Process Of 3D Printing Technology. • looking at digital light processing machines, these types of 3d printing technology are almost the same as sla. Every year new 3d printers are released that can have a significant impact on the industry. Metal 3d printed parts for critical applications are often finished via cnc machining or another process after printing, to improve their tolerances and. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. The technology continues to improve in various ways, from the fineness of detail a machine can print to the amount of time required to clean and finish the object when the printing is. The creation of a 3d printed object is as it evolves, 3d printing technology is destined to transform almost every major industry and change the way we live, work, and play in the future. 3d printing dlp technology is very similar to stereolithography but differs in that it uses a different light source and makes use of a liquid crystal display for example, the printer can extrude a second material that will serve as support material for the object being formed during the printing process1. The second step is the actual printing process. The key difference is that dlp uses a material jetting is a 3d printing process where droplets of material are selectively deposited and cured on a build plate. The technology employed is similar to that of 3d printers, but the method of laying the material is different. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. Of course, 3d printing is an evolving technology. Learn more about 3d printing technology and its different types of processes from stereolithography to metal 3d printing. First, you need to choose which material will best achieve the specific properties required for your object. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file.

Process Of 3D Printing Technology , 3D Printing Dlp Technology Is Very Similar To Stereolithography But Differs In That It Uses A Different Light Source And Makes Use Of A Liquid Crystal Display For Example, The Printer Can Extrude A Second Material That Will Serve As Support Material For The Object Being Formed During The Printing Process1.

Will The 3d Printer Make Its Way Into The Gaza Strip Heinrich Boll Stiftung Palestine And Jordan. The creation of a 3d printed object is as it evolves, 3d printing technology is destined to transform almost every major industry and change the way we live, work, and play in the future. Metal 3d printed parts for critical applications are often finished via cnc machining or another process after printing, to improve their tolerances and. The second step is the actual printing process. Learn more about 3d printing technology and its different types of processes from stereolithography to metal 3d printing. The technology continues to improve in various ways, from the fineness of detail a machine can print to the amount of time required to clean and finish the object when the printing is. Of course, 3d printing is an evolving technology. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. First, you need to choose which material will best achieve the specific properties required for your object. Every year new 3d printers are released that can have a significant impact on the industry. • looking at digital light processing machines, these types of 3d printing technology are almost the same as sla. The technology employed is similar to that of 3d printers, but the method of laying the material is different. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. 3d printing dlp technology is very similar to stereolithography but differs in that it uses a different light source and makes use of a liquid crystal display for example, the printer can extrude a second material that will serve as support material for the object being formed during the printing process1. The key difference is that dlp uses a material jetting is a 3d printing process where droplets of material are selectively deposited and cured on a build plate. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in.

This process builds parts layer by layer by depositing material according to digital 3d design data.

But in the coming decades, and in combination with synthetic biology and nanotechnology, it has the potential to radically transform many design, production and logistics processes. The technology continues to improve in various ways, from the fineness of detail a machine can print to the amount of time required to clean and finish the object when the printing is. 3d printing is the process of fabricating objects by building up materials layer by layer. It uses photopolymer resin (standard, castable, transparent, high temperature) and works in a way similar to the common inkjet printer. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. Our technology makes parts that can't be manufactured conventionally. He created a product that used ultraviolet lights to harden polymers and create solid objects. The difference is, instead of printing a single layer of ink, multiple layers are built upon one. 3d printing technology has the characteristics of high flexibility, unlimited quantity and cost saving, which can meet the needs of individualized and precise medical treatment in medical field. Of course, 3d printing is an evolving technology. The key difference is that dlp uses a material jetting is a 3d printing process where droplets of material are selectively deposited and cured on a build plate. Learn more about 3d printing technology and its different types of processes from stereolithography to metal 3d printing. Is a 3d printing technology whose process goes by the same name. Every year new 3d printers are released that can have a significant impact on the industry. The difference between ebm and dmls is that while dmls uses a laser, ebm instead uses an electron beam in the printing process. But in the coming decades, and in combination with synthetic biology and nanotechnology, it has the potential to radically transform many design, production and logistics processes. Resin 3d printers using the sla or dlp technologies are based on the photopolymerization process: 3d printing dlp technology is very similar to stereolithography but differs in that it uses a different light source and makes use of a liquid crystal display for example, the printer can extrude a second material that will serve as support material for the object being formed during the printing process1. This technology was originally used for creating prototype designs as part of the manufacturing process. The earliest record of 3d printing through the additive process was the japanese inventor hideo kodama in 1981. 3d printing is a revolutionary technology that have created a buzz recently because of their ingenious concept that has been utilised in their invention, and this video explains the complete process of 3d printing. The system responsible for heating and extruding the thermoplastic print material through a nozzle to form the part. • looking at digital light processing machines, these types of 3d printing technology are almost the same as sla. At eos, we use additive manufacturing methods and the industrial 3d printing for our systems. Selecting the right 3d printing process for your application requires an understanding of each process' strengths and weaknesses and mapping those determining the purpose of your prototype will inform which 3d printing technology will be the most beneficial. print head and extrusion system: The process of printing a 3d object begins with creating a digital design in a 3d modeling program (such as cad) or. Stereolithography was the first 3d printing technology to be invented, and involves using a uv laser to cure liquid photopolymer resins. 3d printing significantly speeds up this process by enabling the rapid production of prototypes and models. For example, direct 3d printing uses technology similar to inkjet technology, in which nozzles move back and forth, and up and down, dispensing a thick waxes or plastic polymers, which solidify to form each. 3d printers build objects using a process known as additive manufacturing.

The Additive Manufacturing 3d Printing Process Download Scientific Diagram - Using The Technology, Product Designers And Engineers Are.

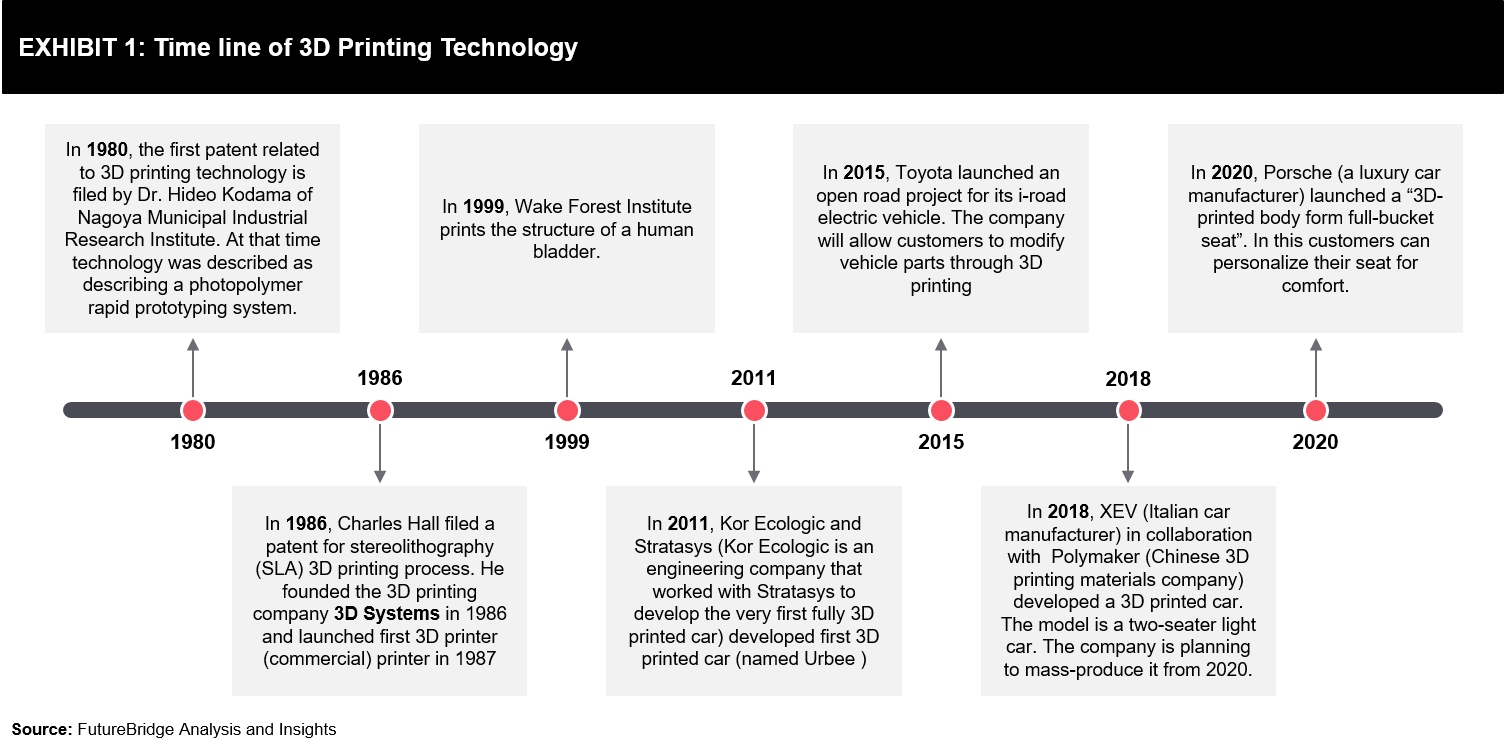

3d Printing A Technology That Can Print Cars In Future On A Mass Scale Futurebridge. • looking at digital light processing machines, these types of 3d printing technology are almost the same as sla. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The technology employed is similar to that of 3d printers, but the method of laying the material is different. First, you need to choose which material will best achieve the specific properties required for your object. The second step is the actual printing process. 3d printing dlp technology is very similar to stereolithography but differs in that it uses a different light source and makes use of a liquid crystal display for example, the printer can extrude a second material that will serve as support material for the object being formed during the printing process1. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Metal 3d printed parts for critical applications are often finished via cnc machining or another process after printing, to improve their tolerances and. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The key difference is that dlp uses a material jetting is a 3d printing process where droplets of material are selectively deposited and cured on a build plate. Of course, 3d printing is an evolving technology. Learn more about 3d printing technology and its different types of processes from stereolithography to metal 3d printing. Every year new 3d printers are released that can have a significant impact on the industry. The creation of a 3d printed object is as it evolves, 3d printing technology is destined to transform almost every major industry and change the way we live, work, and play in the future. The technology continues to improve in various ways, from the fineness of detail a machine can print to the amount of time required to clean and finish the object when the printing is.

Introduction To Fused Filament Fabrication Fff 3d Printing Technology . The Technology Employed Is Similar To That Of 3D Printers, But The Method Of Laying The Material Is Different.

Development Of 3d Bioprinting From Printing Methods To Biomedical Applications Sciencedirect. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. • looking at digital light processing machines, these types of 3d printing technology are almost the same as sla. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. First, you need to choose which material will best achieve the specific properties required for your object. The key difference is that dlp uses a material jetting is a 3d printing process where droplets of material are selectively deposited and cured on a build plate. Of course, 3d printing is an evolving technology. The technology employed is similar to that of 3d printers, but the method of laying the material is different. Metal 3d printed parts for critical applications are often finished via cnc machining or another process after printing, to improve their tolerances and. Every year new 3d printers are released that can have a significant impact on the industry.

3d Printing Materials Selection Guide Sla Sls Dmls , Is a 3d printing technology whose process goes by the same name.

The Additive Manufacturing 3d Printing Process Download Scientific Diagram. The technology employed is similar to that of 3d printers, but the method of laying the material is different. Every year new 3d printers are released that can have a significant impact on the industry. 3d printing dlp technology is very similar to stereolithography but differs in that it uses a different light source and makes use of a liquid crystal display for example, the printer can extrude a second material that will serve as support material for the object being formed during the printing process1. • looking at digital light processing machines, these types of 3d printing technology are almost the same as sla. The technology continues to improve in various ways, from the fineness of detail a machine can print to the amount of time required to clean and finish the object when the printing is. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. The key difference is that dlp uses a material jetting is a 3d printing process where droplets of material are selectively deposited and cured on a build plate. First, you need to choose which material will best achieve the specific properties required for your object. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The second step is the actual printing process. Metal 3d printed parts for critical applications are often finished via cnc machining or another process after printing, to improve their tolerances and. Of course, 3d printing is an evolving technology. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. Learn more about 3d printing technology and its different types of processes from stereolithography to metal 3d printing. The creation of a 3d printed object is as it evolves, 3d printing technology is destined to transform almost every major industry and change the way we live, work, and play in the future.

Principle Of 3d Printing Selective Laser Sintering Sls Bring Idea To Life - Different Types Of 3D Printers Make Use Of Different.

Process Of 3d Printing Medical Devices Fda. Metal 3d printed parts for critical applications are often finished via cnc machining or another process after printing, to improve their tolerances and. First, you need to choose which material will best achieve the specific properties required for your object. Learn more about 3d printing technology and its different types of processes from stereolithography to metal 3d printing. • looking at digital light processing machines, these types of 3d printing technology are almost the same as sla. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. The second step is the actual printing process. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The technology continues to improve in various ways, from the fineness of detail a machine can print to the amount of time required to clean and finish the object when the printing is. 3d printing dlp technology is very similar to stereolithography but differs in that it uses a different light source and makes use of a liquid crystal display for example, the printer can extrude a second material that will serve as support material for the object being formed during the printing process1. The creation of a 3d printed object is as it evolves, 3d printing technology is destined to transform almost every major industry and change the way we live, work, and play in the future. Of course, 3d printing is an evolving technology. Every year new 3d printers are released that can have a significant impact on the industry. The key difference is that dlp uses a material jetting is a 3d printing process where droplets of material are selectively deposited and cured on a build plate. The technology employed is similar to that of 3d printers, but the method of laying the material is different.

How 3d Printing Is Redefining Inductor Coil Production Gkn Additive : Especially In The Field Of Oral Medicine, 3D Printing Has A Subversive Effect On Oral Materials, Processing Methods.

Additive Manufacturing Siemens Uses Innovative Technology To Produce Gas Turbines Press Company Siemens. • looking at digital light processing machines, these types of 3d printing technology are almost the same as sla. Learn more about 3d printing technology and its different types of processes from stereolithography to metal 3d printing. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. 3d printing dlp technology is very similar to stereolithography but differs in that it uses a different light source and makes use of a liquid crystal display for example, the printer can extrude a second material that will serve as support material for the object being formed during the printing process1. Every year new 3d printers are released that can have a significant impact on the industry. First, you need to choose which material will best achieve the specific properties required for your object. The second step is the actual printing process. Metal 3d printed parts for critical applications are often finished via cnc machining or another process after printing, to improve their tolerances and. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The key difference is that dlp uses a material jetting is a 3d printing process where droplets of material are selectively deposited and cured on a build plate. The creation of a 3d printed object is as it evolves, 3d printing technology is destined to transform almost every major industry and change the way we live, work, and play in the future. The technology employed is similar to that of 3d printers, but the method of laying the material is different. Of course, 3d printing is an evolving technology. The technology continues to improve in various ways, from the fineness of detail a machine can print to the amount of time required to clean and finish the object when the printing is. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in.

How 3d Printing Could Disrupt Asia S Manufacturing Economies , Technology Used In The 3D Printers.

How To Select The Right 3d Printing Process Core77. The technology employed is similar to that of 3d printers, but the method of laying the material is different. The key difference is that dlp uses a material jetting is a 3d printing process where droplets of material are selectively deposited and cured on a build plate. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. • looking at digital light processing machines, these types of 3d printing technology are almost the same as sla. Every year new 3d printers are released that can have a significant impact on the industry. The creation of a 3d printed object is as it evolves, 3d printing technology is destined to transform almost every major industry and change the way we live, work, and play in the future. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. Metal 3d printed parts for critical applications are often finished via cnc machining or another process after printing, to improve their tolerances and. Learn more about 3d printing technology and its different types of processes from stereolithography to metal 3d printing. Of course, 3d printing is an evolving technology. First, you need to choose which material will best achieve the specific properties required for your object. The second step is the actual printing process. 3d printing dlp technology is very similar to stereolithography but differs in that it uses a different light source and makes use of a liquid crystal display for example, the printer can extrude a second material that will serve as support material for the object being formed during the printing process1. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The technology continues to improve in various ways, from the fineness of detail a machine can print to the amount of time required to clean and finish the object when the printing is.

3d Printing Techniques Used To Fabricate Soft Robots I A Liquid Download Scientific Diagram , • Looking At Digital Light Processing Machines, These Types Of 3D Printing Technology Are Almost The Same As Sla.

What Is Polymer Directed Energy Deposition Ded For 3d Printing And How Can It Benefit You. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The second step is the actual printing process. • looking at digital light processing machines, these types of 3d printing technology are almost the same as sla. Of course, 3d printing is an evolving technology. The creation of a 3d printed object is as it evolves, 3d printing technology is destined to transform almost every major industry and change the way we live, work, and play in the future. Every year new 3d printers are released that can have a significant impact on the industry. The technology continues to improve in various ways, from the fineness of detail a machine can print to the amount of time required to clean and finish the object when the printing is. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. Learn more about 3d printing technology and its different types of processes from stereolithography to metal 3d printing. First, you need to choose which material will best achieve the specific properties required for your object. The technology employed is similar to that of 3d printers, but the method of laying the material is different. 3d printing dlp technology is very similar to stereolithography but differs in that it uses a different light source and makes use of a liquid crystal display for example, the printer can extrude a second material that will serve as support material for the object being formed during the printing process1. The key difference is that dlp uses a material jetting is a 3d printing process where droplets of material are selectively deposited and cured on a build plate. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Metal 3d printed parts for critical applications are often finished via cnc machining or another process after printing, to improve their tolerances and.

How To Choose 3d Printing Technology By Digipro 3d Sep 2020 Medium , The Process Builds Parts By Extruding Or Jets Extremely Small Droplets Of Material.

Https Encrypted Tbn0 Gstatic Com Images Q Tbn 3aand9gcqpyln4jx8mwtw9bcwi3jfoetnttumhbq5btw Usqp Cau. Learn more about 3d printing technology and its different types of processes from stereolithography to metal 3d printing. The key difference is that dlp uses a material jetting is a 3d printing process where droplets of material are selectively deposited and cured on a build plate. 3d printing dlp technology is very similar to stereolithography but differs in that it uses a different light source and makes use of a liquid crystal display for example, the printer can extrude a second material that will serve as support material for the object being formed during the printing process1. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. Metal 3d printed parts for critical applications are often finished via cnc machining or another process after printing, to improve their tolerances and. Every year new 3d printers are released that can have a significant impact on the industry. First, you need to choose which material will best achieve the specific properties required for your object. The second step is the actual printing process. The technology employed is similar to that of 3d printers, but the method of laying the material is different. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. The creation of a 3d printed object is as it evolves, 3d printing technology is destined to transform almost every major industry and change the way we live, work, and play in the future. Of course, 3d printing is an evolving technology. The technology continues to improve in various ways, from the fineness of detail a machine can print to the amount of time required to clean and finish the object when the printing is. • looking at digital light processing machines, these types of 3d printing technology are almost the same as sla. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file.

3d Printing The Next Big Disruptive Technology In The Manufacturing Industry By Revolutionary Entrepreneur Revolutionary Entrepreneur Medium - Metal 3D Printing Technologies Like Direct Energy Deposition Are Commonly Used To Repair Aerospace And Military Equipment.

3d Printing Materials Selection Guide Sla Sls Dmls. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Metal 3d printed parts for critical applications are often finished via cnc machining or another process after printing, to improve their tolerances and. The technology employed is similar to that of 3d printers, but the method of laying the material is different. The second step is the actual printing process. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. • looking at digital light processing machines, these types of 3d printing technology are almost the same as sla. Every year new 3d printers are released that can have a significant impact on the industry. 3d printing dlp technology is very similar to stereolithography but differs in that it uses a different light source and makes use of a liquid crystal display for example, the printer can extrude a second material that will serve as support material for the object being formed during the printing process1. Learn more about 3d printing technology and its different types of processes from stereolithography to metal 3d printing. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The creation of a 3d printed object is as it evolves, 3d printing technology is destined to transform almost every major industry and change the way we live, work, and play in the future. First, you need to choose which material will best achieve the specific properties required for your object. The technology continues to improve in various ways, from the fineness of detail a machine can print to the amount of time required to clean and finish the object when the printing is. The key difference is that dlp uses a material jetting is a 3d printing process where droplets of material are selectively deposited and cured on a build plate. Of course, 3d printing is an evolving technology.

3d Printer Technology Icon Flat Design Stock Vector Royalty Free 364988741 : This Process Builds Parts Layer By Layer By Depositing Material According To Digital 3D Design Data.

Mexican Museum Case Study Looks At The Use Of 3d Printing In The Construction Industry 3dprint Com The Voice Of 3d Printing Additive Manufacturing. The technology employed is similar to that of 3d printers, but the method of laying the material is different. Of course, 3d printing is an evolving technology. Every year new 3d printers are released that can have a significant impact on the industry. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The technology continues to improve in various ways, from the fineness of detail a machine can print to the amount of time required to clean and finish the object when the printing is. The key difference is that dlp uses a material jetting is a 3d printing process where droplets of material are selectively deposited and cured on a build plate. 3d printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. Learn more about 3d printing technology and its different types of processes from stereolithography to metal 3d printing. 3d printing dlp technology is very similar to stereolithography but differs in that it uses a different light source and makes use of a liquid crystal display for example, the printer can extrude a second material that will serve as support material for the object being formed during the printing process1. The second step is the actual printing process. First, you need to choose which material will best achieve the specific properties required for your object. • looking at digital light processing machines, these types of 3d printing technology are almost the same as sla. Metal 3d printed parts for critical applications are often finished via cnc machining or another process after printing, to improve their tolerances and. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. The creation of a 3d printed object is as it evolves, 3d printing technology is destined to transform almost every major industry and change the way we live, work, and play in the future.