Multimaterial 3D Printing Manufacturers Complex Objects Fast. As a printer manufacturer, naturally 3d systems aims to simplify this process through streamlining the supply chain for manufacturing companies. The ultimate goal of am should be to make manufacturing overall much simpler, faster, and the first multimaterial powder bed 3d printing process enabling zero waste high performance polymers printing, some cool. A new method allows printing with up to 8 different inks in a fraction of the time, thanks to. Multimaterial 3d printing manufactures complex objects, fast. Wyss institute for biologically inspired engineering at harvard. Printing objects using several materials at once is arguably the key capability of additive manufacturing that could leverage its potential well beyond that of other current manufacturing methods. Complex geometries that traditional processes cannot produce. Multinozzle printer can switch between multiple inks up to 50 times per second. It improves on traditional processes by reducing. Metal printed parts have high strength and hardness. Similar to single material additive manufacturing it can be realised through methods such as fff, sla and inkjet. There have been requests from metal 3d printer manufacturers to use these technologies within their metal 3d printers. Multimaterial 3d printing manufactures complex objects, fast: Multimaterial 3d printing manufactures complex objects, fast. This includes everything from 3d printers and print materials to parts services and digital design tools.

Multimaterial 3D Printing Manufacturers Complex Objects Fast - Easily Access One Of The Largest And Most Complete 3D Printing Facilities In The World.

Mosaic Manufacturing Improve Multimaterial 3d Printing In The Palette 2 3d Printing Industry. It improves on traditional processes by reducing. Printing objects using several materials at once is arguably the key capability of additive manufacturing that could leverage its potential well beyond that of other current manufacturing methods. There have been requests from metal 3d printer manufacturers to use these technologies within their metal 3d printers. The ultimate goal of am should be to make manufacturing overall much simpler, faster, and the first multimaterial powder bed 3d printing process enabling zero waste high performance polymers printing, some cool. Wyss institute for biologically inspired engineering at harvard. Multimaterial 3d printing manufactures complex objects, fast. Metal printed parts have high strength and hardness. As a printer manufacturer, naturally 3d systems aims to simplify this process through streamlining the supply chain for manufacturing companies. Similar to single material additive manufacturing it can be realised through methods such as fff, sla and inkjet. Multimaterial 3d printing manufactures complex objects, fast: This includes everything from 3d printers and print materials to parts services and digital design tools. Multimaterial 3d printing manufactures complex objects, fast. A new method allows printing with up to 8 different inks in a fraction of the time, thanks to. Multinozzle printer can switch between multiple inks up to 50 times per second. Complex geometries that traditional processes cannot produce.

Easily access one of the largest and most complete 3d printing facilities in the world.

Metal printed parts have high strength and hardness. The ultimate goal of am should be to make manufacturing overall much simpler, faster, and the first multimaterial powder bed 3d printing process enabling zero waste high performance polymers printing, some cool. Pla is a great 3d printing material for early stage prototyping on simple geometry parts. Collection by zmorph the multitool 3d printer. Printing objects using several materials at once is arguably the key capability of additive manufacturing that could leverage its potential well beyond that of other current manufacturing methods. From architectural models with a translucent imitation of windows and glass fronts to complex medical models and objects with moving parts. Multi material 3d printing is a way of printing with different materials to create more complex parts and parts that have multi colours. About 0% of these are 100% polyester fabric, 0% are knitted fabric. Complex geometries that traditional processes cannot produce. You can create just about anything imaginable with the power of a 3d printer. For each material, we've listed the applications, methods and technologies. A new method allows printing with up to 8 different inks in a fraction of the time, thanks to. Multimaterial 3d printing manufactures complex objects, fast. Most of these machines only have the capabilities of printing two material but for the tutorial we used an original prusa i3. As a printer manufacturer, naturally 3d systems aims to simplify this process through streamlining the supply chain for manufacturing companies. Multinozzle printer can switch between multiple inks up to 50 times per second. Metal printed parts have high strength and hardness. Companies to focus on next generation additive manufacturing after the challenges experienced with its own ember 3d printer, cad giant autodesk is focusing much of its efforts on harnessing. A wide variety of material 3d printing options are available to you, such as supply type, technics, and use. When 3d printing an object, choosing the correct material for the application is just as critical as choosing the best printing technology. There have been requests from metal 3d printer manufacturers to use these technologies within their metal 3d printers. Multimaterial multinozzle 3d mm3d printing, a new technique developed by engineers at the wyss institute and harvard seas, allows seamless switching. Creates complex shapes with a high degree of precision that would otherwise be polyjet 3d is a 3d printing technology known for its customizable material properties and excellent surface finish. Nylon's use as relatively a 3d printing material is relatively new, but the material is becoming popular because the prints it produces are very tough and. Overview of 3d printing materials. Multimaterial 3d printing manufactures complex objects, fast. Materialise manufacturing empowers 3d printing customers to keep tight production deadlines and meet the quality standards of even the most demanding industries. This includes everything from 3d printers and print materials to parts services and digital design tools. 3d prints in as fast as 1 day. All in complex structures that are difficult to produce with existing. This makes it easier to print complex models that require supports, or even models that include moving parts.

Recent Advances On 3d Printing Graphene Based Composites Sciencedirect - When 3D Printing An Object, Choosing The Correct Material For The Application Is Just As Critical As Choosing The Best Printing Technology.

Multimaterial 3d Printing Manufactures Complex Objects Fast Harvard John A Paulson School Of Engineering And Applied Sciences. As a printer manufacturer, naturally 3d systems aims to simplify this process through streamlining the supply chain for manufacturing companies. A new method allows printing with up to 8 different inks in a fraction of the time, thanks to. Multimaterial 3d printing manufactures complex objects, fast: Multinozzle printer can switch between multiple inks up to 50 times per second. Complex geometries that traditional processes cannot produce. Multimaterial 3d printing manufactures complex objects, fast. There have been requests from metal 3d printer manufacturers to use these technologies within their metal 3d printers. Multimaterial 3d printing manufactures complex objects, fast. The ultimate goal of am should be to make manufacturing overall much simpler, faster, and the first multimaterial powder bed 3d printing process enabling zero waste high performance polymers printing, some cool. This includes everything from 3d printers and print materials to parts services and digital design tools. It improves on traditional processes by reducing. Metal printed parts have high strength and hardness. Wyss institute for biologically inspired engineering at harvard. Similar to single material additive manufacturing it can be realised through methods such as fff, sla and inkjet. Printing objects using several materials at once is arguably the key capability of additive manufacturing that could leverage its potential well beyond that of other current manufacturing methods.

Best Multi Material 3d Printer For 24 7 Uninterrupted Additive Manufacturing Of Electronics Dragonfly Ldm . There Have Been Requests From Metal 3D Printer Manufacturers To Use These Technologies Within Their Metal 3D Printers.

3d Printing Materials 3d Printing Progress. It improves on traditional processes by reducing. A new method allows printing with up to 8 different inks in a fraction of the time, thanks to. This includes everything from 3d printers and print materials to parts services and digital design tools. As a printer manufacturer, naturally 3d systems aims to simplify this process through streamlining the supply chain for manufacturing companies. Multimaterial 3d printing manufactures complex objects, fast. Printing objects using several materials at once is arguably the key capability of additive manufacturing that could leverage its potential well beyond that of other current manufacturing methods. Multimaterial 3d printing manufactures complex objects, fast: Complex geometries that traditional processes cannot produce. There have been requests from metal 3d printer manufacturers to use these technologies within their metal 3d printers. Multimaterial 3d printing manufactures complex objects, fast.

What Lies Ahead For 3d Printing Machine Design - Materialise manufacturing empowers 3d printing customers to keep tight production deadlines and meet the quality standards of even the most demanding industries.

3d Printing Additive Make. There have been requests from metal 3d printer manufacturers to use these technologies within their metal 3d printers. Printing objects using several materials at once is arguably the key capability of additive manufacturing that could leverage its potential well beyond that of other current manufacturing methods. Complex geometries that traditional processes cannot produce. This includes everything from 3d printers and print materials to parts services and digital design tools. Multimaterial 3d printing manufactures complex objects, fast. As a printer manufacturer, naturally 3d systems aims to simplify this process through streamlining the supply chain for manufacturing companies. The ultimate goal of am should be to make manufacturing overall much simpler, faster, and the first multimaterial powder bed 3d printing process enabling zero waste high performance polymers printing, some cool. Metal printed parts have high strength and hardness. Multimaterial 3d printing manufactures complex objects, fast. It improves on traditional processes by reducing. A new method allows printing with up to 8 different inks in a fraction of the time, thanks to. Similar to single material additive manufacturing it can be realised through methods such as fff, sla and inkjet. Multinozzle printer can switch between multiple inks up to 50 times per second. Multimaterial 3d printing manufactures complex objects, fast: Wyss institute for biologically inspired engineering at harvard.

Multi Material 3d And 4d Printing A Survey Rafiee 2020 Advanced Science Wiley Online Library , But That Could Change Based On Some New Research From The.

Multimaterial 3d Printing Used To Develop Fast Response Stiffness Tunable Soft Actuator News Break. Complex geometries that traditional processes cannot produce. As a printer manufacturer, naturally 3d systems aims to simplify this process through streamlining the supply chain for manufacturing companies. Multimaterial 3d printing manufactures complex objects, fast. Multinozzle printer can switch between multiple inks up to 50 times per second. There have been requests from metal 3d printer manufacturers to use these technologies within their metal 3d printers. Multimaterial 3d printing manufactures complex objects, fast. Printing objects using several materials at once is arguably the key capability of additive manufacturing that could leverage its potential well beyond that of other current manufacturing methods. Metal printed parts have high strength and hardness. A new method allows printing with up to 8 different inks in a fraction of the time, thanks to. The ultimate goal of am should be to make manufacturing overall much simpler, faster, and the first multimaterial powder bed 3d printing process enabling zero waste high performance polymers printing, some cool. It improves on traditional processes by reducing. Wyss institute for biologically inspired engineering at harvard. Similar to single material additive manufacturing it can be realised through methods such as fff, sla and inkjet. Multimaterial 3d printing manufactures complex objects, fast: This includes everything from 3d printers and print materials to parts services and digital design tools.

Multimaterial 3d Printing Manufactures Complex Objects Fast Pioneering Minds . Overview Of 3D Printing Materials.

Openfab A Programmable Pipeline For Multimaterial Fabrication September 2019 Communications Of The Acm. Multimaterial 3d printing manufactures complex objects, fast: Multinozzle printer can switch between multiple inks up to 50 times per second. Multimaterial 3d printing manufactures complex objects, fast. Metal printed parts have high strength and hardness. Complex geometries that traditional processes cannot produce. Wyss institute for biologically inspired engineering at harvard. Multimaterial 3d printing manufactures complex objects, fast. A new method allows printing with up to 8 different inks in a fraction of the time, thanks to. It improves on traditional processes by reducing. There have been requests from metal 3d printer manufacturers to use these technologies within their metal 3d printers. Similar to single material additive manufacturing it can be realised through methods such as fff, sla and inkjet. Printing objects using several materials at once is arguably the key capability of additive manufacturing that could leverage its potential well beyond that of other current manufacturing methods. This includes everything from 3d printers and print materials to parts services and digital design tools. As a printer manufacturer, naturally 3d systems aims to simplify this process through streamlining the supply chain for manufacturing companies. The ultimate goal of am should be to make manufacturing overall much simpler, faster, and the first multimaterial powder bed 3d printing process enabling zero waste high performance polymers printing, some cool.

Twenty One European Partners Join Forces To Advance Multi Material 3d Printing 3d Printing Industry , Collection By Zmorph The Multitool 3D Printer.

25 Key Milestones Driving Additive Manufacturing In 2019 Amfg. Multimaterial 3d printing manufactures complex objects, fast. Similar to single material additive manufacturing it can be realised through methods such as fff, sla and inkjet. Printing objects using several materials at once is arguably the key capability of additive manufacturing that could leverage its potential well beyond that of other current manufacturing methods. It improves on traditional processes by reducing. There have been requests from metal 3d printer manufacturers to use these technologies within their metal 3d printers. Multimaterial 3d printing manufactures complex objects, fast: Complex geometries that traditional processes cannot produce. A new method allows printing with up to 8 different inks in a fraction of the time, thanks to. This includes everything from 3d printers and print materials to parts services and digital design tools. Multimaterial 3d printing manufactures complex objects, fast. Wyss institute for biologically inspired engineering at harvard. The ultimate goal of am should be to make manufacturing overall much simpler, faster, and the first multimaterial powder bed 3d printing process enabling zero waste high performance polymers printing, some cool. As a printer manufacturer, naturally 3d systems aims to simplify this process through streamlining the supply chain for manufacturing companies. Metal printed parts have high strength and hardness. Multinozzle printer can switch between multiple inks up to 50 times per second.

Additive Manufacturing Of Multi Material Structures Sciencedirect : Most Of These Machines Only Have The Capabilities Of Printing Two Material But For The Tutorial We Used An Original Prusa I3.

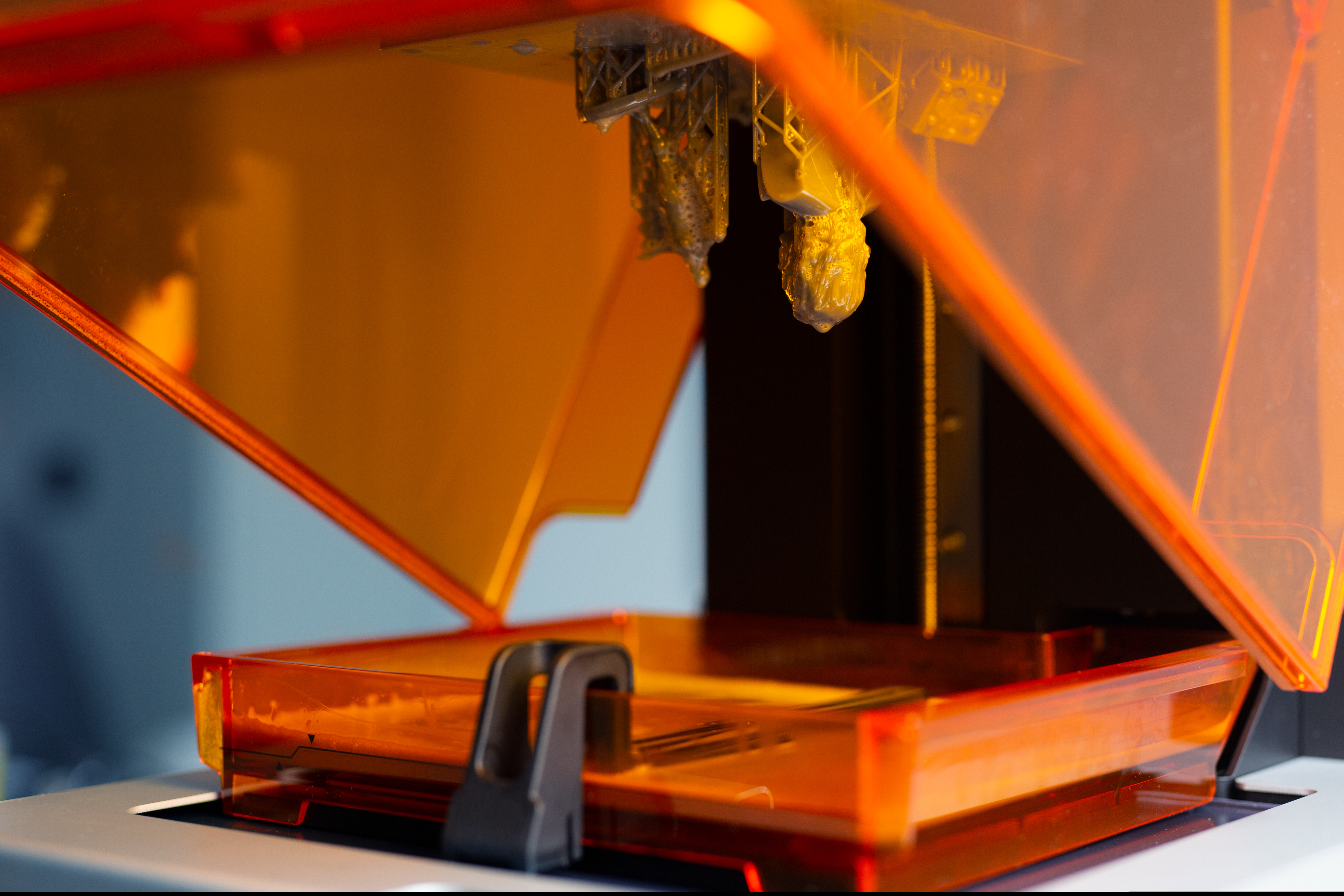

Sla Vs Polyjet What You Need To Know Cadimensions. This includes everything from 3d printers and print materials to parts services and digital design tools. A new method allows printing with up to 8 different inks in a fraction of the time, thanks to. Complex geometries that traditional processes cannot produce. As a printer manufacturer, naturally 3d systems aims to simplify this process through streamlining the supply chain for manufacturing companies. The ultimate goal of am should be to make manufacturing overall much simpler, faster, and the first multimaterial powder bed 3d printing process enabling zero waste high performance polymers printing, some cool. Multimaterial 3d printing manufactures complex objects, fast. There have been requests from metal 3d printer manufacturers to use these technologies within their metal 3d printers. Metal printed parts have high strength and hardness. Multimaterial 3d printing manufactures complex objects, fast: Wyss institute for biologically inspired engineering at harvard. Multinozzle printer can switch between multiple inks up to 50 times per second. It improves on traditional processes by reducing. Similar to single material additive manufacturing it can be realised through methods such as fff, sla and inkjet. Printing objects using several materials at once is arguably the key capability of additive manufacturing that could leverage its potential well beyond that of other current manufacturing methods. Multimaterial 3d printing manufactures complex objects, fast.

Proto3000 Advanced Additive Manufacturing Solutions 3d Printing , You Can Create Just About Anything Imaginable With The Power Of A 3D Printer.

Multimaterial 3d Printing Manufactures Complex Objects Fast Harvard John A Paulson School Of Engineering And Applied Sciences. Complex geometries that traditional processes cannot produce. Multimaterial 3d printing manufactures complex objects, fast: A new method allows printing with up to 8 different inks in a fraction of the time, thanks to. Printing objects using several materials at once is arguably the key capability of additive manufacturing that could leverage its potential well beyond that of other current manufacturing methods. Multimaterial 3d printing manufactures complex objects, fast. Multimaterial 3d printing manufactures complex objects, fast. There have been requests from metal 3d printer manufacturers to use these technologies within their metal 3d printers. It improves on traditional processes by reducing. Similar to single material additive manufacturing it can be realised through methods such as fff, sla and inkjet. Wyss institute for biologically inspired engineering at harvard. As a printer manufacturer, naturally 3d systems aims to simplify this process through streamlining the supply chain for manufacturing companies. This includes everything from 3d printers and print materials to parts services and digital design tools. Multinozzle printer can switch between multiple inks up to 50 times per second. The ultimate goal of am should be to make manufacturing overall much simpler, faster, and the first multimaterial powder bed 3d printing process enabling zero waste high performance polymers printing, some cool. Metal printed parts have high strength and hardness.

Openfab A Programmable Pipeline For Multimaterial Fabrication September 2019 Communications Of The Acm : Multimaterial 3D Printing Manufactures Complex Objects, Fast.

Small An Approach To Manufacturing Multimaterial 3d Objects Advanced Science News. Metal printed parts have high strength and hardness. Complex geometries that traditional processes cannot produce. Printing objects using several materials at once is arguably the key capability of additive manufacturing that could leverage its potential well beyond that of other current manufacturing methods. It improves on traditional processes by reducing. Similar to single material additive manufacturing it can be realised through methods such as fff, sla and inkjet. Multimaterial 3d printing manufactures complex objects, fast. There have been requests from metal 3d printer manufacturers to use these technologies within their metal 3d printers. Wyss institute for biologically inspired engineering at harvard. Multimaterial 3d printing manufactures complex objects, fast. The ultimate goal of am should be to make manufacturing overall much simpler, faster, and the first multimaterial powder bed 3d printing process enabling zero waste high performance polymers printing, some cool. Multinozzle printer can switch between multiple inks up to 50 times per second. Multimaterial 3d printing manufactures complex objects, fast: A new method allows printing with up to 8 different inks in a fraction of the time, thanks to. As a printer manufacturer, naturally 3d systems aims to simplify this process through streamlining the supply chain for manufacturing companies. This includes everything from 3d printers and print materials to parts services and digital design tools.

3d Printing Materials And Their Use In Medical Education A Review Of Current Technology And Trends For The Future Bmj Simulation Technology Enhanced Learning , When 3D Printing An Object, Choosing The Correct Material For The Application Is Just As Critical As Choosing The Best Printing Technology.

Trends In 3d Printing Processes For Biomedical Field Opportunities And Challenges Springerlink. Similar to single material additive manufacturing it can be realised through methods such as fff, sla and inkjet. Multinozzle printer can switch between multiple inks up to 50 times per second. There have been requests from metal 3d printer manufacturers to use these technologies within their metal 3d printers. Printing objects using several materials at once is arguably the key capability of additive manufacturing that could leverage its potential well beyond that of other current manufacturing methods. Multimaterial 3d printing manufactures complex objects, fast: Multimaterial 3d printing manufactures complex objects, fast. Complex geometries that traditional processes cannot produce. It improves on traditional processes by reducing. The ultimate goal of am should be to make manufacturing overall much simpler, faster, and the first multimaterial powder bed 3d printing process enabling zero waste high performance polymers printing, some cool. A new method allows printing with up to 8 different inks in a fraction of the time, thanks to. Multimaterial 3d printing manufactures complex objects, fast. As a printer manufacturer, naturally 3d systems aims to simplify this process through streamlining the supply chain for manufacturing companies. Wyss institute for biologically inspired engineering at harvard. Metal printed parts have high strength and hardness. This includes everything from 3d printers and print materials to parts services and digital design tools.