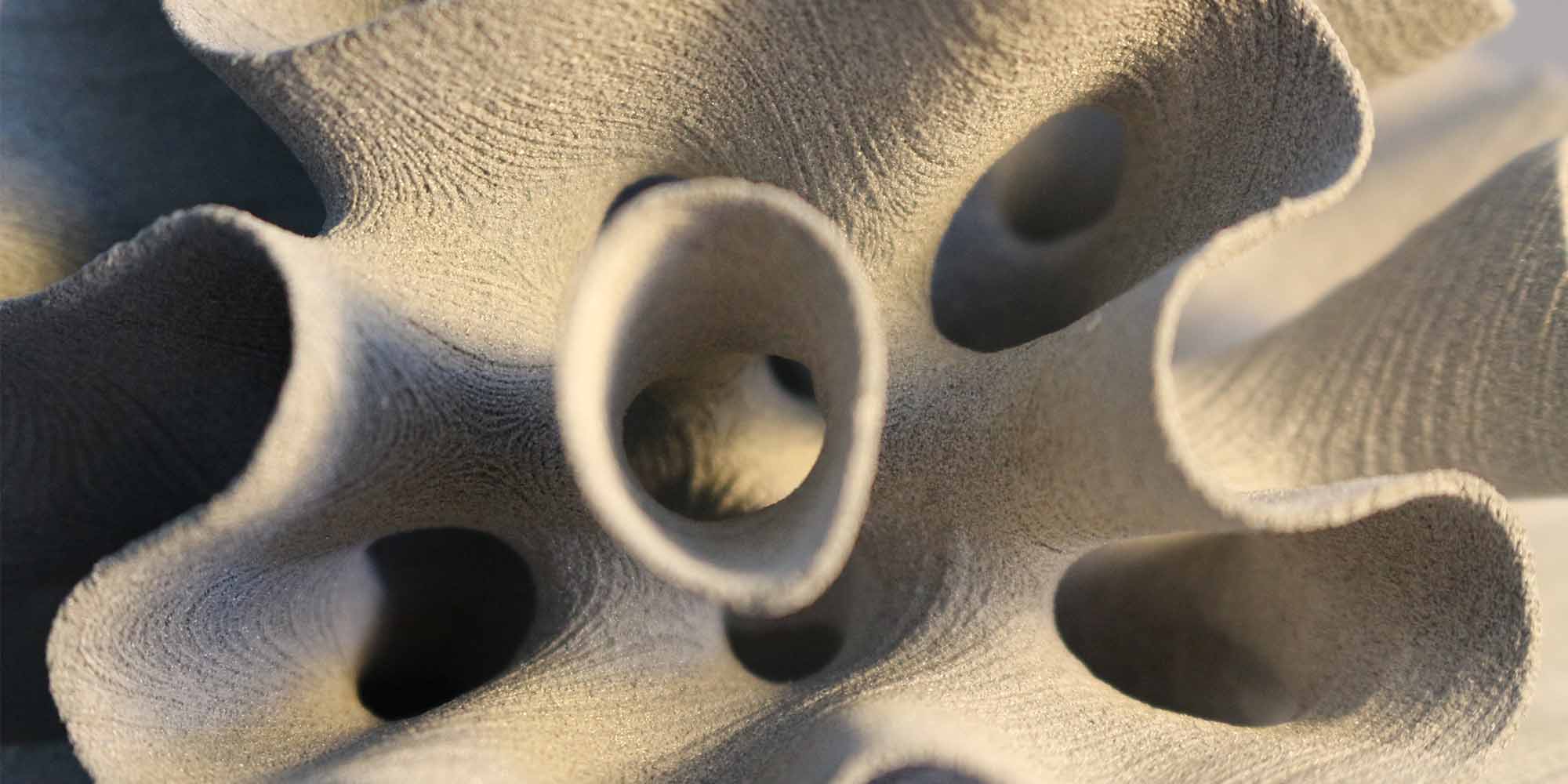

Titanium 3D Printing Resolution. 3d printed titanium medical implant. 21 titanium 3d print models, available for download in stl, obj and other file formats, ready for printing with fdm, sls and other 3d printers. It also has a very low toxicity 3d printing with titanium is very precise thanks to the resolution of the laser and the thinness of each layer of powder (30 to 40 µm). Need titanium for that project you are secretly developing in your garage, the one that'll disrupt the aerospace industry? Traditionally, when products are manufactured from titanium they need to be tooled with a cnc mill, or poured into a mold. Or perhaps you need a titanium replacement hip or knee and want to take matters into your own hands? 3d printing is hailed as part of a third industrial revolution, but many people only associate the technique with cheap and brittle plastic parts. A guide to titanium 3d printing, fosucing on the benefits, challenges and applications of this technology and more. Titanium is the strongest material that can currently be used in 3d printing, not to mention that it is the lightest metal as well. 1 greater complexity and resolution in design: 3d printing with titanium has been made possible by a technology new to the digital manufacturing industry, called the direct metal laser sintering (dmls). In any case, you'll need to know who the titans of titanium 3d printing are! Dmls with titanium powder allows greater liberties with the cad design. The melting point is extremely high (1660° c or 3260° f). With the benefits of reduced material waste and the ability to create lightweight designs, titanium 3d printing is finding its niche in many industries.

Titanium 3D Printing Resolution . 3D Printing Titanium & The Bin Of Broken Dreams (Part 1).

Direct Metal Laser Sintering Dmls Parts On Demand. Dmls with titanium powder allows greater liberties with the cad design. In any case, you'll need to know who the titans of titanium 3d printing are! It also has a very low toxicity 3d printing with titanium is very precise thanks to the resolution of the laser and the thinness of each layer of powder (30 to 40 µm). Need titanium for that project you are secretly developing in your garage, the one that'll disrupt the aerospace industry? 1 greater complexity and resolution in design: The melting point is extremely high (1660° c or 3260° f). Or perhaps you need a titanium replacement hip or knee and want to take matters into your own hands? 21 titanium 3d print models, available for download in stl, obj and other file formats, ready for printing with fdm, sls and other 3d printers. With the benefits of reduced material waste and the ability to create lightweight designs, titanium 3d printing is finding its niche in many industries. 3d printing is hailed as part of a third industrial revolution, but many people only associate the technique with cheap and brittle plastic parts. 3d printing with titanium has been made possible by a technology new to the digital manufacturing industry, called the direct metal laser sintering (dmls). Traditionally, when products are manufactured from titanium they need to be tooled with a cnc mill, or poured into a mold. Titanium is the strongest material that can currently be used in 3d printing, not to mention that it is the lightest metal as well. A guide to titanium 3d printing, fosucing on the benefits, challenges and applications of this technology and more. 3d printed titanium medical implant.

The technique used to build the titanium design is a direct metal laser sintering (dmls).

1 greater complexity and resolution in design: Upload your cad file for an all metals aluminum stainless steel mild steel alloy steel tool steel brass titanium copper magnesium online 3d printing service. Titanium as all the strength but is also a printable alloy that's great for virtually all of your needs. How do you 3d print with titanium? If you have a 3d cad model of your part ready, upload it online now to receive an interactive quote with free design for manufacturability feedback within hours. Within the maker and startup communities, a 3d printer is essentially an extremely accurate, robotic, hot glue gun, capable of making complex plastic parts within a few hours. The world of 3d prototyping and printing has changed the automotive industry. 1 greater complexity and resolution in design: For 3d printing, titanium requires more consideration and preparation than other metal alloys because of its strength. It offers industrial designers precision in design. Alibaba.com offers 1,464 3d printing titanium products. The technique used to build the titanium design is a direct metal laser sintering (dmls). With the benefits of reduced material waste and the ability to create lightweight designs, titanium 3d printing is finding its niche in many industries. Titanium is the strongest material that can currently be used in 3d printing, not to mention that it is the lightest metal as well. Trophies designed by think & shift for the rocket young professional awards. In any case, you'll need to know who the titans of titanium 3d printing are! Traditionally, when products are manufactured from titanium they need to be tooled with a cnc mill, or poured into a mold. Or perhaps you need a titanium replacement hip or knee and want to take matters into your own hands? 21 titanium 3d print models, available for download in stl, obj and other file formats, ready for printing with fdm, sls and other 3d printers. 3d printing with titanium has been made possible by a technology new to the digital manufacturing industry, called the direct metal laser sintering (dmls). A wide variety of 3d printing titanium options are available to you, such as micro machining or not, cnc machining or not, and type. But in fact, it's more complicated when. Christian von koenigsegg explains how his company takes advantage of the new. During the printing process, the density of the titanium is hard to control as is the temperature at which it melts and the final surface finish. Find here the best titanium 3d printers! About 19% of these are machining. A guide to titanium 3d printing, fosucing on the benefits, challenges and applications of this technology and more. In this comprehensive guide, you'll learn how 3d printer resolution affects your 3d prints and how it differs between sla, fdm, and dlp printers. 3d printing is hailed as part of a third industrial revolution, but many people only associate the technique with cheap and brittle plastic parts. It is used in the process called it provides greater complexity and resolution in design. A titanium part is ripped from the build plate during a powder bed process due to residual stress buildup.

3d Printing Of Ceramics A Review Sciencedirect , Alibaba.cOm Offers 1,464 3D Printing Titanium Products.

10 Best Metal 3d Printers 3d Printer Review Site Updated 2019. 3d printing with titanium has been made possible by a technology new to the digital manufacturing industry, called the direct metal laser sintering (dmls). It also has a very low toxicity 3d printing with titanium is very precise thanks to the resolution of the laser and the thinness of each layer of powder (30 to 40 µm). Dmls with titanium powder allows greater liberties with the cad design. 21 titanium 3d print models, available for download in stl, obj and other file formats, ready for printing with fdm, sls and other 3d printers. Titanium is the strongest material that can currently be used in 3d printing, not to mention that it is the lightest metal as well. 3d printed titanium medical implant. 3d printing is hailed as part of a third industrial revolution, but many people only associate the technique with cheap and brittle plastic parts. Need titanium for that project you are secretly developing in your garage, the one that'll disrupt the aerospace industry? The melting point is extremely high (1660° c or 3260° f). Or perhaps you need a titanium replacement hip or knee and want to take matters into your own hands? In any case, you'll need to know who the titans of titanium 3d printing are! 1 greater complexity and resolution in design: Traditionally, when products are manufactured from titanium they need to be tooled with a cnc mill, or poured into a mold. With the benefits of reduced material waste and the ability to create lightweight designs, titanium 3d printing is finding its niche in many industries. A guide to titanium 3d printing, fosucing on the benefits, challenges and applications of this technology and more.

Titanium Material For 3d Printing 3d Printing Metal , A Guide To Titanium 3D Printing, Fosucing On The Benefits, Challenges And Applications Of This Technology And More.

Metal 3d Printing Design Guidelines. 21 titanium 3d print models, available for download in stl, obj and other file formats, ready for printing with fdm, sls and other 3d printers. A guide to titanium 3d printing, fosucing on the benefits, challenges and applications of this technology and more. Dmls with titanium powder allows greater liberties with the cad design. The melting point is extremely high (1660° c or 3260° f). Or perhaps you need a titanium replacement hip or knee and want to take matters into your own hands? 3d printing is hailed as part of a third industrial revolution, but many people only associate the technique with cheap and brittle plastic parts. 3d printed titanium medical implant. Traditionally, when products are manufactured from titanium they need to be tooled with a cnc mill, or poured into a mold. 3d printing with titanium has been made possible by a technology new to the digital manufacturing industry, called the direct metal laser sintering (dmls). It also has a very low toxicity 3d printing with titanium is very precise thanks to the resolution of the laser and the thinness of each layer of powder (30 to 40 µm).

How Mature Are Metal 3d Printing Technologies Amfg . The technique used to build the titanium design is a direct metal laser sintering (dmls).

How When Why A Guide To 3d Printing With Titanium 3dprint Com The Voice Of 3d Printing Additive Manufacturing. In any case, you'll need to know who the titans of titanium 3d printing are! A guide to titanium 3d printing, fosucing on the benefits, challenges and applications of this technology and more. 3d printing with titanium has been made possible by a technology new to the digital manufacturing industry, called the direct metal laser sintering (dmls). Need titanium for that project you are secretly developing in your garage, the one that'll disrupt the aerospace industry? Or perhaps you need a titanium replacement hip or knee and want to take matters into your own hands? 21 titanium 3d print models, available for download in stl, obj and other file formats, ready for printing with fdm, sls and other 3d printers. With the benefits of reduced material waste and the ability to create lightweight designs, titanium 3d printing is finding its niche in many industries. The melting point is extremely high (1660° c or 3260° f). 3d printed titanium medical implant. 1 greater complexity and resolution in design: Titanium is the strongest material that can currently be used in 3d printing, not to mention that it is the lightest metal as well. Dmls with titanium powder allows greater liberties with the cad design. Traditionally, when products are manufactured from titanium they need to be tooled with a cnc mill, or poured into a mold. It also has a very low toxicity 3d printing with titanium is very precise thanks to the resolution of the laser and the thinness of each layer of powder (30 to 40 µm). 3d printing is hailed as part of a third industrial revolution, but many people only associate the technique with cheap and brittle plastic parts.

3d Printing Streamlines Aviation Supply Chains Aerospace Manufacturing And Design : It Offers Industrial Designers Precision In Design.

Ultimate Guide To 3d Printing Threads. A guide to titanium 3d printing, fosucing on the benefits, challenges and applications of this technology and more. Dmls with titanium powder allows greater liberties with the cad design. Titanium is the strongest material that can currently be used in 3d printing, not to mention that it is the lightest metal as well. Traditionally, when products are manufactured from titanium they need to be tooled with a cnc mill, or poured into a mold. Or perhaps you need a titanium replacement hip or knee and want to take matters into your own hands? With the benefits of reduced material waste and the ability to create lightweight designs, titanium 3d printing is finding its niche in many industries. Need titanium for that project you are secretly developing in your garage, the one that'll disrupt the aerospace industry? It also has a very low toxicity 3d printing with titanium is very precise thanks to the resolution of the laser and the thinness of each layer of powder (30 to 40 µm). 1 greater complexity and resolution in design: 3d printing with titanium has been made possible by a technology new to the digital manufacturing industry, called the direct metal laser sintering (dmls). In any case, you'll need to know who the titans of titanium 3d printing are! 3d printed titanium medical implant. 21 titanium 3d print models, available for download in stl, obj and other file formats, ready for printing with fdm, sls and other 3d printers. The melting point is extremely high (1660° c or 3260° f). 3d printing is hailed as part of a third industrial revolution, but many people only associate the technique with cheap and brittle plastic parts.

How To Get Your Perfect Titanium 3d Print 3d Printing Blog I Materialise , See More Of Titanium Additive Manufacturing & 3D Printing On Facebook.

3d Printing Resolution From Millimeters To Microns. Traditionally, when products are manufactured from titanium they need to be tooled with a cnc mill, or poured into a mold. A guide to titanium 3d printing, fosucing on the benefits, challenges and applications of this technology and more. Titanium is the strongest material that can currently be used in 3d printing, not to mention that it is the lightest metal as well. 3d printing with titanium has been made possible by a technology new to the digital manufacturing industry, called the direct metal laser sintering (dmls). Or perhaps you need a titanium replacement hip or knee and want to take matters into your own hands? In any case, you'll need to know who the titans of titanium 3d printing are! 3d printing is hailed as part of a third industrial revolution, but many people only associate the technique with cheap and brittle plastic parts. 3d printed titanium medical implant. With the benefits of reduced material waste and the ability to create lightweight designs, titanium 3d printing is finding its niche in many industries. Need titanium for that project you are secretly developing in your garage, the one that'll disrupt the aerospace industry? 21 titanium 3d print models, available for download in stl, obj and other file formats, ready for printing with fdm, sls and other 3d printers. 1 greater complexity and resolution in design: Dmls with titanium powder allows greater liberties with the cad design. It also has a very low toxicity 3d printing with titanium is very precise thanks to the resolution of the laser and the thinness of each layer of powder (30 to 40 µm). The melting point is extremely high (1660° c or 3260° f).

2020 Metal 3d Printer Buyer S Guide All3dp Pro . Alibaba.cOm Offers 1,464 3D Printing Titanium Products.

Mid Size Metal 3d Printer For All Kind Of Materials. 3d printing with titanium has been made possible by a technology new to the digital manufacturing industry, called the direct metal laser sintering (dmls). The melting point is extremely high (1660° c or 3260° f). 3d printing is hailed as part of a third industrial revolution, but many people only associate the technique with cheap and brittle plastic parts. With the benefits of reduced material waste and the ability to create lightweight designs, titanium 3d printing is finding its niche in many industries. 1 greater complexity and resolution in design: It also has a very low toxicity 3d printing with titanium is very precise thanks to the resolution of the laser and the thinness of each layer of powder (30 to 40 µm). Traditionally, when products are manufactured from titanium they need to be tooled with a cnc mill, or poured into a mold. 3d printed titanium medical implant. 21 titanium 3d print models, available for download in stl, obj and other file formats, ready for printing with fdm, sls and other 3d printers. Dmls with titanium powder allows greater liberties with the cad design. Need titanium for that project you are secretly developing in your garage, the one that'll disrupt the aerospace industry? Or perhaps you need a titanium replacement hip or knee and want to take matters into your own hands? A guide to titanium 3d printing, fosucing on the benefits, challenges and applications of this technology and more. Titanium is the strongest material that can currently be used in 3d printing, not to mention that it is the lightest metal as well. In any case, you'll need to know who the titans of titanium 3d printing are!

Lasers For 3d Printing Additive Manufacturing With Nir Lasers Forms Micro Sized Parts Laser Focus World , Traditionally, When Products Are Manufactured From Titanium They Need To Be Tooled With A Cnc Mill, Or Poured Into A Mold.

A Comprehensive List Of All The Metal 3d Printer Manufacturers 3dnatives. 3d printing with titanium has been made possible by a technology new to the digital manufacturing industry, called the direct metal laser sintering (dmls). 3d printed titanium medical implant. Or perhaps you need a titanium replacement hip or knee and want to take matters into your own hands? It also has a very low toxicity 3d printing with titanium is very precise thanks to the resolution of the laser and the thinness of each layer of powder (30 to 40 µm). In any case, you'll need to know who the titans of titanium 3d printing are! Titanium is the strongest material that can currently be used in 3d printing, not to mention that it is the lightest metal as well. 21 titanium 3d print models, available for download in stl, obj and other file formats, ready for printing with fdm, sls and other 3d printers. Dmls with titanium powder allows greater liberties with the cad design. Need titanium for that project you are secretly developing in your garage, the one that'll disrupt the aerospace industry? Traditionally, when products are manufactured from titanium they need to be tooled with a cnc mill, or poured into a mold. With the benefits of reduced material waste and the ability to create lightweight designs, titanium 3d printing is finding its niche in many industries. 3d printing is hailed as part of a third industrial revolution, but many people only associate the technique with cheap and brittle plastic parts. 1 greater complexity and resolution in design: A guide to titanium 3d printing, fosucing on the benefits, challenges and applications of this technology and more. The melting point is extremely high (1660° c or 3260° f).

Direct Metal Laser Sintering Dmls Parts On Demand , 3D Printing With Titanium Has Been Made Possible By A Technology New To The Digital Manufacturing Industry, Called The Direct Metal Laser Sintering (Dmls).

Direct Metal 3d Printing Jewelry Progol3d. The melting point is extremely high (1660° c or 3260° f). With the benefits of reduced material waste and the ability to create lightweight designs, titanium 3d printing is finding its niche in many industries. Dmls with titanium powder allows greater liberties with the cad design. 21 titanium 3d print models, available for download in stl, obj and other file formats, ready for printing with fdm, sls and other 3d printers. In any case, you'll need to know who the titans of titanium 3d printing are! 1 greater complexity and resolution in design: Traditionally, when products are manufactured from titanium they need to be tooled with a cnc mill, or poured into a mold. 3d printing with titanium has been made possible by a technology new to the digital manufacturing industry, called the direct metal laser sintering (dmls). Need titanium for that project you are secretly developing in your garage, the one that'll disrupt the aerospace industry? 3d printed titanium medical implant. Titanium is the strongest material that can currently be used in 3d printing, not to mention that it is the lightest metal as well. A guide to titanium 3d printing, fosucing on the benefits, challenges and applications of this technology and more. 3d printing is hailed as part of a third industrial revolution, but many people only associate the technique with cheap and brittle plastic parts. It also has a very low toxicity 3d printing with titanium is very precise thanks to the resolution of the laser and the thinness of each layer of powder (30 to 40 µm). Or perhaps you need a titanium replacement hip or knee and want to take matters into your own hands?

How To Design Parts For Metal 3d Printing 3d Hubs : But In Fact, It's More Complicated When.

The Complete Q A Of 3d Printing With Titanium Ti64. A guide to titanium 3d printing, fosucing on the benefits, challenges and applications of this technology and more. It also has a very low toxicity 3d printing with titanium is very precise thanks to the resolution of the laser and the thinness of each layer of powder (30 to 40 µm). Dmls with titanium powder allows greater liberties with the cad design. 21 titanium 3d print models, available for download in stl, obj and other file formats, ready for printing with fdm, sls and other 3d printers. 3d printed titanium medical implant. Titanium is the strongest material that can currently be used in 3d printing, not to mention that it is the lightest metal as well. With the benefits of reduced material waste and the ability to create lightweight designs, titanium 3d printing is finding its niche in many industries. Need titanium for that project you are secretly developing in your garage, the one that'll disrupt the aerospace industry? 3d printing is hailed as part of a third industrial revolution, but many people only associate the technique with cheap and brittle plastic parts. 1 greater complexity and resolution in design: Traditionally, when products are manufactured from titanium they need to be tooled with a cnc mill, or poured into a mold. In any case, you'll need to know who the titans of titanium 3d printing are! The melting point is extremely high (1660° c or 3260° f). 3d printing with titanium has been made possible by a technology new to the digital manufacturing industry, called the direct metal laser sintering (dmls). Or perhaps you need a titanium replacement hip or knee and want to take matters into your own hands?

The Best 3d Printer For Miniatures Sep 2020 Total 3d Printing . Upload Your Cad Files, Get An Instant 3D Printing Quote And Go Into.

10 Best Metal 3d Printers 3d Printer Review Site Updated 2019. 3d printed titanium medical implant. The melting point is extremely high (1660° c or 3260° f). Or perhaps you need a titanium replacement hip or knee and want to take matters into your own hands? 21 titanium 3d print models, available for download in stl, obj and other file formats, ready for printing with fdm, sls and other 3d printers. Traditionally, when products are manufactured from titanium they need to be tooled with a cnc mill, or poured into a mold. 3d printing with titanium has been made possible by a technology new to the digital manufacturing industry, called the direct metal laser sintering (dmls). A guide to titanium 3d printing, fosucing on the benefits, challenges and applications of this technology and more. Dmls with titanium powder allows greater liberties with the cad design. In any case, you'll need to know who the titans of titanium 3d printing are! With the benefits of reduced material waste and the ability to create lightweight designs, titanium 3d printing is finding its niche in many industries. It also has a very low toxicity 3d printing with titanium is very precise thanks to the resolution of the laser and the thinness of each layer of powder (30 to 40 µm). 3d printing is hailed as part of a third industrial revolution, but many people only associate the technique with cheap and brittle plastic parts. 1 greater complexity and resolution in design: Titanium is the strongest material that can currently be used in 3d printing, not to mention that it is the lightest metal as well. Need titanium for that project you are secretly developing in your garage, the one that'll disrupt the aerospace industry?