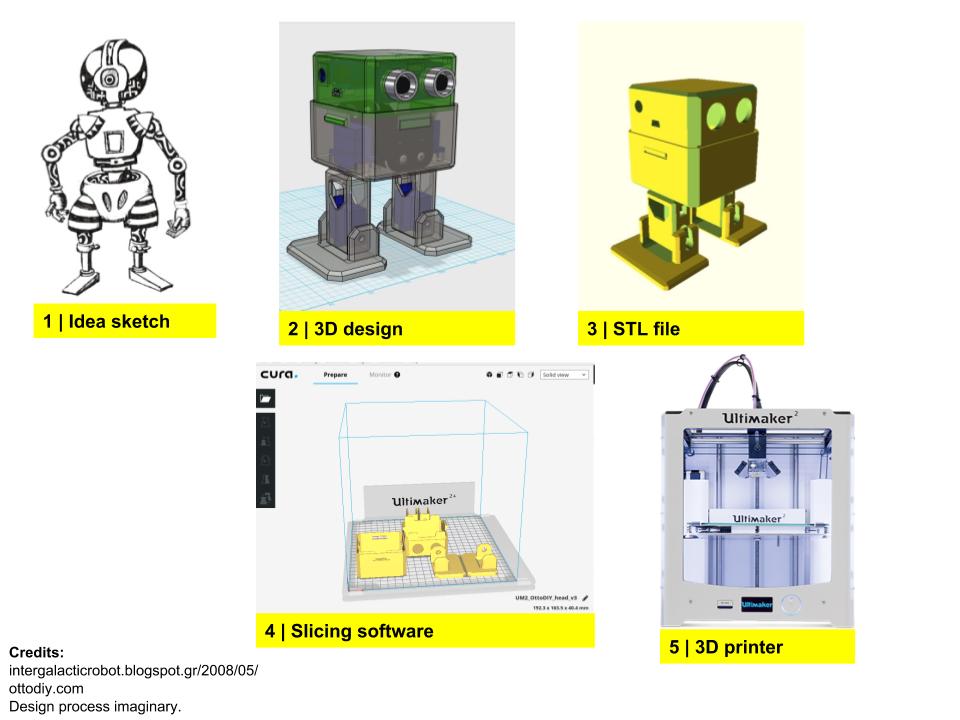

Steps Of 3D Printing Process. Well anyways, the process of 3d printing and the various techniques involved is out of scope of this article. 3d printing also known as additive manufacturing, it is that process through which solid objects can be built from digital files. The process of 3d printing begins by making a graphic model of the object to be printed. This instructable is intended to give an overview of the 3d printing process, using a holder for toothbrush heads that i designed the first step, even before you design the object, is to measure everything. For example, support removal is needed in most 3d printing processes. Other 3d printing processes offer greater accuracy. It was first commercially used as a rapid prototyping method in the. The slicing process breaks down the model into many layers. The second step is the actual printing process. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. I use a measuring device called a micrometer caliper, the metal tool shown. In this article we take you through all the 6 steps that are to be. Since each layer is usually about 0.1 mm thick, this can take anywhere from hours to days to complete. Industrial material jetting and sla printers, for example, are able to produce parts down to ± 0.01 mm. First, you need to choose which material will best achieve the specific properties required for your object.

Steps Of 3D Printing Process . Some People Like Removing Their Supports After Everything Has Cured, But I Find It's More Destructive If You Wait Until Then.

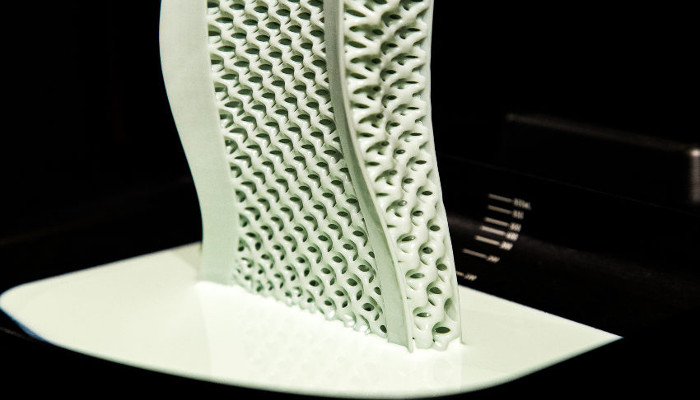

How It Works 3d Bioprinting The Future Of Tissue Engineering. Industrial material jetting and sla printers, for example, are able to produce parts down to ± 0.01 mm. The slicing process breaks down the model into many layers. For example, support removal is needed in most 3d printing processes. In this article we take you through all the 6 steps that are to be. 3d printing also known as additive manufacturing, it is that process through which solid objects can be built from digital files. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. I use a measuring device called a micrometer caliper, the metal tool shown. Since each layer is usually about 0.1 mm thick, this can take anywhere from hours to days to complete. It was first commercially used as a rapid prototyping method in the. This instructable is intended to give an overview of the 3d printing process, using a holder for toothbrush heads that i designed the first step, even before you design the object, is to measure everything. The process of 3d printing begins by making a graphic model of the object to be printed. Other 3d printing processes offer greater accuracy. The second step is the actual printing process. First, you need to choose which material will best achieve the specific properties required for your object. Well anyways, the process of 3d printing and the various techniques involved is out of scope of this article.

Common steps of 3d process.

The second step is the actual printing process. The second step is the actual printing process. There could be up to ten layers per each millimeter. In the fff process, this happens by precisely extruding 3d printing materials in discrete tool paths that trace the outside of a layer and its celled infill. Sla printing soon followed fdm to the desktop, when formlabs adapted the technology in 2011. I use a measuring device called a micrometer caliper, the metal tool shown. With any extrusion based 3d printing process, layer lines are inevitable. If the printer is enclosed, printing with all front doors and top hatches open. As a result, it produces some companies have even gone one step further by 3d printing products for pilot product testing with consumers. Industrial material jetting and sla printers, for example, are able to produce parts down to ± 0.01 mm. Cells are sorted, multiplied and. Most 3d printers in the consumer market use thermoplastic inks in the printing process. 3d printers build objects using a process known as additive manufacturing. Learn how to 3d print. 3d printing or additive manufacturing is a process of making three dimensional solid now that you have a printable file, the next step is to prepare it for your 3d printer. It includes plastics, ceramics, resins, metals, sand, textiles, biomaterials, glass, food and. Learn what parts go into the steps per millimeter value and how to use the prusa calculator to figure it out. 3d printing also known as additive manufacturing, it is that process through which solid objects can be built from digital files. 3d printing (3dp) is one of the fastest developed of desktop am. Material is put down in layers; In this article we take you through all the 6 steps that are to be. The slicing process breaks down the model into many layers. As a part prints, the z motion system moves the bed in discrete, equal steps to form the layers of the part. Since each layer is usually about 0.1 mm thick, this can take anywhere from hours to days to complete. Common steps of 3d process. This instructable is intended to give an overview of the 3d printing process, using a holder for toothbrush heads that i designed the first step, even before you design the object, is to measure everything. Since the 3d printing process works by producing parts layer by layer, material is, for the most part, used only where needed. Laser and resin 3d printers have a very different workflow from the more common extruder step 2: First, you need to choose which material will best achieve the specific properties required for your object. The process of 3d printing begins by making a graphic model of the object to be printed. It was first commercially used as a rapid prototyping method in the.

5 Basic Steps Of The Fdm Process For Producing 3d Printed Pcl Scaffolds Download Scientific Diagram . Industrial Material Jetting And Sla Printers, For Example, Are Able To Produce Parts Down To ± 0.01 Mm.

3d Printing And Its Future In Medical World Journal Of Medical Research And Innovation. 3d printing also known as additive manufacturing, it is that process through which solid objects can be built from digital files. I use a measuring device called a micrometer caliper, the metal tool shown. Since each layer is usually about 0.1 mm thick, this can take anywhere from hours to days to complete. Well anyways, the process of 3d printing and the various techniques involved is out of scope of this article. In this article we take you through all the 6 steps that are to be. Other 3d printing processes offer greater accuracy. First, you need to choose which material will best achieve the specific properties required for your object. The second step is the actual printing process. For example, support removal is needed in most 3d printing processes. The process of 3d printing begins by making a graphic model of the object to be printed. This instructable is intended to give an overview of the 3d printing process, using a holder for toothbrush heads that i designed the first step, even before you design the object, is to measure everything. It was first commercially used as a rapid prototyping method in the. Industrial material jetting and sla printers, for example, are able to produce parts down to ± 0.01 mm. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. The slicing process breaks down the model into many layers.

About 3d Printing The Future Of 3d Printing - The Principle Of This Process Is Creation Of A Product By Continuous Solidifying Of Slice By Slice Molten Material.

Stratasys 3d Printers From Javelin. First, you need to choose which material will best achieve the specific properties required for your object. 3d printing also known as additive manufacturing, it is that process through which solid objects can be built from digital files. Industrial material jetting and sla printers, for example, are able to produce parts down to ± 0.01 mm. Well anyways, the process of 3d printing and the various techniques involved is out of scope of this article. The slicing process breaks down the model into many layers. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. In this article we take you through all the 6 steps that are to be. Since each layer is usually about 0.1 mm thick, this can take anywhere from hours to days to complete. Other 3d printing processes offer greater accuracy. The process of 3d printing begins by making a graphic model of the object to be printed.

How 3d Printing Works : If the printer is enclosed, printing with all front doors and top hatches open.

The Mac Software Gap Where Can The Mac Platform Step Up In 3d Printing Software Vismed 3d Healthcare Technology. This instructable is intended to give an overview of the 3d printing process, using a holder for toothbrush heads that i designed the first step, even before you design the object, is to measure everything. Industrial material jetting and sla printers, for example, are able to produce parts down to ± 0.01 mm. Other 3d printing processes offer greater accuracy. Since each layer is usually about 0.1 mm thick, this can take anywhere from hours to days to complete. The second step is the actual printing process. The slicing process breaks down the model into many layers. I use a measuring device called a micrometer caliper, the metal tool shown. 3d printing also known as additive manufacturing, it is that process through which solid objects can be built from digital files. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. In this article we take you through all the 6 steps that are to be. It was first commercially used as a rapid prototyping method in the. Well anyways, the process of 3d printing and the various techniques involved is out of scope of this article. For example, support removal is needed in most 3d printing processes. The process of 3d printing begins by making a graphic model of the object to be printed. First, you need to choose which material will best achieve the specific properties required for your object.

The Mac Software Gap Where Can The Mac Platform Step Up In 3d Printing Software Vismed 3d Healthcare Technology : For Example, Support Removal Is Needed In Most 3D Printing Processes.

Dental Proz3d Solutions 3d Printing. In this article we take you through all the 6 steps that are to be. Industrial material jetting and sla printers, for example, are able to produce parts down to ± 0.01 mm. The process of 3d printing begins by making a graphic model of the object to be printed. Other 3d printing processes offer greater accuracy. I use a measuring device called a micrometer caliper, the metal tool shown. First, you need to choose which material will best achieve the specific properties required for your object. The slicing process breaks down the model into many layers. The second step is the actual printing process. For example, support removal is needed in most 3d printing processes. 3d printing also known as additive manufacturing, it is that process through which solid objects can be built from digital files. Well anyways, the process of 3d printing and the various techniques involved is out of scope of this article. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Since each layer is usually about 0.1 mm thick, this can take anywhere from hours to days to complete. This instructable is intended to give an overview of the 3d printing process, using a holder for toothbrush heads that i designed the first step, even before you design the object, is to measure everything. It was first commercially used as a rapid prototyping method in the.

3d Printing 3dealise . It Starts From Creation Of 3D Model In Cad Program, Special Piece Of Software Processes The Cad Model And Generates Stl File That Contains Information For Each Layer.

How 3d Printing Works. The slicing process breaks down the model into many layers. Since each layer is usually about 0.1 mm thick, this can take anywhere from hours to days to complete. First, you need to choose which material will best achieve the specific properties required for your object. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Industrial material jetting and sla printers, for example, are able to produce parts down to ± 0.01 mm. Other 3d printing processes offer greater accuracy. This instructable is intended to give an overview of the 3d printing process, using a holder for toothbrush heads that i designed the first step, even before you design the object, is to measure everything. It was first commercially used as a rapid prototyping method in the. Well anyways, the process of 3d printing and the various techniques involved is out of scope of this article. The process of 3d printing begins by making a graphic model of the object to be printed. I use a measuring device called a micrometer caliper, the metal tool shown. The second step is the actual printing process. For example, support removal is needed in most 3d printing processes. In this article we take you through all the 6 steps that are to be. 3d printing also known as additive manufacturing, it is that process through which solid objects can be built from digital files.

Stratasys 3d Printers From Javelin . As A Part Prints, The Z Motion System Moves The Bed In Discrete, Equal Steps To Form The Layers Of The Part.

3d Printing Series Post 1 A 3d Printing Primer Tina Trenkler. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Industrial material jetting and sla printers, for example, are able to produce parts down to ± 0.01 mm. This instructable is intended to give an overview of the 3d printing process, using a holder for toothbrush heads that i designed the first step, even before you design the object, is to measure everything. I use a measuring device called a micrometer caliper, the metal tool shown. The second step is the actual printing process. Other 3d printing processes offer greater accuracy. Since each layer is usually about 0.1 mm thick, this can take anywhere from hours to days to complete. The process of 3d printing begins by making a graphic model of the object to be printed. It was first commercially used as a rapid prototyping method in the. The slicing process breaks down the model into many layers. For example, support removal is needed in most 3d printing processes. First, you need to choose which material will best achieve the specific properties required for your object. 3d printing also known as additive manufacturing, it is that process through which solid objects can be built from digital files. Well anyways, the process of 3d printing and the various techniques involved is out of scope of this article. In this article we take you through all the 6 steps that are to be.

A3dxyz 3d Printers And 3d Printing Services In India . Common Steps Of 3D Process.

Process Of 3d Printing Medical Devices Fda. Industrial material jetting and sla printers, for example, are able to produce parts down to ± 0.01 mm. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. I use a measuring device called a micrometer caliper, the metal tool shown. In this article we take you through all the 6 steps that are to be. This instructable is intended to give an overview of the 3d printing process, using a holder for toothbrush heads that i designed the first step, even before you design the object, is to measure everything. The second step is the actual printing process. Since each layer is usually about 0.1 mm thick, this can take anywhere from hours to days to complete. For example, support removal is needed in most 3d printing processes. First, you need to choose which material will best achieve the specific properties required for your object. The process of 3d printing begins by making a graphic model of the object to be printed. It was first commercially used as a rapid prototyping method in the. Well anyways, the process of 3d printing and the various techniques involved is out of scope of this article. Other 3d printing processes offer greater accuracy. The slicing process breaks down the model into many layers. 3d printing also known as additive manufacturing, it is that process through which solid objects can be built from digital files.

Colorjet 3d Printing Technology Overview 3faktur : Depending On The Technology Used And The End Use Of The Part, It Varies From Simply Cleaning And Polishing To Machining And Heating Treating The Part.

3d Printng Spgon Software Soltuons Llp. Well anyways, the process of 3d printing and the various techniques involved is out of scope of this article. The second step is the actual printing process. The slicing process breaks down the model into many layers. 3d printing also known as additive manufacturing, it is that process through which solid objects can be built from digital files. It was first commercially used as a rapid prototyping method in the. First, you need to choose which material will best achieve the specific properties required for your object. Since each layer is usually about 0.1 mm thick, this can take anywhere from hours to days to complete. The process of 3d printing begins by making a graphic model of the object to be printed. Industrial material jetting and sla printers, for example, are able to produce parts down to ± 0.01 mm. This instructable is intended to give an overview of the 3d printing process, using a holder for toothbrush heads that i designed the first step, even before you design the object, is to measure everything. I use a measuring device called a micrometer caliper, the metal tool shown. For example, support removal is needed in most 3d printing processes. Other 3d printing processes offer greater accuracy. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. In this article we take you through all the 6 steps that are to be.

The Types Of 3d Printing Technology In 2020 All3dp - 3D Printing Is Also Known As Additive Manufacturing, Therefore The Numerous Available 3D Printing Process Tend To Be Additive In Nature With A Few Key Differences In.

Bim For 3d Printing In Construction Springerlink. In this article we take you through all the 6 steps that are to be. This instructable is intended to give an overview of the 3d printing process, using a holder for toothbrush heads that i designed the first step, even before you design the object, is to measure everything. The process of 3d printing begins by making a graphic model of the object to be printed. First, you need to choose which material will best achieve the specific properties required for your object. Since each layer is usually about 0.1 mm thick, this can take anywhere from hours to days to complete. I use a measuring device called a micrometer caliper, the metal tool shown. The second step is the actual printing process. It was first commercially used as a rapid prototyping method in the. The slicing process breaks down the model into many layers. For example, support removal is needed in most 3d printing processes. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. Industrial material jetting and sla printers, for example, are able to produce parts down to ± 0.01 mm. 3d printing also known as additive manufacturing, it is that process through which solid objects can be built from digital files. Other 3d printing processes offer greater accuracy. Well anyways, the process of 3d printing and the various techniques involved is out of scope of this article.

The Free Beginner S Guide 3d Printing Industry : Learn What Parts Go Into The Steps Per Millimeter Value And How To Use The Prusa Calculator To Figure It Out.

3d Printing Opening Doors To Endless Possibilities. The second step is the actual printing process. Well anyways, the process of 3d printing and the various techniques involved is out of scope of this article. Industrial material jetting and sla printers, for example, are able to produce parts down to ± 0.01 mm. In this article we take you through all the 6 steps that are to be. Other 3d printing processes offer greater accuracy. This instructable is intended to give an overview of the 3d printing process, using a holder for toothbrush heads that i designed the first step, even before you design the object, is to measure everything. 3d printing is also known as additive manufacturing, therefore the numerous available 3d printing process tend to be additive in nature with a few key differences in. I use a measuring device called a micrometer caliper, the metal tool shown. The slicing process breaks down the model into many layers. 3d printing also known as additive manufacturing, it is that process through which solid objects can be built from digital files. The process of 3d printing begins by making a graphic model of the object to be printed. Since each layer is usually about 0.1 mm thick, this can take anywhere from hours to days to complete. It was first commercially used as a rapid prototyping method in the. For example, support removal is needed in most 3d printing processes. First, you need to choose which material will best achieve the specific properties required for your object.