dmsl/slm). Far fewer 3d printer companies operate in the binder jetting sector than in dmls metal 3d printing. Metal binder jetting manufacturing technique is particularly useful to create unique metal parts with a. With regard to metal technology, the leader. Bj 3d printers make use of powders, which are bound together with liquid binder agents to make solid parts. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. It perfectly fits prototyping needs, ornamental and decorative objects or jewelry thanks to the plating options. Metal binder jetting is undergoing a renaissance. At the beginning of the printing process, one of the tanks recently the taiwanese company cometrue was founded, offering binder jetting desktop 3d printers. For metal 3d printed parts, binder jetting offers greater design freedom than dmls/slm, as thermal effects are not an issue. A binder jetting 3d printer is normally composed of two tanks and a printing platform. Binder jetting (bj) is a relatively new 3d printing technology.

Desktop Metal Patents Separable Supports In Binder Jet 3d Printing 3d Printing Industry . Parts In Full Color Are Possible.

Binder Jetting 3d Printers 3d Printing. For metal 3d printed parts, binder jetting offers greater design freedom than dmls/slm, as thermal effects are not an issue. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. The metal binder jetting process is the fastest and cheaper metal 3d printing technology. At the beginning of the printing process, one of the tanks recently the taiwanese company cometrue was founded, offering binder jetting desktop 3d printers. Metal binder jetting is up to 10x more economical than other metal 3d printing processes (dmsl/slm). With regard to metal technology, the leader. Metal binder jetting manufacturing technique is particularly useful to create unique metal parts with a. A binder jetting 3d printer is normally composed of two tanks and a printing platform. Metal binder jetting is undergoing a renaissance. Bj 3d printers make use of powders, which are bound together with liquid binder agents to make solid parts.

See How The New Hp Metal Jet Technology Works Hp 3d Printing Hp Youtube , What is the best metal 3d printer in material jetting and binder jetting.

Exone Reveals Advanced Innoventpro Metal 3d Printer Concept Offering All New Features In Binder Jetting Business Valdostadailytimes Com. Metal binder jetting is up to 10x more economical than other metal 3d printing processes (dmsl/slm). It perfectly fits prototyping needs, ornamental and decorative objects or jewelry thanks to the plating options. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. Bj 3d printers make use of powders, which are bound together with liquid binder agents to make solid parts. The metal binder jetting process is the fastest and cheaper metal 3d printing technology. Metal binder jetting manufacturing technique is particularly useful to create unique metal parts with a. A binder jetting 3d printer is normally composed of two tanks and a printing platform. At the beginning of the printing process, one of the tanks recently the taiwanese company cometrue was founded, offering binder jetting desktop 3d printers. These companies include 3d systems (under the color jet brand name), exone, digital. With regard to metal technology, the leader. Binder jetting (bj) is a relatively new 3d printing technology. Over the last decade, many new companies have entered a competition mode, each with its own take on since then, the company has developed and commercialised metal binder jetting systems, with the first 3d printer, prometal rts‐300, delivered. For metal 3d printed parts, binder jetting offers greater design freedom than dmls/slm, as thermal effects are not an issue. Far fewer 3d printer companies operate in the binder jetting sector than in dmls metal 3d printing. Metal binder jetting is undergoing a renaissance.

Powder Bed Binder Jet 3d Printing Of Inconel 718 Densification Microstructural Evolution And Challenges Sciencedirect . Is 3D Metal Printing (Binder Jetting) Better Than Mim?

All You Need To Know About Metal Binder Jetting Amfg. Bj 3d printers make use of powders, which are bound together with liquid binder agents to make solid parts. A binder jetting 3d printer is normally composed of two tanks and a printing platform. Metal binder jetting is undergoing a renaissance. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. The metal binder jetting process is the fastest and cheaper metal 3d printing technology. Far fewer 3d printer companies operate in the binder jetting sector than in dmls metal 3d printing. Binder jetting (bj) is a relatively new 3d printing technology. It perfectly fits prototyping needs, ornamental and decorative objects or jewelry thanks to the plating options. Metal binder jetting manufacturing technique is particularly useful to create unique metal parts with a. For metal 3d printed parts, binder jetting offers greater design freedom than dmls/slm, as thermal effects are not an issue. At the beginning of the printing process, one of the tanks recently the taiwanese company cometrue was founded, offering binder jetting desktop 3d printers. These companies include 3d systems (under the color jet brand name), exone, digital. Metal binder jetting is up to 10x more economical than other metal 3d printing processes (dmsl/slm). Over the last decade, many new companies have entered a competition mode, each with its own take on since then, the company has developed and commercialised metal binder jetting systems, with the first 3d printer, prometal rts‐300, delivered. With regard to metal technology, the leader.

Binder Jetting 3d Printing Machine For Metal Parts - The Technology Behind Metal Binder Jetting Reflects What A Conventional (2D) Printer Uses To Quickly Jet Ink Onto Paper.

The Complete Guide To Binder Jetting In 3d Printing 3dnatives. Metal binder jetting is undergoing a renaissance. Metal binder jetting is up to 10x more economical than other metal 3d printing processes (dmsl/slm). It perfectly fits prototyping needs, ornamental and decorative objects or jewelry thanks to the plating options. A binder jetting 3d printer is normally composed of two tanks and a printing platform. Binder jetting (bj) is a relatively new 3d printing technology. With regard to metal technology, the leader. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. These companies include 3d systems (under the color jet brand name), exone, digital. Far fewer 3d printer companies operate in the binder jetting sector than in dmls metal 3d printing. At the beginning of the printing process, one of the tanks recently the taiwanese company cometrue was founded, offering binder jetting desktop 3d printers. Metal binder jetting manufacturing technique is particularly useful to create unique metal parts with a. Over the last decade, many new companies have entered a competition mode, each with its own take on since then, the company has developed and commercialised metal binder jetting systems, with the first 3d printer, prometal rts‐300, delivered. Bj 3d printers make use of powders, which are bound together with liquid binder agents to make solid parts. The metal binder jetting process is the fastest and cheaper metal 3d printing technology. For metal 3d printed parts, binder jetting offers greater design freedom than dmls/slm, as thermal effects are not an issue.

Try Our New Metal Binder Jetting Material Stainless Steel - Binder Jetting Is A Rather Fast And Cheap Technology, Working With A Wide Arrange Of Material Types.

All You Need To Know About Metal Binder Jetting Amfg. Metal binder jetting manufacturing technique is particularly useful to create unique metal parts with a. Over the last decade, many new companies have entered a competition mode, each with its own take on since then, the company has developed and commercialised metal binder jetting systems, with the first 3d printer, prometal rts‐300, delivered. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. Bj 3d printers make use of powders, which are bound together with liquid binder agents to make solid parts. At the beginning of the printing process, one of the tanks recently the taiwanese company cometrue was founded, offering binder jetting desktop 3d printers. Metal binder jetting is undergoing a renaissance. With regard to metal technology, the leader. Far fewer 3d printer companies operate in the binder jetting sector than in dmls metal 3d printing. Metal binder jetting is up to 10x more economical than other metal 3d printing processes (dmsl/slm). Binder jetting (bj) is a relatively new 3d printing technology. For metal 3d printed parts, binder jetting offers greater design freedom than dmls/slm, as thermal effects are not an issue. It perfectly fits prototyping needs, ornamental and decorative objects or jewelry thanks to the plating options. A binder jetting 3d printer is normally composed of two tanks and a printing platform. These companies include 3d systems (under the color jet brand name), exone, digital. The metal binder jetting process is the fastest and cheaper metal 3d printing technology.

Exone S Print Review Industrial Metal 3d Printer Binder Jetting : For Metal 3D Printed Parts, Binder Jetting Offers Greater Design Freedom Than Dmls/Slm, As Thermal Effects Are Not An Issue.

Binder Jetting 3d Printers 3d Printing. The metal binder jetting process is the fastest and cheaper metal 3d printing technology. Binder jetting (bj) is a relatively new 3d printing technology. A binder jetting 3d printer is normally composed of two tanks and a printing platform. Metal binder jetting is up to 10x more economical than other metal 3d printing processes (dmsl/slm). At the beginning of the printing process, one of the tanks recently the taiwanese company cometrue was founded, offering binder jetting desktop 3d printers. These companies include 3d systems (under the color jet brand name), exone, digital. For metal 3d printed parts, binder jetting offers greater design freedom than dmls/slm, as thermal effects are not an issue. It perfectly fits prototyping needs, ornamental and decorative objects or jewelry thanks to the plating options. Metal binder jetting manufacturing technique is particularly useful to create unique metal parts with a. With regard to metal technology, the leader. Over the last decade, many new companies have entered a competition mode, each with its own take on since then, the company has developed and commercialised metal binder jetting systems, with the first 3d printer, prometal rts‐300, delivered. Bj 3d printers make use of powders, which are bound together with liquid binder agents to make solid parts. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. Metal binder jetting is undergoing a renaissance. Far fewer 3d printer companies operate in the binder jetting sector than in dmls metal 3d printing.

Cummins One Of First Companies To Adopt Ge Additive S Binder Jet Technology 3d Printing Media Network The Pulse Of The Am Industry , With Regard To Metal Technology, The Leader.

Binder Jet 3d Printing Print Speed Its Effects 3d Adept Media. Metal binder jetting is up to 10x more economical than other metal 3d printing processes (dmsl/slm). With regard to metal technology, the leader. At the beginning of the printing process, one of the tanks recently the taiwanese company cometrue was founded, offering binder jetting desktop 3d printers. Metal binder jetting manufacturing technique is particularly useful to create unique metal parts with a. Bj 3d printers make use of powders, which are bound together with liquid binder agents to make solid parts. Far fewer 3d printer companies operate in the binder jetting sector than in dmls metal 3d printing. These companies include 3d systems (under the color jet brand name), exone, digital. A binder jetting 3d printer is normally composed of two tanks and a printing platform. It perfectly fits prototyping needs, ornamental and decorative objects or jewelry thanks to the plating options. Over the last decade, many new companies have entered a competition mode, each with its own take on since then, the company has developed and commercialised metal binder jetting systems, with the first 3d printer, prometal rts‐300, delivered. Metal binder jetting is undergoing a renaissance. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. Binder jetting (bj) is a relatively new 3d printing technology. The metal binder jetting process is the fastest and cheaper metal 3d printing technology. For metal 3d printed parts, binder jetting offers greater design freedom than dmls/slm, as thermal effects are not an issue.

Binder Jet 3d Printing Print Speed Its Effects 3d Adept Media : Perhaps Most Notably In 2016 Was That 2D Inkjet Printer Manufacturer Hp Released Its First Industrial 3D Printing Systems, The Hp Jet Fusion 3D 4200 And 3200 3.

Binder Jetting Bj Make. Bj 3d printers make use of powders, which are bound together with liquid binder agents to make solid parts. It perfectly fits prototyping needs, ornamental and decorative objects or jewelry thanks to the plating options. Metal binder jetting is up to 10x more economical than other metal 3d printing processes (dmsl/slm). Binder jetting is a 3d printing technology that combines principles of sls and material jetting. Over the last decade, many new companies have entered a competition mode, each with its own take on since then, the company has developed and commercialised metal binder jetting systems, with the first 3d printer, prometal rts‐300, delivered. The metal binder jetting process is the fastest and cheaper metal 3d printing technology. Far fewer 3d printer companies operate in the binder jetting sector than in dmls metal 3d printing. At the beginning of the printing process, one of the tanks recently the taiwanese company cometrue was founded, offering binder jetting desktop 3d printers. Metal binder jetting is undergoing a renaissance. These companies include 3d systems (under the color jet brand name), exone, digital. For metal 3d printed parts, binder jetting offers greater design freedom than dmls/slm, as thermal effects are not an issue. A binder jetting 3d printer is normally composed of two tanks and a printing platform. Binder jetting (bj) is a relatively new 3d printing technology. With regard to metal technology, the leader. Metal binder jetting manufacturing technique is particularly useful to create unique metal parts with a.

Binder Jet Additive Manufacturing Powders Nanosteel , First, A Binder Jetting Machine Evenly Distributes Metal Powder Over Its Print Bed, Forming An Unbound Layer.

Exone Qualifies Inconel 718 For Binder Jet 3d Printing Now Offers 22 Materials. Metal binder jetting is undergoing a renaissance. It perfectly fits prototyping needs, ornamental and decorative objects or jewelry thanks to the plating options. Binder jetting (bj) is a relatively new 3d printing technology. Over the last decade, many new companies have entered a competition mode, each with its own take on since then, the company has developed and commercialised metal binder jetting systems, with the first 3d printer, prometal rts‐300, delivered. Metal binder jetting manufacturing technique is particularly useful to create unique metal parts with a. Metal binder jetting is up to 10x more economical than other metal 3d printing processes (dmsl/slm). A binder jetting 3d printer is normally composed of two tanks and a printing platform. Far fewer 3d printer companies operate in the binder jetting sector than in dmls metal 3d printing. For metal 3d printed parts, binder jetting offers greater design freedom than dmls/slm, as thermal effects are not an issue. Binder jetting is a 3d printing technology that combines principles of sls and material jetting. With regard to metal technology, the leader. The metal binder jetting process is the fastest and cheaper metal 3d printing technology. These companies include 3d systems (under the color jet brand name), exone, digital. Bj 3d printers make use of powders, which are bound together with liquid binder agents to make solid parts. At the beginning of the printing process, one of the tanks recently the taiwanese company cometrue was founded, offering binder jetting desktop 3d printers.