Sls 3D Printing Definition. Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again. 3d systems' duraform® sls get superior accuracy, part resolution, edge definition, and surface finish with 3d systems' sls solutions. In this introduction to sls 3d printing, we cover the basic principles of the technology. Introduction to sls 3d printing. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. A vital aspect is the way of. After reading this article you will understand the fundamental mechanics of the sls process and how these relate to its benefits and limitations. Here are some model from the. The bin is then placed into the. Learn about selective laser sintering (sls) 3d printing, including different systems, materials, and applications. Written by alkaios bournias varotsis. Sls 3d printing is an amazing 3d printer technology that uses lasers to sintering a nylon powder to form awesome models! * same part file printed on prox sls. Heart model printed with sinterit lisa sls 3d printer.

Sls 3D Printing Definition - Benefits And Limits Of Sls 3D Printing.

3d Printing Technology Sla Vs Sls. Introduction to sls 3d printing. Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again. 3d systems' duraform® sls get superior accuracy, part resolution, edge definition, and surface finish with 3d systems' sls solutions. After reading this article you will understand the fundamental mechanics of the sls process and how these relate to its benefits and limitations. Written by alkaios bournias varotsis. The bin is then placed into the. A vital aspect is the way of. Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. Heart model printed with sinterit lisa sls 3d printer. Sls 3d printing is an amazing 3d printer technology that uses lasers to sintering a nylon powder to form awesome models! Learn about selective laser sintering (sls) 3d printing, including different systems, materials, and applications. In this introduction to sls 3d printing, we cover the basic principles of the technology. Here are some model from the. * same part file printed on prox sls. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide).

At the same time, they both will likely have much finer surface finishes and definition than fdm and won't need added support structures, as the.

The bin is then placed into the. Yet despite this, the process from design to end product follows a similar sls is quite similar to sla technology with regards to speed and quality. Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again. As rapiwith fused deposition modeling, the part is. Benefits and limits of sls 3d printing. 3d printing as a production technology. It creates parts additively by sintering fine sculpteo provides you the best online 3d printing services for your plastic parts. Here are some model from the. An overview of the most common types. The bin is then placed into the. They can fit in an office environment (with the right precautions) and be of overview of the best desktop sls printers. After reading this article you will understand the fundamental mechanics of the sls process and how these relate to its benefits and limitations. As more patents begin to expire for other 3d printing technologies, similar explosions in affordable additive manufacturing are expected to take place. Sls printing would have set you back a few hundred thousand dollars years ago, but now you can get one for your workshop desktop. Find out more about how sls 3d printing works and the process involved in manufacturing your parts. Heart model printed with sinterit lisa sls 3d printer. Sls 3d printing involves plastic polymer powders which are sintered using a laser inside the sls 3d printer. Ok, so printers, printing materials, printed objects, and 3d printing software can all vary. Written by alkaios bournias varotsis. 3d systems' duraform® sls get superior accuracy, part resolution, edge definition, and surface finish with 3d systems' sls solutions. * same part file printed on prox sls. Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). Using a laser the machines melt certain areas of the print bed 'colouring in' the areas to be printed. Thanks to our expertise in sls technology, you can choose between. Large scale 3d printers big enough to print furniture. Introduction to sls 3d printing. Compact sls 3d printers offer highly detailed prints without the need for support material. At the same time, they both will likely have much finer surface finishes and definition than fdm and won't need added support structures, as the. Stereolithography (sla) in many ways, sla printing works in a manner that's almost opposite to the way that fdm printing works. Sls (selective laser sintering) is an additive manufacturing method.

Sharebot Releases Improved Snowwhite2 Low Cost Sls 3d Printer 3dprint Com The Voice Of 3d Printing Additive Manufacturing : The Process Works Using A Print Bed Covered With White Nylon Powder.

3d Printing Vs Cnc Machining Which Is Best For Prototyping 3dnatives. Sls 3d printing is an amazing 3d printer technology that uses lasers to sintering a nylon powder to form awesome models! Heart model printed with sinterit lisa sls 3d printer. After reading this article you will understand the fundamental mechanics of the sls process and how these relate to its benefits and limitations. The bin is then placed into the. * same part file printed on prox sls. In this introduction to sls 3d printing, we cover the basic principles of the technology. Here are some model from the. 3d systems' duraform® sls get superior accuracy, part resolution, edge definition, and surface finish with 3d systems' sls solutions. Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again. A vital aspect is the way of. Introduction to sls 3d printing. Written by alkaios bournias varotsis. Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. Learn about selective laser sintering (sls) 3d printing, including different systems, materials, and applications. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide).

Resin 3d Printers Sla Dlp And Led Lcd : Learn About Selective Laser Sintering (Sls) 3D Printing, Including Different Systems, Materials, And Applications.

Chapter 1 An Introduction To 3d Printing Rsc Publishing Doi 10 1039 9781788015745 00001. 3d systems' duraform® sls get superior accuracy, part resolution, edge definition, and surface finish with 3d systems' sls solutions. A vital aspect is the way of. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). Written by alkaios bournias varotsis. Learn about selective laser sintering (sls) 3d printing, including different systems, materials, and applications. Introduction to sls 3d printing. In this introduction to sls 3d printing, we cover the basic principles of the technology. * same part file printed on prox sls. The bin is then placed into the. Heart model printed with sinterit lisa sls 3d printer.

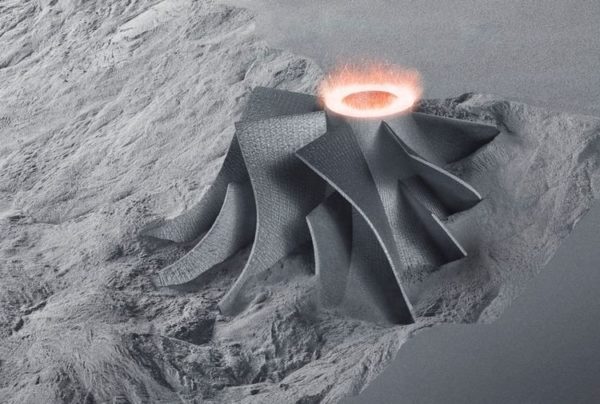

Laser Sintering Melting And Others Sls Slm Dmls Dmp Ebm Shs : * same part file printed on prox sls.

What Is Sls 3d Printing Sinterit Manufacturer Of High Quality Desktop Sls 3d Printers. In this introduction to sls 3d printing, we cover the basic principles of the technology. * same part file printed on prox sls. Introduction to sls 3d printing. 3d systems' duraform® sls get superior accuracy, part resolution, edge definition, and surface finish with 3d systems' sls solutions. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). Written by alkaios bournias varotsis. Learn about selective laser sintering (sls) 3d printing, including different systems, materials, and applications. Here are some model from the. Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. Heart model printed with sinterit lisa sls 3d printer. A vital aspect is the way of. Sls 3d printing is an amazing 3d printer technology that uses lasers to sintering a nylon powder to form awesome models! After reading this article you will understand the fundamental mechanics of the sls process and how these relate to its benefits and limitations. The bin is then placed into the. Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again.

What Is Sls 3d Printing Sinterit Manufacturer Of High Quality Desktop Sls 3d Printers - We Researched The Market To Create Our List Of The 15 Best Sls 3D Printers Available At All Price Ranges.

What Is Sls 3d Printing Kul 3d. Introduction to sls 3d printing. Written by alkaios bournias varotsis. A vital aspect is the way of. Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. Sls 3d printing is an amazing 3d printer technology that uses lasers to sintering a nylon powder to form awesome models! Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again. After reading this article you will understand the fundamental mechanics of the sls process and how these relate to its benefits and limitations. Heart model printed with sinterit lisa sls 3d printer. Learn about selective laser sintering (sls) 3d printing, including different systems, materials, and applications. * same part file printed on prox sls. In this introduction to sls 3d printing, we cover the basic principles of the technology. 3d systems' duraform® sls get superior accuracy, part resolution, edge definition, and surface finish with 3d systems' sls solutions. Here are some model from the. The bin is then placed into the.

3d Printing Supplier In China First Part 3d Printing . After Reading This Article You Will Understand The Fundamental Mechanics Of The Sls Process And How These Relate To Its Benefits And Limitations.

Selective Laser Sintering Sls Systems Agile Manufacturing Inc 3d Printing Solutions. * same part file printed on prox sls. A vital aspect is the way of. Written by alkaios bournias varotsis. Sls 3d printing is an amazing 3d printer technology that uses lasers to sintering a nylon powder to form awesome models! Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). Learn about selective laser sintering (sls) 3d printing, including different systems, materials, and applications. 3d systems' duraform® sls get superior accuracy, part resolution, edge definition, and surface finish with 3d systems' sls solutions. After reading this article you will understand the fundamental mechanics of the sls process and how these relate to its benefits and limitations. Heart model printed with sinterit lisa sls 3d printer. Introduction to sls 3d printing. Here are some model from the. In this introduction to sls 3d printing, we cover the basic principles of the technology. The bin is then placed into the. Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again.

Which 3d Printer Should You Get 3d Printing Radiology Corner Embodi3d Com : A Vital Aspect Is The Way Of.

3d Printing Technology Comparison Fdm Vs Sla Vs Sls Formlabs. Learn about selective laser sintering (sls) 3d printing, including different systems, materials, and applications. Heart model printed with sinterit lisa sls 3d printer. Introduction to sls 3d printing. A vital aspect is the way of. The bin is then placed into the. In this introduction to sls 3d printing, we cover the basic principles of the technology. Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. Written by alkaios bournias varotsis. Here are some model from the. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). Sls 3d printing is an amazing 3d printer technology that uses lasers to sintering a nylon powder to form awesome models! Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again. 3d systems' duraform® sls get superior accuracy, part resolution, edge definition, and surface finish with 3d systems' sls solutions. * same part file printed on prox sls. After reading this article you will understand the fundamental mechanics of the sls process and how these relate to its benefits and limitations.

Schematic Of Selective Laser Sintering Sls Process A Laser Source Download Scientific Diagram : Thanks To Our Expertise In Sls Technology, You Can Choose Between.

What S The Difference Between Stereolithography And Selective Laser Sintering Machine Design. Heart model printed with sinterit lisa sls 3d printer. 3d systems' duraform® sls get superior accuracy, part resolution, edge definition, and surface finish with 3d systems' sls solutions. After reading this article you will understand the fundamental mechanics of the sls process and how these relate to its benefits and limitations. A vital aspect is the way of. The bin is then placed into the. Written by alkaios bournias varotsis. Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. Introduction to sls 3d printing. Here are some model from the. Sls 3d printing is an amazing 3d printer technology that uses lasers to sintering a nylon powder to form awesome models! * same part file printed on prox sls. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). In this introduction to sls 3d printing, we cover the basic principles of the technology. Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again. Learn about selective laser sintering (sls) 3d printing, including different systems, materials, and applications.

Sharebot Snowwhite 2 Sls Sharebot Professional 3d Printers . Written By Alkaios Bournias Varotsis.

Modeling And Simulation Of Sls 3d Printing Process Computational Manufacturing And Materials Research Lab Computational Manufacturing And Materials Research Lab. Heart model printed with sinterit lisa sls 3d printer. Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. Written by alkaios bournias varotsis. After reading this article you will understand the fundamental mechanics of the sls process and how these relate to its benefits and limitations. Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again. In this introduction to sls 3d printing, we cover the basic principles of the technology. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). A vital aspect is the way of. * same part file printed on prox sls. Introduction to sls 3d printing. Sls 3d printing is an amazing 3d printer technology that uses lasers to sintering a nylon powder to form awesome models! 3d systems' duraform® sls get superior accuracy, part resolution, edge definition, and surface finish with 3d systems' sls solutions. The bin is then placed into the. Learn about selective laser sintering (sls) 3d printing, including different systems, materials, and applications. Here are some model from the.

3d Printing Market Growth Trends And Forecasts 2020 2025 - In This Introduction To Sls 3D Printing, We Cover The Basic Principles Of The Technology.

Materials Free Full Text Current Status And Prospects Of Polymer Powder 3d Printing Technologies Html. A vital aspect is the way of. * same part file printed on prox sls. 3d systems' duraform® sls get superior accuracy, part resolution, edge definition, and surface finish with 3d systems' sls solutions. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). In this introduction to sls 3d printing, we cover the basic principles of the technology. Here are some model from the. Heart model printed with sinterit lisa sls 3d printer. Introduction to sls 3d printing. The bin is then placed into the. After reading this article you will understand the fundamental mechanics of the sls process and how these relate to its benefits and limitations. Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. Learn about selective laser sintering (sls) 3d printing, including different systems, materials, and applications. Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again. Sls 3d printing is an amazing 3d printer technology that uses lasers to sintering a nylon powder to form awesome models! Written by alkaios bournias varotsis.

Guide To Selective Laser Sintering Sls 3d Printing Formlabs . We Researched The Market To Create Our List Of The 15 Best Sls 3D Printers Available At All Price Ranges.

Selective Laser Sintering Sls Mks Technologies Pvt Ltd. After reading this article you will understand the fundamental mechanics of the sls process and how these relate to its benefits and limitations. Selective laser sintering (sls) is an additive manufacturing (am) technique that uses a laser as the power source to sinter powdered material (typically nylon or polyamide). Introduction to sls 3d printing. Learn about selective laser sintering (sls) 3d printing, including different systems, materials, and applications. Here are some model from the. Generally speaking, the printing process begins with filling the powder bin with a certain amount of polymer powder. 3d systems' duraform® sls get superior accuracy, part resolution, edge definition, and surface finish with 3d systems' sls solutions. Afterwards the platform moves down by a small increment and the process repeats until the last layer sls is actually a zero waste technology where the unsintered powder can be used for next prints over and over again. In this introduction to sls 3d printing, we cover the basic principles of the technology. Written by alkaios bournias varotsis. Heart model printed with sinterit lisa sls 3d printer. * same part file printed on prox sls. The bin is then placed into the. A vital aspect is the way of. Sls 3d printing is an amazing 3d printer technology that uses lasers to sintering a nylon powder to form awesome models!